you have not washers between bearings and carbon ?I discovered that there is no grease in the screws areas, should grease be applied to these areas or is this intended because the frame is carbon?

View attachment 87543

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dengfu E10 - The CHEEB V1.0 - Discussion

- Thread starter Rob Rides EMTB

- Start date

for all parts who are in contact with carbon (and normally doesn't move) you can use carbon assembly pasteI discovered that there is no grease in the screws areas, should grease be applied to these areas or is this intended because the frame is carbon?

View attachment 87543

Graisse Anti-Grippage pour Composants Carbone FINISH LINE CARBON FIBER (50 g) | Probikeshop

SchadowMaster

Member

I have inner washers on each side.you have not washers between bearings and carbon ?

SchadowMaster

Member

I will only apply grease to the internal parts that are likely to be subjected to friction.Why would you put grease on the outside of the bearing seal or am I reading your question incorrectly. All the action takes place within the bearing where only a light smear of grease is needed as its a low speed movement. Technically if you fill the void between the bearings then all you are doing is attracting dirt which eventually will get under the seal and damage the internals.

SchadowMaster

Member

I think all these parts are movable and therefore need grease?

bram.biesiekierski

Active member

I dont think you need to put grease anywhere where you have sealed bearings. You could put a bit of anti-seize on the fasteners, and if you ever have the bearings pulled out, then you could put a bit of that on the surfaces when replacing.

SchadowMaster

Member

But I think a little grease is useful in preventing the entry of water and moisture.I dont think you need to put grease anywhere where you have sealed bearings. You could put a bit of anti-seize on the fasteners, and if you ever have the bearings pulled out, then you could put a bit of that on the surfaces when replacing.

There are different opinions about this.

Last edited:

SchadowMaster

Member

Can anyone confirm that these two pieces should be pressed into the frame?

thaeber

Well-known member

Yes!Can anyone confirm that these two pieces should be pressed into the frame?

View attachment 87617

SchadowMaster

Member

Much appreciated.Yes!

Freeze them first for a good hour.

Gentle heat on the frame with a hair dryer.

The shell should just fall in (make sure you are nice a square)

Gentle heat on the frame with a hair dryer.

The shell should just fall in (make sure you are nice a square)

Can anyone confirm that these two pieces should be pressed into the frame?

View attachment 87617

SchadowMaster

Member

I hammered them with a rubber mallet.Freeze them first for a good hour.

Gentle heat on the frame with a hair dryer.

The shell should just fall in (make sure you are nice a square)

