bram.biesiekierski

Active member

Looks like the same part to me. Except with a hole cut near the terminals to prevent water pooling.

I am in contact with Works components and also have the first response. Unfortunately not really helpfull since yet...

View attachment 102260

I am also afraid the dengfu's toleranz is a problem.. but if its true 4mm toleranz is also a big thing...

Next test is with the cane creek -1° under cup. The under cup has cost only 15€ so I give it a try with the works upper cup. Works components said it may can also work with a normal under cup but not for sure because of the different angle. I see a guy how cut 2mm from the headtube inside of that would be my latest option.That's unfortunate. I was about to order the same headset but is a glaring issue that I'd rather not risk. Keep us updated.

Hi e22ers ,

Dungfu (Mia) ask me if I want a square or circle charging port, it looks like the square charging port is more modern since it is not available yet (3 weeks delay). Any comment on that ?

Reading from ... I don't remember where, it looks like the circle one is limited to 2A/h charging rate , what about the square one.

Hello,Hello,

So I've tested the throttle and I got some weird effects from the motor.

First test:

I lifted the bike from the ground, chose assistance n*9 and went full throttle. At first the motor was outputting ~250W, nothing special. I kept full throttle and over a span of 1min30sec the bike was slowly and progressively running faster until I decided stop the throttle. The did not stop (just before 18:54 mark), it kept going like it had an auto-throttle activated. Does Eggrider or the controller even have that function?

View attachment 101899

2nd test:

Went outside testing throttle and no pedalling, at first it was slow like it was running at 250W (I can't remember the displayed wattage and forgot to record trip). But after a minute or while going uphill, the motor started to progressively give out more and more power (It felt good). So I tried to stop using the throttle and start pedalling. It seemed to be working fine just as expected, in some sense I had full power. Using the throttle again, it was running like a real M620.

But after another small hill, the motor stopped whether i was using the throttle or pedalling. This is when I saw the A10 error code on the display. After a quick check online, that error code is said to be "Over heating" (based on eggrider's website). Of course I forgot to actually check the motor's temperature with my hand

I got very similar result afterwards until I gave up and went back home to right this.

I don't know what is going on. I think I will use a different display tomorrow and see how the motor reacts.

Any ideas?

Man I am loving this bike. Everytime I ride it, it's KOMs. I got 9 on this ride. And this is at one of the most popular MTB trail networks on this side of the continent.

Stupid Kindernay Shifter has stopped shifting up gears now aswell. Think the fluid has leaked out. Hoping a re-bleed will fix it.

Check out my activity on Strava: https://strava.app.link/atvk6SNDTub

View attachment 101308

Hi. Thanks for the detailed reply. That sounds like a horrible issue to have. And sad part is, I'm not even surprised when it comes from kindernay....Does it feel like the shifting lever is stuck when you push it. If yes then I think I know exactly what the problem is and bleeding will not fix it. I have Kindernay XIV and I had exactly the same issue.

The issue is inside the shifting block. There are two rails with teeth, those rails slide and push the shifting axle teeth on the gear hub twisting it. The problem is those rails with teeth (and some actuation mechanism parts) are steel laser cut parts and are not very accurate. What basically is going on here is one rail does not seat completely flush or deep enough when it is retracted and interferes with the shifting axle and does not allow the second rail to twist the shifting axle.

You need to take the shifting block out and look closely into the hole where the shifting axle sticks. You will see the rails with teeth and you can actuate the shifter levers to see how they move. And you will see that one of them does not retract back completely. You need to disassemble the mechanism and file the back face of the interfering rail to let it seal a little bit deeper so it will not interfere with the shifting axle when it is retracted.

I fixed mine shifting mechanism this way more than a year ago and it works flawlessly since then.

I use the "twosie" type shifter. I'm sure it does not matter if the shifter is "onesie" or "twosie", they should work the same. "onesie" is just mounter together shifters from "twosie".Hi. Thanks for the detailed reply. That sounds like a horrible issue to have. And sad part is, I'm not even surprised when it comes from kindernay....

Is that problem on the "onesie" or the "twosie" type? Or does it not matter? Do you know if kindernay has made revisions to the manufacturing or acceptable tolerances. (If they even measure such things.)

I am curious if you discussed this with kindernay, and what thier response was. (If they even responded at all.)

On mine, i believe the main problem to be hydraulic related or fluid level related, and not as you described with the shift pawls/rails. I am very surprised if they have laser cut such small critical components. Typically, these type of parts like pawls and other such parts are EDM manufactured, because they need to be made of hard material, very small, and very precise. And EDM is perfect process for such components.

The reason I think i am having hydraulic issues, is it is not consistent. Like it worked ok for a while, then it went bad on the upshift. I progressively lost ability to shift up to higher gears, starting at the highest, and working down. Then I re-bled it, and it was good for a short period, then it went bad again. I suspect, when i put the bike from horozontal, to vertical on my bike carrier, then back to horizontal, it might have got a air bubble or something from the reservoir, into the master cylinder??? I have again re-bled it, and it is now feeling good again. But I have yet to take bike out a long ride, or put it onto the bike carrier etc. But my suspicion is the fluid leaks down to the point where it won't shift anymore. I had alot of trouble getting the bleed screws to seal up after bleeding. The 5mm hex bleed nipples are so small, and it takes an excessive amount of torque to get them to seal. I also had weeping on the hose compression fittings. But I have resolved this. They barely give you enough hose length for a large frame dengfu e22. I had just enough to cut the ends off once, run the hose, then re-terminate the hose. And that is it.

I also always find oil inside the shifter actuator / slave mechanism, where it meets the hub, when I remove the wheel. I always make note of it, and wipe it up with a rag before re-assembling. And everythime the wheel comes off, I find more oil inside. I think it is hub gear oil leaking from the hub, but it could just aswell be hydraulic oil coming the shifter actuator.

I have always had trouble shifting when the motor is pushing. Even at very low power. The feeling of this, is like you describe. You push the lever, feel the resistance, and feel the hydraulic pressure build, but you don't get any shift action. But this only happen when when the motor is pushing. When it's working right without the hydraulic issues explained above, and without load in the drivetrain, It shifts well. It's like, if there is any load on the drivetrain, it forces the gear mechanism together, so the shifter cannot un-mate the gears. As soon as the load is removed, it shifts effortlessly. Actually to effortlessly, as it is very hard to not shift multiple gears at once.

Overall, I think the shift system used by Kindernay is crap. It has potential to be great, but the way they have implemented it is not good in practice. It's such a shame, because the shifter looks amazing. It is a beautiful thing to look at. Just crap for actually riding the bike haha.

One last question. Have you had any other issues with your Kindernay XIV??? How long have you had it now?

Not what I wanted to hear with one incomingOverall, I think the shift system used by Kindernay is crap.

I guess I feel a bit better.I love my Kindernay gear hub.

Not what I wanted to hear with one incoming...

I guess I feel a bit better.

I use the "twosie" type shifter. I'm sure it does not matter if the shifter is "onesie" or "twosie", they should work the same. "onesie" is just mounter together shifters from "twosie".

I do not know if Kindernay did revisions of the shifters or the hubs. I purchased my system about 2 years ago by the way.

I did not discussed with kindernay about this problem, I just went straight to disassembly the shifter block to figure out the issue and fixed it.

If you feel the shifter lever is soft or something then it might be hydraulic related. I never experienced not shifting while the lever is actuated. I do experience shifting in between the gears so the gear hub skips the rotation but in this case I just shift it up and down to engage the gears properly.

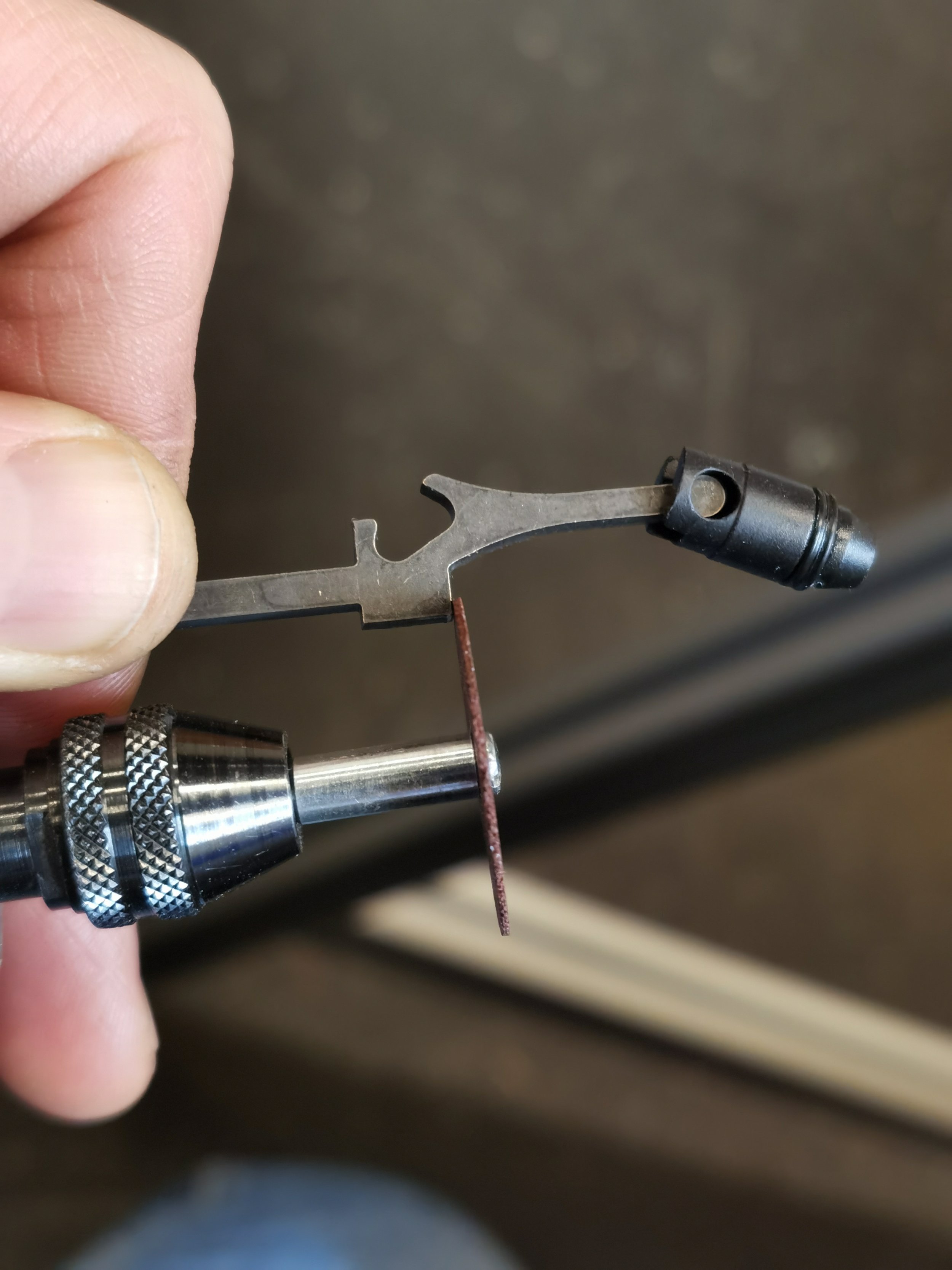

I believe those parts are laser cut because of I saw some melted metal artifacts on the parts, a little draft angle on the walls and the artifacts at the cutting start points. But EDM might do the same ardifacts, maybe they cut those parts with EDM. But anyway one pars was a little too long so I had to file it a little to let it seat properly.

I see some oil in the gear hub to shifter block interface too when I take the wheel off, I think it is OK.

You actually do not want to shift under the load, even under lighter load. Kindernay gear hub has shifting resistance if it is under load. My Kindernay XIV behaves the same when I shift under load I can not shift it (it is too hard) or I feel significant resistance and noises from the hub when I shift even under light load. So I always try to ease the load on pedals and sift the hub without cranking the pedals or cranking the pedals with no load just coasting and I always give a second to the motor to stop providing the power after stopping loading the pedals (the pedal assisted motors have some lag before they stop rotating under power). Resistance to shift under the load is normal, but you have to avoid to shift it under the load because of it is stress for the gear hub and reduces the gear hub lifespan.

I love my Kindernay gear hub. The only my complain is it shifts in between the gears sometimes, but I can leave with that.

It will take some time to train your brain to shift precisely without jumping over the gears and shiftiong multiple gears. I lever my palm gripping the handlebar so it is supported the way my finger moves in very controllable manner so I shift precisely without issues. I did shift

I used my Kindernay XIV for 2 years already and it might have around 3000 miles. I had not any issues other than the stuck shifting mechanism I fixed and the quirks with shifting in between the gears time to time.

I would recommend you to disassemble the shifting block completely (the one which actuated the gear hub), inspect it, inspect the seals, clean it, lube it, assemble it back and fill with fresh hydraulic fluid (I filled mine with Magura Blood Hydraulic mineral oil). The mechanism of the shifting block which connected to the gear hub is pretty simple, so it should be easy. You might want to see what is going on on the shifter lever mechanism if rebuilding the shifting block will not fix the issue.

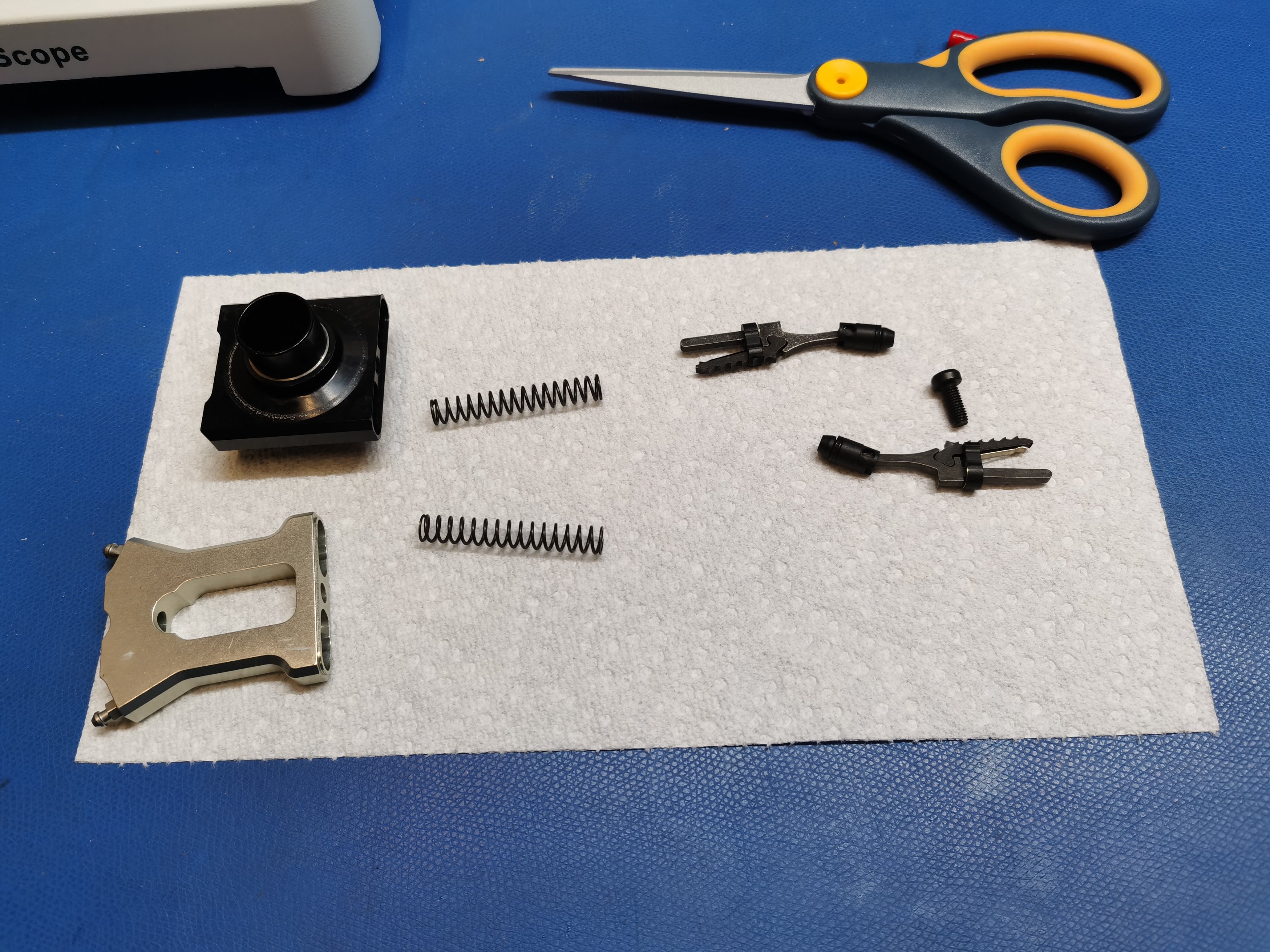

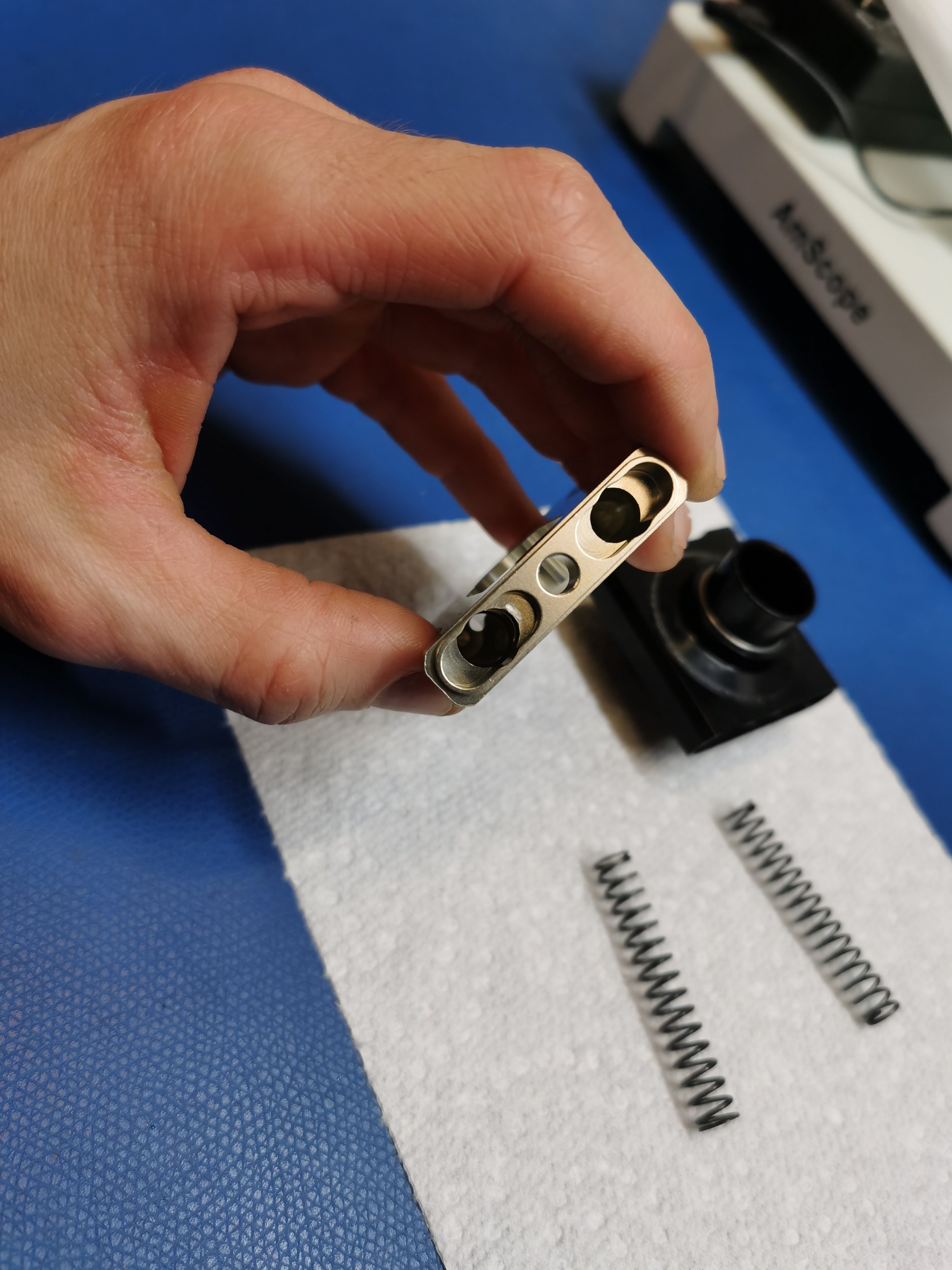

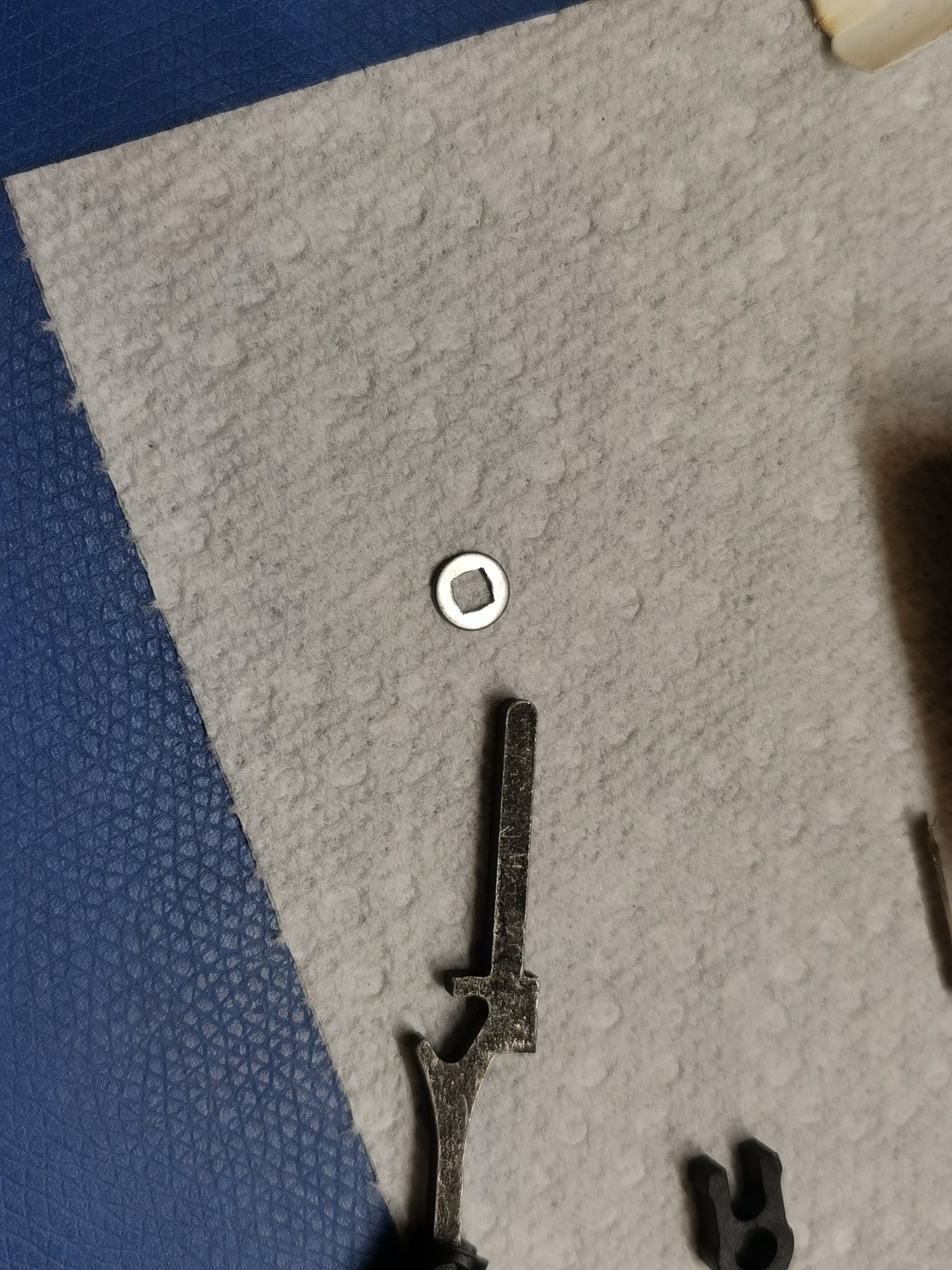

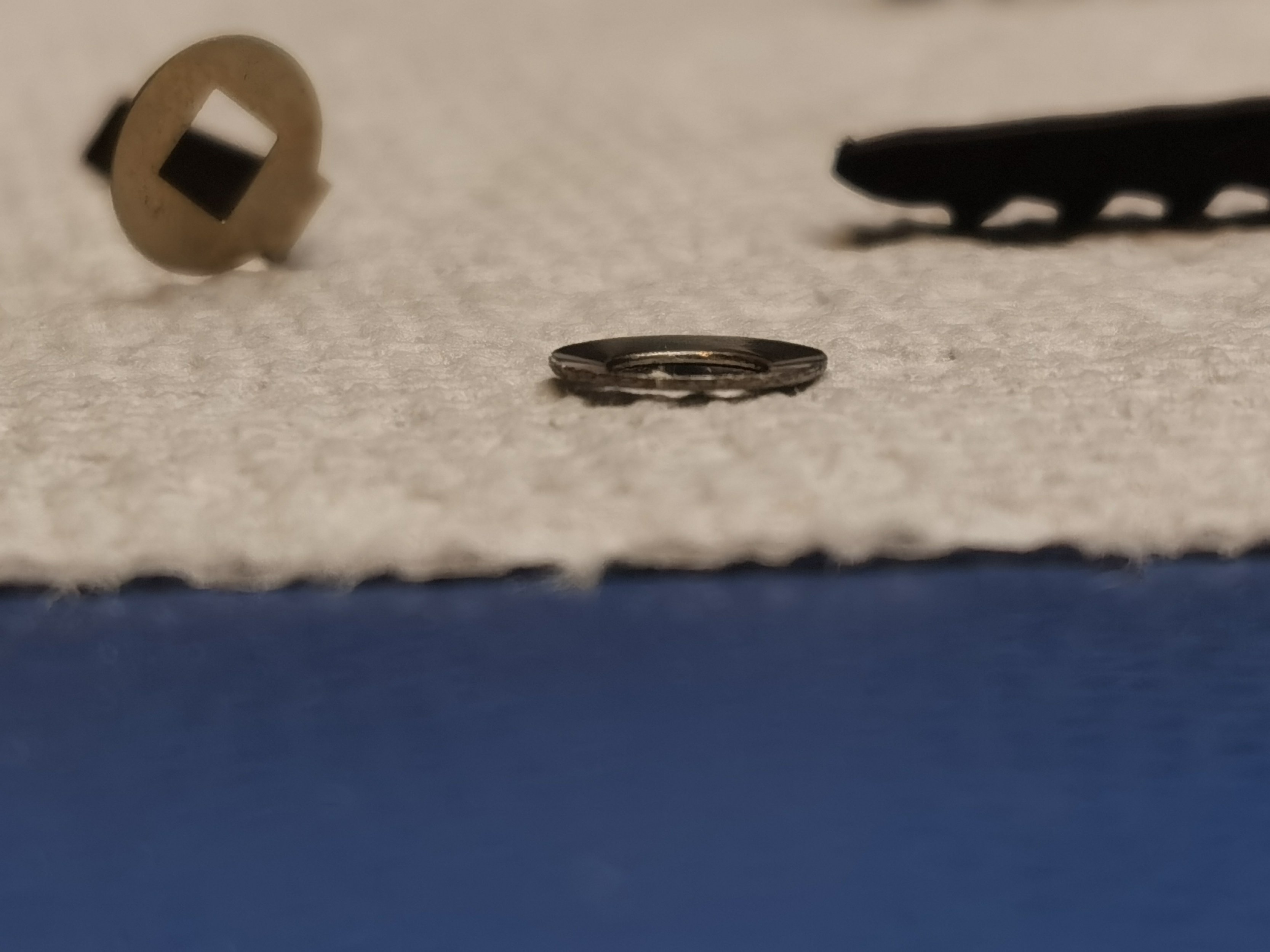

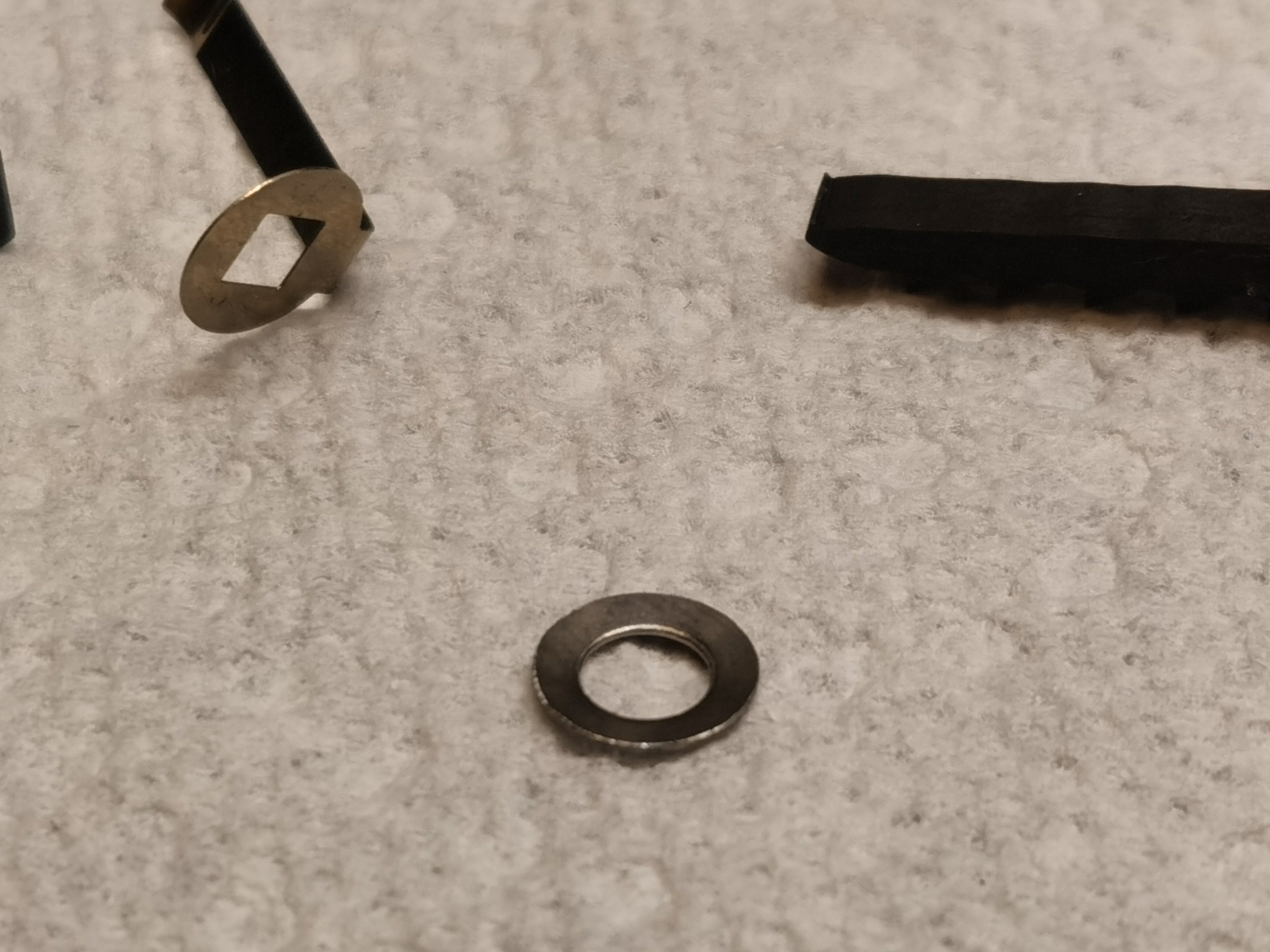

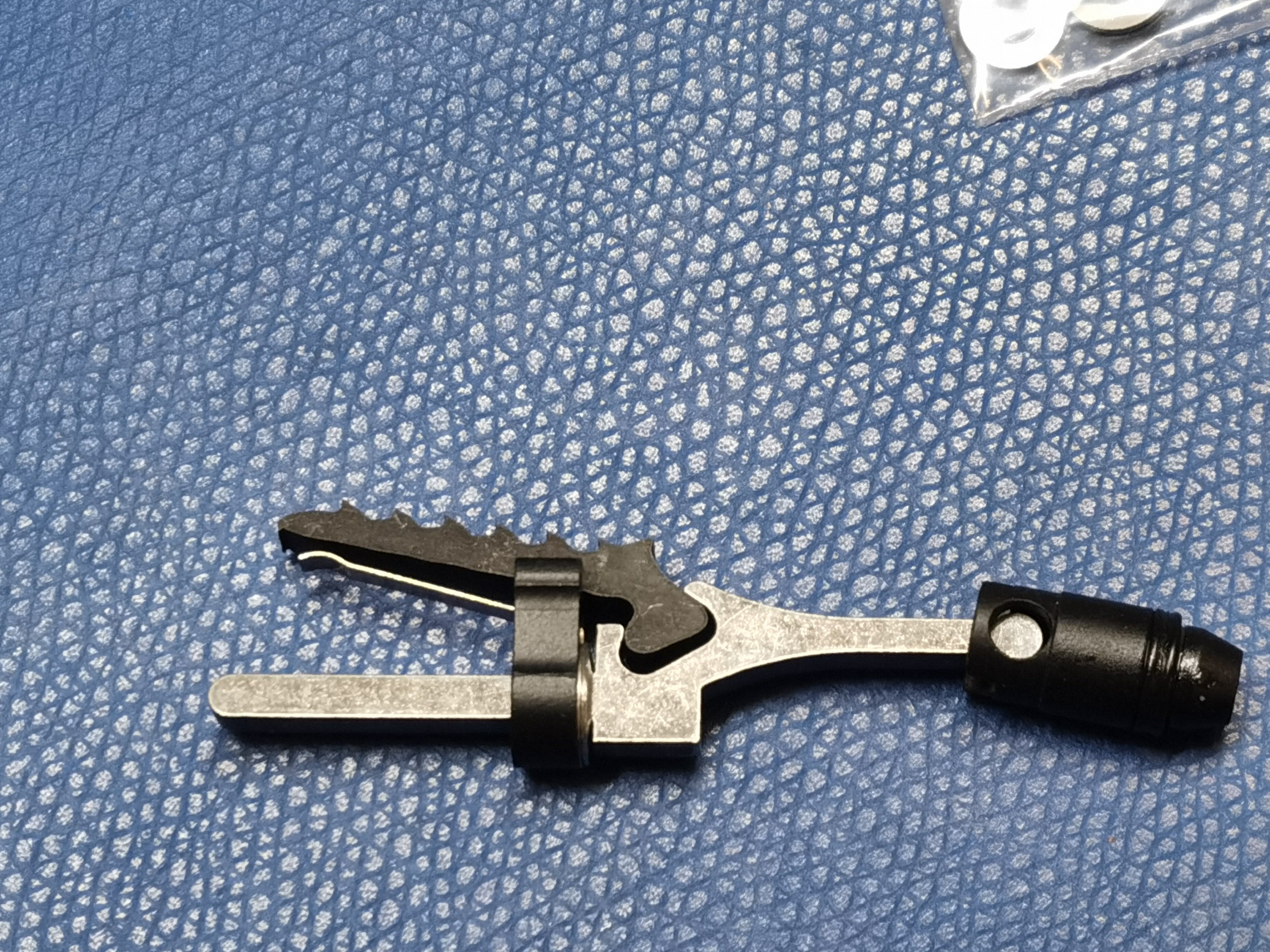

Here are some pictures. It looks like I forgot to mention I not only grinded the back face of the pawl a little but I also put a thin washer to space the spring out a little. Unfortunately I do not remember exactly why I put the washer to space the spring. It looks like I put this washer to space the spring out a little because of (the third picture shows it) there is a bump in the aluminum casing right above the bore might interfered with the spring and tilted this spring the way it does not pressed the pawl the right way. But I remember for sure one pawl sat too much out and engaged with the shifting drum on the gear hub preventing it from rotating opposite way by the opposite pawl.

