slickrock

Active member

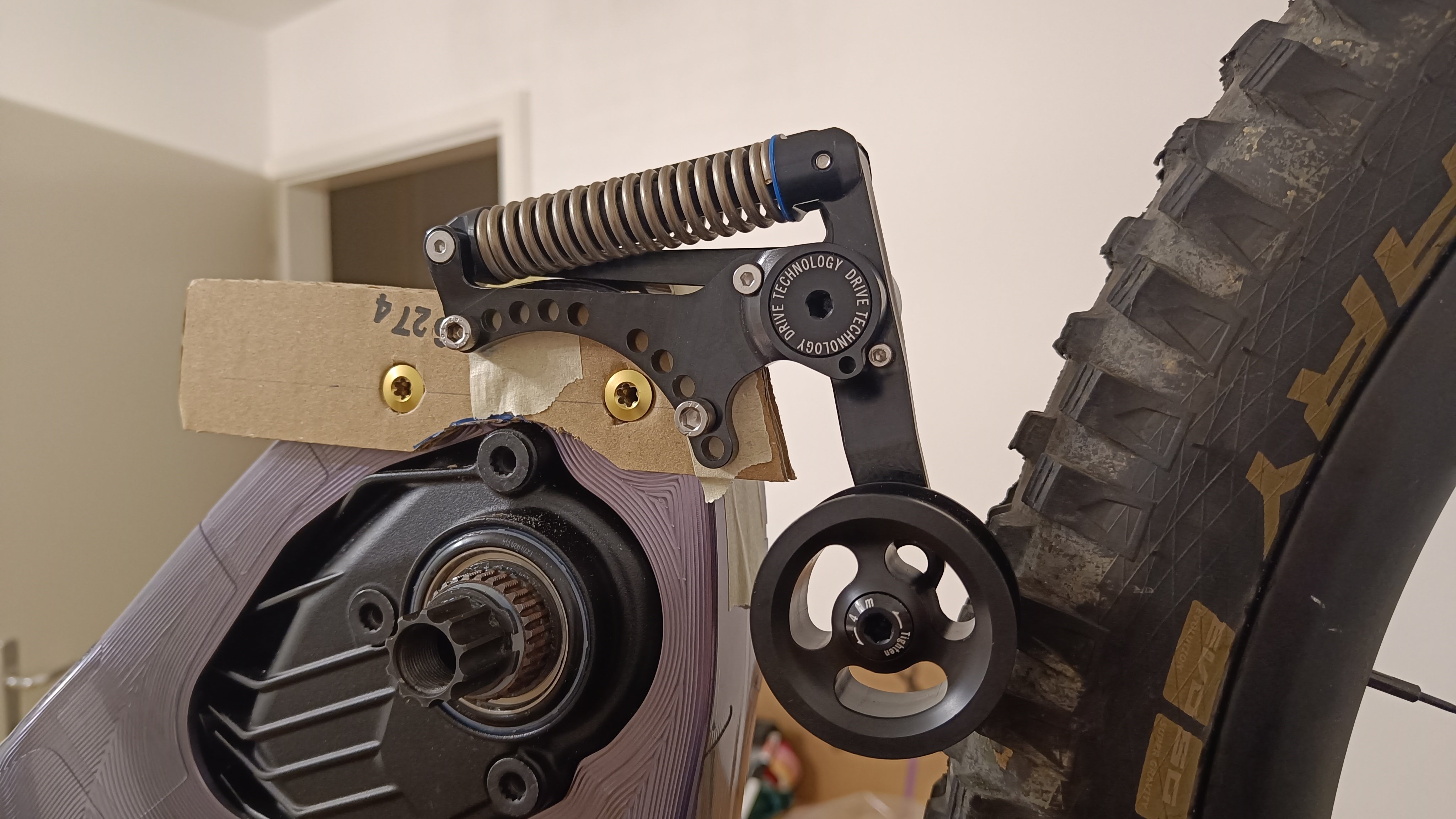

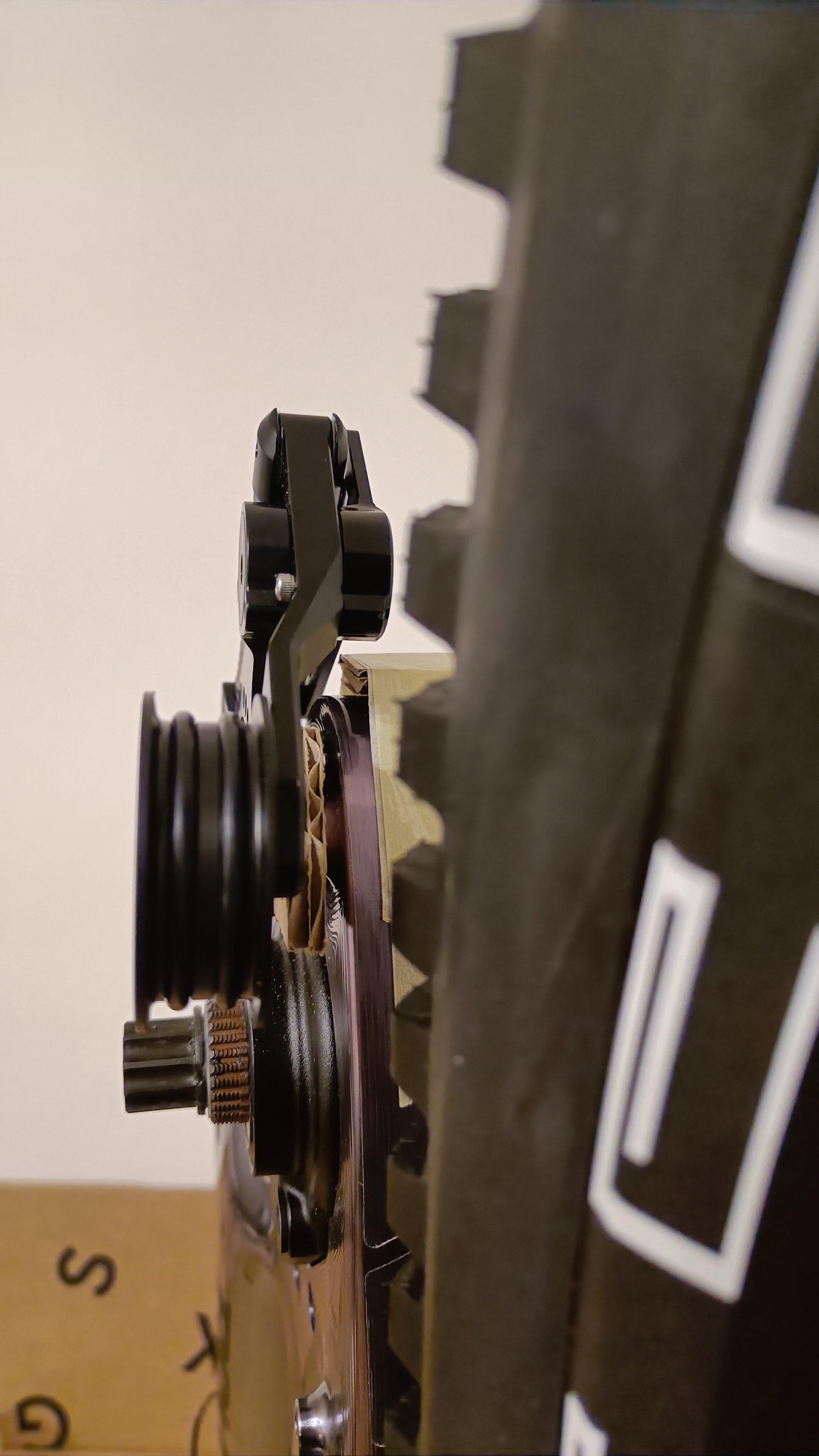

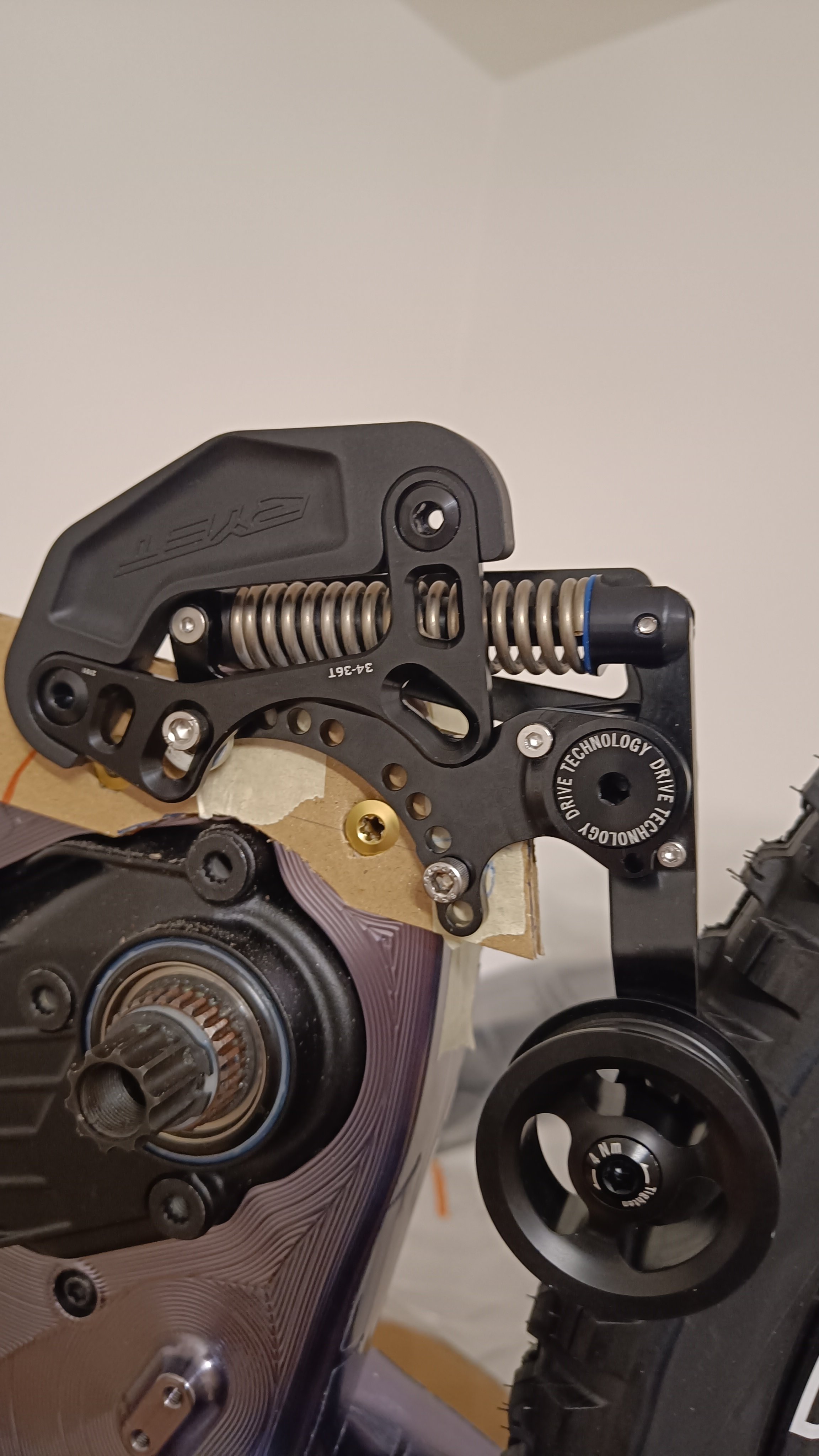

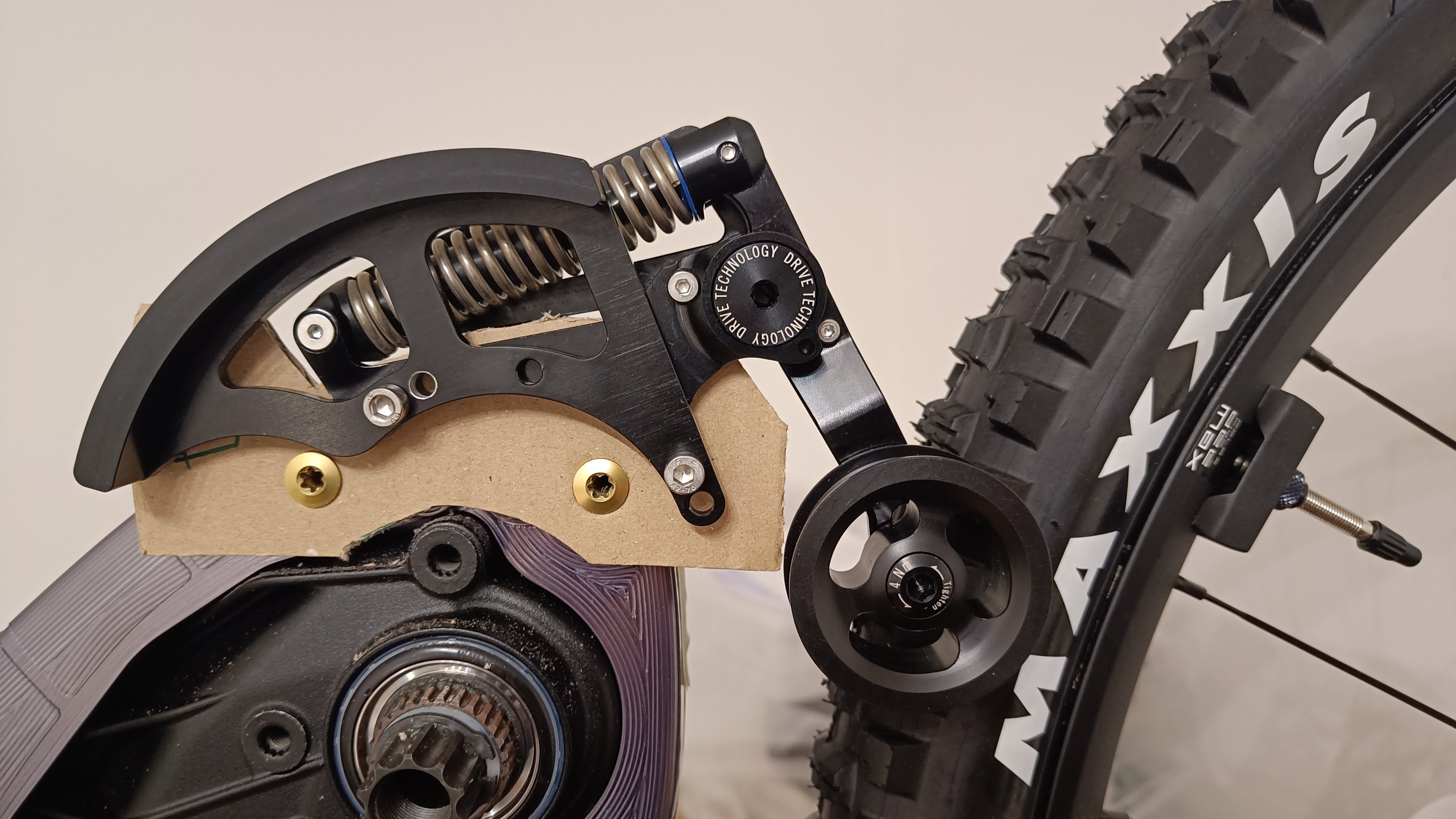

Update: Above image says it all. Taken without permission from V86.

A number of people in this forum are expressing interest in some form of internal geared transmission system integrated with Pole EMTBs, whether it be new-fangled motor/gear units (MGU) or hub-based integration with a secondary objective of eschewing chains in favor of a kevlar-based belt drive. There have been a number of posts on this topic that I felt it the need for a separate thread to discuss this rather than clog up the other threads.

From a product perspective, it is clear that having a combined internally geared transmission system with e-bike motor in a single mechanism (i.e. MGU) is the best synergistic confluence of bike technologies for full-power EMTB. Combining these two technologies affords an unsprung, automatic transmission, sealed mechanism, low-maintenance drivetrain solution and can open up the option to use belt drive instead of chain linkages and dangling derailleurs. Additionally, the downsides of internal-gear solutions, such as added weight and reduced efficiency, don't rear their heads as much with full-power, enduro-sized e-bikes, as they are already heavy and power-assisted to begin with.