djol

Member

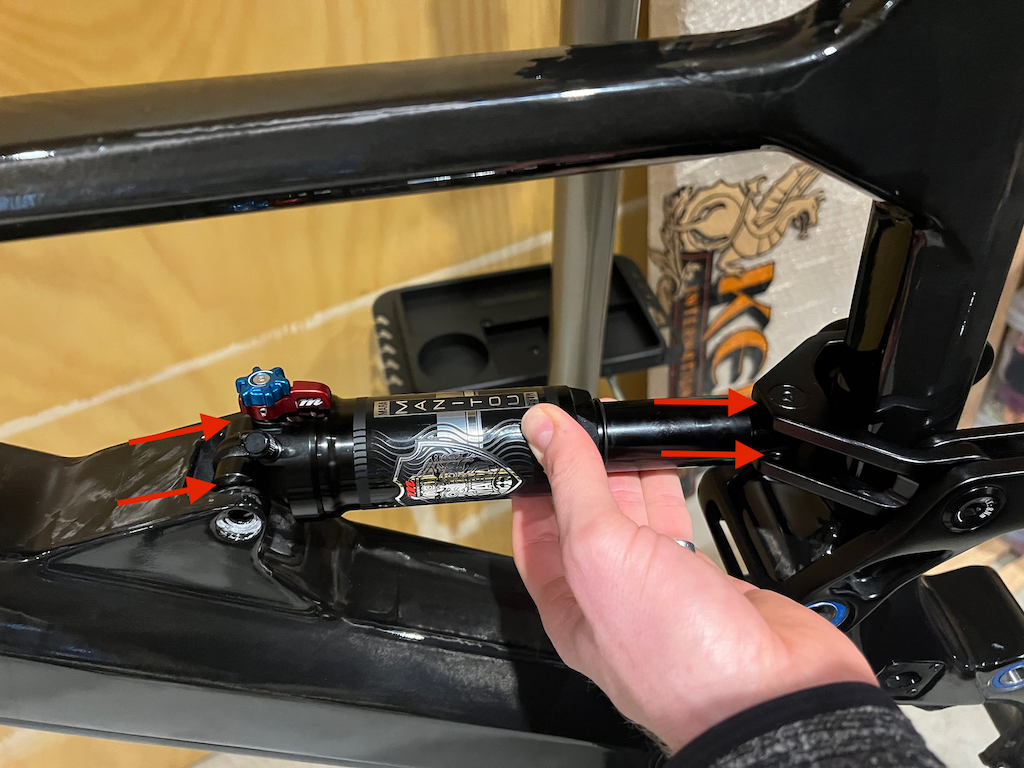

Assembling my E10 frame:

Does someone know where these four ~20mm o-rings should go?

My E10 frame came from Dengfu completely disassembled (it seems earlier frames came pre-assembled with a plastic rear shock spacer).

In addition to the five main frame pieces & shock mount, there's a little bag with three dozen bolts and washers etc. Many of them are subtly (but importantly!) different. Four washers already have o-rings fitted in a 1mm groove. No other washers have a similar groove (though many have a one-sided lip, which despite trying, will not reliably hold an o-ring).

Melody very kindly shared an assembly video with me taken in the Dengfu factory (showing assembly of a branded bike for the US market ) which has made it pretty easy to do a dry-run build, making sure I have all the right parts.

) which has made it pretty easy to do a dry-run build, making sure I have all the right parts.

But... I have four rubber o-rings roughly 20mm in diameter that I do not see used in the assembly video???

My thoughts are:

1. These are spare o-rings in case the pre-fitted ones on the four washers are damaged. (unlikely I think)

2. These o-rings should go between the shock bushings and frame articulation points (see image below & red arrows) to protect the bushings from moisture.

3. They're intended for another articulation point????

Thanks for your help!

Does someone know where these four ~20mm o-rings should go?

My E10 frame came from Dengfu completely disassembled (it seems earlier frames came pre-assembled with a plastic rear shock spacer).

In addition to the five main frame pieces & shock mount, there's a little bag with three dozen bolts and washers etc. Many of them are subtly (but importantly!) different. Four washers already have o-rings fitted in a 1mm groove. No other washers have a similar groove (though many have a one-sided lip, which despite trying, will not reliably hold an o-ring).

Melody very kindly shared an assembly video with me taken in the Dengfu factory (showing assembly of a branded bike for the US market

But... I have four rubber o-rings roughly 20mm in diameter that I do not see used in the assembly video???

My thoughts are:

1. These are spare o-rings in case the pre-fitted ones on the four washers are damaged. (unlikely I think)

2. These o-rings should go between the shock bushings and frame articulation points (see image below & red arrows) to protect the bushings from moisture.

3. They're intended for another articulation point????

Thanks for your help!

bram.biesiekierski

Active member

They go on the spacers that go between the joints for the seat stay and chain stay pivots.Assembling my E10 frame:

Does someone know where these four ~20mm o-rings should go?

View attachment 89088

My E10 frame came from Dengfu completely disassembled (it seems earlier frames came pre-assembled with a plastic rear shock spacer).

In addition to the five main frame pieces & shock mount, there's a little bag with three dozen bolts and washers etc. Many of them are subtly (but importantly!) different. Four washers already have o-rings fitted in a 1mm groove. No other washers have a similar groove (though many have a one-sided lip, which despite trying, will not reliably hold an o-ring).

View attachment 89089

View attachment 89090

Melody very kindly shared an assembly video with me taken in the Dengfu factory (showing assembly of a branded bike for the US market) which has made it pretty easy to do a dry-run build, making sure I have all the right parts.

But... I have four rubber o-rings roughly 20mm in diameter that I do not see used in the assembly video???

My thoughts are:

1. These are spare o-rings in case the pre-fitted ones on the four washers are damaged. (unlikely I think)

2. These o-rings should go between the shock bushings and frame articulation points (see image below & red arrows) to protect the bushings from moisture.

3. They're intended for another articulation point????

View attachment 89091

Thanks for your help!

