That's cristal clear > The "Y" goes to the BMS, not to the motor

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can you build your own battery for the E10 ?

- Thread starter Waynemarlow

- Start date

Aye thats what i meant thank you. So we all good like that with the Y?That's cristal clear > The "Y" goes to the BMS, not to the motor

BMS to the Motor and Charger to the BMSThat's cristal clear > The "Y" goes to the BMS, not to the motor

Not charger and BMS to the motor

Waynemarlow

E*POWAH Master

- Thread starter

- #125

Most chargers have a conditioning charge rate in the last 1 volt before switching off to allow the BMS to balance off the cells.BMS Should cut voltage right?

Did you ever accomplish this??? I have been trying to do this!Hi Wayne, great idea and helpful information.

What irritates me a bit is your starting post with the possible 'caveats based on the manufacturers use of proprietory Can Bus signals'. What does this mean exactly. Can I build my DIY battery within the motor spec and it will work or do I need a special tool like BESST or a special BMS to make the battery work with the rest of the CANBUS system.

Reason I am asking is that I try to build multiple 100Wh basic packs to parallel them together being able to take the 100Wh blocks on an airline. For sure not the state-of-the-art Amp monster when talking 48V but at least a chance to get an EMTB abroad.

If there is more knowledge required than a DIY battery I would appreciate a helpful link where I can find the required info. For the moment still waiting for the frame and initial Bafang set to arrive here.

Thanks in advance.

