You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bafang M560

- Thread starter vext

- Start date

Swannking

Member

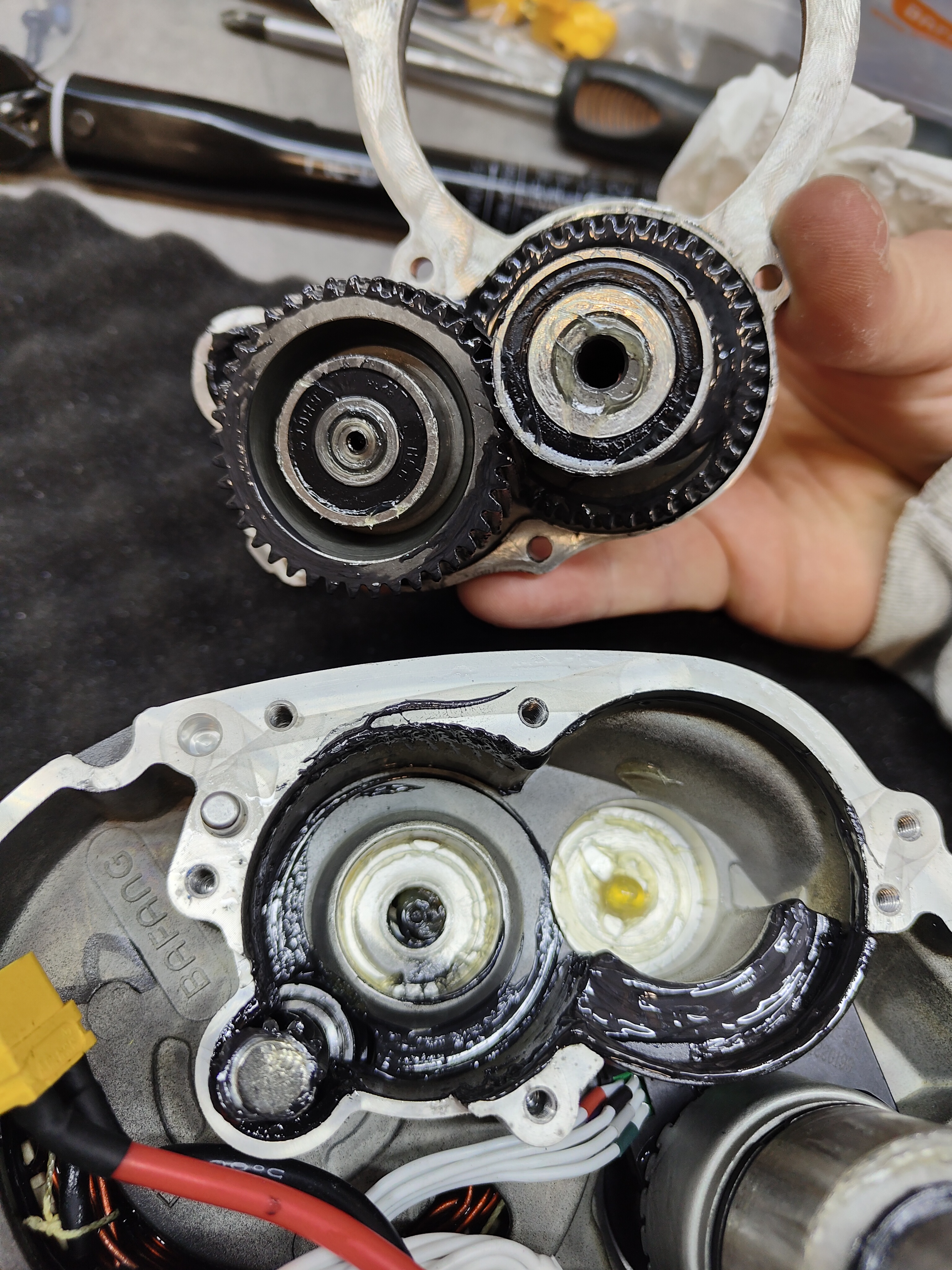

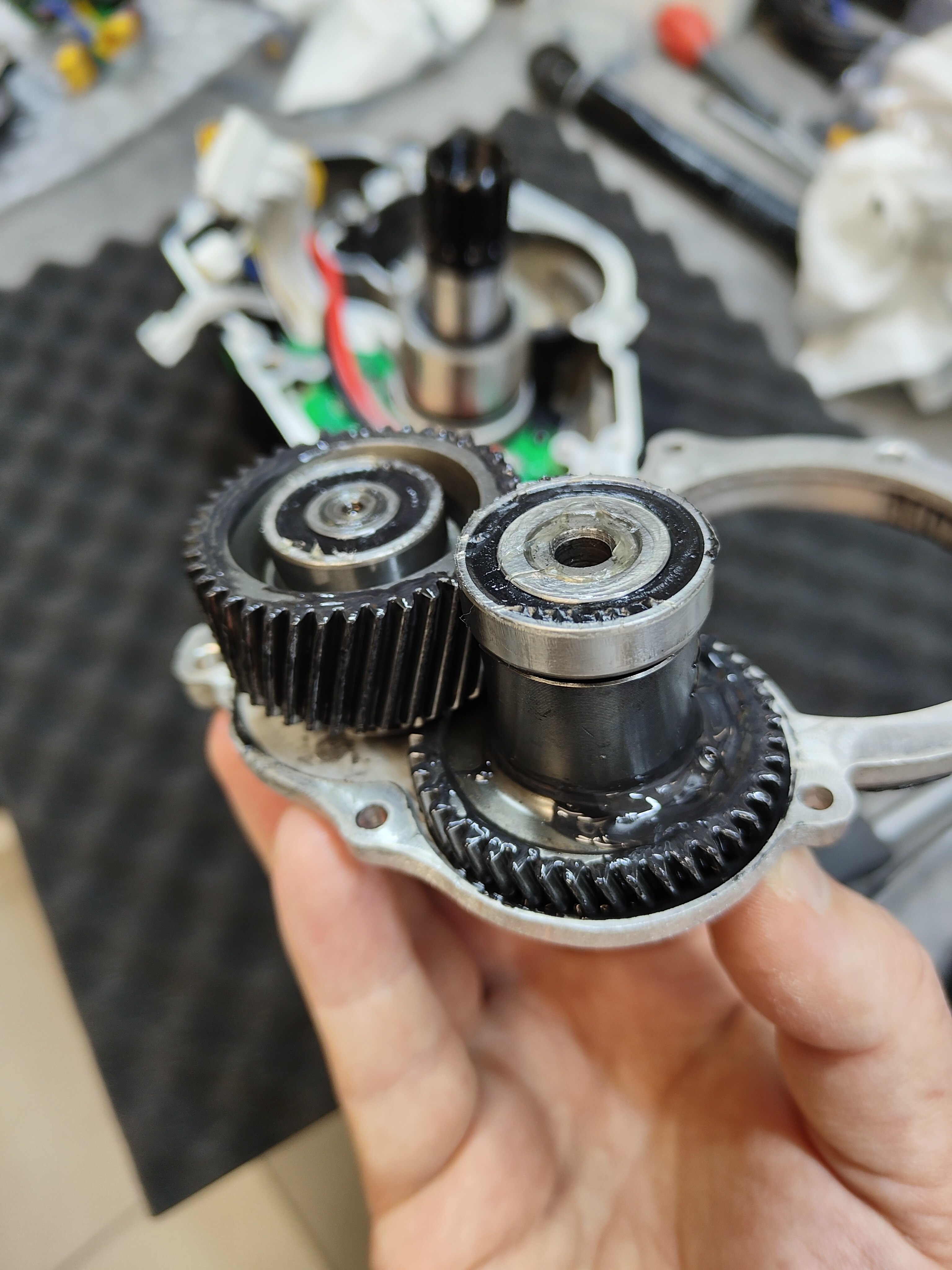

What tools are required for bearing removal and Re assembly? Can you post pictures of your tooling? I just finished my bid with the M560. The motor is loud and even louder than my stock M620 without grease.The reason why I started disassembling it was, that I read about the noise levels. I did not ride that thing yet and took my brand new M560 appart and de-greased it in order to examine the gears and bearings closer. I'll order FAG/SKFs soon and replace them. The bearings on the M560 (mostlikely M510 aswell) are nearly identical to the ones on M600.

I think there is not much that can be done about the noise level, since it might come from the stator itself, except swapping the stock controller for a different one. As of today, I don't know any third-party controller for the M510/M560. I might hook mine up to a VESC and see if this reduces the noise. This has been done for the M600 motor.

