You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SZZS specific CEF50-main thread (initial builds and troubleshooting related only)

- Thread starter TCFlowClyde

- Start date

WOW, metal 9g is pretty small, well done, you know you don't really even need a arduino, you can flash the same code from same IDE on ATtiny chip, look up ATtiny85/45/25, for a smaller footprint... worth looking into to make everything smaller,.Hey! I am designin the exact same thing

I use seeduino xiao and nrf24l01 and a servo, it’s working, I designed the 3d model to insert in the seat tube, but I don’t have a 3d printer, I will work with a friend to test it.

Honestly, wired will be mich easier as you can use only 1 arduino, but you need to run the cable…

Regarding the servo, I used a metal 9g but it fits exactly in the seat tube and not sure it’s powerful enought

happy to help w ideas, it sounds like you have a solid apporoch, for strong stuff try MJF (PA12 or PA6) from JLPCB (3d printing section) its pretty much the cheapest MJF prints I have found< so, proto on FDM printers and for strength on final version make it on MJF, strong in everydirection unlike FDM printing.

try solid state relay, its heaps smaller!!, the DC-DC modules are too big!! we are trying to make a smaller oneReagrding the lights I did the same on my lce930, light cable triggering relay and dc dc converter for 12v from my main battery.

But I finally took of the relay as there was not enough free space in the frame

thx so much for the offer!! I think the first job is getting a small DC-DC, PCB done, so 48v to 12v, this is needed as all the other are pretty bigIf you need assistance - I am an electronics engineer - specialized in schematics design and pcb layout.

Also having several 3d-Printers and waiting for my frame.

If you need someone to help or test things - let me know.

As the cef50 will be for my wife and she will use it as a main transportation vehicle, I plan to build rear lights using led ribbons on the rear triangle, red all the time and when she activates the turn signal, one side blinks orange. The goal is also to add a brake light but based on the gyrometer. I have ordered a test tuen signal actionner from Ali, I’ll test all of it when I will receive the parts

What exactly do you mean with "small"?thx so much for the offer!! I think the first job is getting a small DC-DC, PCB done, so 48v to 12v, this is needed as all the other are pretty big

There should not be much load, right?

for

for a powerful light, we might need 3AWhat exactly do you mean with "small"?

There should not be much load, right?

Okay, now I see the problem.for

for a powerful light, we might need 3A

we might not need any more than 36w for lights, but for me, as a light designer IMO 2A max @12v would be enough, for me anyway... we should start another thread for electroinc add ons or something....Okay, now I see the problem.

voigtkampff

Active member

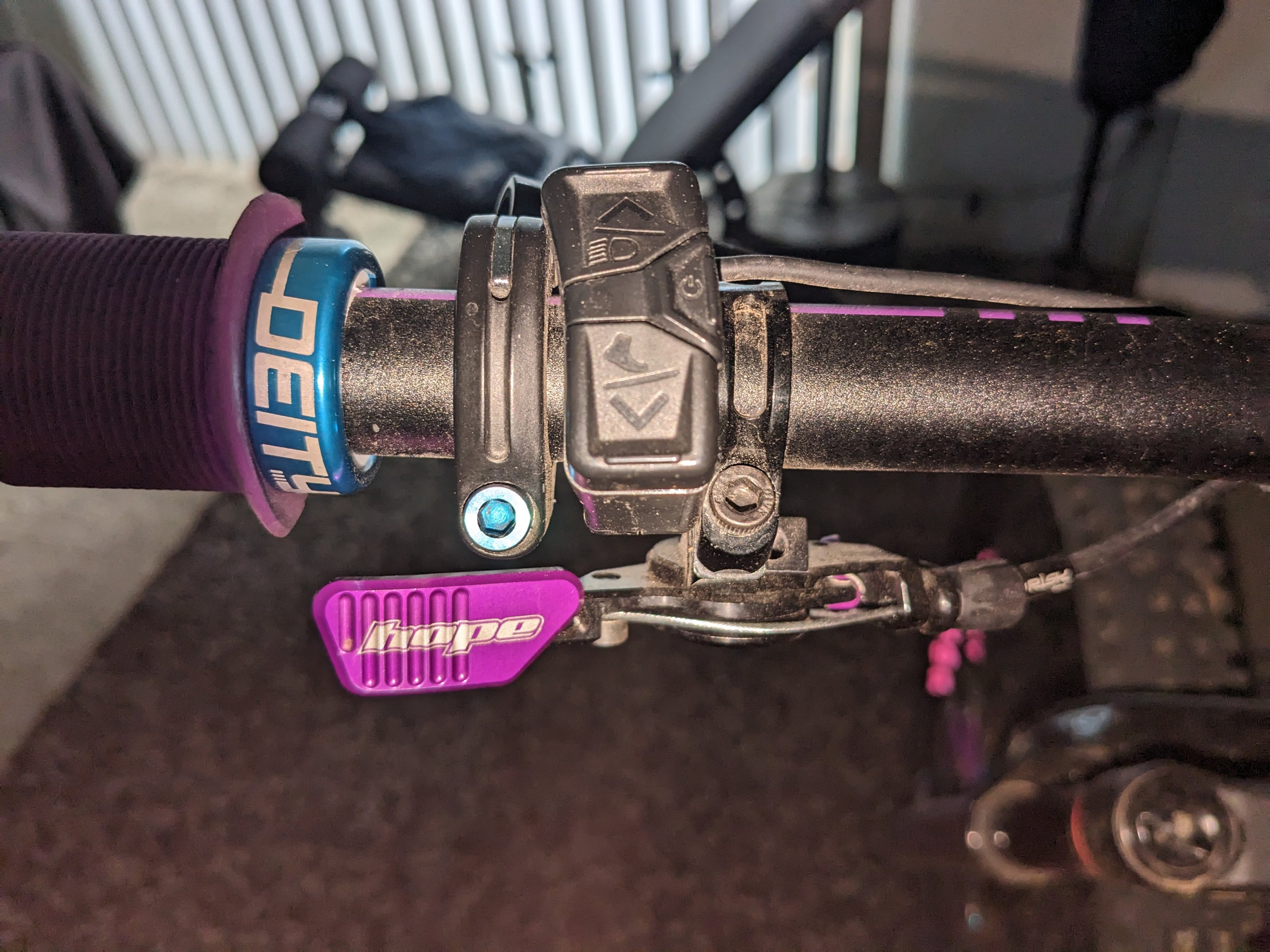

As I'm still waiting for my kit and can't check it myself, I was wondering if anyone was able to install Bafang control unit (the part with mode up/down buttons) together with Shimano brake levers for 12-speed groupset (m8100, m7100 etc) in a way that the control unit is located between brake lever clamp and the additional contact point touching the handlebar to ensure stiffness. I'm planning to use ispec-ev mounted shimano sl-mt800 dropper lever and it seems like the buttons might fit in this space. Can anyone share a photo of such arrangement?

TCFlowClyde

Active member

- Thread starter

- #3,402

My setup: XT M8100 levers, generic HB dropper clamp, DPC245 power button/mode selector.As I'm still waiting for my kit and can't check it myself, I was wondering if anyone was able to install Bafang control unit (the part with mode up/down buttons) together with Shimano brake levers for 12-speed groupset (m8100, m7100 etc) in a way that the control unit is located between brake lever clamp and the additional contact point touching the handlebar to ensure stiffness. I'm planning to use ispec-ev mounted shimano sl-mt800 dropper lever and it seems like the buttons might fit in this space. Can anyone share a photo of such arrangement?

TCFlowClyde

Active member

- Thread starter

- #3,404

XTM8120 w/DPC 245 power mode selector.My setup: XT M8100 levers, generic HB dropper clamp, DPC245 power button/mode selector.

View attachment 133094 View attachment 133095

It fits between the clamp and bridge but creates an angle that might not work for all.

Extra info.

Additionally, I have high rise 40 mm which effectively shortens the power mode cable to the display, hence the odd angle of the mode selector.

All the nuances of the custom cockpit.

Although, it's is a major hepatic improvement over the old DPC 242 as well as now having a color screen and an HB clamp that actually fits a 35 mm handlebar!🫡

Last edited:

voigtkampff

Active member

Thanks, this setup is exactly what i’m hoping to do. I have rather small hands, short fingers and moving the control unit further inside will probably be highly uncomfortable.XTM8120 w/DPC 245 power mode selector.

It fits between the clamp and bridge but creates an angle that might not work for all. View attachment 133099 I run 800 mm bars and needed the dropper lever further out (not showing currently) so I used the solo clamp rather than I-spec ev integrated brake clamp. From M600 rig.

View attachment 133098

Extra info.

Additionally, I have high rise 40 mm which effectively shortens the power mode cable to the display, hence the odd angle of the mode selector.

All the nuances of the custom cockpit.Also why would be nice to have a wireless selector.

And a little lower profile like on the Forestal Siryon M820 for future designs would be desirable.

Although, it's is a major hepatic improvement over the old DPC 242 as well as now having a color screen and an HB clamp that actually fits a 35 mm handlebar!🫡

I did not see this message, thanks I will check for this!WOW, metal 9g is pretty small, well done, you know you don't really even need a arduino, you can flash the same code from same IDE on ATtiny chip, look up ATtiny85/45/25, for a smaller footprint... worth looking into to make everything smaller,.

happy to help w ideas, it sounds like you have a solid apporoch, for strong stuff try MJF (PA12 or PA6) from JLPCB (3d printing section) its pretty much the cheapest MJF prints I have found< so, proto on FDM printers and for strength on final version make it on MJF, strong in everydirection unlike FDM printing.