Martin

Slapbassmunky

Active member

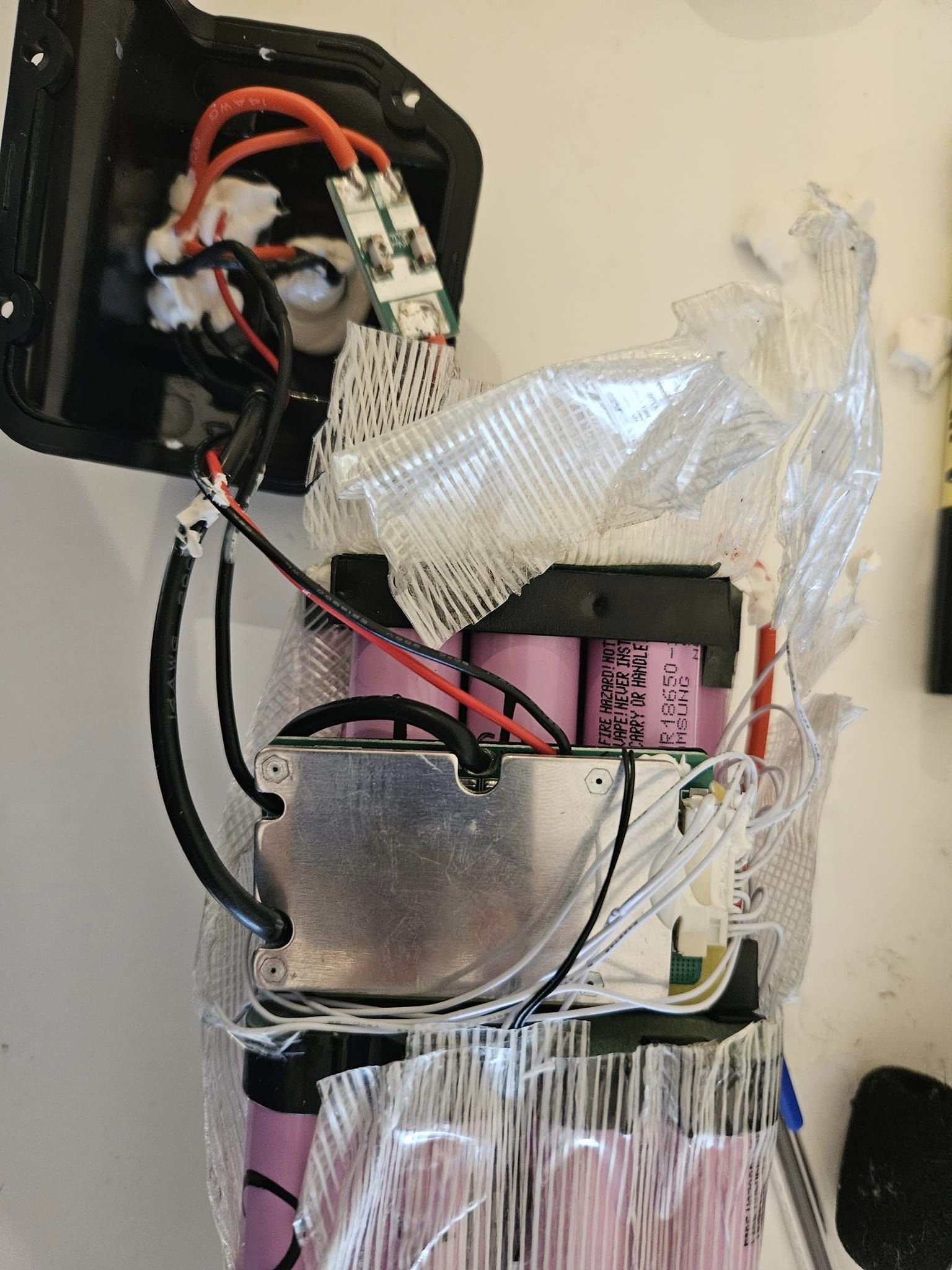

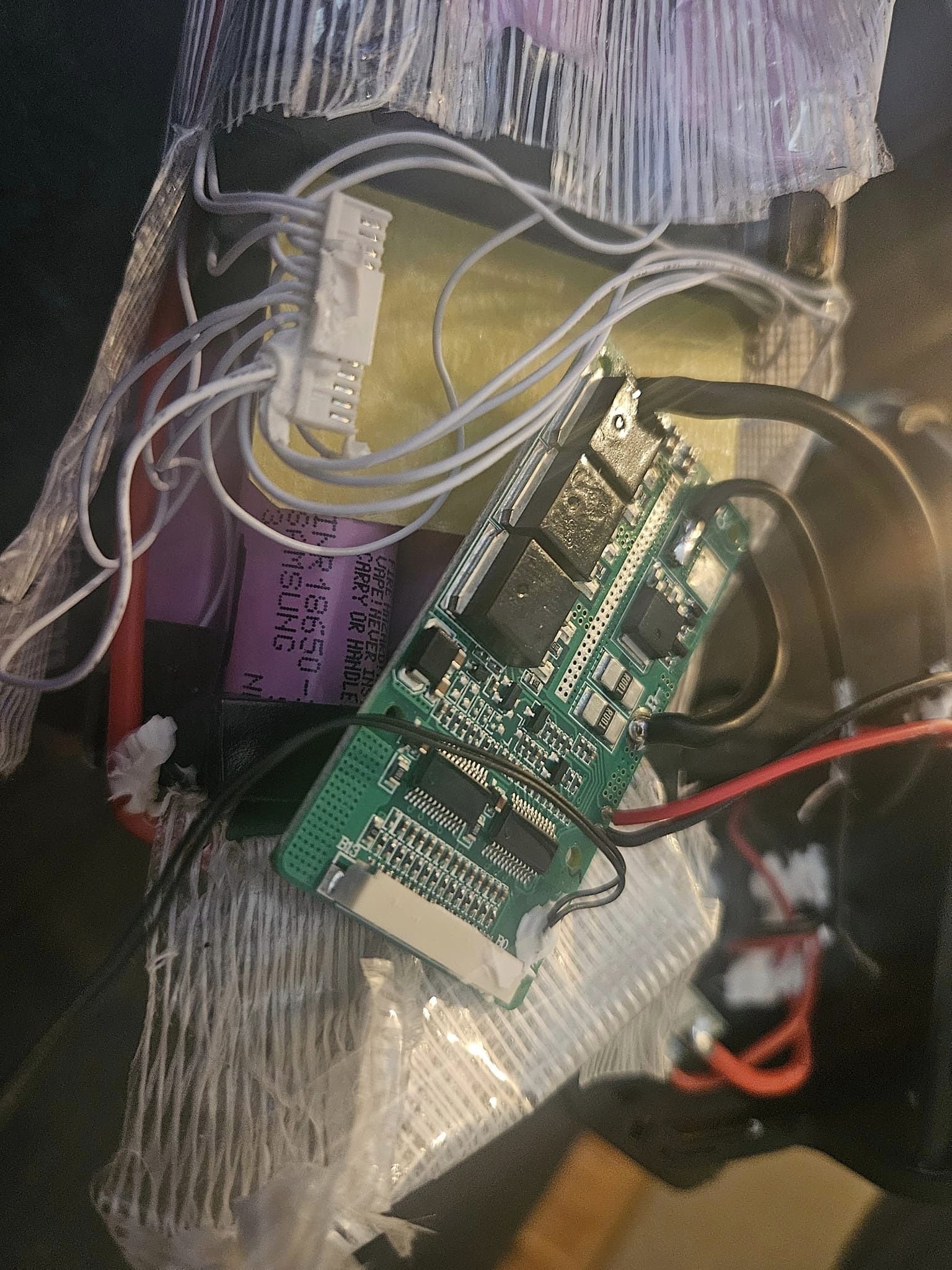

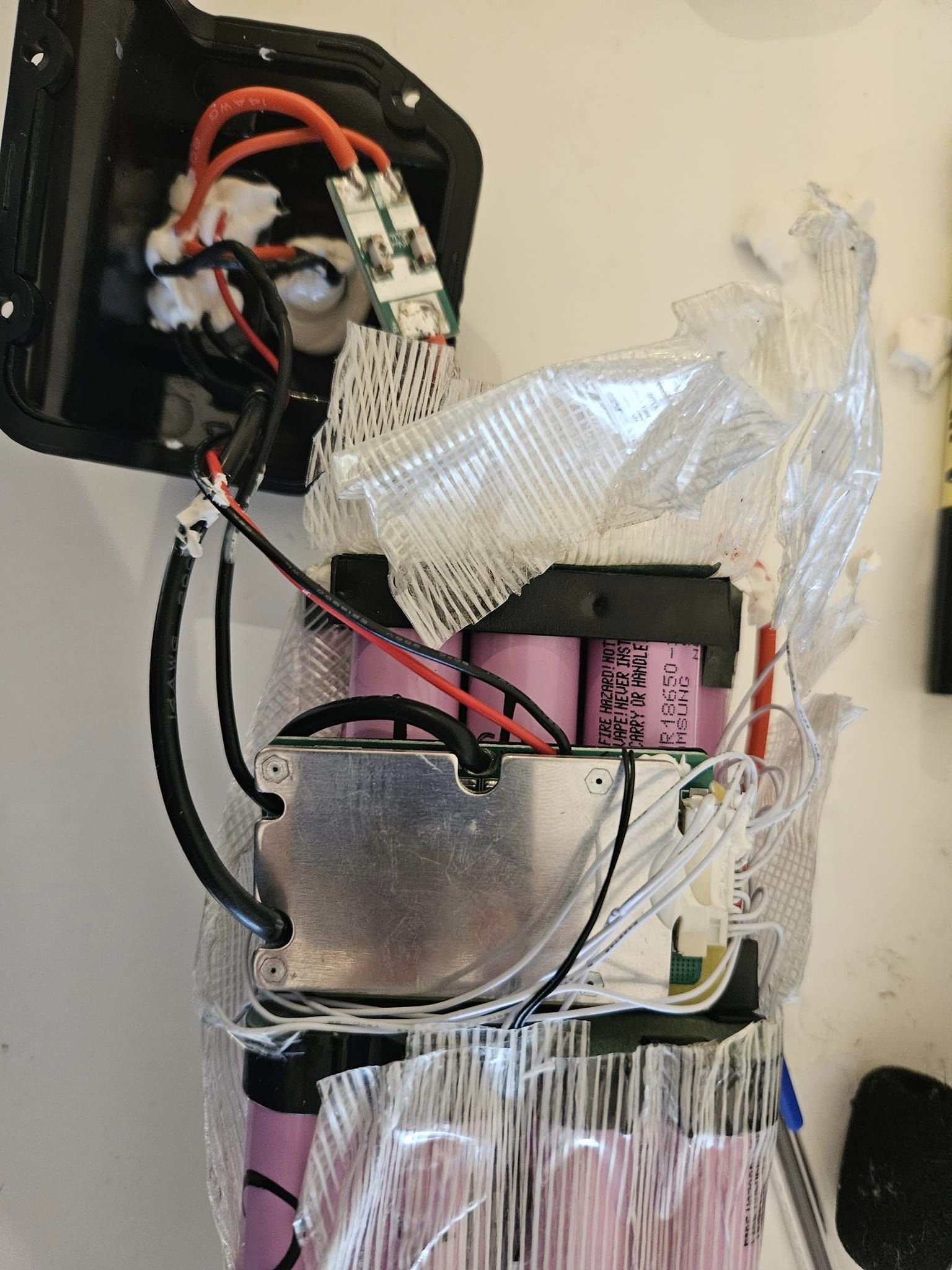

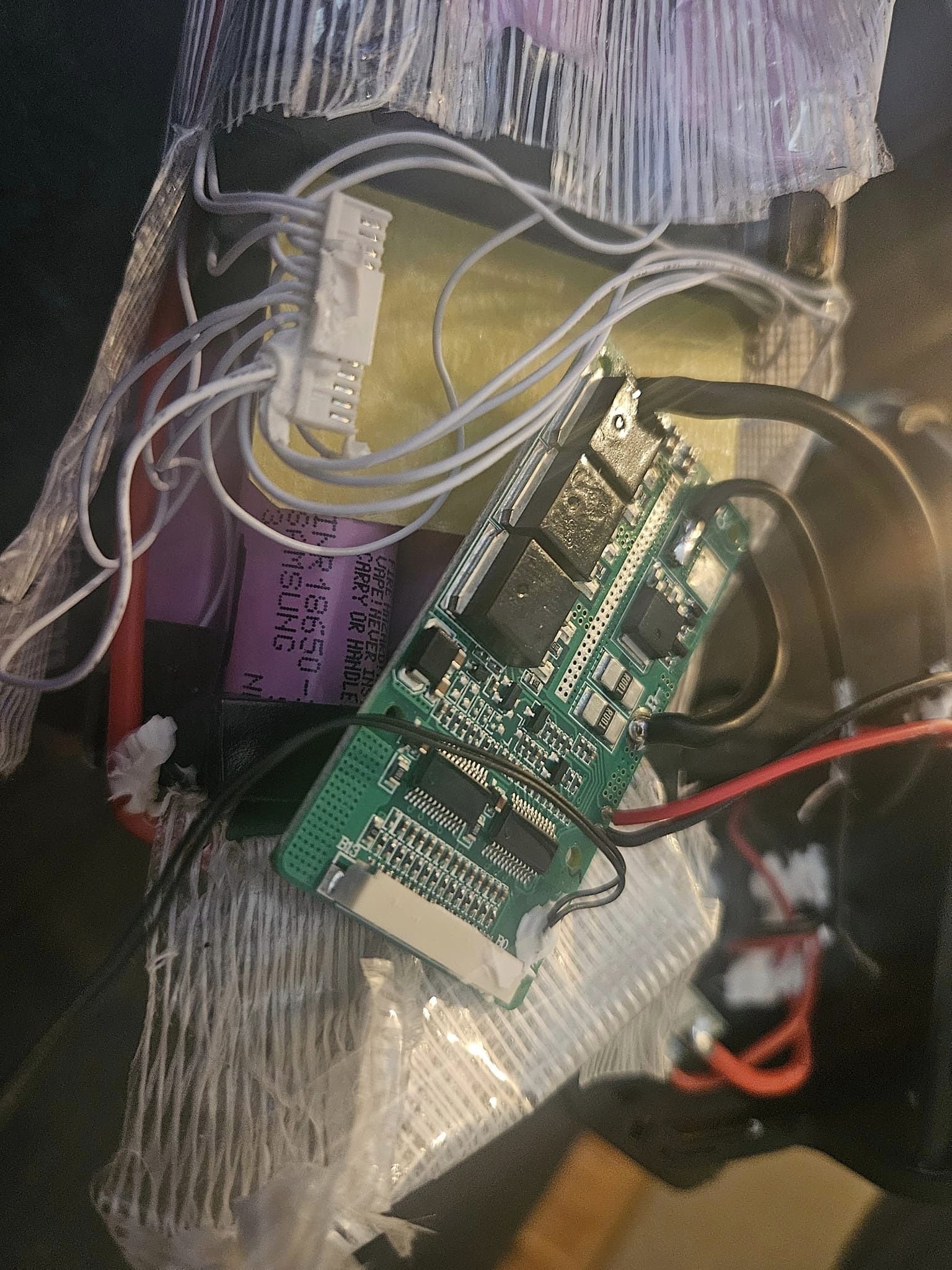

I've made many packs over the years. I wouldn't be happy with this one, corners have been cut - and the soldering iron tip wasn't big enough or hot enough.To whom it may concern: yesterday finally got my custom 14s4p 52v 20ah battery for E10. It took me a lot of time to get this battery due to having to wait for 14s BMS which turned out to be faulty and then needing to wait another month for a replacement one. But finally it came and I have the battery installed.

The battery was a very tight fit and it wasn't easy to get it in. On the bright side there is very little play left in the frame and it's secured my velcro straps and some dense foam padding.

Got a chance to test the battery today and was pleased with the performance. I believe there's some noticeable power increase, but difficult to judge due to weather conditions changed