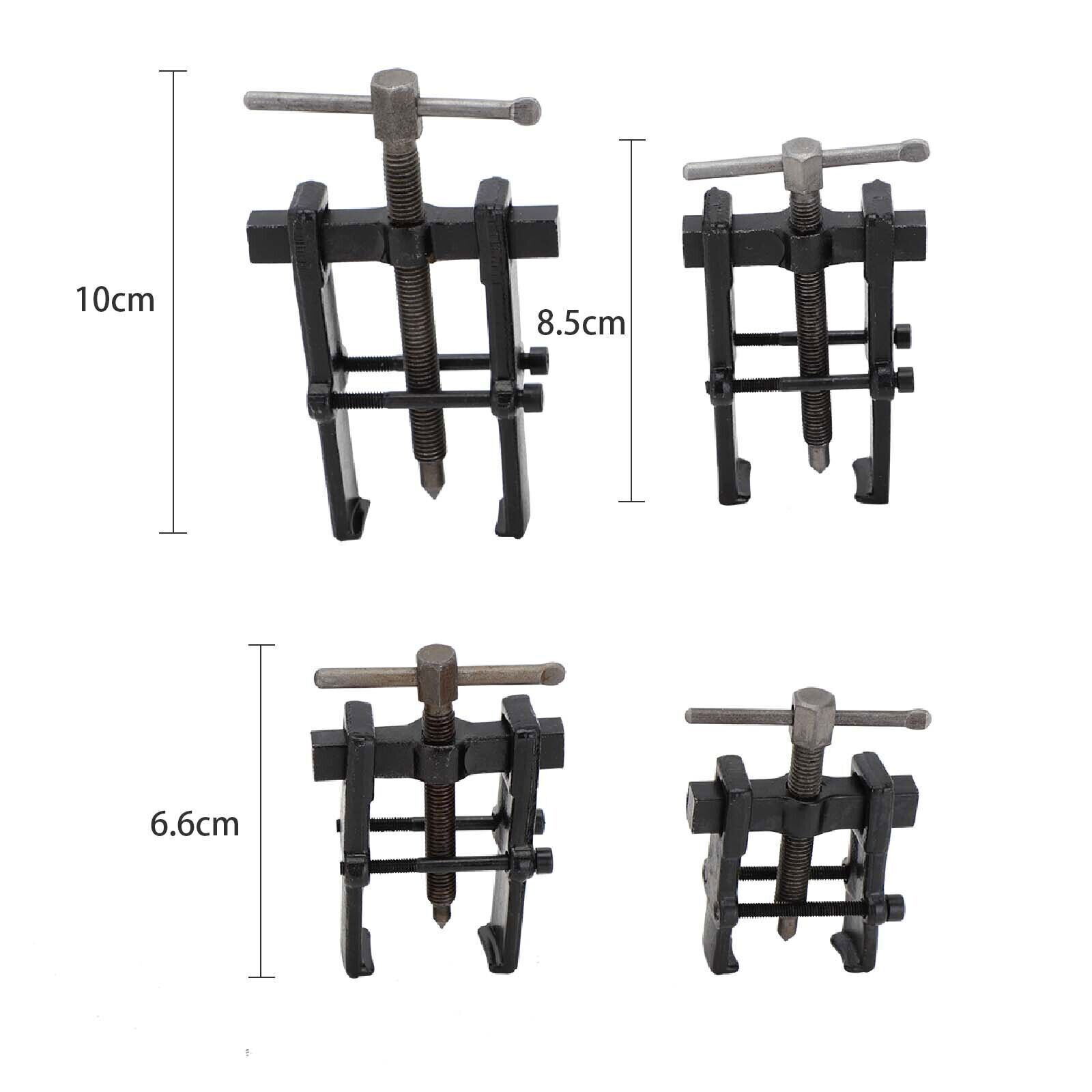

I used very simple tools, like a torx screwdriver and a pair of snap ring removal pliers (150mm). For the bearing you need some bearing pullers. They worked fine, but for the stator I unscrewed the magnet, used two wrenches and knocked it through with a hammer. The lower bearing of 3rd streel gear (sometimes called "Nylon Gear"), was tricky and had to be destroyed for removal. I did it by levering with flathead screwdriver.What tools are required for bearing removal and Re assembly?

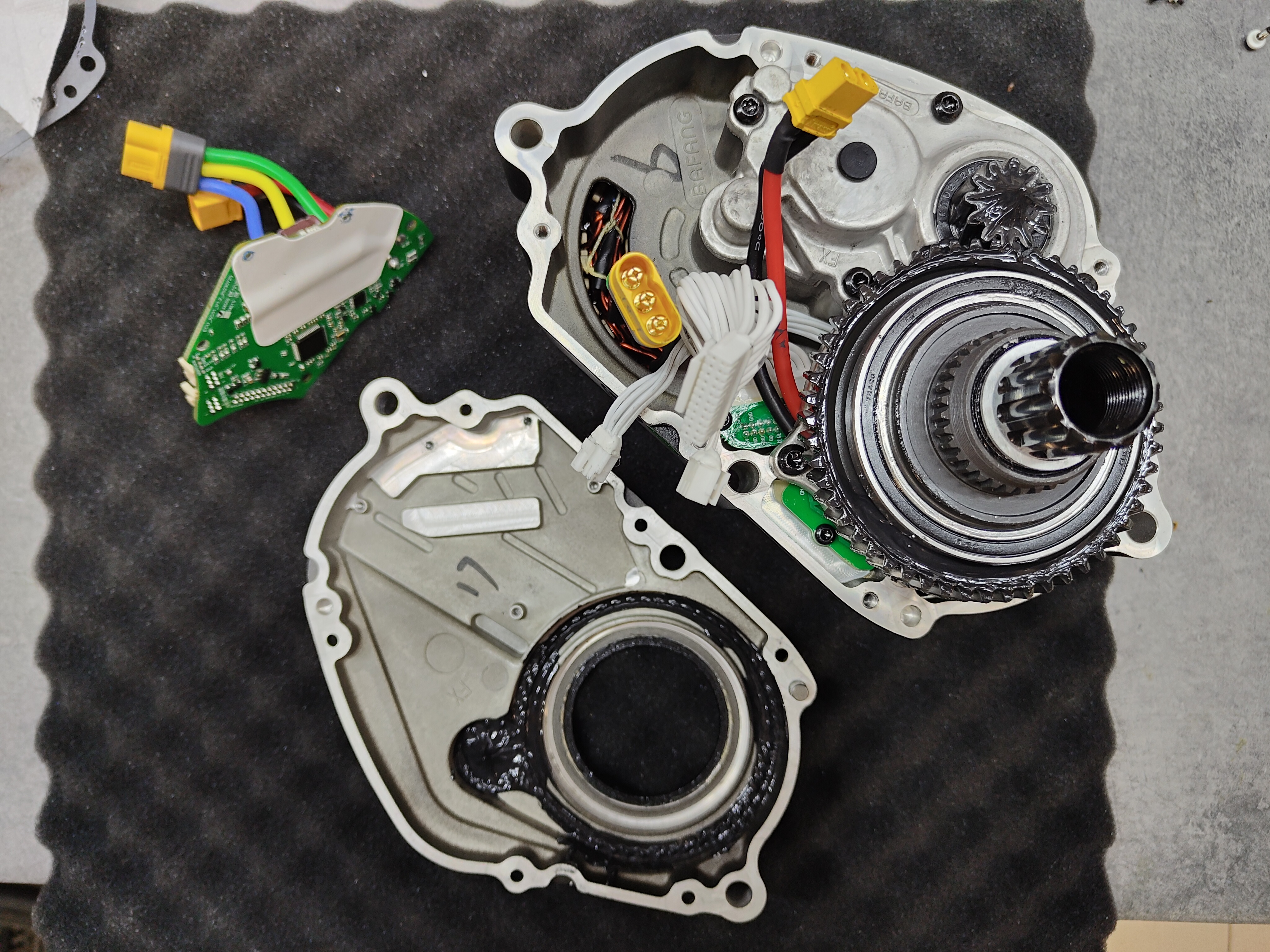

M560 Controller-side:

https://www.emtbforums.com/threads/bafang-m560.33293/post-515666

M560 Motor-side:

View attachment 130548 View attachment 130549

M560 Stator/Rotor:

View attachment 130545 View attachment 130544

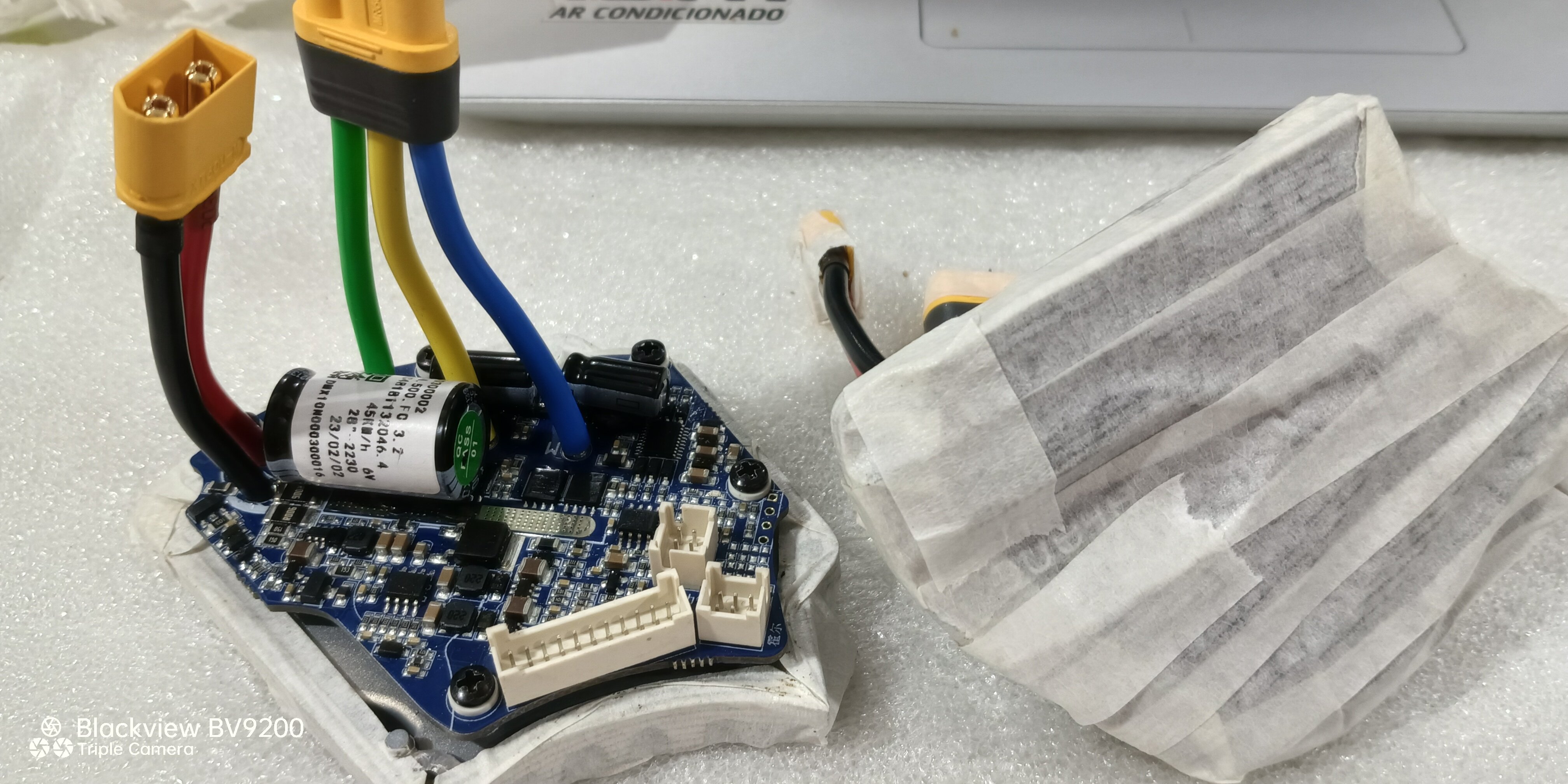

M560 PCB Connector Board:

