Durrti

Active member

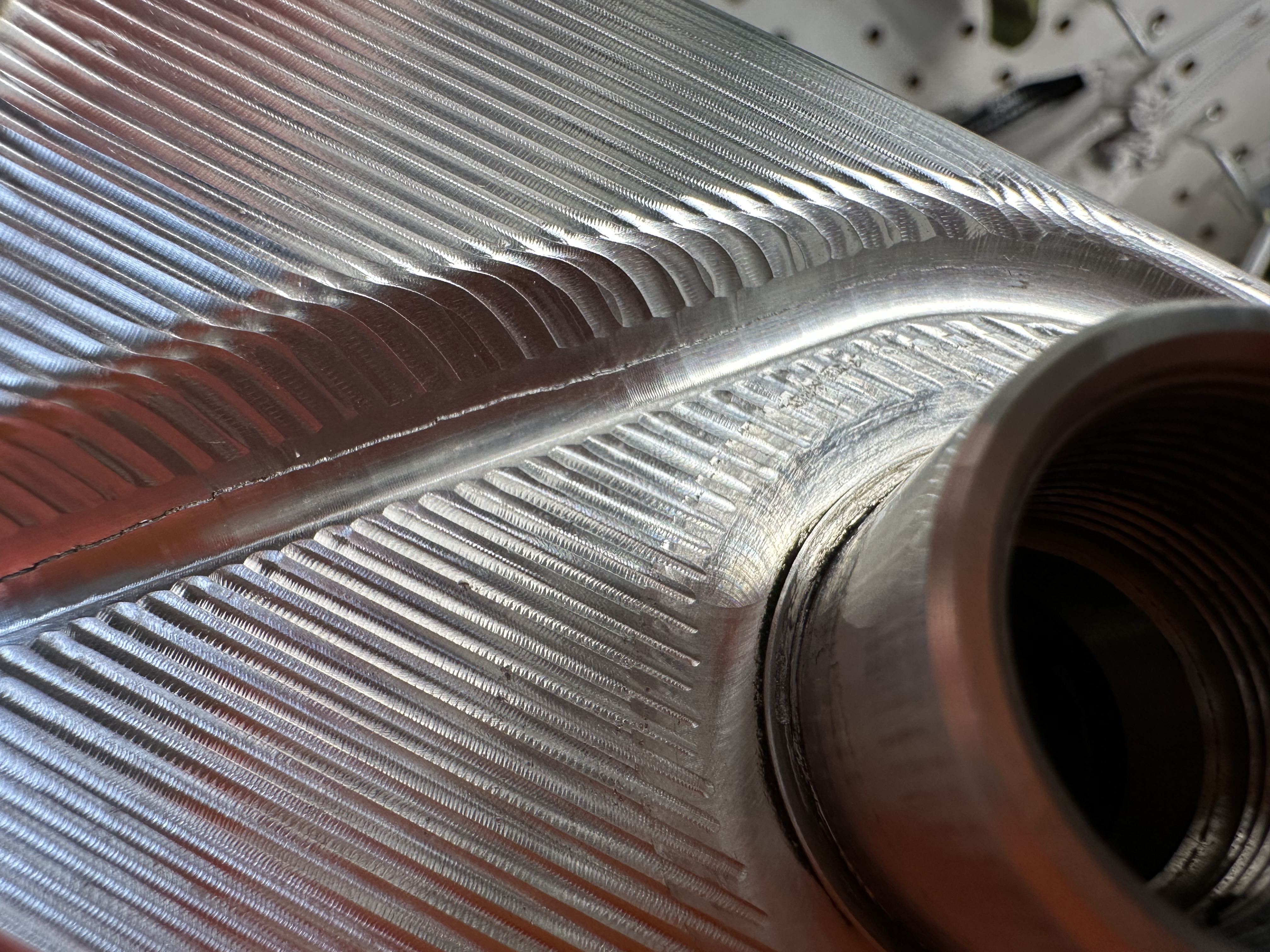

This is my right swing arm from my less than 6 month old Voima!! Noticed the arm was beginning to separate in the upper seam and crack at the rear link after my last ride. Pole wants to inspect the arm before they will replace  will keep you all updated.

will keep you all updated.

[mod update]

UPDATE!!

Pole has shipped new parts my way!

Parts include:

I was initially very concerned by the issue and had some reservations about my Voima. However after seeing the candid responses and honesty, I feel like the integrity of Pole is bar none. I truly think the issue of shipping parts immediately may have been due to the lack of issues the Voima has experienced.

I can honestly say that I love this bike! Still very happy that I bought a Pole, and looking forward to getting on the trails ASAP.

Thanks to all for the posts!

And a big shout out to @Rob Rides EMTB for giving us this community to connect

[mod update]

UPDATE!!

Pole has shipped new parts my way!

Parts include:

- Both swingarms and links for both sides preassembled

- All bolts, bolt covers, caps/extractors

- New rear mech hanger

- New rear axle

I was initially very concerned by the issue and had some reservations about my Voima. However after seeing the candid responses and honesty, I feel like the integrity of Pole is bar none. I truly think the issue of shipping parts immediately may have been due to the lack of issues the Voima has experienced.

I can honestly say that I love this bike! Still very happy that I bought a Pole, and looking forward to getting on the trails ASAP.

Thanks to all for the posts!

And a big shout out to @Rob Rides EMTB for giving us this community to connect

Last edited by a moderator: