Swagger

New Member

Thanks Mteam. Looks like I'll need to remove the motor for this. I'll give it a shot over the weekend.Read this post ( the exact one that is linked with the excerpts from the tq motor installation guide)

Tq hpr50 clicking sound

I owe scott lumen 900, while i pedal alot with assistance turned off, i hear ticking noise from motor when right pedal is between 10 and 12 hour, i check all, change pedals, torque bolts, chainrings, cranks...all, i noticed when i turn on assistance even on most little possible setting ticking...www.emtbforums.com

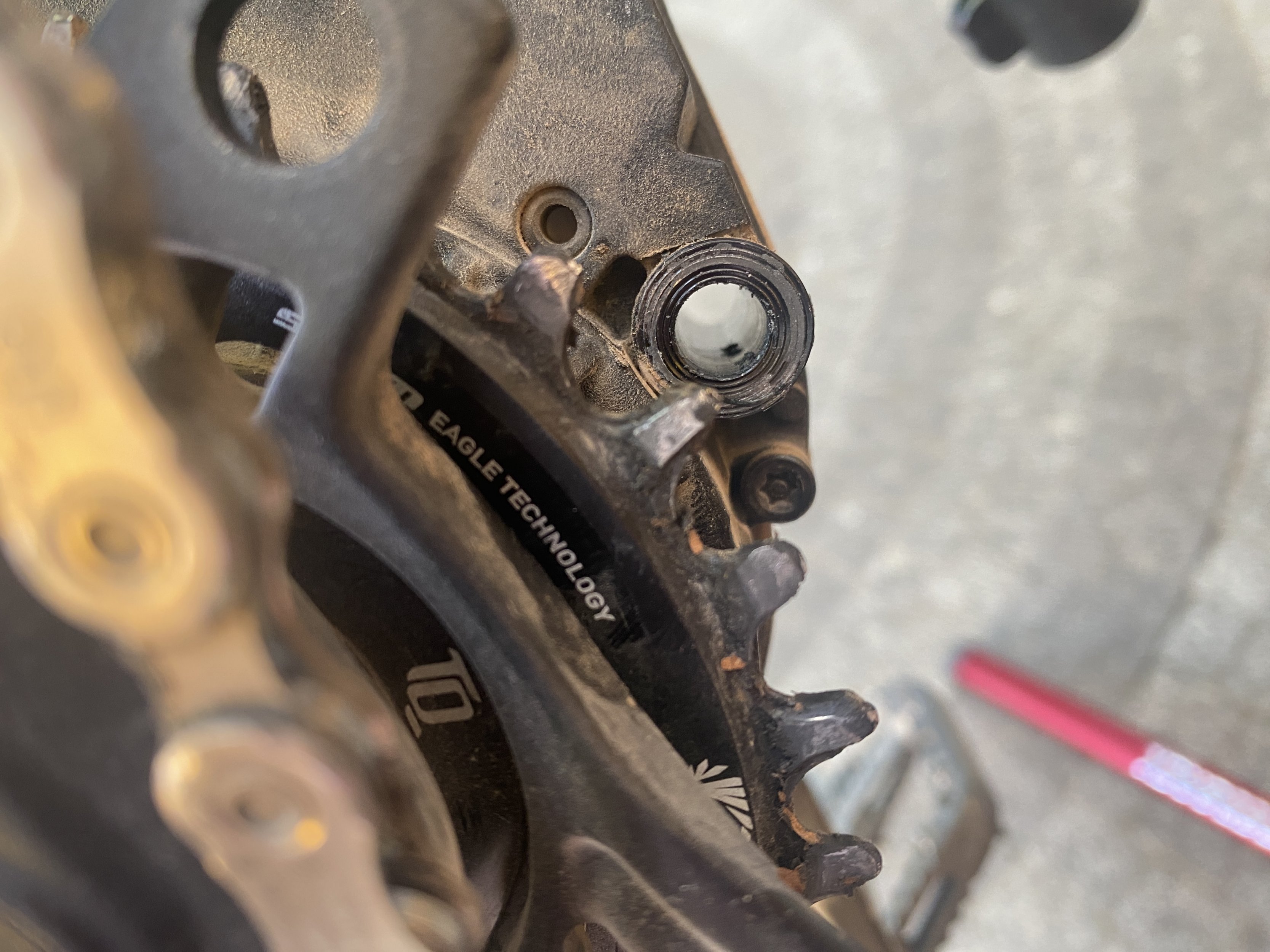

The motor is adjustable for width using what TQ refer to as motor compensation screws (these are not the bolts that fix the motor to the frame,but those bolts do pass through the middle of the motor compensation screws). Due to variances in the frames , it's necessary to be able to adjust the width of the motor so it fits perfectly in the gap between the motor mounting points of the frame. You use the Vernier calipers to measure the distance between the two motor mounting tabs on the frame, then you set the motor compensation screws to the same width so that the motor fits perfectly into the gap in the frame, then you use the motor mounting bolts to fix the motor to the frame.