View attachment 130546 View attachment 130547

M560 Torquesensor:

View attachment 130550 View attachment 130551

M560 Mainshaft assembly:

View attachment 130556

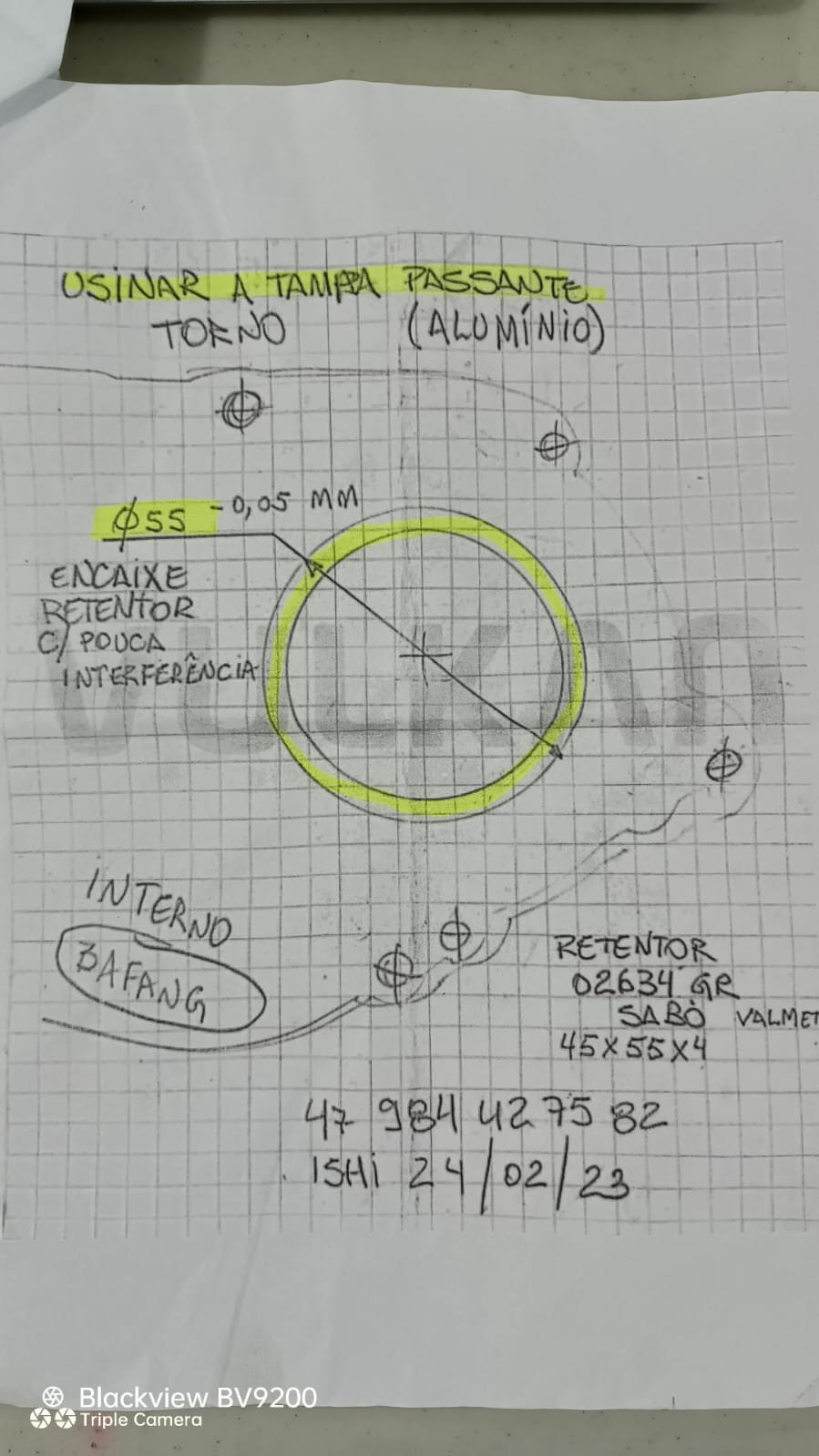

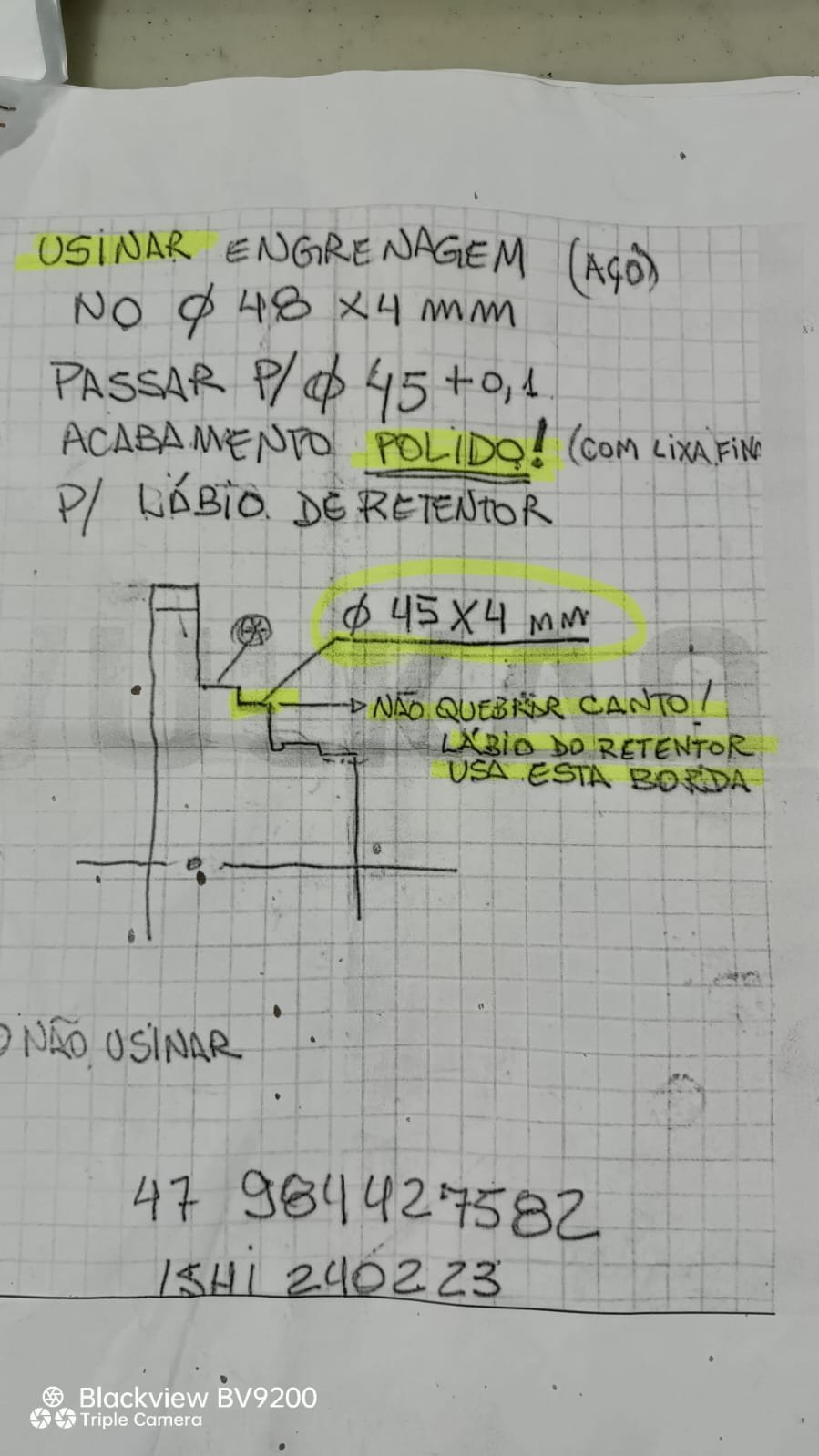

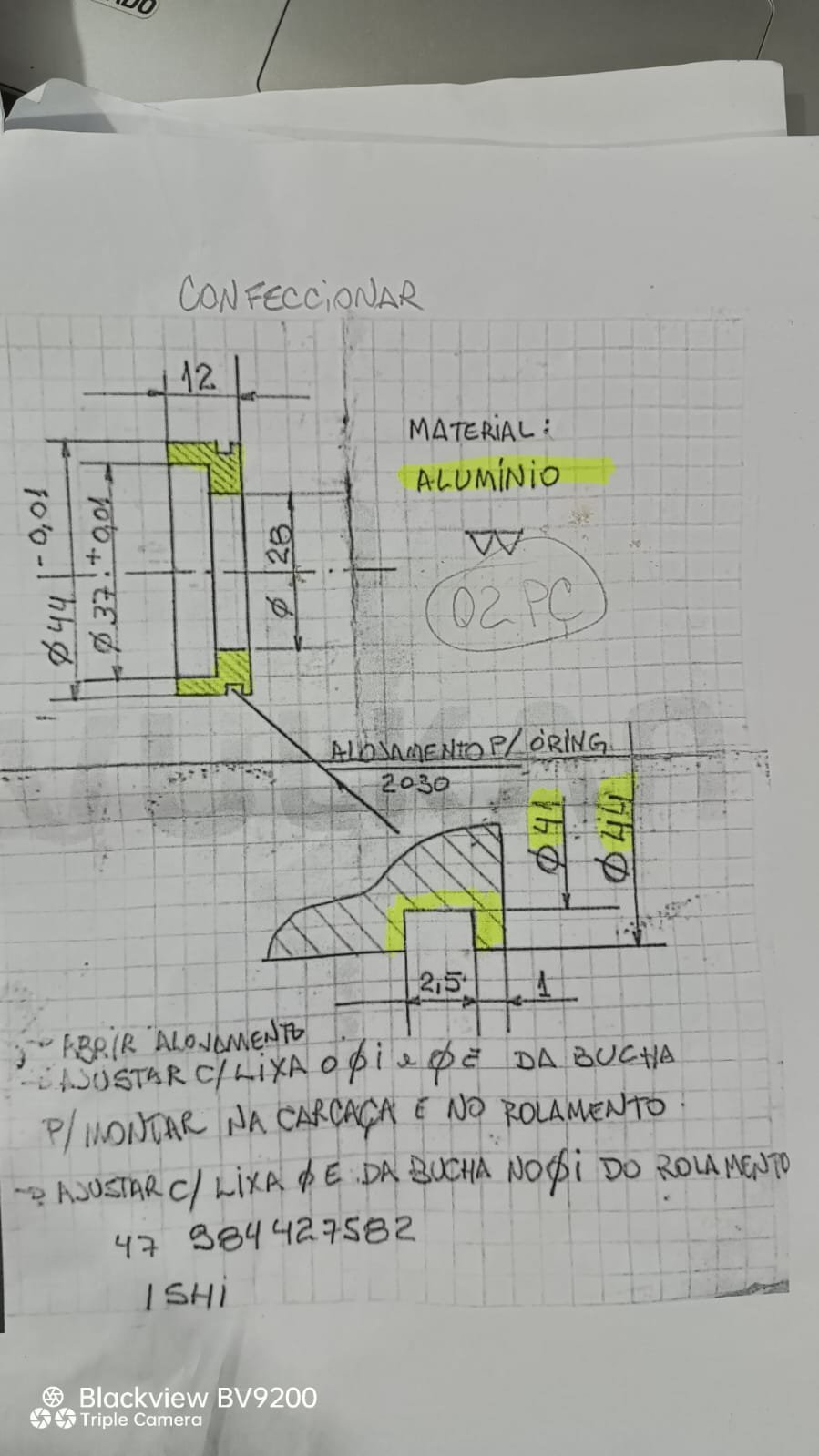

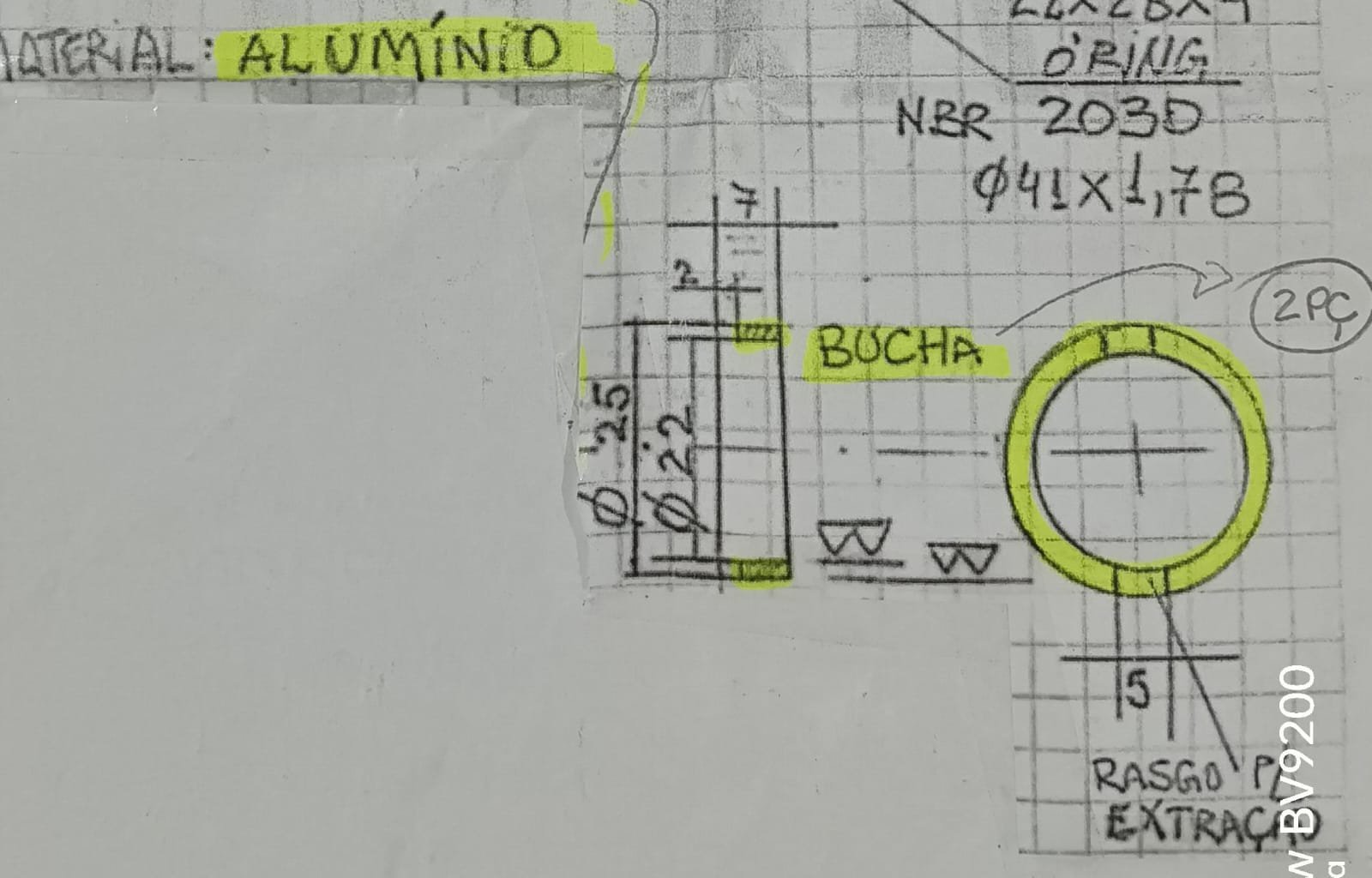

