You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

STEPS E8000 Motor Service

- Thread starter SmokeyBear

- Start date

andrzejwodejszo

Member

O dont know the bosch  i repair only Shimano

i repair only Shimano

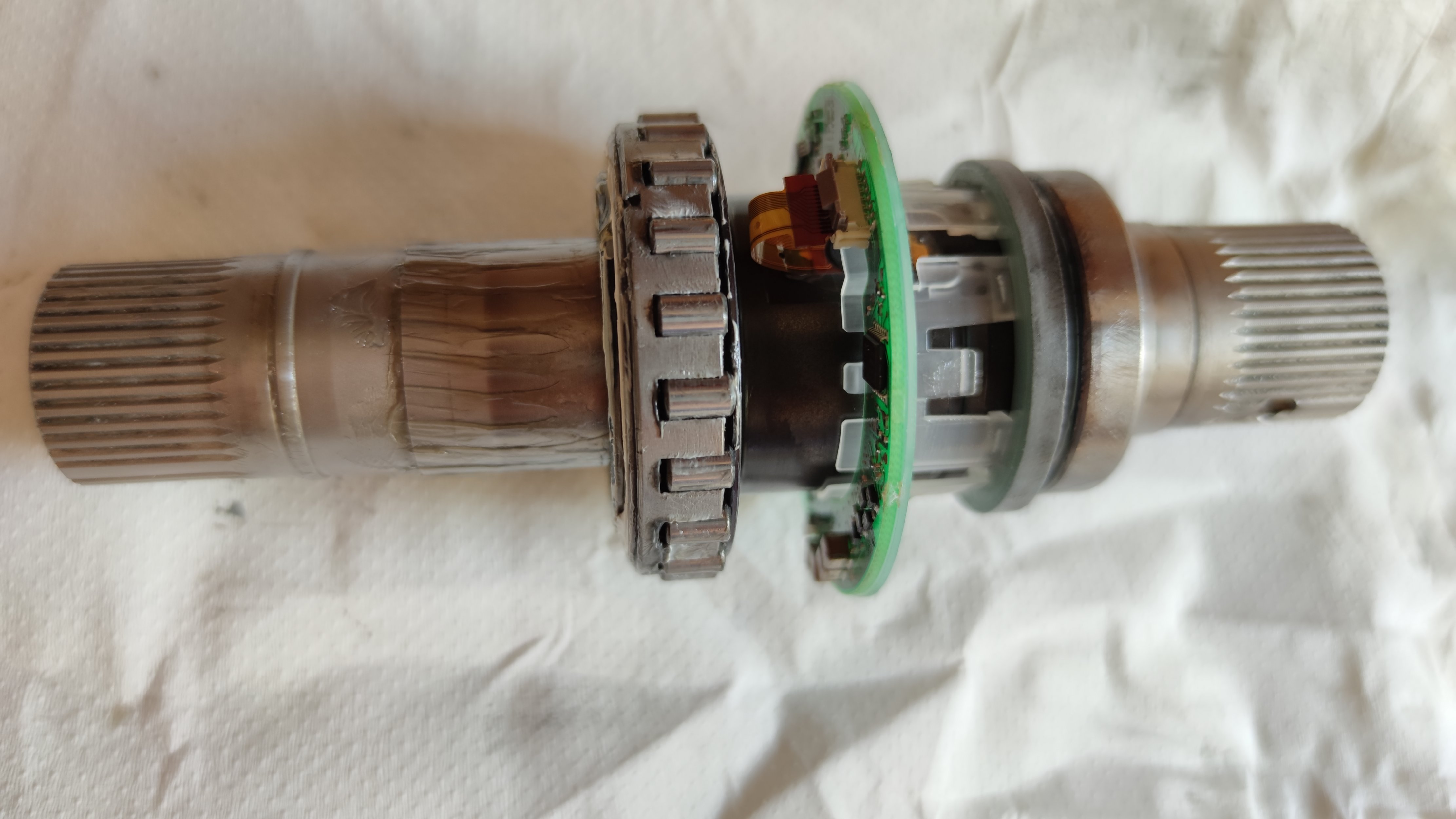

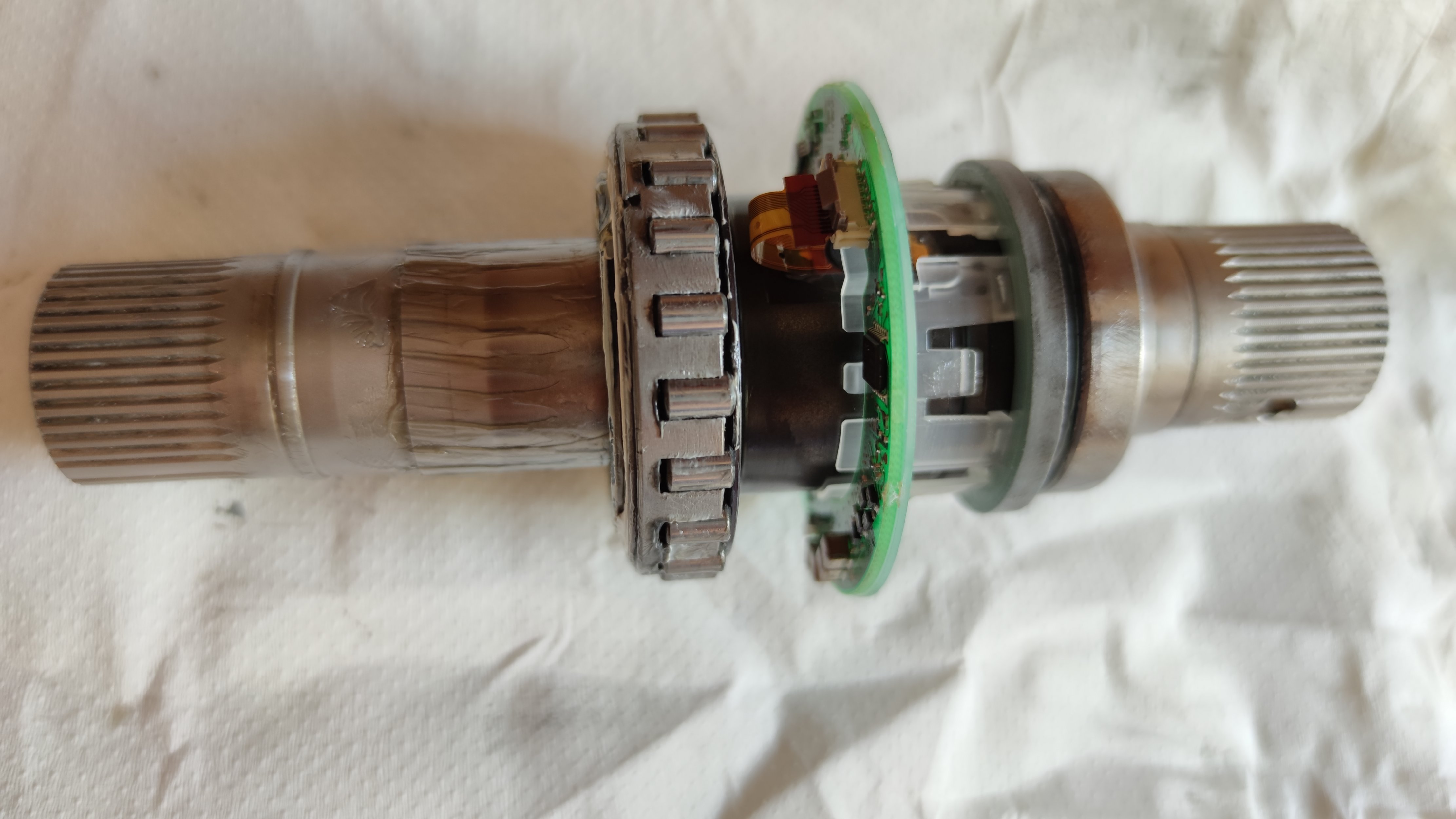

I have taken apart my other motor, which was manufactured in 2018 and I am trying carefully to separate the Torque Sensor Assembly from the Crankshaft, as the Motor is from 2018, it is not glued, I am pulling the assembly to the left direction in the picture, but it does not move. Any recommendation on how to do it?

