My 2019 Superior EXF 949R finally threw in the towel after barely 4000km, I'm no longer a Shimano fan.

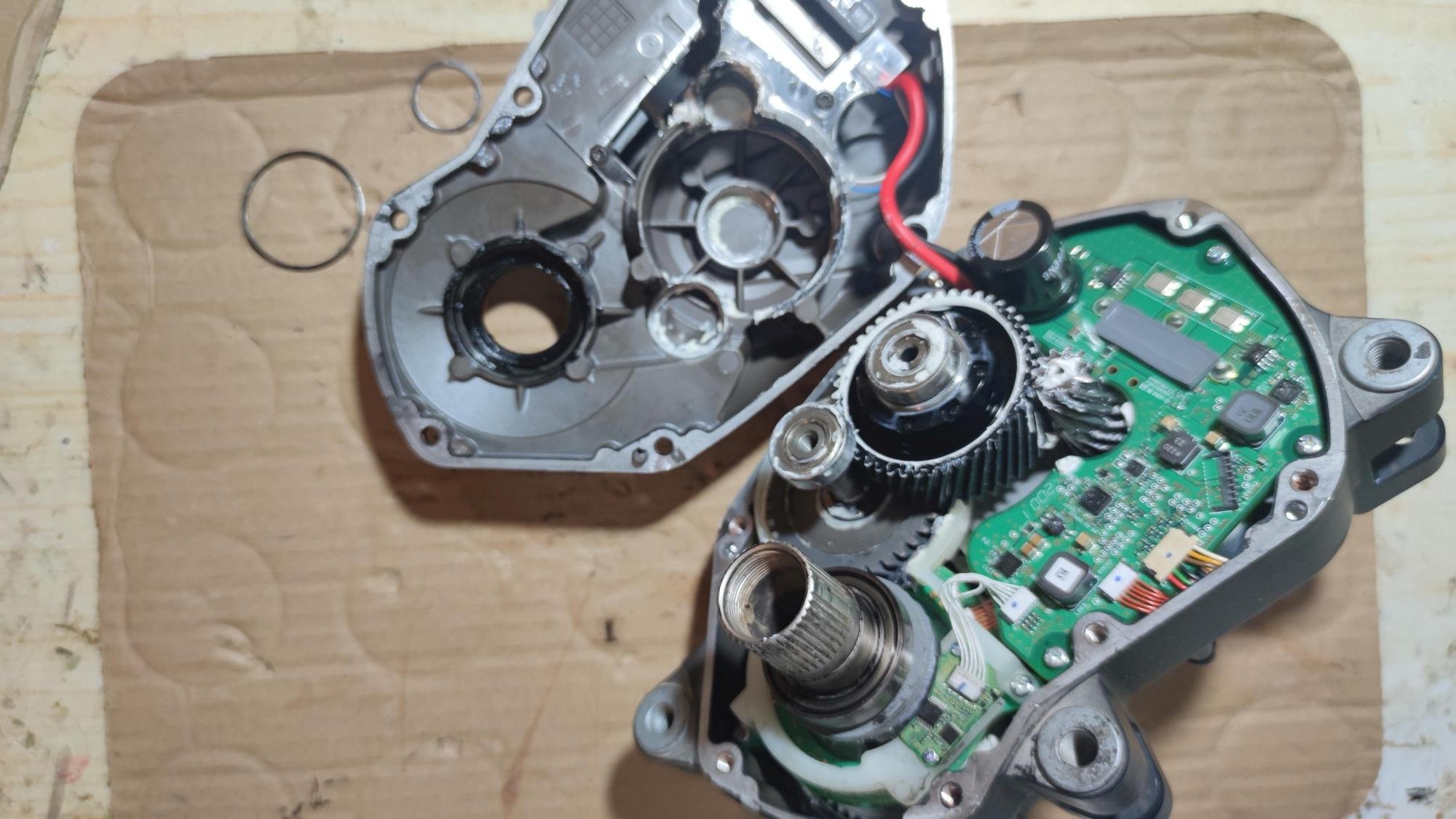

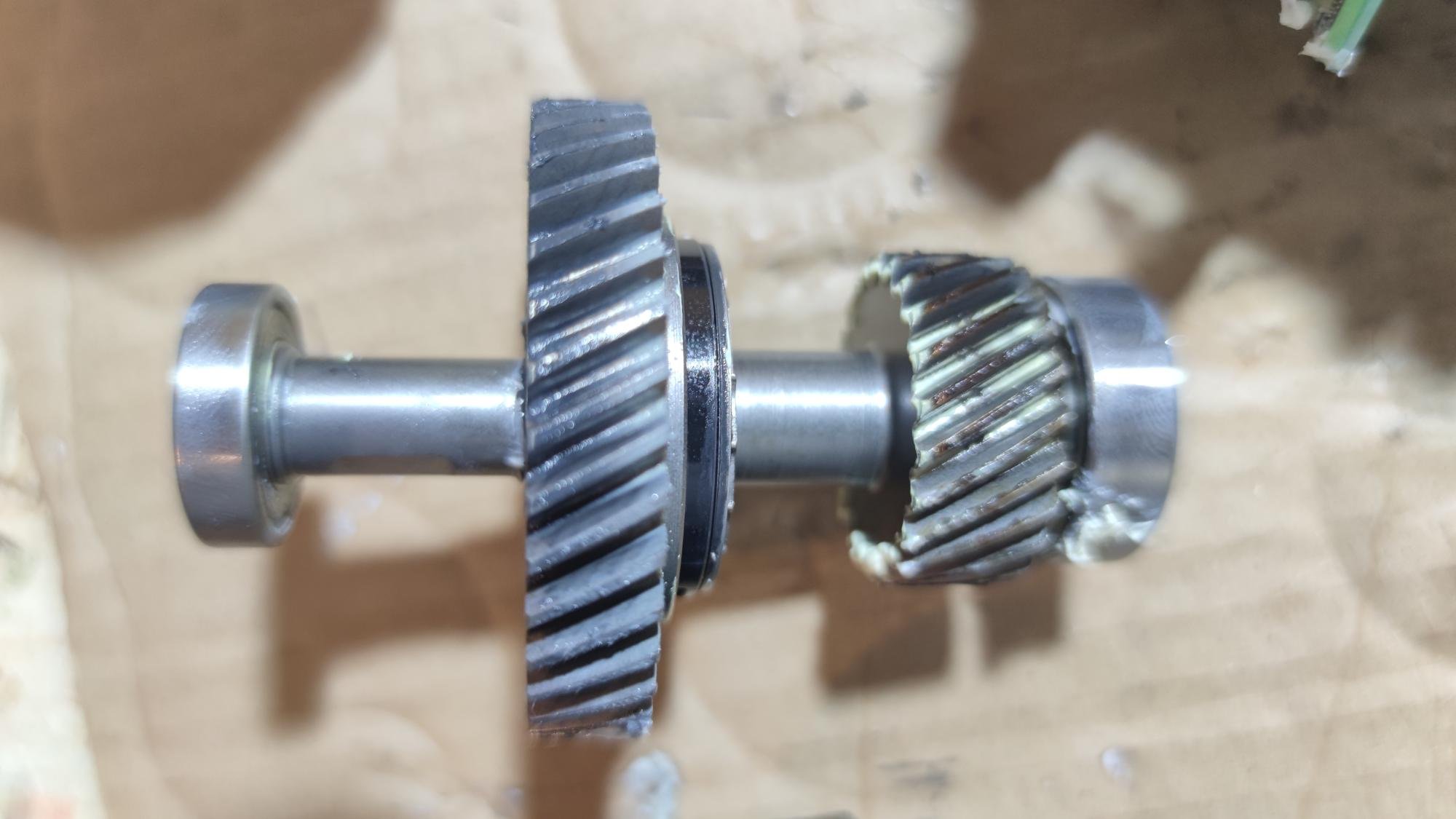

The motor was starting to make a grinding noise so I followed the Yorkshire rebuild video.