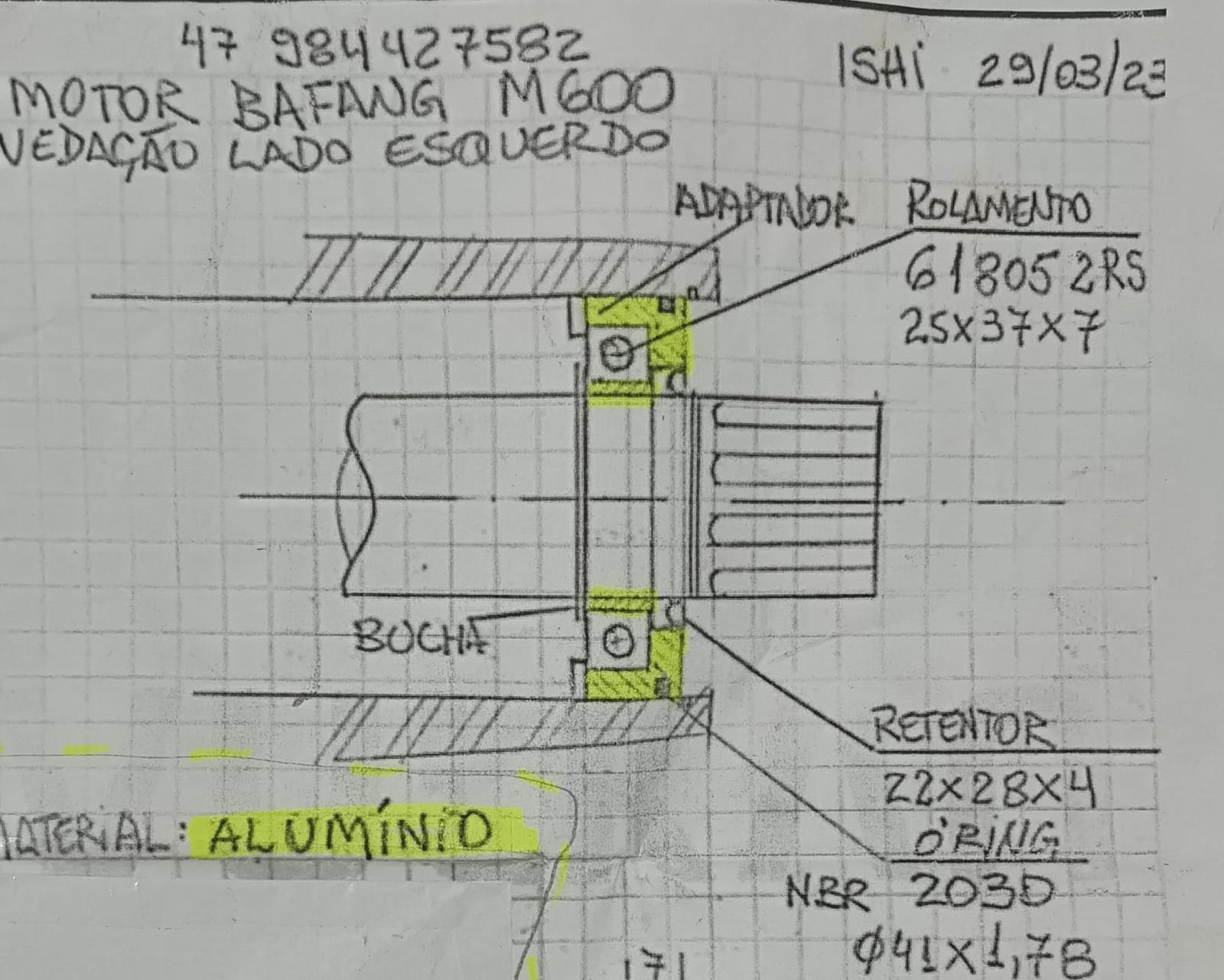

Here in Brazil I had some problems with the power plate burning and internal bearings damaged by water ingress on my M600 BAFANG engines. (just like other brands of engines, they also enter water)

I opened them, studied and made some modifications to prevent any more water from entering, I machined bushings and adapted seals.

I did the test with positive pressure of 10 psi and also tested with a vacuum gauge. Furthermore, I started the engine in the water. The water never came in again!

I also took all the internal plates and gave them a coat of motor coil varnish.

It was excellent!

Currently I realize that the internal noise of the M600 is much lower than the SMAG BROSE!

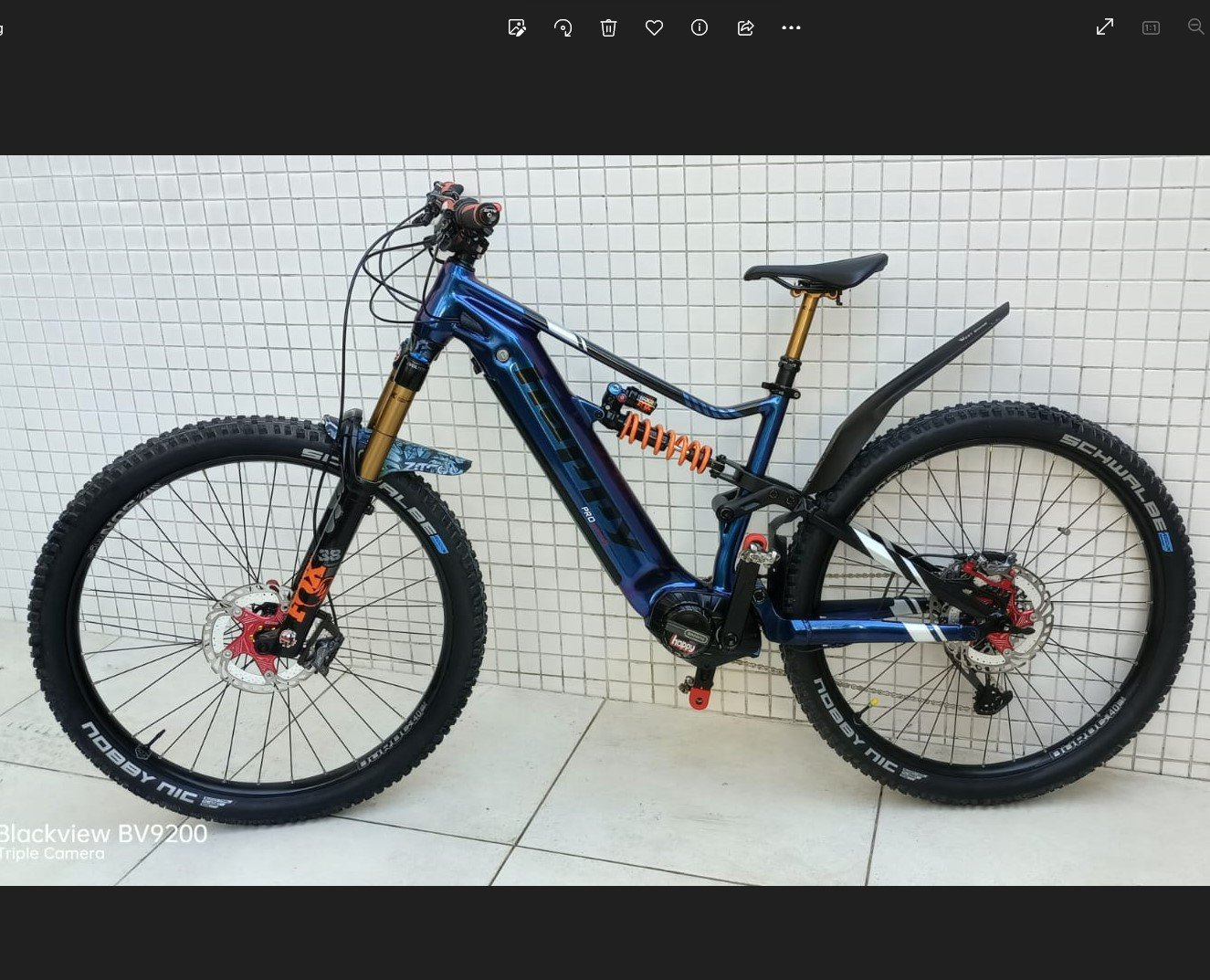

I bought M560 engines and will start testing.

Mara2000

New Member

Hi, do you know if anyone is planning to produce nylon gears for the M560? I just got a new ebike with the M560. The motor is not very noisy compared to the BBS02 750W that I have on the other bike. However, if an upgrade to nylon gears could be made, it wouldn't go amiss  Thanks, Marek.

Thanks, Marek.

Wow! What is that frame?Here in Brazil I had some problems with the power plate burning and internal bearings damaged by water ingress on my M600 BAFANG engines. (just like other brands of engines, they also enter water)

I opened them, studied and made some modifications to prevent any more water from entering, I machined bushings and adapted seals.

I did the test with positive pressure of 10 psi and also tested with a vacuum gauge. Furthermore, I started the engine in the water. The water never came in again!

I also took all the internal plates and gave them a coat of motor coil varnish.

It was excellent!

Currently I realize that the internal noise of the M600 is much lower than the SMAG BROSE!

I bought M560 engines and will start testing.

View attachment 130952 View attachment 130953 View attachment 130954 View attachment 130955 View attachment 130956 View attachment 130957 View attachment 130958 View attachment 130959 View attachment 130961 View attachment 130962 View attachment 130963 View attachment 130964 View attachment 130965 View attachment 130966

What do you think of the m560?

Any updates?For anyone interested, I got the info from Jason from Changzhou Victory that the production of the new revision of the M560 will start early next year.

How did that go? Did it last 3x longer?Thanks for the info. So I just bit the bullet so to speak and got the new Shimano "Linkglide" M8130 11 speed.

It's apparently the unit that Shimano's built for EMTB's. Apparently 3x stronger than the current hyperglide units like mine. I wish i'd known before I bought the 12 speed unit i have now.

i'll report back.

Oh. What kind of probems? How is the motor? Does yours overheat? Is it super loud?Ha! I ran into trouble with my controller and have been wrestling with that. Unsure yet. Sorry.

Give us an update when you get more experienced with that shimano!

Hello everyone. I received my m560 engine, 750W version. The first quick test on the table and it turns out that it is not that loud at all. Of course, it is not as quiet as the m600 and will not be due to the use of a steel gear. After disassembling it, it turns out that there is a controller with the new marking M560. As for the grease, it is also good - the grease is well distributed everywhere and there is the right amount of it, unlike in the case of my m620 where there was very little grease. The engine will be mounted in a Dengu E82 frame with a 48V 1008Wh battery. Unfortunately, I'm still waiting for the frame and battery.

Controller info:

Hardware version: MM G5300.750.C 1.0

Software version: MMG5300C4825F801001.4

Link to video:

m560 test

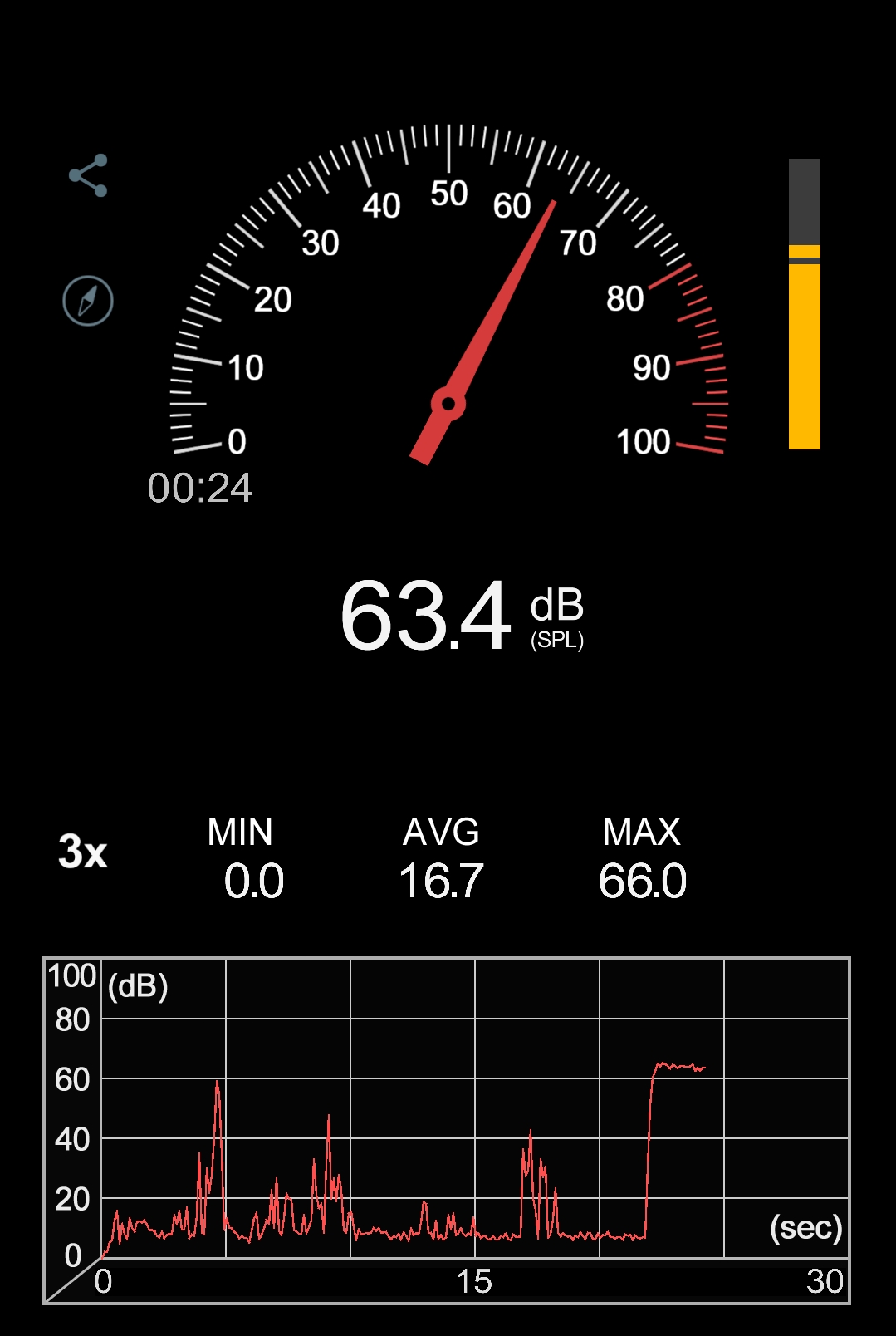

Test from 10 cm distance:

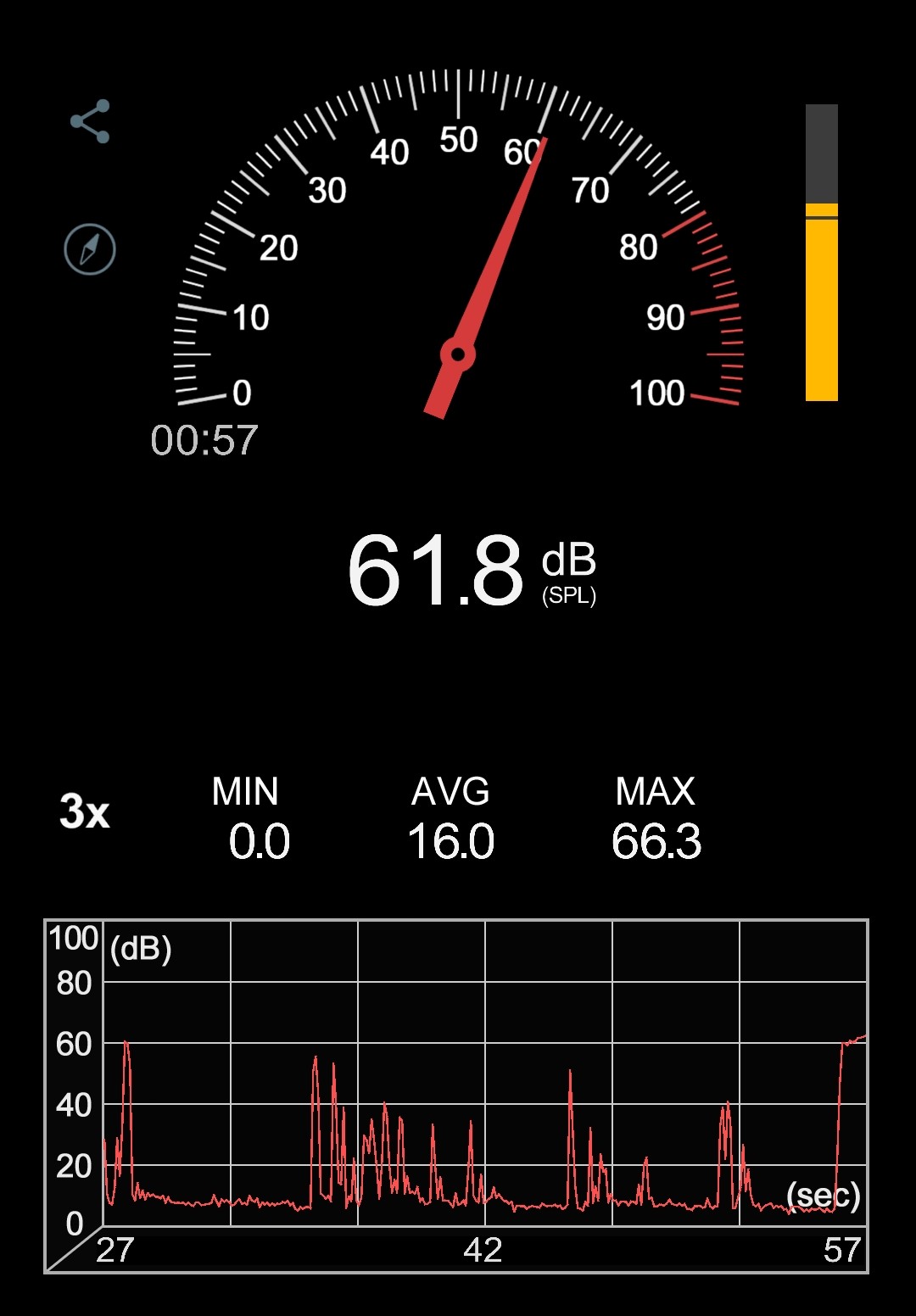

Test from 50 cm distance:

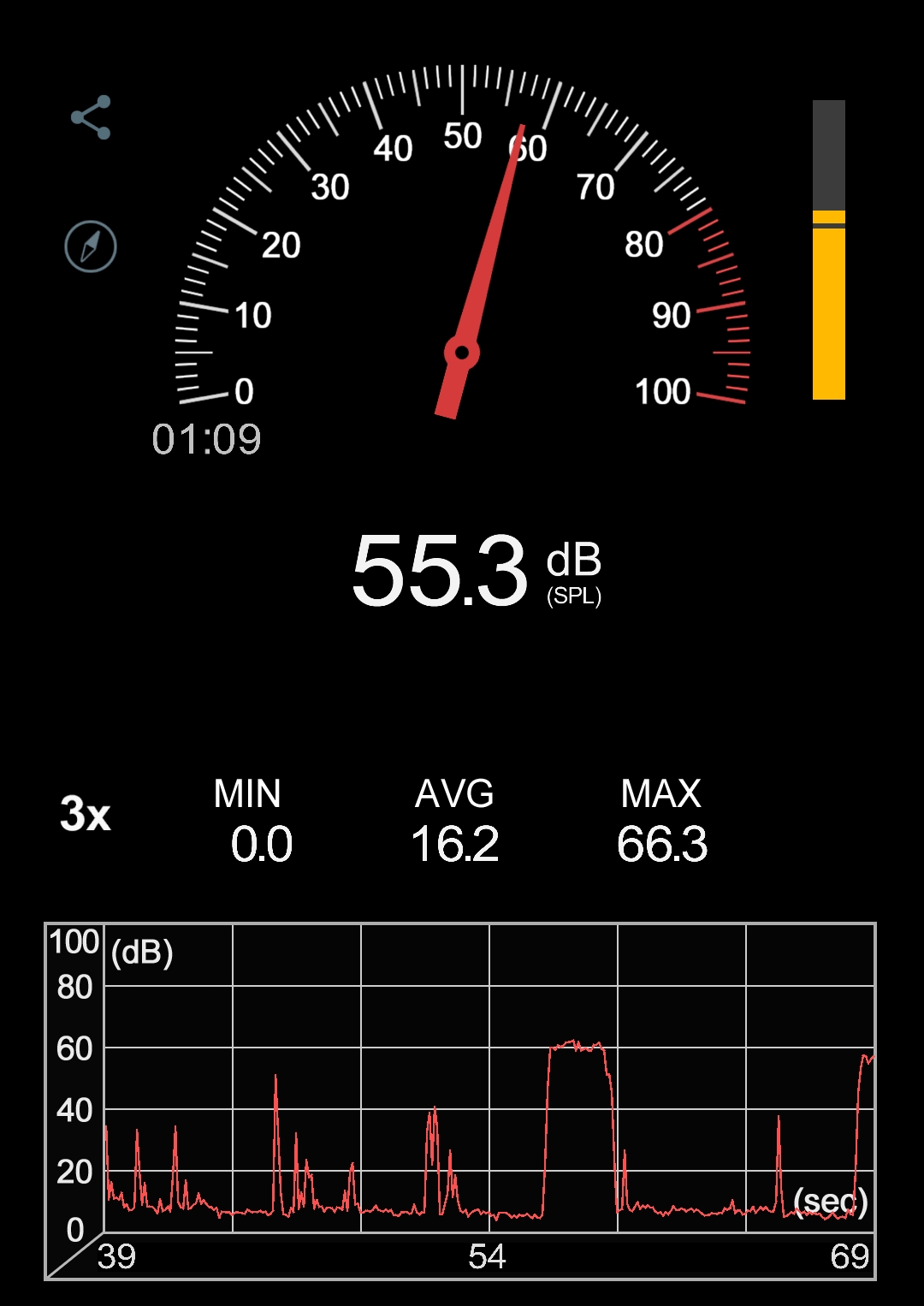

Test from 100 cm distance:

Controller info:

Hardware version: MM G5300.750.C 1.0

Software version: MMG5300C4825F801001.4

Link to video:

m560 test

Test from 10 cm distance:

Test from 50 cm distance:

Test from 100 cm distance:

Last edited:

I wonder how much the noise will increase when it is on a bike and needs to move the bike + rider. Then the engine has to work much harder.Hello everyone. I received my m560 engine, 750W version. The first quick test on the table and it turns out that it is not that loud at all. Of course, it is not as quiet as the m600 and will not be due to the use of a steel gear. After disassembling it, it turns out that there is a controller with the new marking M560. As for the grease, it is also good - the grease is well distributed everywhere and there is the right amount of it, unlike in the case of my m620 where there was very little grease. The engine will be mounted in a Dengu E82 frame with a 48V 1008Wh battery. Unfortunately, I'm still waiting for the frame and battery.

