Hi Sander,

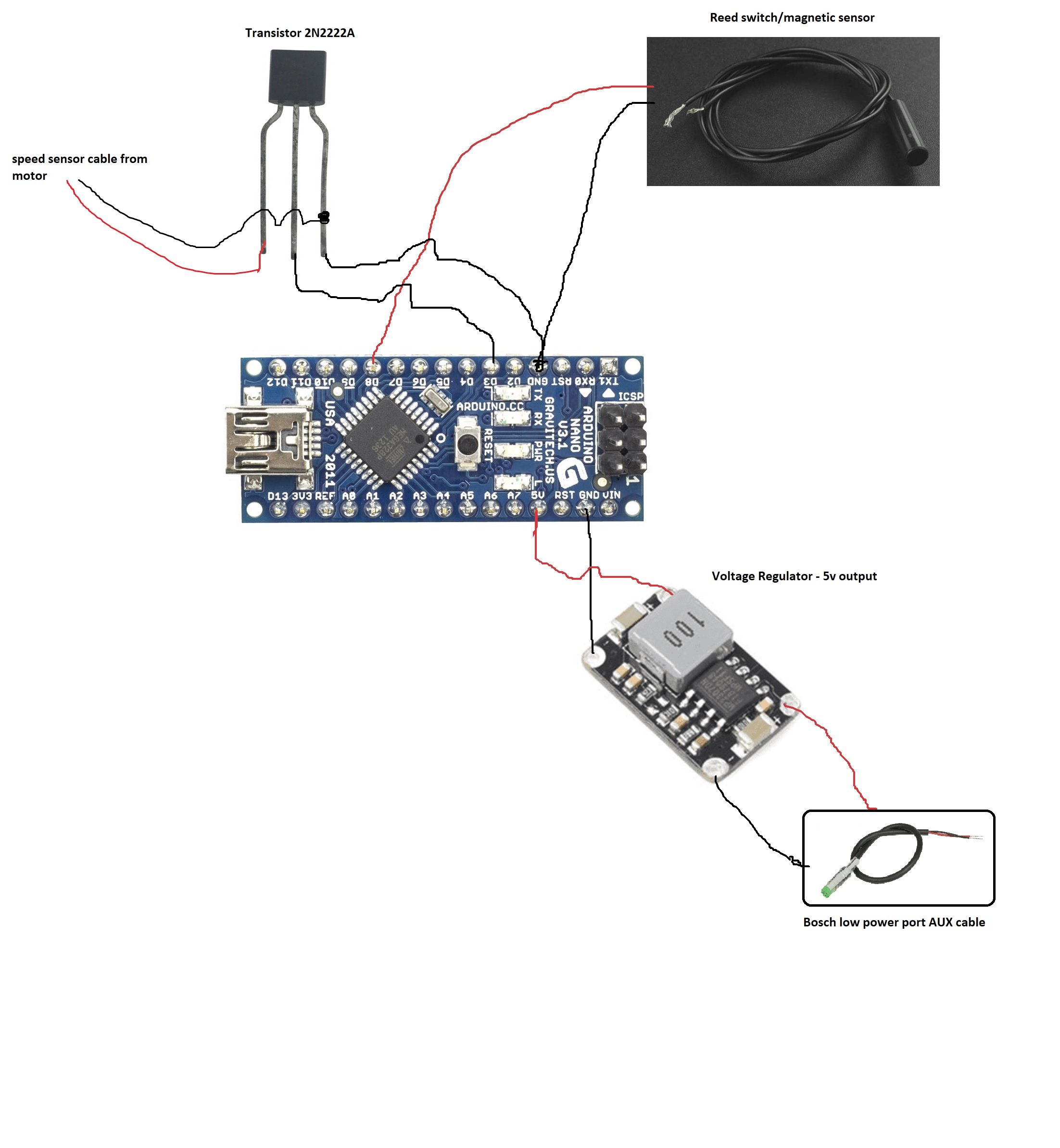

I used 0.25mm wire for magnet I wound. If you're on 5v and approx that diameter, you shouldn't need a resistor. Just add a few more turns if you find your resistance isn't there. But in this case, close enough is good enough, as you can always adjust the placement of the coil a little as well!