Others were able to do it, as in second picture from S13.

Also, there is the 10mm Cage bearing inside this assembly, but the assembly is fixed to the crankshaft it does not rotate, so I do not know the reason of the 10mm Cage Bearing. Any idea?

Others were able to do it, as in second picture from S13.

Also, there is the 10mm Cage bearing inside this assembly, but the assembly is fixed to the crankshaft it does not rotate, so I do not know the reason of the 10mm Cage Bearing. Any idea?

I have taken apart my other motor, which was manufactured in 2018 and I am trying carefully to separate the Torque Sensor Assembly from the Crankshaft, as the Motor is from 2018, it is not glued, I am pulling the assembly to the left direction in the picture, but it does not move. Any recommendation on how to do it?

Others were able to do it, as in second picture from S13.

Well, i was only able to do that with my spare parts motor, which was an earlier revision E8000.

But my later model E8000 that came with my bike also had a fixed torque sensor assembly on the crankshaft that i couldnt remove.

But as mentioned earlier, its not required to remove this part. The needle bearing inside doesnt wear that much and doesnt get dirty. From what i understand, the bearing is there to allow the torque assembly to rotate ever so slightly. The assembly basically twists a tiny bit under the force of the cranks. And that is what allows the torque sensor to measure the force. So without that needle bearing the torque sensor wouldnt be able to do its job.

Husky430

E*POWAH Elite

Just changed the whole crank assembly from my mates bike into my bricked motor, with the torque sensor still on it.

My mates motor was making a racket and all worked out well, my old motor which was silent and just stopped dead, now has his torque sensor and crank in it and is silent and up and running. Shimano should sell a crank and torque sensor as a unit for people to replace as this seems to be a recurring problem with them.

My mates motor was making a racket and all worked out well, my old motor which was silent and just stopped dead, now has his torque sensor and crank in it and is silent and up and running. Shimano should sell a crank and torque sensor as a unit for people to replace as this seems to be a recurring problem with them.

Well, i was only able to do that with my spare parts motor, which was an earlier revision E8000.

My motor is the original bike purchased in August 2018, so it is also an earlier version. Do you remember if you had to do anything special to dissassembly it, or you just pulled it with your hands and it fell off?

Last edited:

Ok Marty McFly, did they make any improvements in the next 5 years? Or when you say an earlier version, was it a '25 bike you picked up cheap in '28 ? ;-)My motor is the original bike purchased in August 2028

Ok Marty McFly, did they make any improvements in the next 5 years? Or when you say an earlier version, was it a '25 bike you picked up cheap in '28 ? ;-)

Ha ha ha, Sticky fingers. I corrected the year in the original post

Mobilgrease 28 & BBSHD/BBS02 : Because A Good Mid-drive Is Better Seen And Not Heard

There has been a near-mutiny of BBS02 owners (rioting in the streets) who have been disgruntled that their BBS02 units have shipped either without any grease in the secondary reduction gears or wit…

I found this link interesting, what do you think about Mobilgrease 28?

I'm having a hard time finding Molykote PG-75 for a decent price.

Mobilgrease 28 & BBSHD/BBS02 : Because A Good Mid-drive Is Better Seen And Not Heard

There has been a near-mutiny of BBS02 owners (rioting in the streets) who have been disgruntled that their BBS02 units have shipped either without any grease in the secondary reduction gears or wit…electricbike-blog.com

I found this link interesting, what do you think about Mobilgrease 28?

I'm having a hard time finding Molykote PG-75 for a decent price.

If you wish to buy PG-75, these stores sell small cans:

Gear grease for ebike motors - eBike Motor Centre (Performance Line Bearings)

https://www.tiendamtb.com/es/varios/2013-grasa-molykote-pg-75-para-plastico-y-metal-30ml.html?search_query=molykote&results=2#/formato-150ml

It just fell apart when i was trying to remove the crank from the casing. So it shouldnt take any effort or tools. If its loose, its loose. If not, then dont mess with it.My motor is the original bike purchased in August 2018, so it is also an earlier version. Do you remember if you had to do anything special to dissassembly it, or you just pulled it with your hands and it fell off?