The spacers have a machined groove to accept the o rings on thier outer circumferecne. Although, looking at the counter bore they go into, I very much doubt they would do anything.

djol

Member

Thanks @bram.biesiekierski !! Really helpful! ...parts left over is never a good thing!

captainhightop

Active member

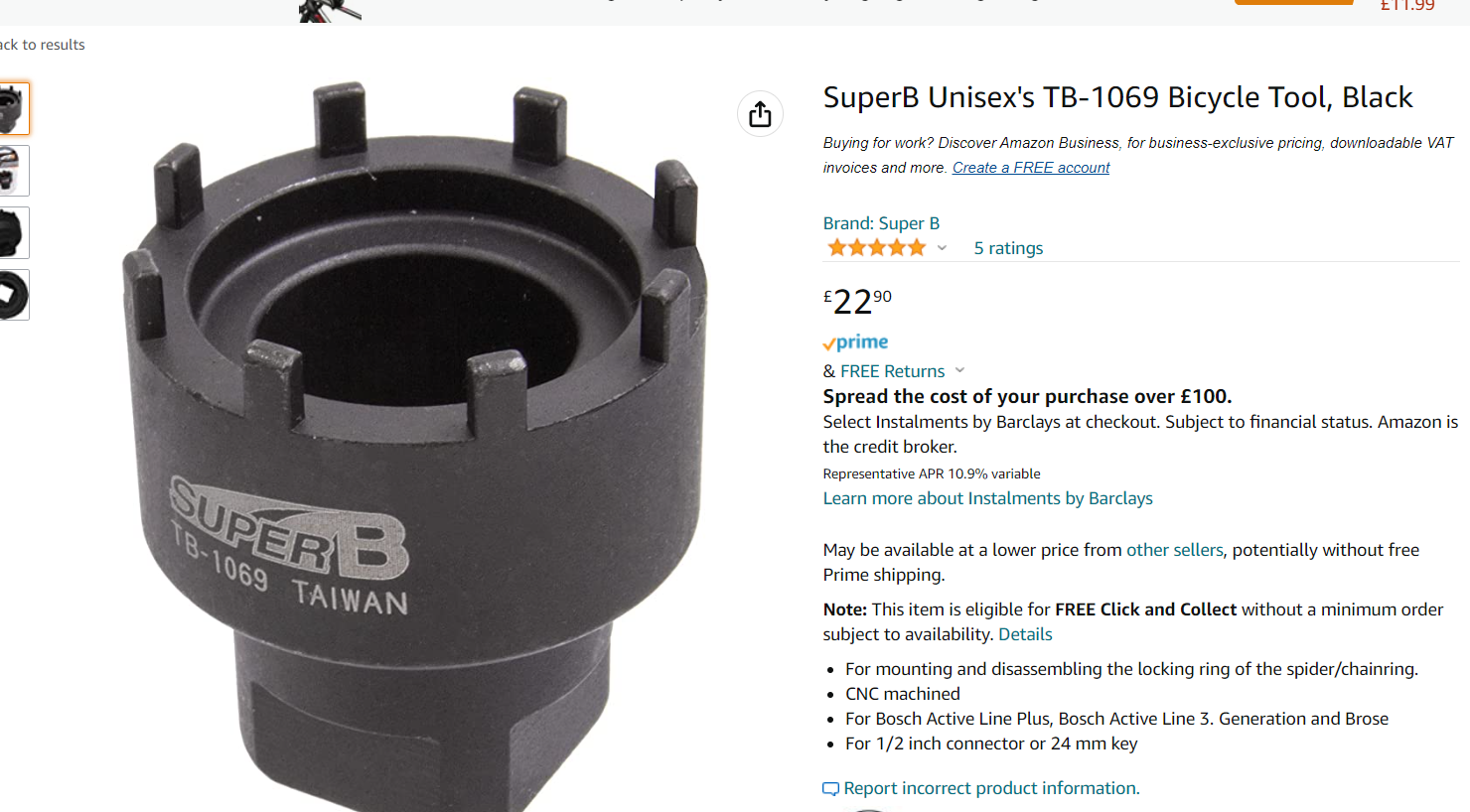

Anyone fitted one of these, is it the same tool as a BOSCH mid-drive?

The Bosch one seems to look right but I'd rather confirm that someone has used it before ordering. I'm using the old silver lockring from the M600 at the moment which works with the tool I already have, but I'd rather use the one supplied with the M510 below.

The Bosch one seems to look right but I'd rather confirm that someone has used it before ordering. I'm using the old silver lockring from the M600 at the moment which works with the tool I already have, but I'd rather use the one supplied with the M510 below.

SchadowMaster

Member

I think it fits and I ordered it still in shipping, in case you're not in a hurry I'll let you know after testing.Anyone fitted one of these, is it the same tool as a BOSCH mid-drive?