CarolinaCrawler

Active member

Are you currently powering the light with just the Bafang light cable? How is that working? I've been thinking of doing what you did with the direct battery power and a relay on my M510 bike.Reagrding the lights I did the same on my lce930, light cable triggering relay and dc dc converter for 12v from my main battery.

But I finally took of the relay as there was not enough free space in the frame

I've found a few light bars that are 6-40 volt. That would make a DC to DC converter not needed. It just sounds like alot of work and money when I have a battery powered light that works well. I just hate having a button that does nothing knowing that it could. lol

Also, I don't know if it has a sensor or something, but when we turn on our M510 bikes in low light situations, it automatically turns the headlight on and dims the display.

I'm using a DC DC converter directly, as the light cable fails to deliver enough power. I'm using my bike in the night in the forest so I need powerful lightAre you currently powering the light with just the Bafang light cable? How is that working? I've been thinking of doing what you did with the direct battery power and a relay on my M510 bike.

I've found a few light bars that are 6-40 volt. That would make a DC to DC converter not needed. It just sounds like alot of work and money when I have a battery powered light that works well. I just hate having a button that does nothing knowing that it could. lol

Also, I don't know if it has a sensor or something, but when we turn on our M510 bikes in low light situations, it automatically turns the headlight on and dims the display.

The relay option is simple, but in my LCE930, everything was so tightly installed, it was very painful to reinstall the motor properly, I gave up on the relay...

You have high voltage ebike lights, I think some big brands are making it such as supernova

TCFlowClyde

Active member

- Thread starter

- #3,411

There's 3 generations. The most recent one may be the most robust. But time will tell....Anyone have a good bash guard option? Mine is destroyed with one log roll. Please send link for purchase. Thanks.

View attachment 133243

I got DC-DC converter and relay as well. It is nice when it is working, but as you said, it is a pain in the ass to get all the cables in and connected when installing the motor!The relay option is simple, but in my LCE930, everything was so tightly installed, it was very painful to reinstall the motor properly, I gave up on the relay...

You have high voltage ebike lights, I think some big brands are making it such as supernova

The DC-DC converter is very small and inexpensive. Mine gives 3 amps, so 36W maximum. I think that is enough. I think best solution is to forget about the relay and use a light with dedicated on/off switch. Much less hazzle this way.

92se-r

New Member

Why do you guys bother with a relay? The current is insignificant. Most little switches like freda says will be fine. Just fuse the battery wire to the dcdc proportional to wire size as close to the battery as possible. The output wires to the light just size to 5a or up capacity and the dcdc will fold back if there is a short.I got DC-DC converter and relay as well. It is nice when it is working, but as you said, it is a pain in the ass to get all the cables in and connected when installing the motor!

The DC-DC converter is very small and inexpensive. Mine gives 3 amps, so 36W maximum. I think that is enough. I think best solution is to forget about the relay and use a light with dedicated on/off switch. Much less hazzle this way.

Link please?There's 3 generations. The most recent one may be the most robust. But time will tell....

TCFlowClyde

Active member

- Thread starter

- #3,415

You'd order from Jean/Linda at SZZS. They make it in-house for the CEF50 frame. Latest release was last November/December but a few have banged Gen 3 up a little and it's held so far.Link please?

For me: Gen 1 and Gen 2 broke on a soft log step up and a sand ridge on a steep bank roll down respectively...super fragile like an eggshell.

I reinforced my Gen 2 guard with carbon fiber...it added another 60 +/- g in weight, but it's very stout so far.

AAAAALRIGHTYYYY Fellas...

I just FINALLY pulled the trigger on a frameset.

I am going for a painted one in size large with headset cable routing, 48V, 480Wh carbon case battery, but standard aluminium cranks.

All components are already bought and at home and are only waiting for the frame.

Shipping shall be around march, we'll see how long it takes to europe.

I just FINALLY pulled the trigger on a frameset.

I am going for a painted one in size large with headset cable routing, 48V, 480Wh carbon case battery, but standard aluminium cranks.

All components are already bought and at home and are only waiting for the frame.

Shipping shall be around march, we'll see how long it takes to europe.

Congratulations for your new bike bro... Hope u like itAAAAALRIGHTYYYY Fellas...

I just FINALLY pulled the trigger on a frameset.

I am going for a painted one in size large with headset cable routing, 48V, 480Wh carbon case battery, but standard aluminium cranks.

All components are already bought and at home and are only waiting for the frame.

Shipping shall be around march, we'll see how long it takes to europe.

Nice! When did you order?

7th of JanNice! When did you order?

Similar threads

- Replies

- 48

- Views

- 7K

- Replies

- 17

- Views

- 2K

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 564K

- Messages

- 28,598

- Members

Latest articles

-

Ebike motor sensors - cadence vs torque sensor

I received a question a few weeks ago, and I decided I wanted to answer... -

Shimano E6090 vs. KMC e10 – 10 speed chain test

We’ve tested 12-speed Shimano chains before and that wasn’t too much...- Knut Nes

- 3 min read

- Views: 2K

- Comments: 6