View attachment 102448 View attachment 102449 View attachment 102450 View attachment 102451 View attachment 102452 View attachment 102453 View attachment 102454 View attachment 102455 View attachment 102456 View attachment 102457 View attachment 102458 View attachment 102459

Ya, I was just jokin (well 80-85%I did mention these shift issues before you bought. I thought you bought the kindernay because there was a lack of alternatives. Not because it is the best. Atleast that's why I bought mine haha

Yeah. Its tight. I am afraid to tighten it any further, for fear of snapping it off. It is only a 5mm hex. I havent put a torque wrench on there or anything. But i work with tools all day every day. And i have a pretty good feel for doing up fasteners. Atleast, i kwow when things are getting too tight and are at risk of snapping or spinning the threads. It shouldn't need to be done that tight.The upshifting bleed screw is leaking? Did you tighten it properly? Maybe it is damaged?

It is leaking. That's why the dust stick to it. See how the dust is wet looking??? I ride in a very dry environment. That means there is fluid coming out of the bleed screw area. It is only a small amount. But after about 3 rides or so, it is enough to cause shifting problems again. Because only a small amount of fluid needs to leak out to cause issues.That does not look like it leaks. It looks like there is just a little dust on it.

It also does not require a lot of torque to seal it. If you lightly tightened it and it still leaks then maybe the sealing interface is damaged or contaminated.

By the way I covered the nozzles with 4 mm inside diameter vinyl caps to protect it from contamination

Caps

View attachment 102514 View attachment 102515

Nice build.Hi Guys, sharing some finished build photos and some feedback. I tested the wireless EDS from wheeltop. I will never use anything else anymore. Swift and smooth shifting, no more chain cracking and easy adjust. I love it.

