Neeko DeVinchi

E*POWAH Elite World Champion

I'm starting this thread in anticipation of a series of videos I'm currently editing.

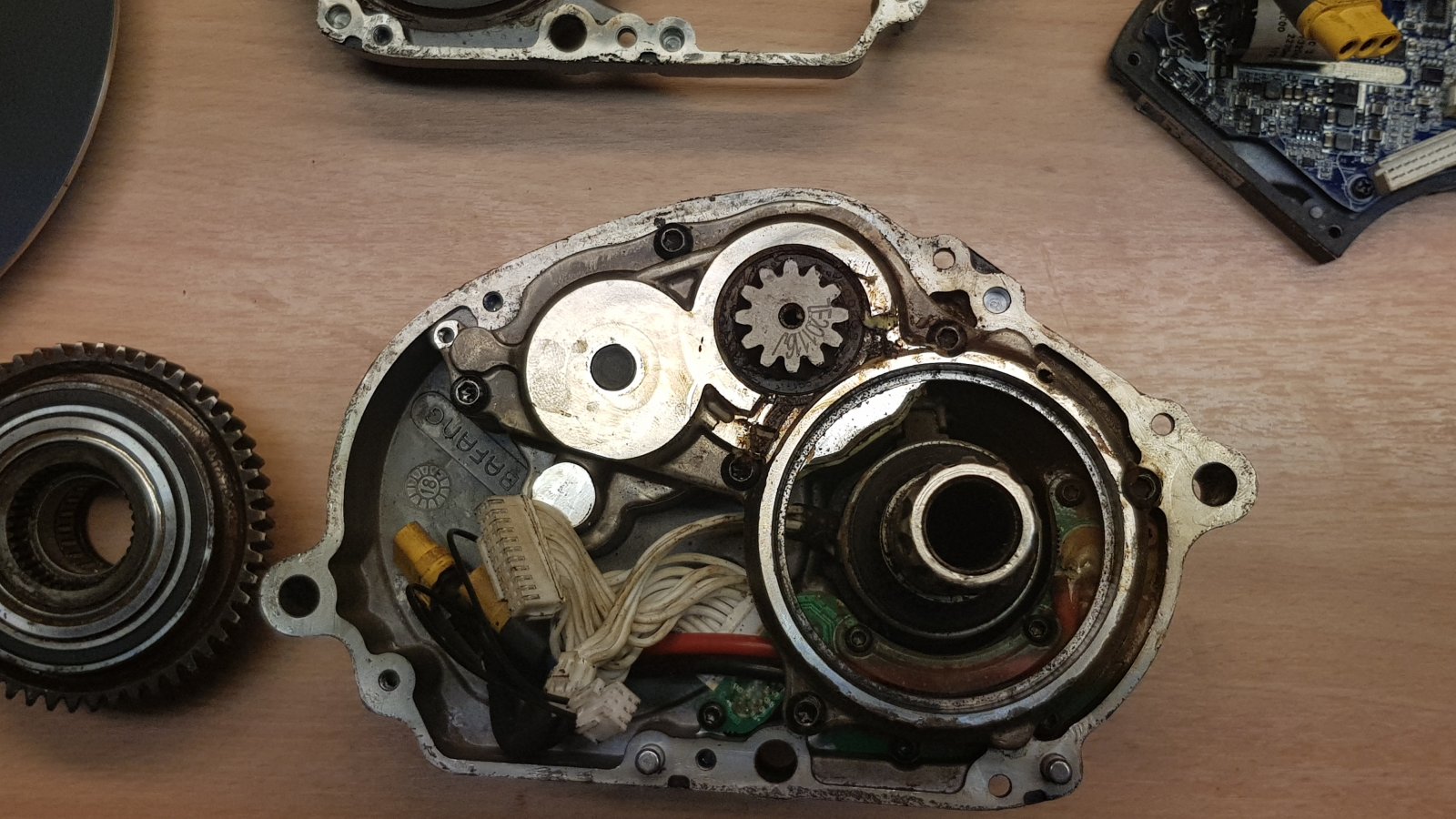

In accordance with the moderators request, this thread is strictly about the servicing & repairs of the Bafang M600 motor. And should not be mistaken for either the M500 and M510. Certain components for the M600 are specific to this motor including but not limited too,

Main reduction gear

and the controller.

In addition, more durable needle bearings are surfacing, which promises more reliability and longevity.

The grease used in particular areas within the motor and how much to apply, can also determine how long specific components last. So I'll do my utmost to carefully explain what grease in specific areas and where to source them from.

In the meantime please don't hesitate to reach out to me on this thread.

I may start another thread, specific to the servicing and repair of the M620 (UART & CANBus and the differences internally between the two). So please bare with

In accordance with the moderators request, this thread is strictly about the servicing & repairs of the Bafang M600 motor. And should not be mistaken for either the M500 and M510. Certain components for the M600 are specific to this motor including but not limited too,

Main reduction gear

and the controller.

In addition, more durable needle bearings are surfacing, which promises more reliability and longevity.

The grease used in particular areas within the motor and how much to apply, can also determine how long specific components last. So I'll do my utmost to carefully explain what grease in specific areas and where to source them from.

In the meantime please don't hesitate to reach out to me on this thread.

I may start another thread, specific to the servicing and repair of the M620 (UART & CANBus and the differences internally between the two). So please bare with