View attachment 89118

The Bosch one seems to look right but I'd rather confirm that someone has used it before ordering. I'm using the old silver lockring from the M600 at the moment which works with the tool I already have, but I'd rather use the one supplied with the M510 below.

View attachment 89117

Alan Simpson

New Member

Finally finished and really pleased with set up. First time using a coil and I am converted! 216x63 Cane Creek with Progressive Valt coil. 170mm front travel. Being XL it is big but suits me (192cm and 98kg).

With a bit of care I also managed to fit the standard Bafang chain guard with no modification or rubbing. Just needs to go as far forward as possible.

With a bit of care I also managed to fit the standard Bafang chain guard with no modification or rubbing. Just needs to go as far forward as possible.

SchadowMaster

Member

Nice Build!Finally finished and really pleased with set up. First time using a coil and I am converted! 216x63 Cane Creek with Progressive Valt coil. 170mm front travel. Being XL it is big but suits me (192cm and 98kg). View attachment 89282 View attachment 89280 View attachment 89281

With a bit of care I also managed to fit the standard Bafang chain guard with no modification or rubbing. Just needs to go as far forward as possible.

Is the motor M600 and what is the chainring size?

Alan Simpson

New Member

I went for the M500 to stay legal. It is definitely less powerful that a Bosch, but to be honest I want (and need) to feel like I have put some effort into a ride so the M500 is very natural and quiet and works for me.Nice Build!

Is the motor M600 and what is the chainring size?

The chainring is the standard one that comes with the motor - 34T I believe......

SchadowMaster

Member

captainhightop

Active member

Yet another Bafang innovation then, I think there are 2 types of Bosch lockring but not sure how different they are. I've not seen a specific tool for Bafang other than the one I've got for then older silver lockring.@captainhightop Unfortunately the tool is not compatible with the lock ring.

View attachment 89452 View attachment 89453

SchadowMaster

Member

The tool is compatible with this lock ring from Bosch, but can we use this ring to tighten the chainring with Bafang M510 motor?

I'm looking for a solution because I don't have an extra old lock ring.

This is cheaper than the old Bafang lock ring and more available for sale.

I'm looking for a solution because I don't have an extra old lock ring.

This is cheaper than the old Bafang lock ring and more available for sale.

Last edited:

i bought it on aliexpress. it needs a little sanding on the inside. or on a milling machine.@captainhightop Unfortunately the tool is not compatible with the lock ring.

View attachment 89452 View attachment 89453

HRK 26.33 40%OFF | Bike 8 Notch Cartridge Bottom Bracket Tool Carbon Steel Bicycle Crank Remover Axis Sleeve Cycling Shaft Repair Tool Bicycle Part

SchadowMaster

Member

HRK 29.85 15%OFF | Bicycle Frame Inner Cable Guide Road Bike MTB Mountain Bike Derallieur inner Line Buckle For GIANT ATX XTC ATX830 TRANCE Frame

a.aliexpress.com

a.aliexpress.com

if someone wants to change the inner cable guide to a chainstay. fits perfectly in the hole.

2.84£ 15% OFF|Bicycle Frame Inner Cable Guide Road Bike Mtb Mountain Bike Derallieur Inner Line Buckle For Giant Atx Xtc Atx830 Trance Frame - Bicycle Frame - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

if someone wants to change the inner cable guide to a chainstay. fits perfectly in the hole.

I put the M600 controller to M500, its still legal, i have 1.1 kW in peak and Bosch may "see rear tyre"I went for the M500 to stay legal. It is definitely less powerful that a Bosch, but to be honest I want (and need) to feel like I have put some effort into a ride so the M500 is very natural and quiet and works for me.

The chainring is the standard one that comes with the motor - 34T I believe......

SchadowMaster

Member

Can you climb steep hills for a long time without the engine overheating and reducing the power?I put the M600 controller to M500, its still legal, i have 1.1 kW in peak and Bosch may "see rear tyre".

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 554K

- Messages

- 27,989

- Members

Latest articles

-

Bosch-powered Merida is here – the eOne-Sixty SL and eOne-Eighty intro and test

Merida has used Bosch-motors for years, but not on the emtbs. The full...- Knut Nes

- 10 min read

- Views: 5K

- Reaction score: 5

- Comments: 9

-

Bosch ABS Pro and Trail Pro - an interview about the new ABS profiles

When testing the new Bosch Performance CX gen5, we were also introduced...- Knut Nes

- 2 min read

- Views: 6K

- Reaction score: 2

- Comments: 5