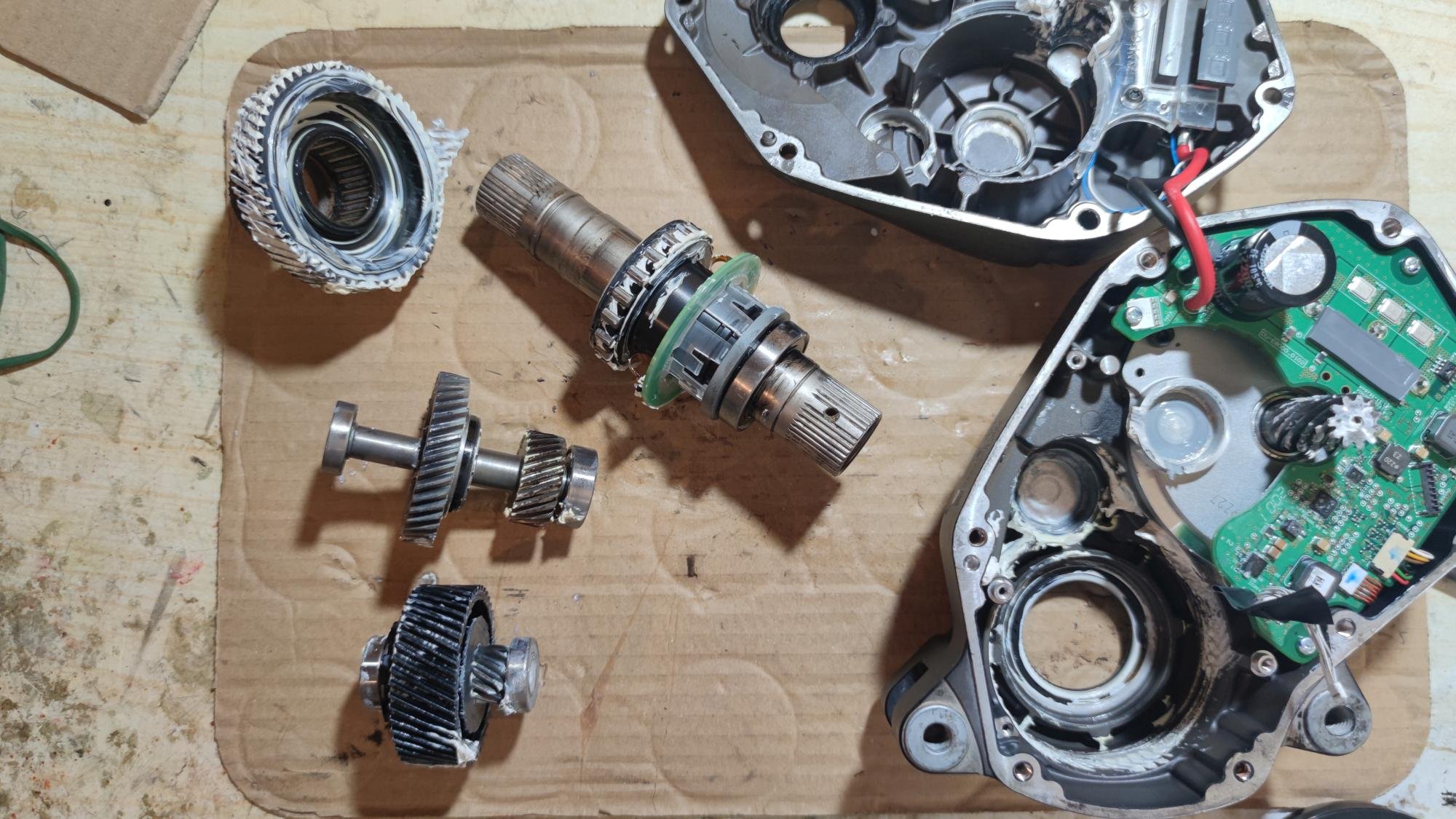

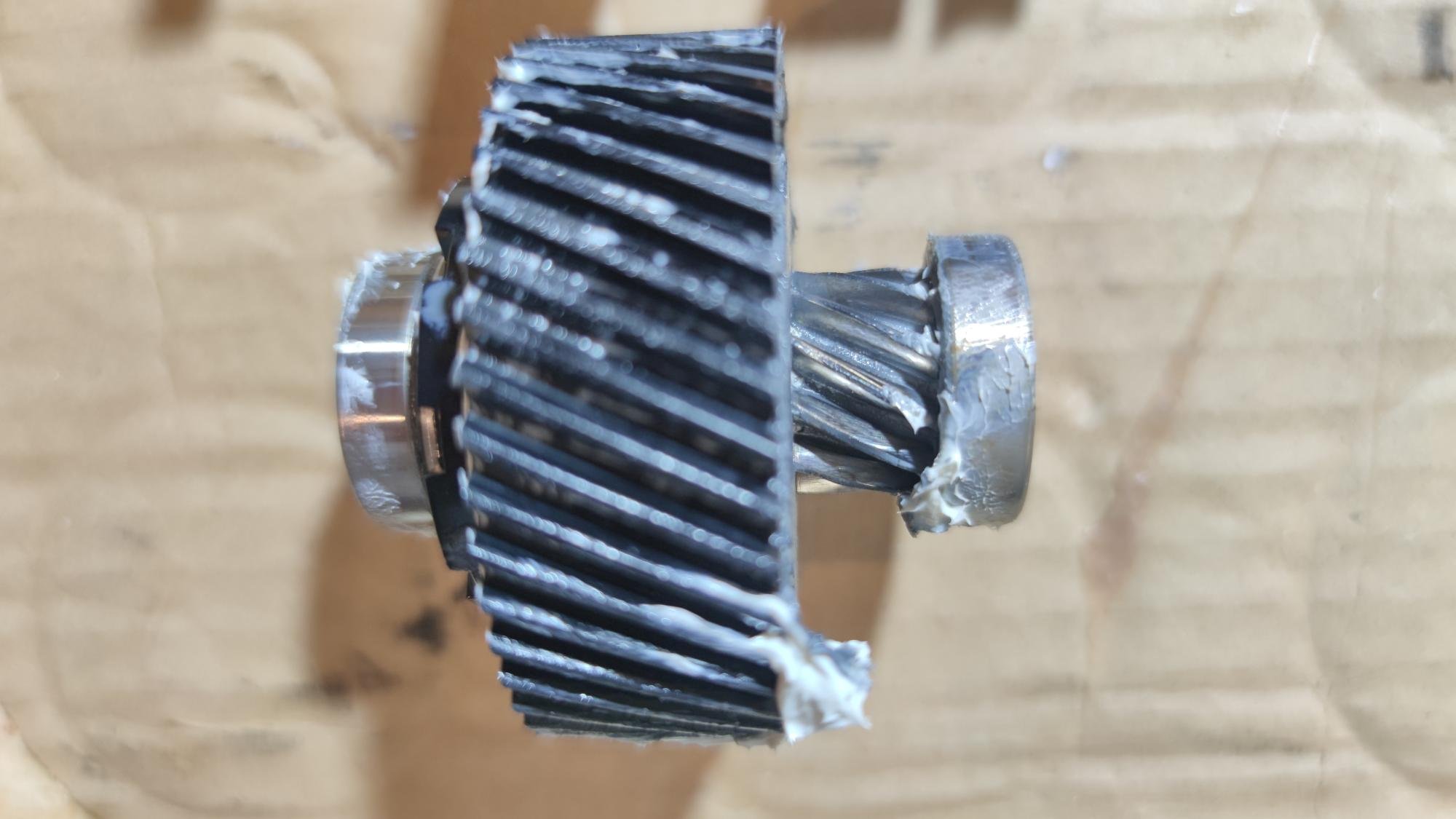

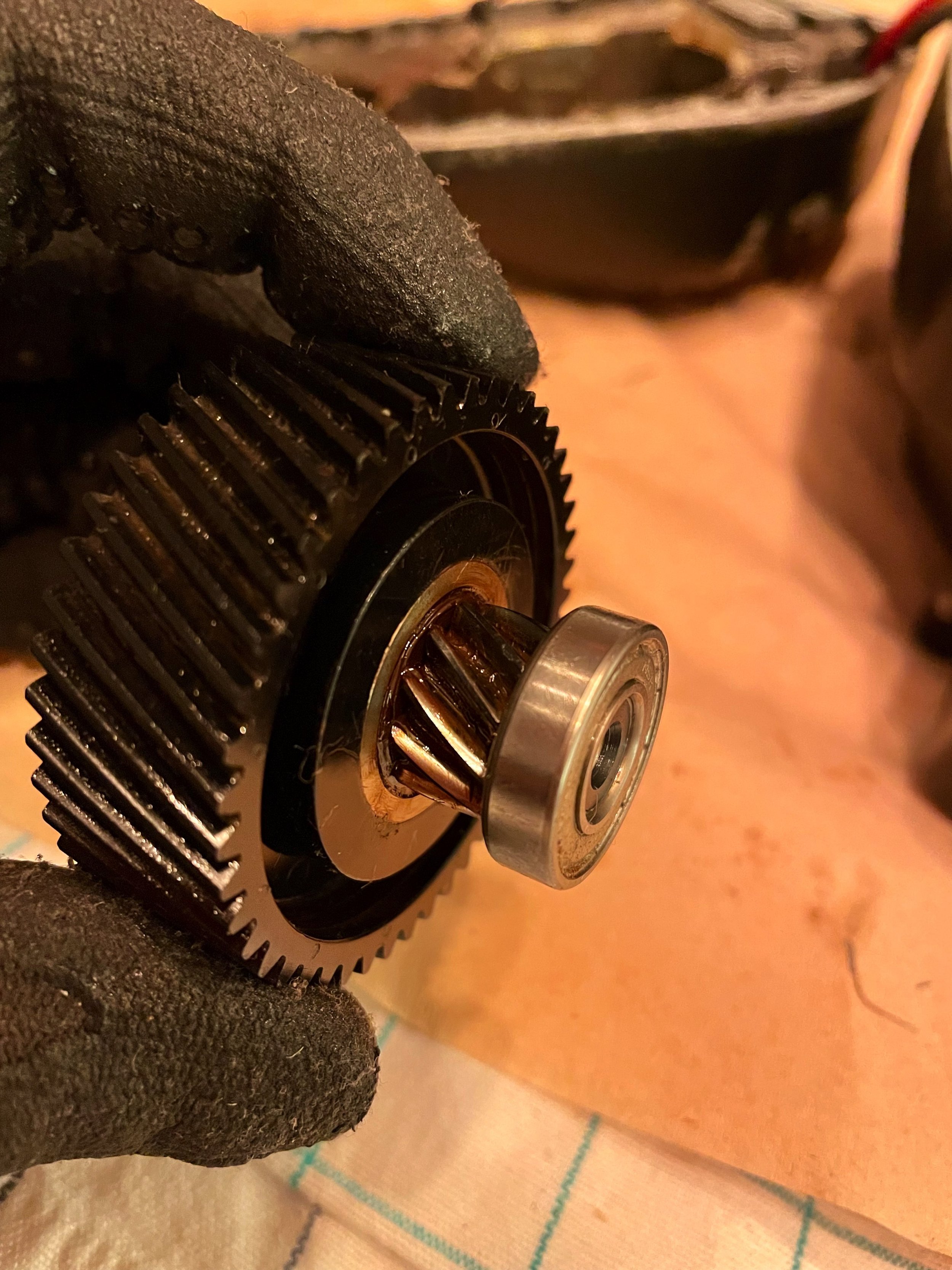

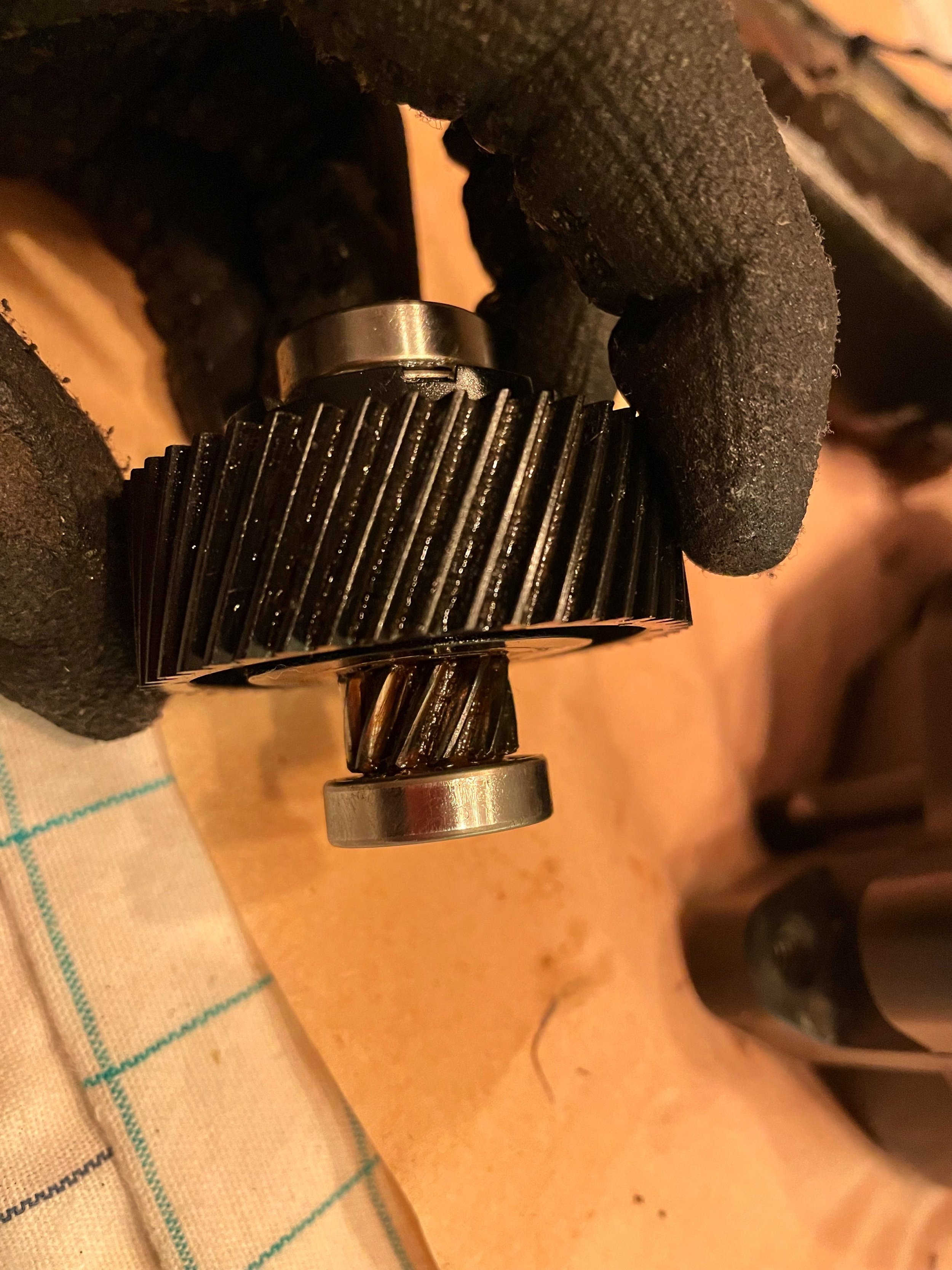

I cleaned it up real nice and replaced the grease which had hardened to black in some places.