View attachment 136467

View attachment 136468

View attachment 136469

View attachment 136470

View attachment 136471

Link to video:

m560 test

Test from 10 cm distance:

View attachment 136472

Test from 50 cm distance:

View attachment 136473

Test from 100 cm distance:

View attachment 136474

We will see if the engine will over heat or did they fix it

I hope all goes well! I want to get this motor as well

Dado

Well-known member

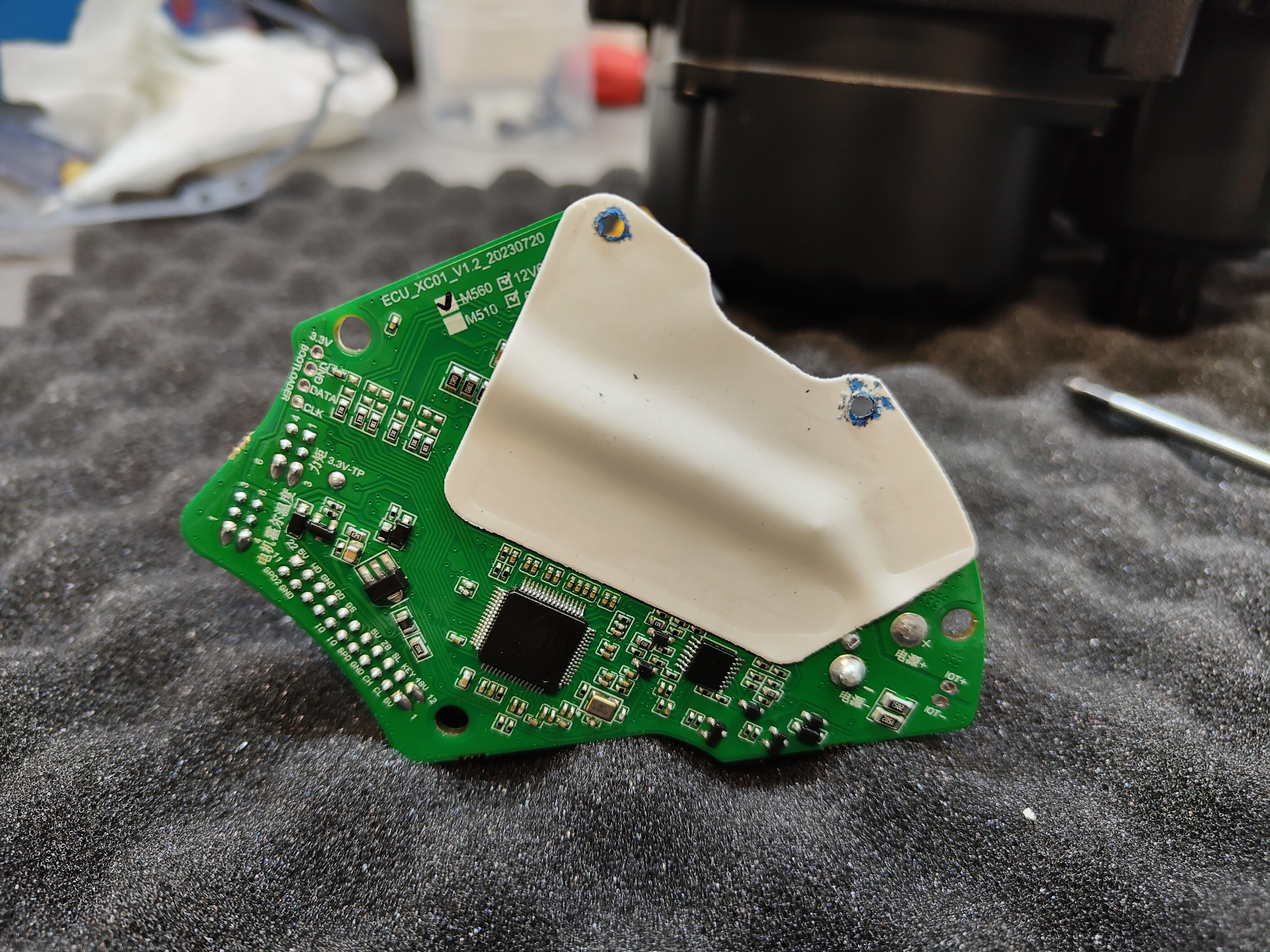

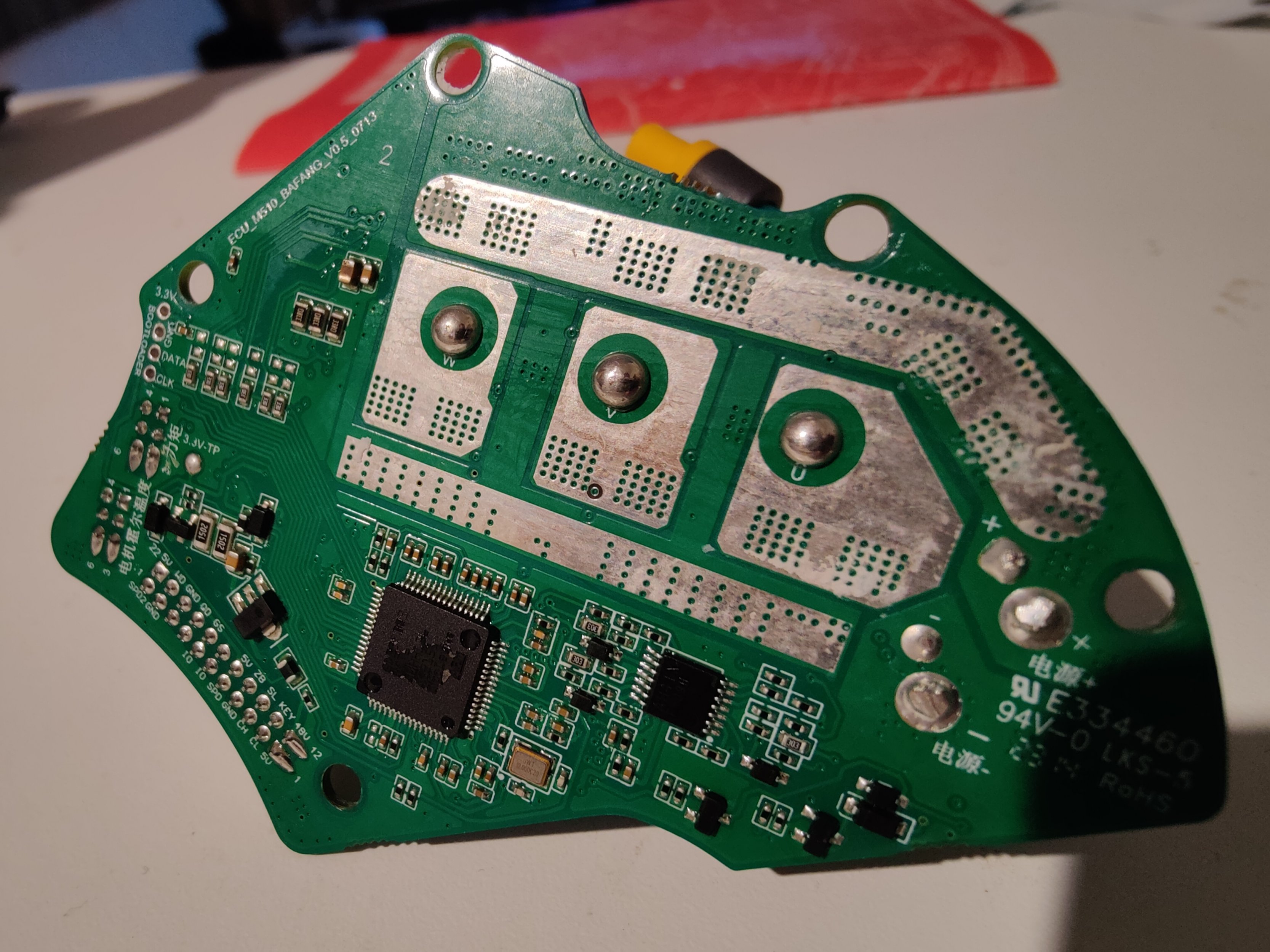

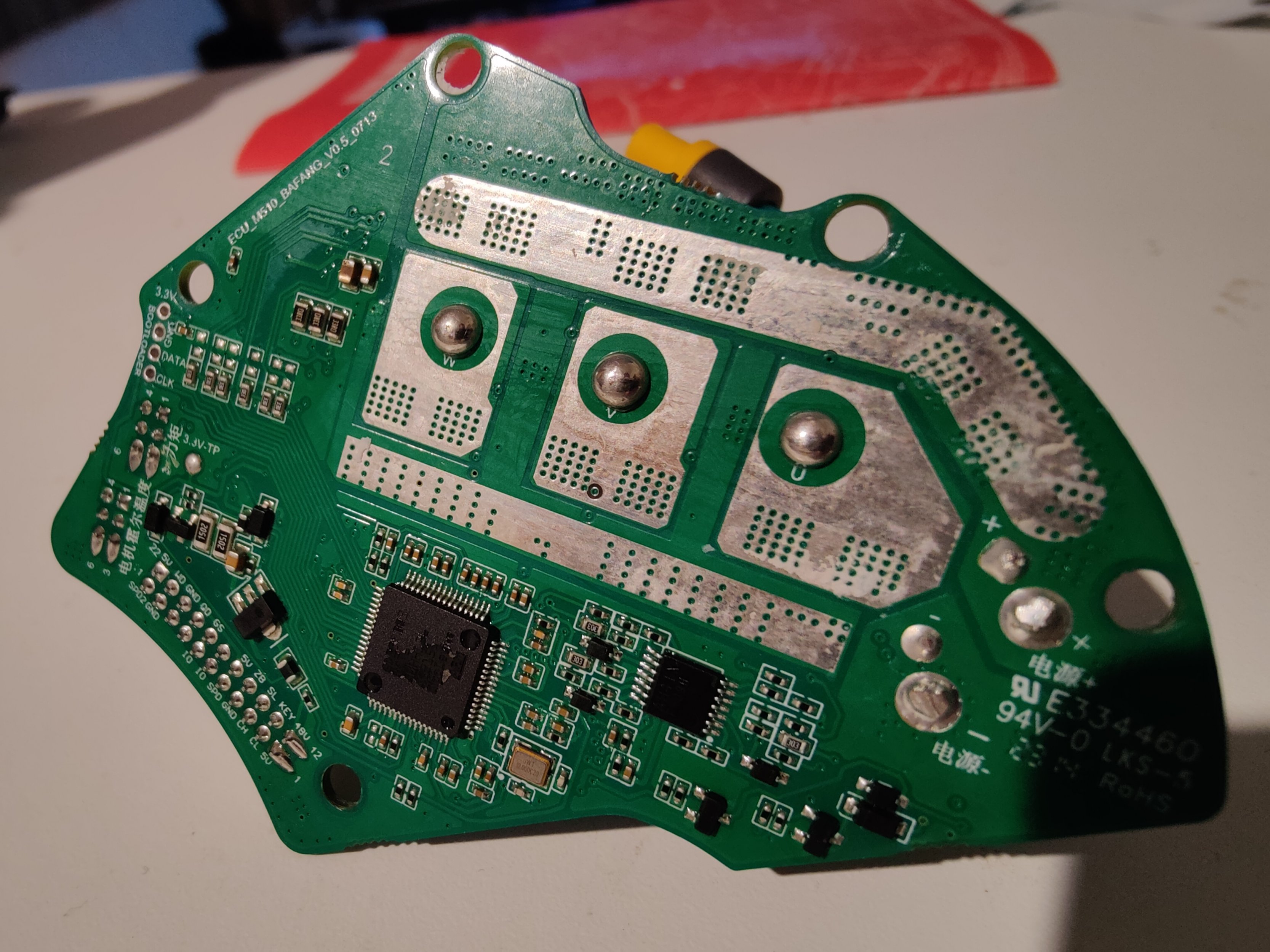

Looks like depends where you put the tick, if M510 or M560.  ) I see this PCB board is from July 2023 - that was the time when first people were getting beta versions.

) I see this PCB board is from July 2023 - that was the time when first people were getting beta versions.

Can you please check for firmware version, which is in? When new controller version, can be also a new firmware.

Hope, soon will be out final revision of this motor.

For comparrison old beta version controller.

Can you please check for firmware version, which is in? When new controller version, can be also a new firmware.

Hope, soon will be out final revision of this motor.

For comparrison old beta version controller.

Hardware version: MM G5300.750.C 1.0Can you please check for firmware version, which is in? When new controller version, can be also a new firmware.

Software version: MMG5300C4825F801001.4

Dado

Well-known member

Looks like no new firmware.

vext

Member

- Thread starter

- #167

It's not a bug in Bafang 's eyes.Delay after stop pedalling [on the m560] - It is a bug and I don't understand how Bafang can not get rid of this. One firmware has longer delay, other does not. Getting sick of it.

They design their system to use a brake cut off switch on the brake lever. No one in our world uses the switches because we want better levers. But...

If you use a brake-cut-off it cuts all power instantly. It works intuitively and is easy to learn to tap the brakes to stop any unwanted power delivery upon pedal stop.

I found myself doing it automatically without even thinking about it.

I use this so I can use any lever...

Magura eBike Brake Pressure Switch - For Magura Rim and MT Disc Brakes Black

Magura eBike Brake Pressure Switch - For Magura Rim and MT Disc Brakes Black. The Magura hydraulic brake pressure/motor cut-off switch is specifically designed to control functions such as the on/off features of the lights and motor cut-off on your e-bike. Pressure switch is supplied with all...

I never ever feel the negative effects of the overrun everyone complains about.

10 out of 10 would recommend.

Also note they now make "nice" aftermarket hydraulic levers that have built in switches. If anyone has used them let's us know how they work with the m560 (or any other bafang motor)

Dado

Well-known member

Had also brake cut offs on old ebike. Then I realized it is not needed, just another possible point of failure. If you saying you dont find overrun negative, you did not ride technical trails yet.

Anyway, you can put sensor and magnet almost on any brake. Hot glue did job just well.

Anyway, you can put sensor and magnet almost on any brake. Hot glue did job just well.

vext

Member

- Thread starter

- #169

Sorry if i did not explain it enough. I ride technical trails.Had also brake cut offs on old ebike. Then I realized it is not needed, just another possible point of failure. If you saying you dont find overrun negative, you did not ride technical trails yet.

Anyway, you can put sensor and magnet almost on any brake. Hot glue did job just well.

I don't feel the override because I stop it by tapping the rear brake lever. When i'm on the uphill in a technical section where any residual override would cause a problem and need to depower fast I just tap the rear lever. You can tap it without even feeling the brake. The "kill switch" engages before the brake is even felt.

In fact I had the bike set up without the brake switch and hated it like everyone else. I only added the in-line switch sensor to fix it as a hunch.

Is it ideal? No. Does it work? Yes.

I feel like the bafang engineers don't chase the override out of the system because they expect their motors to be used in conjunction with a brake-mounted kill switch. That's my guess anyway.

It's not a bug in Bafang 's eyes.

They design their system to use a brake cut off switch on the brake lever. No one in our world uses the switches because we want better levers. But...

If you use a brake-cut-off it cuts all power instantly. It works intuitively and is easy to learn to tap the brakes to stop any unwanted power delivery upon pedal stop.

I found myself doing it automatically without even thinking about it.

I use this so I can use any lever...

Magura eBike Brake Pressure Switch - For Magura Rim and MT Disc Brakes Black

Magura eBike Brake Pressure Switch - For Magura Rim and MT Disc Brakes Black. The Magura hydraulic brake pressure/motor cut-off switch is specifically designed to control functions such as the on/off features of the lights and motor cut-off on your e-bike. Pressure switch is supplied with all...northwestbicycle.com