Some time ago ( Around 2 years) there was a forum member who bought the large 1kg can of PG - 75 and was offering to sell small cans, his user name is SEBA, I do not know if he is still around, but you can PM himThanks but first one doesn't ship to Sweden and second is out of stock.

Quotes from the web:

Looks very promising and easy to find, priced ~€15 for 380g!

I'll let you know if my motor explodes.

I've been studying lubricants and industrial fluids for 15 years and applying them in every manner of electric drive systems, hydraulics, pneumatics, every kind of bearing, machine tools, cutting fluids, gearboxes, compressors/vacuum, robotics, bikes, cars, trucks, entire production vehicles and modules, aircraft and engines, et cetera. Have studied hundreds of fluids and their material/interactive properties. Fuchs, Mobil, Castrol, Shell, Dow Corning, 3M, Henkel, DuPont, and that great smelling LPS for good measure, to name a few I deal with.

Hopefully by now I'm not guessing how grease works or how to select it, or a hundred million dollars worth of equipment and vehicles are fucked!

Greasing a mundane electric bike motor gearbox uses about a dollar or two worth of SHC 100, by the way. Also, I like Mobil's grease products after using the past hundred tubes of various greases over the years... I use that particular grease a lot elsewhere on the job.

As far as I can tell from several threads on different forums, SHC 100 is recommended for ebike motors like BBSxx by Mobil engineers over 28 - something something lithium base better than clay base for high speed electric motors, won't cause any issues if you don't fully clean out the existing grease.

I think problems people were having was more than they packed their motors full if it and that's not really how it's supposed to be applied. Just a healthy coating of everything with a little extra around any axles or where anything moves against other parts. You don't want the motor to have to fight a bunch of grease to spin.

THIS is the grease Mobile suggests for use in electric eBike motors. Lithium-based designed for electric motors. Compatible with the grease Bafang uses on the nylon gear.

Mobilith SHC 100 is an antiwear and extreme pressure grease primarily recommended for higher speed applications such as electric motors, where reduced friction, low wear and long service life are required. It is an NLGI 2 Grade / ISO VG 100 grease with a synthetic base fluid. Its operating temperature range is -40º C* to 150º C.

Looks very promising and easy to find, priced ~€15 for 380g!

I'll let you know if my motor explodes.

Just another word of warning. I am sure if the motor manufacturers could get away with one cheap grease to do the lot they would. But eBike manufacturers are not stupid, they can use several different greases throughout the motor, to ensure each part is using the lubricant best suited for its application. These include different consistency greases depending on the load and speed of the part to be lubricated.Quotes from the web:

Looks very promising and easy to find, priced ~€15 for 380g!

I'll let you know if my motor explodes.

Greases can be very problematic too: If you put Mobilith SHC 100 on your clutch bearings for example, they will slip. High pressure grease is not good for this application. Another example: many lithium greases are not suitable for certain plastics, and many greases do not get on with brass.

Putting any grease that is not dielectric, such as grease containing copper or Molybdenum disulphide, will play havoc with your electronic components, and we also often see motors where people have used aluminium based marine greases, that have affected the hydrocarbon bearing greases, turning it back to oil

I and others have said in this thread that MolyKote PG-75 is not the best grease for Shimano motors. If anything, you might want to look at Molykote EM-50L. I can't guarantee this grease in a Shimano motor, but it may have better properties for this application. I would not use it on the clutch bearings though.

I also have a big can of PG75, that i would be willing to sell in small batches. However im currently in France and unable to ship things from here. In september i can ship you some from the netherlands. And next year i will be back in sweden, but doubt you can wait that long

For the gears only, what about "Bosch drive unit grease for gears and bearings within the motor." ?

I'm using SHC 100 for the gears only, the rest is fine. My main problem is the electric motor bearing behind the PCB that I'm not going to desolder and risk bricking the whole unit.