View attachment 102580 View attachment 102581 View attachment 102582 View attachment 102583

You don't need to change the firmware, you change the settings in the app.too easyNice build.

For me a intressting thing is the Eds shifter !

Dont know that they exist. I have riding my sram axs gx for around 700km but than soild it. 12s chain and cassette is heavy expensive with Innotrace x1 Controller. So I went to Microshift advent 9s. Cassette is from 11-46 enaugh and 9fach e bike chain is also strong. Shifting is okay but when you know a axs... So I read you can change the eds firmware! Vervy intressting for me to ride a eds with 9s cassette!

The translation of the app doesn't reflect it properly. It is the flywheel change menu . Goes from 3 SPD to 12 sod. And you can define also the brand of the cassetteOh I read in some reviews that you have the change the firmware in case of other cassette. Thats realy what I was looking for from my axs shifter ! But in the app I cant see the setting for cassette? Or is it the speed setting ? I was thinking its for speed of Shift time.

Okay, thats realy a nice thing and also the point what I was missing for on my sram axs!The translation of the app doesn't reflect it properly. It is the flywheel change menu . Goes from 3 SPD to 12 sod. And you can define also the brand of the cassette

I have a good relationship with the factory. It comes complete with 2 batteries, charger, and manuals .and cheap . Paid $350 delivered in Australia.Okay, thats realy a nice thing and also the point what I was missing for on my sram axs!

interesting, but how we can order (invalid in site) ?I have a good relationship with the factory. It comes complete with 2 batteries, charger, and manuals .and cheap . Paid $350 delivered in Australia.

The World's largest electric mountain bike community.