I never ever feel the negative effects of the overrun everyone complains about.

10 out of 10 would recommend.

Also note they now make "nice" aftermarket hydraulic levers that have built in switches. If anyone has used them let's us know how they work with the m560 (or any other bafang motor)

Does that fit the motors original brake sensor wire or do you need some sort of adapter? I might consider getting one of these as well.

Waynemarlow

E*POWAH Master

For every rider who hates the over run there are an equal number who ride technical trails that like it. I think your perception that " everyone" hates over run maybe a bit flawed.In fact I had the bike set up without the brake switch and hated it like everyone else. I only added the in-line switch sensor to fix it as a hunch.

In my case I have learnt to use it to advantage and can now climb up over extended rough steep uphill short bursts that I would have no chance of climbing without that over run. A short partial turn of the pedals will push you through stuff that you couldn't normally turn a full revolution of the pedals in say 4x4 tracks, a quick partial turn will get you up over that rocky bit that you would clash your pedal on, I could go on.

Why fit brake cut outs when all you have to do is turn your pedals a 1/8 turn approx. rearwards, its shuts the motor down much like the brake cut off. Sure thats a new skill to some but to many of those used to old school coaster brakes, then its nothing new.

To be frank guys, no motor manufacturer is going to be able to stop fully over run without very expensive sensors and someway of dumping the electrical energy within the active motor back into the battery. Equally without that electronic sophistication ( which costs plenty ) you will also build in the likelyhood of inducing unwanted delay when first rotating the pedals. You can't have one without the other unless you want to pay a lot more for your motor.

vext

Member

- Thread starter

- #173

You do have to mod it. I did this:Does that fit the motors original brake sensor wire or do you need some sort of adapter? I might consider getting one of these as well.

1) Using a multitester I tested the lever switch that came from Bafang and noted which two wires (of the three pins in the harness) broke/opened the circuit and if the circuit was normally open or normally closed. I unfortunately forget what it was but you can figure that out easily.

2) After noting which wires were involved in the circuit on the lever switch. I cut the connector off the switch and wired it to directly to the hydraulic sensor. I did not have to do any additional special wiring so that hydraulic switch worked with the same default configuration.

It was easy and works great.

Alternatively you might try this LEVER or something like it. They did not make these when I first did this but they do now. I get that folks might be reluctant to use a lever like this because the stock Shimano levers may be lighter or have more features but I find those distinctions might be overrated for most E bike users. In any case it makes installation of this feature incredibly simple and bolt on.

vext

Member

- Thread starter

- #174

For every rider who hates the over run there are an equal number who ride technical trails that like it. I think your perception that " everyone" hates over run maybe a bit flawed.

Yes, I should have said "everyone SEEMS to hate it". i'm glad you find a way to use it. I actually do too and only tap the brakes when I feel I need to execute a quick uphill turn and want to prevent a surge from pushing off the intended line or spinning the rear, etc..

I don't like the coaster brake solution as much because there are times where I want the pedals "loaded up" for the above mentioned turn momentum - just not too much. I'm probably not as good a rider as you are and need the confidence of the forward pedal pressure on the hard parts. Hell, I like to use the throttle in some technical parts if needed (like wrong gear situations because I'm just not that good at it

Clearly the brake switch method of modulating over-run is not for everyone because it does require a little more work, some small extra weight and complexity I suppose, or slightly different equipment. FWIW - the Maguro in-line sensor has worked flawlessly for me. I wish I could say that about the rest of the drivetrain

it looks like another version of this engine has been released with new firmware 001.5Looks like no new firmware.

Update us

Do you have any info what has changed?

it looks like another version of this engine has been released with new firmware 001.5

View attachment 137061

Do you have any info what has changed?

can you share some images of the controller PCB? Is still "M510" written on there?I'm trying to find out something about this firmware release.

Similar threads

- Replies

- 1

- Views

- 546

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 579K

- Messages

- 29,451

- Members