drastically. Half of the ride was on the snow covered trails with snow about 15cm deep. But the bike was doing well and I was able to ride through using 60-80% of max current. Used about 7v on my 31km ride which is not bad considering the conditions

I am attaching some photos below to show the insights and the fit

View attachment 102709 View attachment 102710 View attachment 102711 View attachment 102712 View attachment 102713

guys greetings. please help. do you know anyone who assembles batteries? I have the following problem. I have Panasonic tableless cells, plus the contact is made of aluminum. so I need someone who can do it or give advice on how to solve it. because the nickel strip is not good, it cannot be punctured. thank you

El Topo

Member

Great thread, thanks! May I ask a few questions?

So the Dengfu 840Wh battery is made with 18500 cells, and the 780Wh battery is made with 21700 cells?

Is the 780Wh the better choice overall then?

Is there anyone building battery packs with the 21700 5800mah cells? I wonder why they aren't used by almost anyone. A rather light 14s3p would be over 900Wh.

How much weight does a softpack save, over the regular battery case, 1kg?

So to get this clear, you use put industrial velcro on the backplate (of the battery pack), and then velcro the softpack the backplate? The backplate is held onto the frame by the locking mechanism, right? No rattling, etc.? Any foam to keep it firmly in the downtube?

By doing this, one could have a spare softpack in the backpack, and swap it in a minute in the field?

So the Dengfu 840Wh battery is made with 18500 cells, and the 780Wh battery is made with 21700 cells?

Is the 780Wh the better choice overall then?

Is there anyone building battery packs with the 21700 5800mah cells? I wonder why they aren't used by almost anyone. A rather light 14s3p would be over 900Wh.

How much weight does a softpack save, over the regular battery case, 1kg?

So to get this clear, you use put industrial velcro on the backplate (of the battery pack), and then velcro the softpack the backplate? The backplate is held onto the frame by the locking mechanism, right? No rattling, etc.? Any foam to keep it firmly in the downtube?

By doing this, one could have a spare softpack in the backpack, and swap it in a minute in the field?

Last edited:

thaeber

Well-known member

The battery housing of the E10 is made to fit maximum number of 18650 cells, 65 pcs in 13S5P configuration. This is the best weight to capacity ratio You can get by using the dedicated battery housing. Using 21700 cells, they need to be installed in longitudinal direction, the 18650 in cross direction to the housing longitudinal axis. The available space is not fully used with the 21700 cells. If You go softpack, You can build the pack with 21700 cells in cross direction (the fit into the frame) and build the biggest capacity battery with the latest cell technology. Your decision.

Great thread, thanks! May I ask a few questions?

So the Dengfu 840Wh battery is made with 18500 cells, and the 780Wh battery is made with 21700 cells?

Is the 780Wh the better choice overall then?