I'll ride this motor as is with the slightly increased bearing noise, I'll look for a replacement in the meantime.

On a tangent Pinion told me this about their upcoming motor gearbox unit:

One year oil change and fully serviceable by the manufacturer, none of this crap we have to deal with currently.

I'll ride this motor as is with the slightly increased bearing noise, I'll look for a replacement in the meantime.

On a tangent Pinion told me this about their upcoming motor gearbox unit:

Yes, full serviceable, we internally make the service of the MGU.

Service videos are in the making at the moment, unfortunately I have no timeline yet when they will be released.

One year oil change and fully serviceable by the manufacturer, none of this crap we have to deal with currently.

Interesting topic and interesting discussion. From previous posts I understood that Molykote PG-75 was the way to go, but now we have another contender, Molykote EM-50L.Just another word of warning. I am sure if the motor manufacturers could get away with one cheap grease to do the lot they would. But eBike manufacturers are not stupid, they can use several different greases throughout the motor, to ensure each part is using the lubricant best suited for its application. These include different consistency greases depending on the load and speed of the part to be lubricated.

Greases can be very problematic too: If you put Mobilith SHC 100 on your clutch bearings for example, they will slip. High pressure grease is not good for this application. Another example: many lithium greases are not suitable for certain plastics, and many greases do not get on with brass.

Putting any grease that is not dielectric, such as grease containing copper or Molybdenum disulphide, will play havoc with your electronic components, and we also often see motors where people have used aluminium based marine greases, that have affected the hydrocarbon bearing greases, turning it back to oil

I and others have said in this thread that MolyKote PG-75 is not the best grease for Shimano motors. If anything, you might want to look at Molykote EM-50L. I can't guarantee this grease in a Shimano motor, but it may have better properties for this application. I would not use it on the clutch bearings though.

Food for thought: I am attaching technical specs of both greases so somebody with the right knowledge can justify and explain which and why is better

PG-75

Lubricating grease for plastic/plastic and plastic/metal combinations with slow to medium-fast movements and light loads

Features & benefits

• Suitable for long-term lubrication

• Good low-temperature characteristics (usable down to -40°C)

• Very low coefficient of friction

• Compatible with many plastics and elastomers

Composition

• Mineral oil

• Polyalphaolefin

• Lithium soap

• Solid lubricants

Applications

MOLYKOTE® PG-75 High Performance Grease is used on vehicle trackrod joints; control cables, gearboxes, worms, planetary gears and other plastic/plastic and plastic/metal contacts in automotive and electrical appliances; and electromechanical actuators such as automotive sun roof tracks, window mechanism and HVAC.

How to use

Clean points of contact. Apply in same way as lubricating greases, using brush, spatula, grease gun or automatic lubricating device. Suitable for delivery by central lubricating

system. In the event of long breaks in service (e.g., overnight), the pressure in the delivery equipment should be relieved. Not to be mixed with other greases.

Because of variation in quality of plastics and elastomers, compatibility tests should be carried out for swelling and shrinkage, stresscrack formation, and changes in strength and hardness.

EM-50L

Lubricating grease developed for plastic components

Features

• Compatible with most plastics

• Effective in reducing noise from plastic gears

• Long service life

• Low seepage, so it can be used in places wherein cleanliness is required

• Does not contain silicone, thereby preventing problems with contact point failures

Composition

• Polyalphaolefin

• Lithium soap

Applications

Automobiles, electrical appliances, precision equipment, audio equipment, and office equipment with plastic parts. Used as a damper grease to reduce noise in moving parts, such as gears.

How to use

Clean points of application. As is usual with lubricating greases, apply or fill by means of a brush, spatula, or automatic lubrication device

Attachments

Last edited:

Strindberg

Active member

21 december 2021

I wrote here

www.emtbforums.com

www.emtbforums.com

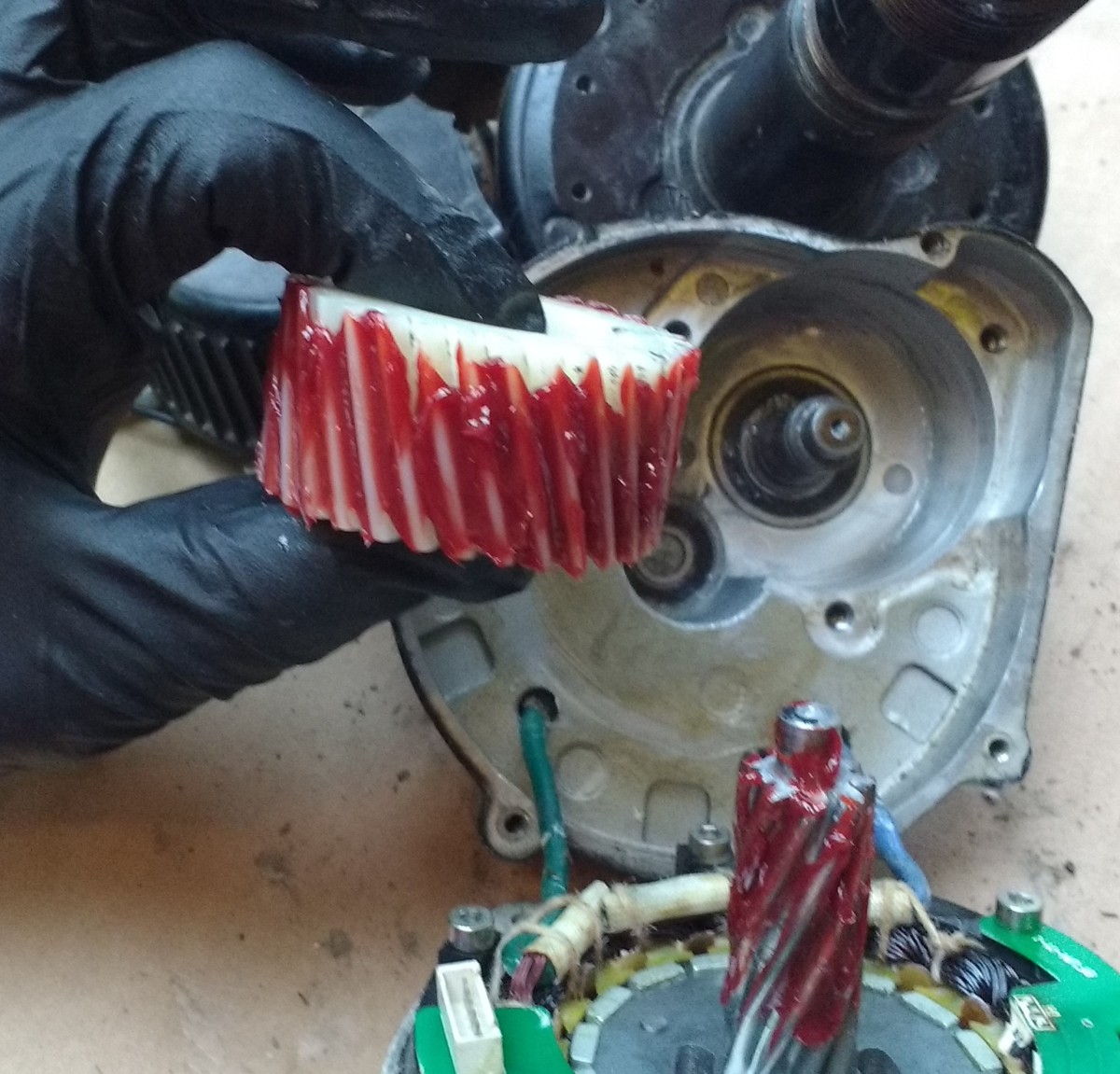

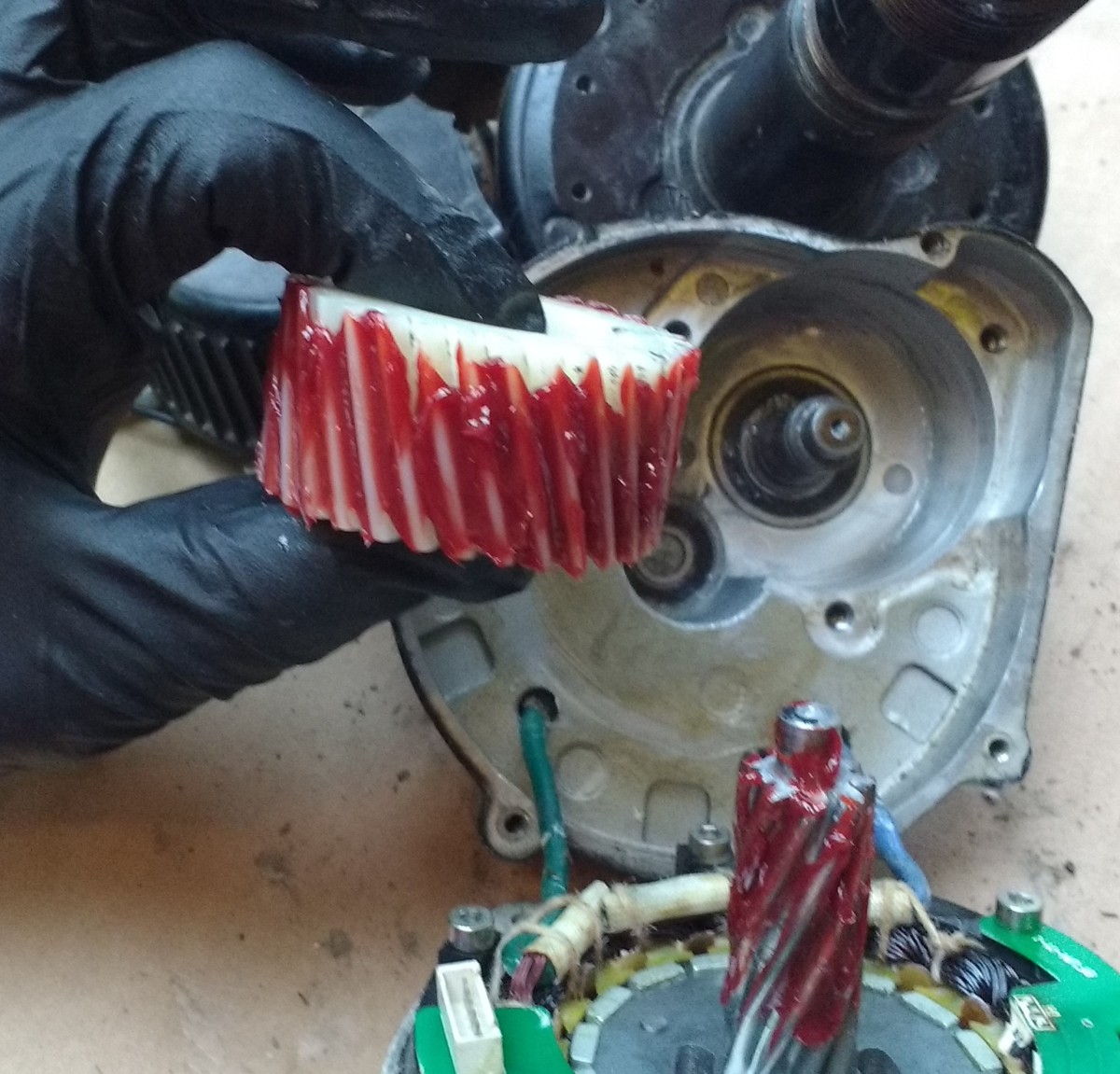

I reused the "old" white grease for the clutch and OKS 270 for the teeth.

All my ball bearings are now sealed and on both sides.

Originally, only the ball bearing on the right of the axle is sealed on both sides,

and the one on the left only on one side... !!!

The clutch has a good grip like new.

But if you reed the OKS papers, this grease should do all what we need >>>

metal/metal,

plastic/metal,

non corosive for platsic, rubber and coated and non-coated PCBs,

high pressure,

heat,

non dispersive by "high" rotations and quickly done "stop-an-go"

Please see Data Sheet pdf in GB or in DE.

I wrote here

STEPS E8000 Motor Service

which could be too slippery for clutch bearings. If I remember, I reused the "old" white grease for the clutch and OKS 270 for the teeth. All my ball bearings are now sealed and on both sides. Originally, only the ball bearing on the right of the axle is sealed on both sides, and the one on...

I reused the "old" white grease for the clutch and OKS 270 for the teeth.

All my ball bearings are now sealed and on both sides.

Originally, only the ball bearing on the right of the axle is sealed on both sides,

and the one on the left only on one side... !!!

The clutch has a good grip like new.

But if you reed the OKS papers, this grease should do all what we need >>>

metal/metal,

plastic/metal,

non corosive for platsic, rubber and coated and non-coated PCBs,

high pressure,

heat,

non dispersive by "high" rotations and quickly done "stop-an-go"

Please see Data Sheet pdf in GB or in DE.

If you open your motor again, please, let us know and show pictures of how the OKS270 has performed.21 december 2021

I wrote here

STEPS E8000 Motor Service

which could be too slippery for clutch bearings. If I remember, I reused the "old" white grease for the clutch and OKS 270 for the teeth. All my ball bearings are now sealed and on both sides. Originally, only the ball bearing on the right of the axle is sealed on both sides, and the one on...www.emtbforums.com

I reused the "old" white grease for the clutch and OKS 270 for the teeth.

STEPS E8000 Motor Service

which could be too slippery for clutch bearings. If I remember, I reused the "old" white grease for the clutch and OKS 270 for the teeth. All my ball bearings are now sealed and on both sides. Originally, only the ball bearing on the right of the axle is sealed on both sides, and the one on...www.emtbforums.com

But if you reed the OKS papers, this grease should do all what we need >>>

metal/metal,

plastic/metal,

non corosive for platsic, rubber and coated and non-coated PCBs,

high pressure,

heat,

non dispersive by "high" rotations and quickly done "stop-an-go"

It states "High Pressure" so wont quite do all you need. I know you haven't used it on your clutch bearings but others might, so please be warned.

Yesterday evening I did a bearing change on my e8000 with 4500km, it went almost smoothly until powering up the motor.

In short, no error message, but no assistance in any mode.

Long story :

I did change only few slightly worn bearings.

Wanted to change the longer Needle roller bearing K25 29 17 (25x29x17mm), but didn't find the way to change, was not damage, so no bid deal, I hope.

I had to disconnect both PCB, dismount the crank shaft from torque sensor to change the smaller needle bearing.

Is it a common issue that the motor don't show any error and don't give assist ?

To be honest I'm a bit upset to myself right now.

In short, no error message, but no assistance in any mode.

Long story :

I did change only few slightly worn bearings.

- Bearing 6808DD (40x52x7mm)

- Bearing 6805ZZ (25x37x7mm)

- Bearing 6000ZZ (10x26x8mm)

- Needle roller bearing K25 29 10 (25x29x10mm)

Wanted to change the longer Needle roller bearing K25 29 17 (25x29x17mm), but didn't find the way to change, was not damage, so no bid deal, I hope.

I had to disconnect both PCB, dismount the crank shaft from torque sensor to change the smaller needle bearing.

Is it a common issue that the motor don't show any error and don't give assist ?

To be honest I'm a bit upset to myself right now.

Last edited:

I will answer to myself.

No torque is detected when it was on the bike stand.

When riding motor activate and give normal assistance.

I have the feeling that I need a bit more torque to activate the motor, maybe in my mind, but what a relief that my motor and torque sensor are not broken.

No torque is detected when it was on the bike stand.

When riding motor activate and give normal assistance.

I have the feeling that I need a bit more torque to activate the motor, maybe in my mind, but what a relief that my motor and torque sensor are not broken.

It's a little over a year and 8000 or so more miles since my motor started sounding rough and I subsequently rebuilt it (new bearings and grease). Coming back after a 50 odd mile ride earlier this week it occurred to me it still sounds as sweet as a nut. There was some debate around grease at the time, I used PG-75 (from bearing man) and can only assume it's doing an excellent job.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 578K

- Messages

- 29,437

- Members