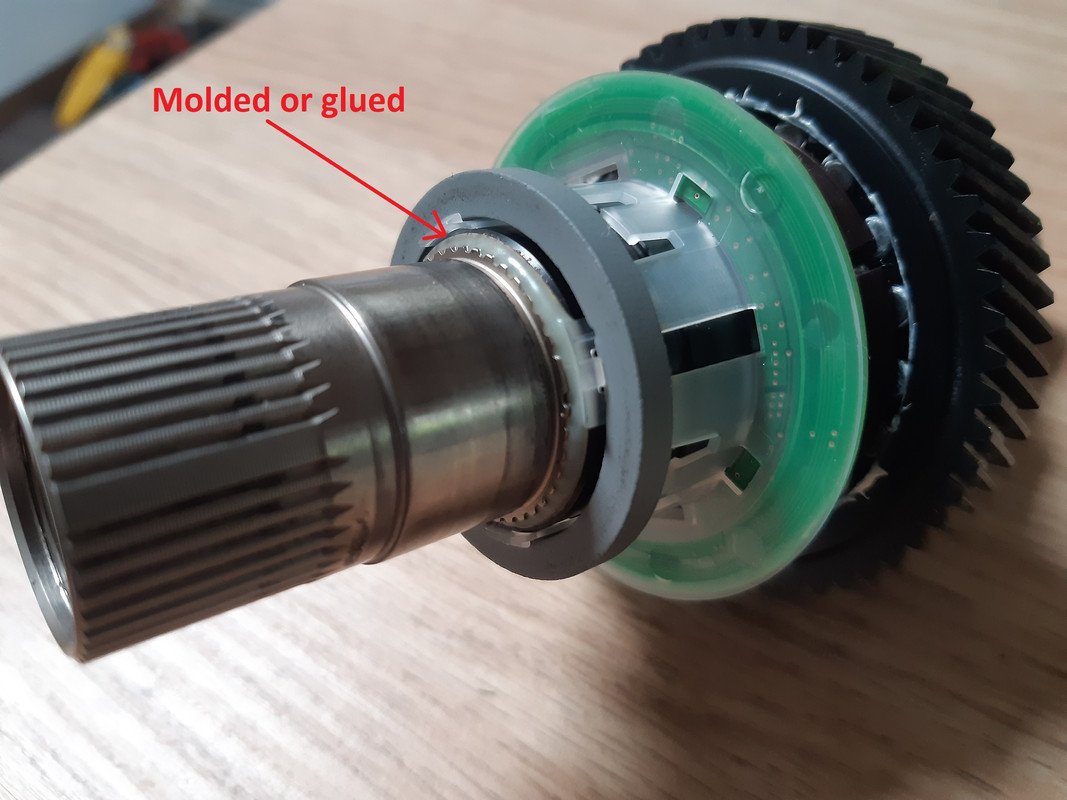

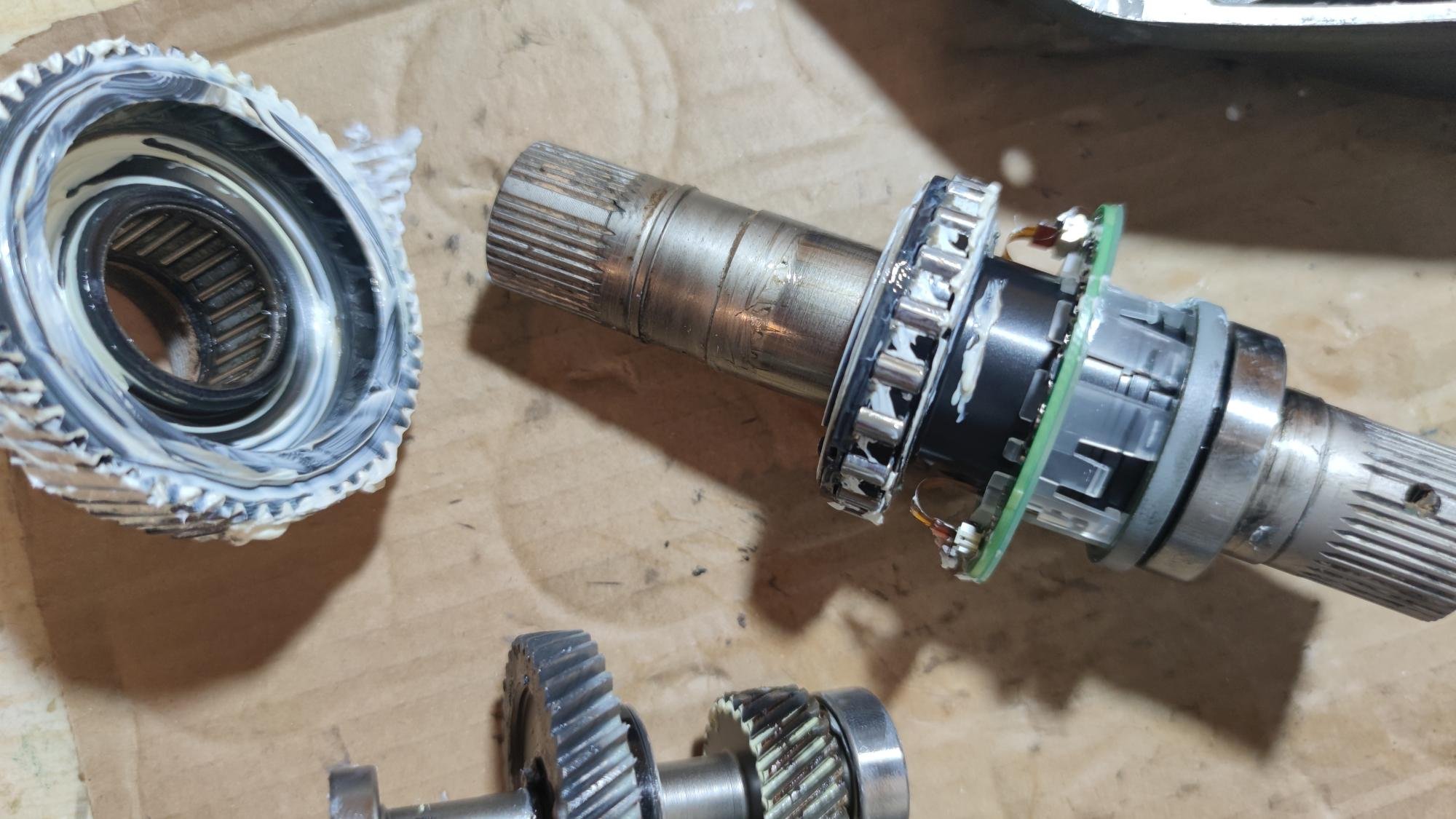

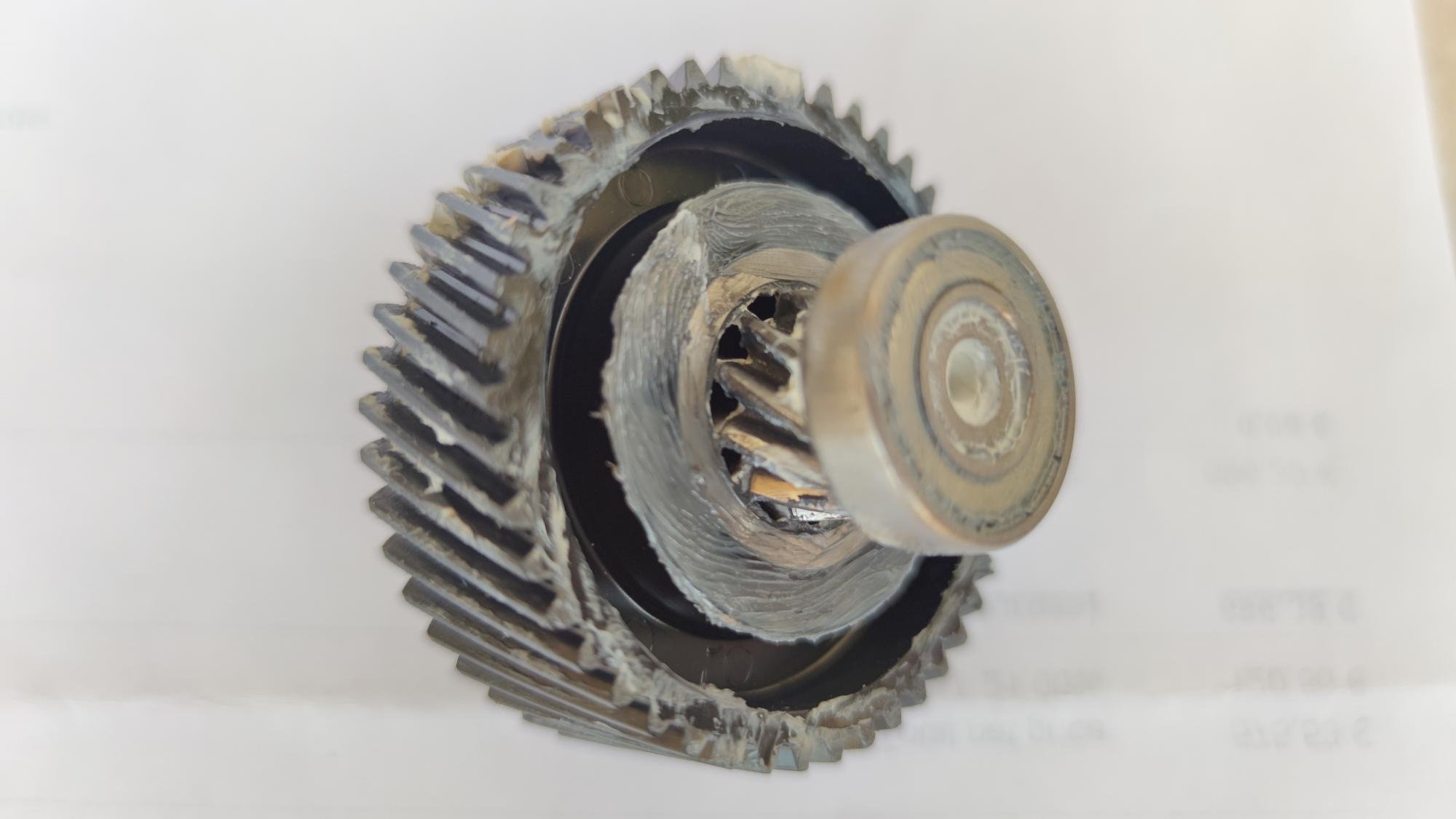

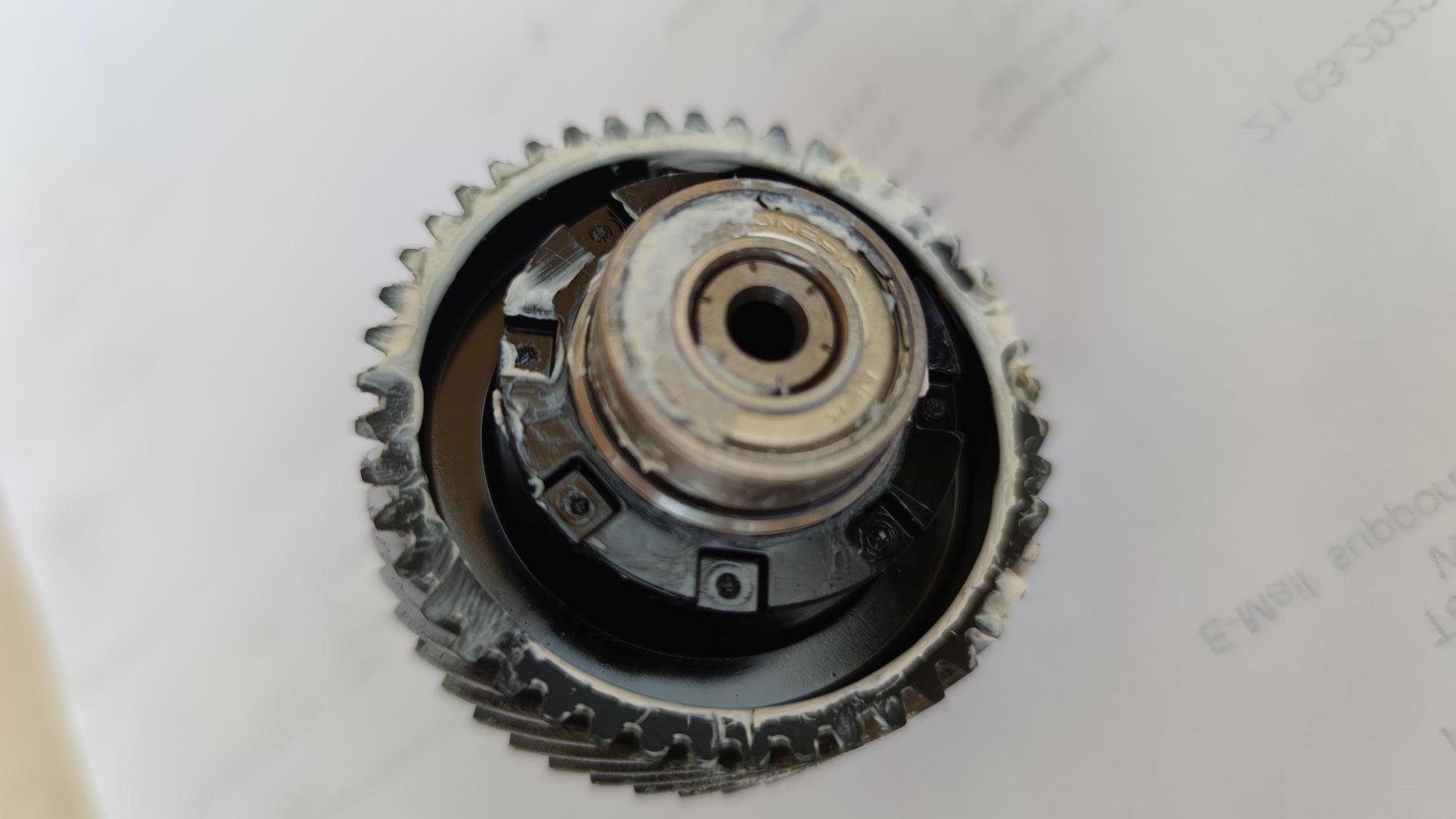

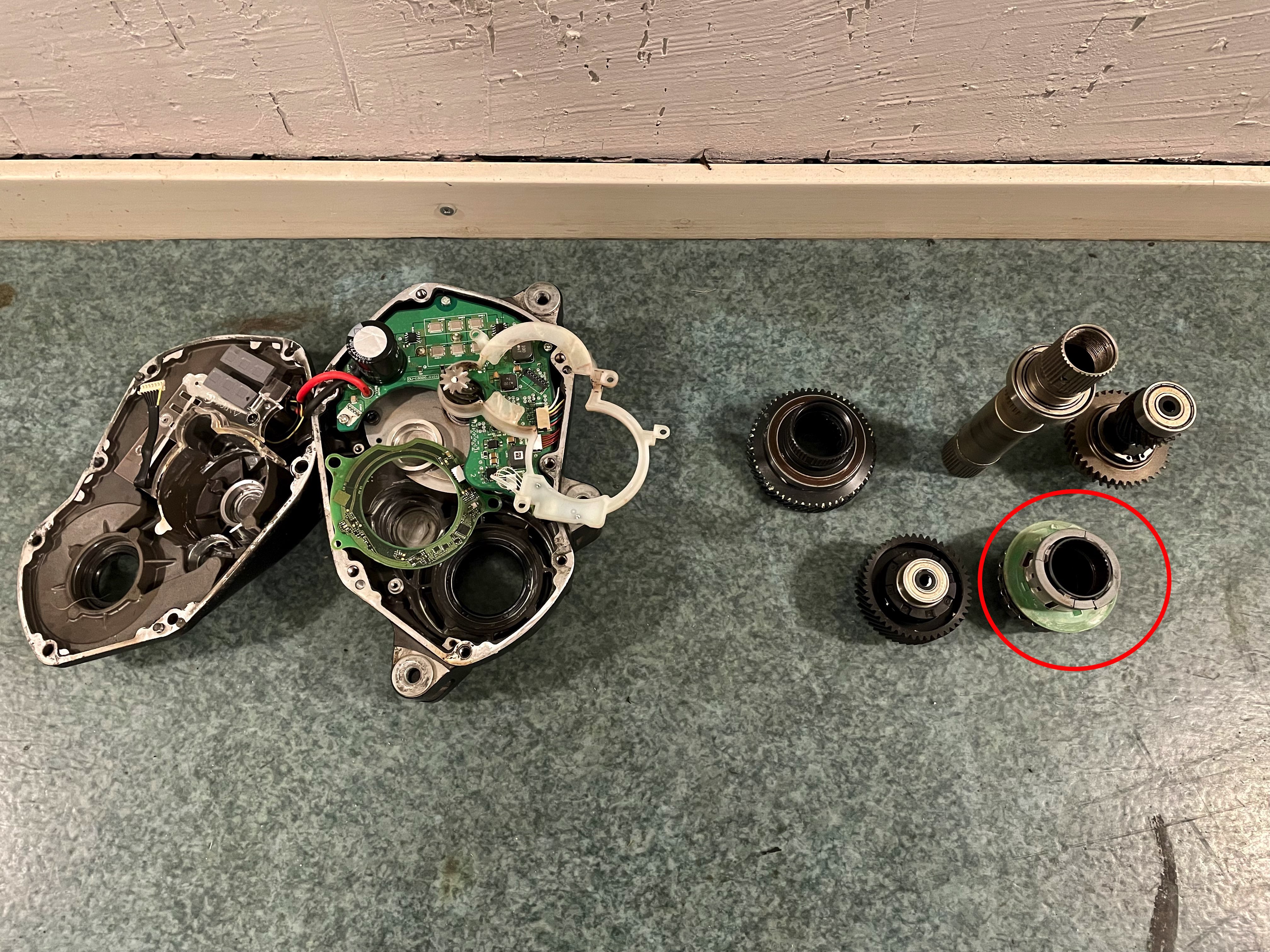

The bearings were all fine; then I dropped the torque sensor and cracked the magnet like a clumsy idiot.

Now I have a nice E010.

Is it possible to replace this part and have it work again? I'm thinking of salvaging it from another motor maybe.

Markus @ eMax tuning (great guy btw) told me this:

Cheers

The motor was starting to make a grinding noise so I followed the Yorkshire rebuild video.

I cleaned it up real nice and replaced the grease which had hardened to black in some places.

The bearings were all fine; then I dropped the torque sensor and cracked the magnet like a clumsy idiot.

Now I have a nice E010.

Is it possible to replace this part and have it work again? I'm thinking of salvaging it from another motor maybe.

Markus @ eMax tuning (great guy btw) told me this:

The torque sensor looks intact and the circuit boards look very good too, I was expecting a lot more crap inside.And if the magnetic ring is broken, game is completely over… You even cannot change the torque sensor to another one of another motor, because each motor need its own calibration data which will be measured and programmed in the Shimano production factory after its assembly in the final test. There is no chance to do this calibration on your own…

Cheers