Is there anyone building battery packs with the 21700 5800mah cells? I wonder why they aren't used by almost anyone. A rather light 14s3p would be over 900Wh.

How much weight does a softpack save, over the regular battery case, 1kg?

So to get this clear, you use put industrial velcro on the backplate (of the battery pack), and then velcro the softpack the backplate? The backplate is held onto the frame by the locking mechanism, right? No rattling, etc.? Any foam to keep it firmly in the downtube?

By doing this, one could have a spare softpack in the backpack, and swap it in a minute in the field?

I think the reason you are not seeing many people use the super high capacity 21700's right now at least (I have seen a few builds with them not E10 though) is that they are still not easily obtainable, at least in the USA they are not sold at the main online retailers and buying from alibaba / aliexpress feels sketchy. I think once they hit the mainstream stores they will become more popular, it also doesn't help that the main distributor is Vapcell who rewraps them, so the name isn't a big brand that most would think of when looking for cells. There are even 6ah rated 21700's now on the market, Vapcell F60

Slapbassmunky

Active member

You can indeed use 21700 cells width ways. I've made a 13s4p pack that mounts to an aluminium plate that picks up on the existing mounting holes.The battery housing of the E10 is made to fit maximum number of 18650 cells, 65 pcs in 13S5P configuration. This is the best weight to capacity ratio You can get by using the dedicated battery housing. Using 21700 cells, they need to be installed in longitudinal direction, the 18650 in cross direction to the housing longitudinal axis. The available space is not fully used with the 21700 cells. If You go softpack, You can build the pack with 21700 cells in cross direction (the fit into the frame) and build the biggest capacity battery with the latest cell technology. Your decision.

Last edited:

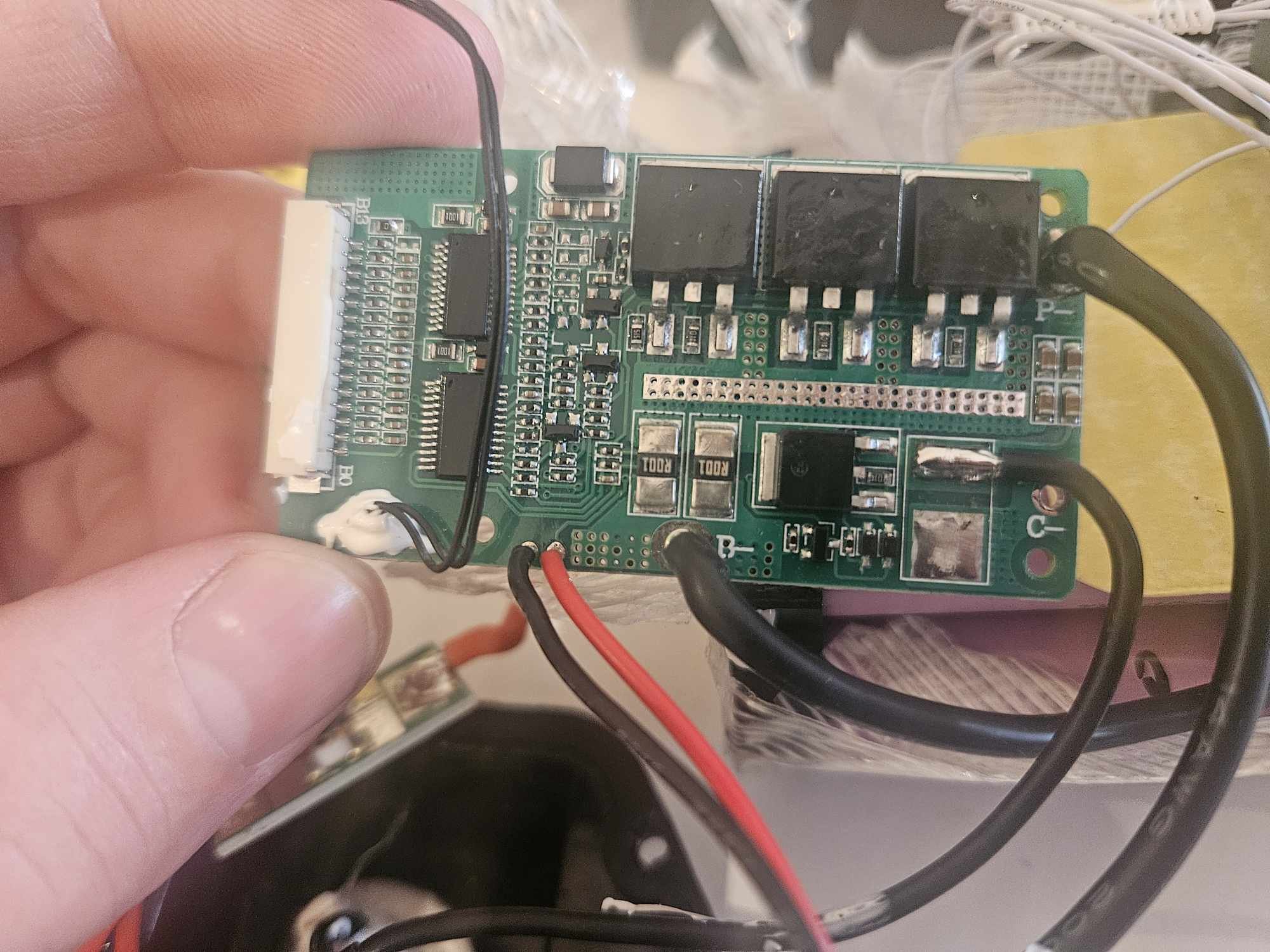

My E10s battery wont charge. It has 70% of power left, and it works in the bike. The problem is that it doesent charge. After a lot of trubleshooting I am 100% sure that the BMS is failing.

Question is where can I buy a new BMS?

The specification should be 13S 30A BMS for 48V battery and size is 35mm x 65mm x 7mm (it need to fit inside the battery-case). It also have a temp-sensor.

Connections is:

B-

P-

C-

Switch -

Switch ?

Hopefully its posible to get a new BMS with the same connector from the battery cells.

I dont need the power switch.

GreenBikeKit.com sells one BMS thats rated for E10 battery, but from what I can see it does not have C- connection

Question is where can I buy a new BMS?

The specification should be 13S 30A BMS for 48V battery and size is 35mm x 65mm x 7mm (it need to fit inside the battery-case). It also have a temp-sensor.

Connections is:

B-

P-

C-

Switch -

Switch ?

Hopefully its posible to get a new BMS with the same connector from the battery cells.

I dont need the power switch.

GreenBikeKit.com sells one BMS thats rated for E10 battery, but from what I can see it does not have C- connection

vext

Member

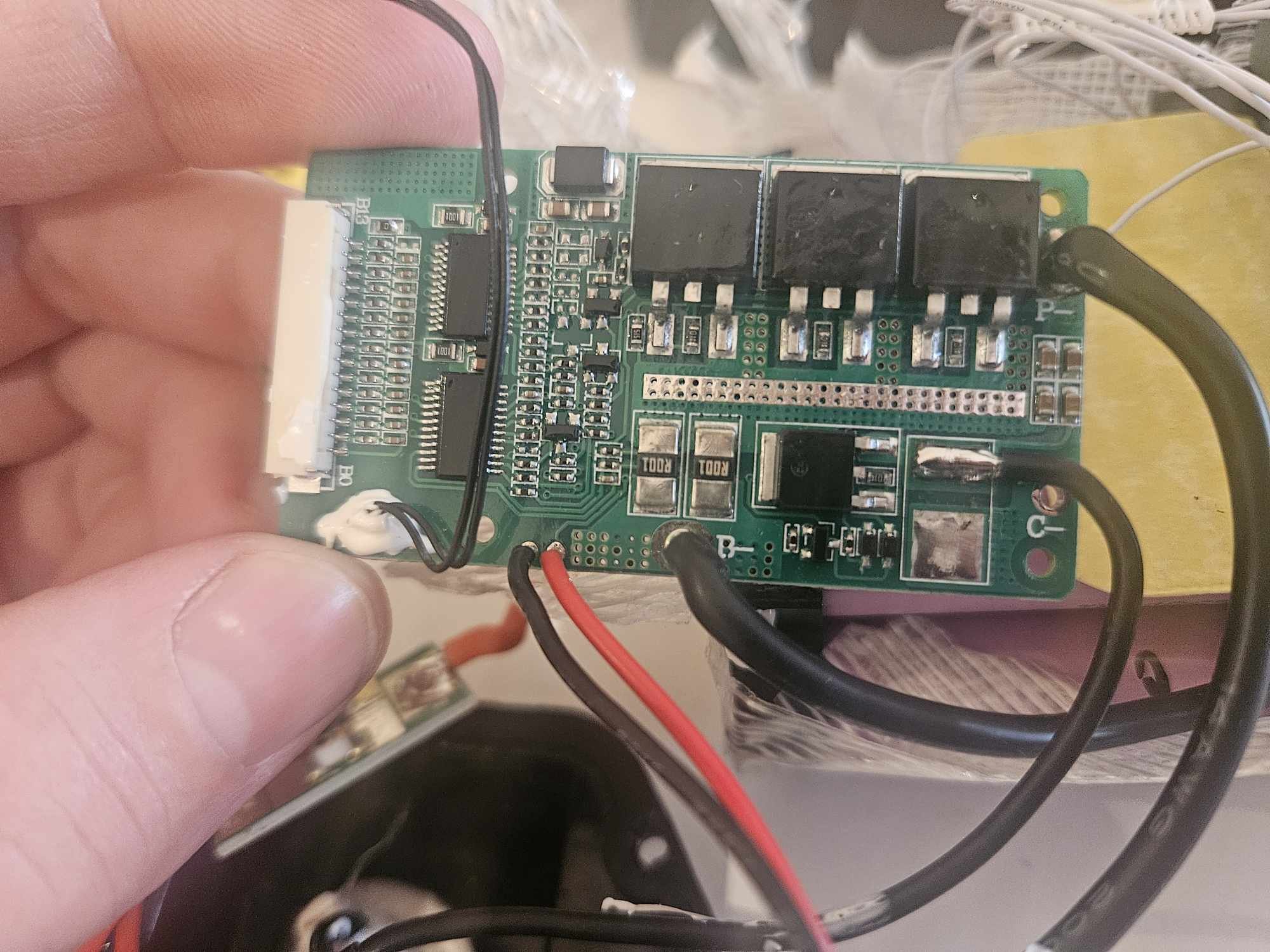

I had the same issue.

I bought the one above on aliexpress as a replacement.

I have yet to install it and test it.

I HAVE NO IDEA IF I GOT THE RIGHT ONE

Let me know if it looks right to you!

I hope it helps. Here's a link

EDIT:

I installed this and used the stock harness. It DID NOT WORK. There was some magic smoke (but just a little). I'm guessing it was coming from the resistors trying to balance the strings. I got cold feet and removed the board. the voltage readings were oddly low too. My other guess is the individual string wires were in a different order so when I plugged in the "strip" something was amiss.

I have to admit i'm new to BMS systems so I don't know how to troubleshoot.

That said the new BMS is a very tight fit FWIW. Maybe too tight. But it looks like it could have fit.

I'd look for a different board or if anyone can tell me what was wrong Or can direct us to the correct board. I'd love to know too.

Last edited:

thaeber

Well-known member

Oh looks like I wrote shit - the 18650 cells are in longitudinal direction as well, but maximum packed into the housing..sorry…The battery housing of the E10 is made to fit maximum number of 18650 cells, 65 pcs in 13S5P configuration. This is the best weight to capacity ratio You can get by using the dedicated battery housing. Using 21700 cells, they need to be installed in longitudinal direction, the 18650 in cross direction to the housing longitudinal axis. The available space is not fully used with the 21700 cells. If You go softpack, You can build the pack with 21700 cells in cross direction (the fit into the frame) and build the biggest capacity battery with the latest cell technology. Your decision.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 555K

- Messages

- 28,042

- Members

Latest articles

-

Introducing the Forestal e-Cygnus - a downcountry and XC emtb

The new Forestal e-Cygnus is a slightly unusual emtb. It comes in two... -

2025 M1 Sporttechnik EN 8.0 review

The M1 EN is one of four M1 models built on the same frame. Well, it’s...