But... we have to wait for this technology to develop, mature, and become reliable, and without the big players entering the market (SRAM, Shimano, Bosch) placing bets on a particular solution for a boutique bike manufacture may be too much to currently entertain. Poles' EMTB product space is arguably too crowded already with quite a bit of marketing effort put forth to distinguish the brand new Sonni from the still relatively new Voima. Pole currently has no internal gear offerings and it’s not clear if Pole would create a new EMTB model or graft a solution onto its existing offerings at some in the future. Of course, we could abandon Pole and jump to the likes of Bulls Bikes (or maybe Orange when gets is prototype out the door) to get an MGU fix, but we'd also be abandoning the affinity to Pole's geometry, design, performance and manufacturing prowess.

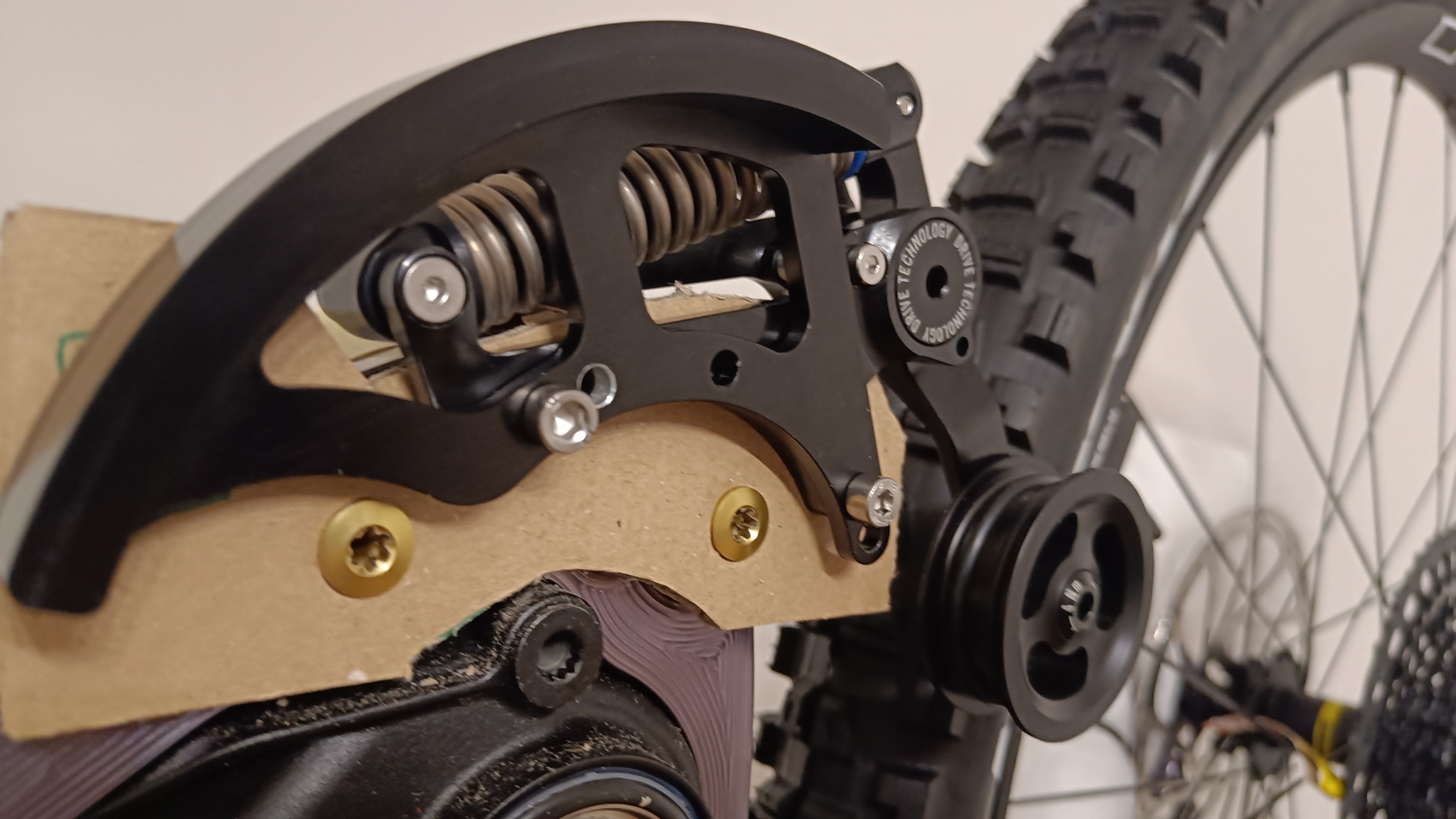

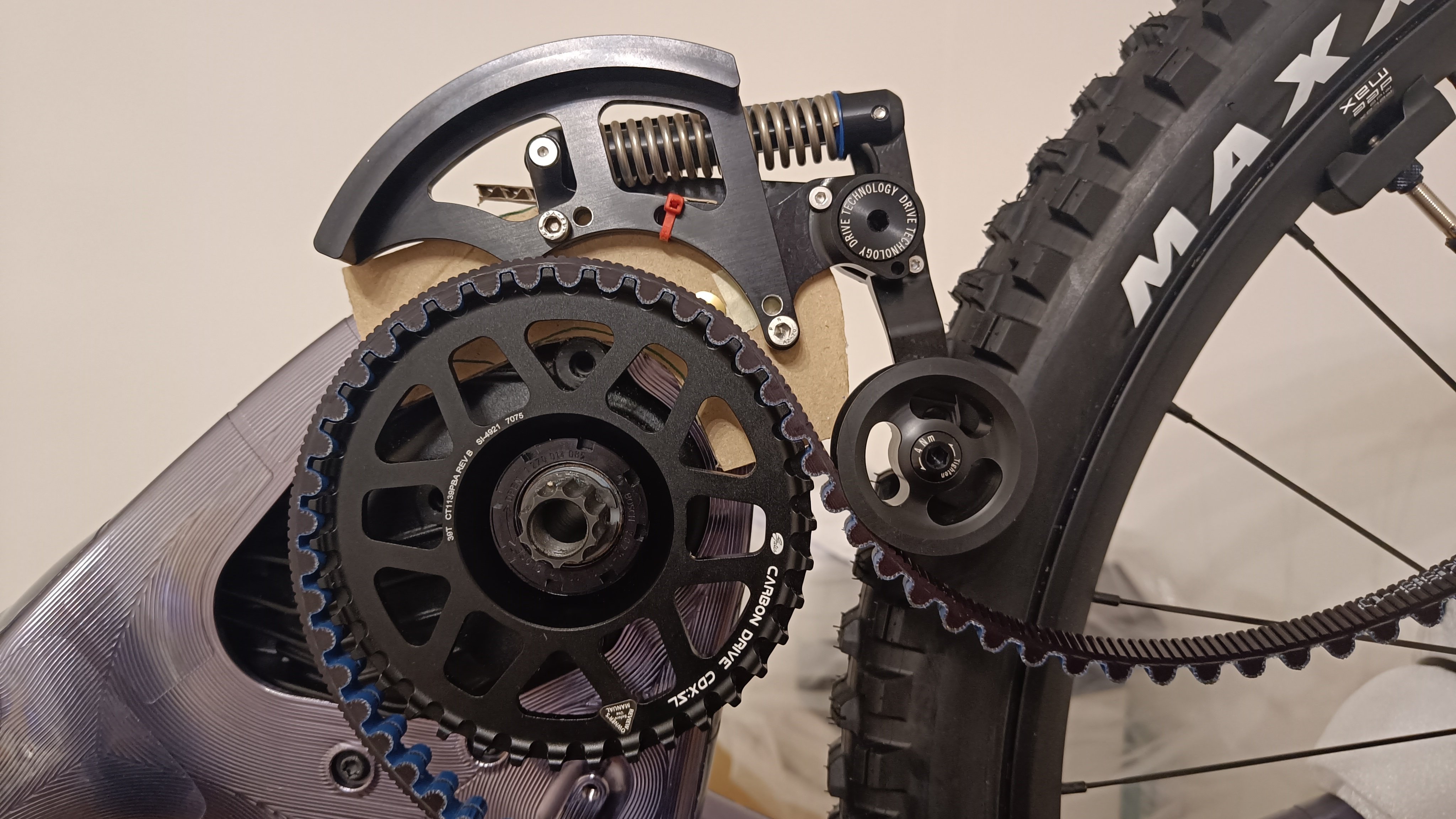

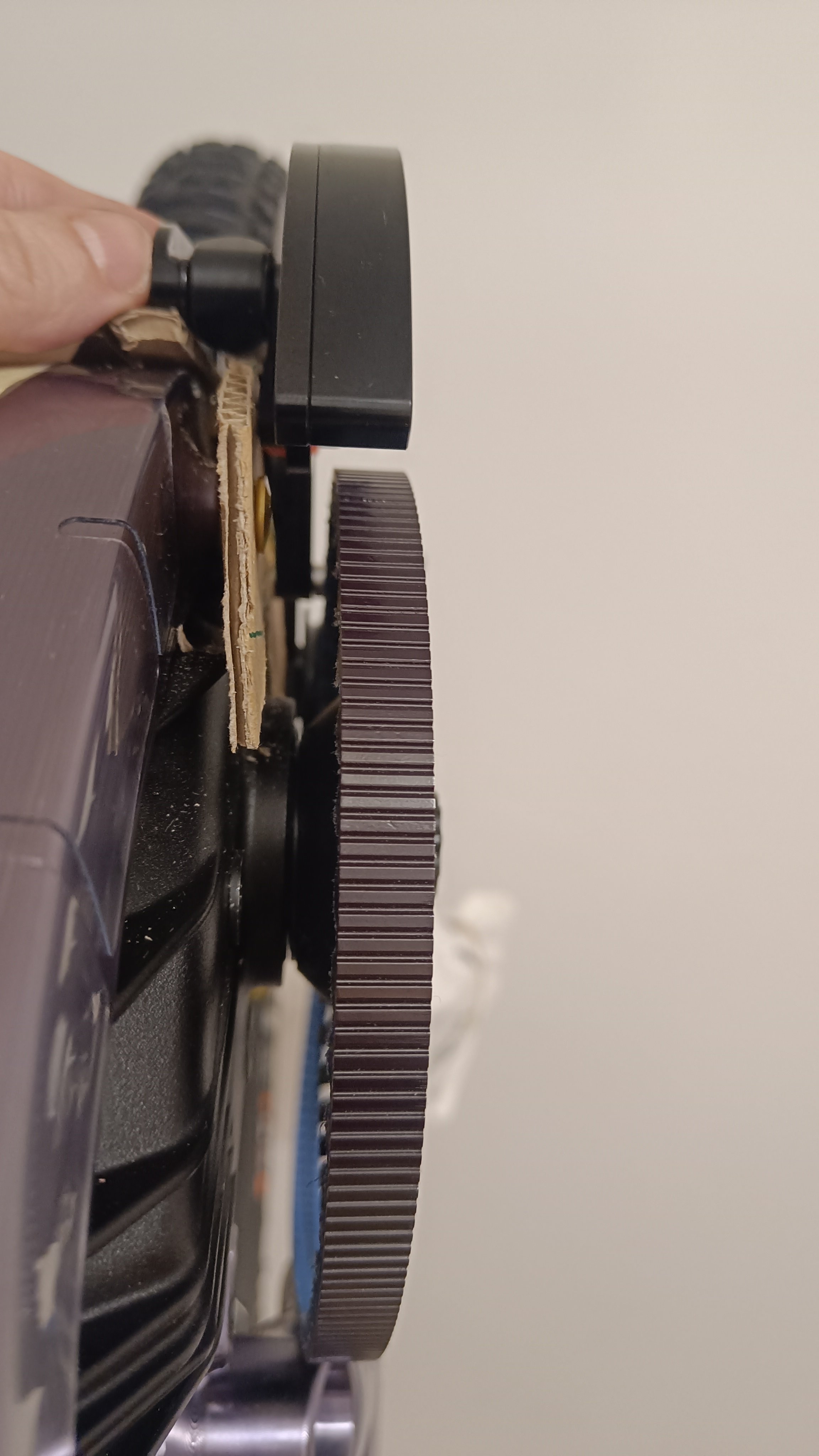

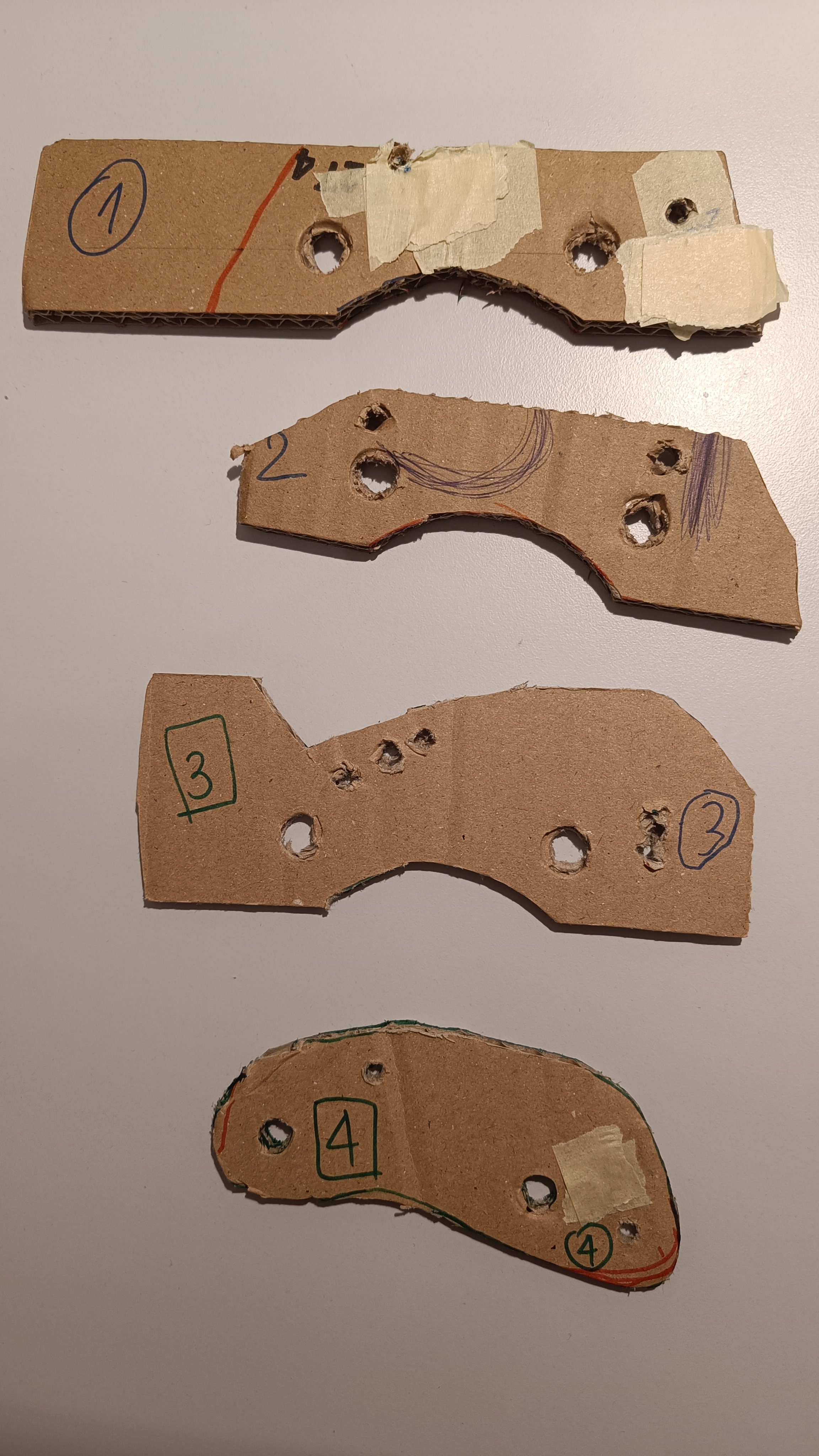

In meantime, I'm exploring getting close to nearly 90% of the MGU benefit by incorporating an internal geared hub (IGH) and integrating it with the Bosch motor via a Gates CDX belt-drive. The target bike is a Sonni K1, which I have on order, and it will probably be sometime in November before it arrives. For the IGH, I'm strongly in favor of using the Rohloff Speedhub, for a number of reasons, namely that I’ve been using a Speedhub for about 8 years on my acoustic dual suspension MTB (see below) with flawless performance and near-zero maintenance.

I would like to hear how others feel about alternatives such as Nuvinci, Nine 3x3, Kindernay, etc. I’ll also be exploring electronic shifting as part of the solution, as this would be implied with an MGU setup, not to mention that a lot of folks are choosing AXS/DI2 electronic shifting on their current rigs. My intention is to add to this thread with my findings and welcome feedback.

Last edited: