- Thread starter

- #91

Ground clearance for the motor bottom is 315 mm. Ground clearance for the 44t chainring is 265mm. Wheel diameter with inflated 29"x2.8" tire is 760mm.

29x2.8 tires with the rims I use maintain about 5-4mm clearance with the swingarm and allow to mound Mudhugger on the front fork I use.

Note Dengfu recommends maximum sizes of the tire for the swingarm 2.8" for 27.5" rim and 2.6" for 29" rim

www.dengfubike.com

www.dengfubike.com

29x2.8 tires with the rims I use maintain about 5-4mm clearance with the swingarm and allow to mound Mudhugger on the front fork I use.

Note Dengfu recommends maximum sizes of the tire for the swingarm 2.8" for 27.5" rim and 2.6" for 29" rim

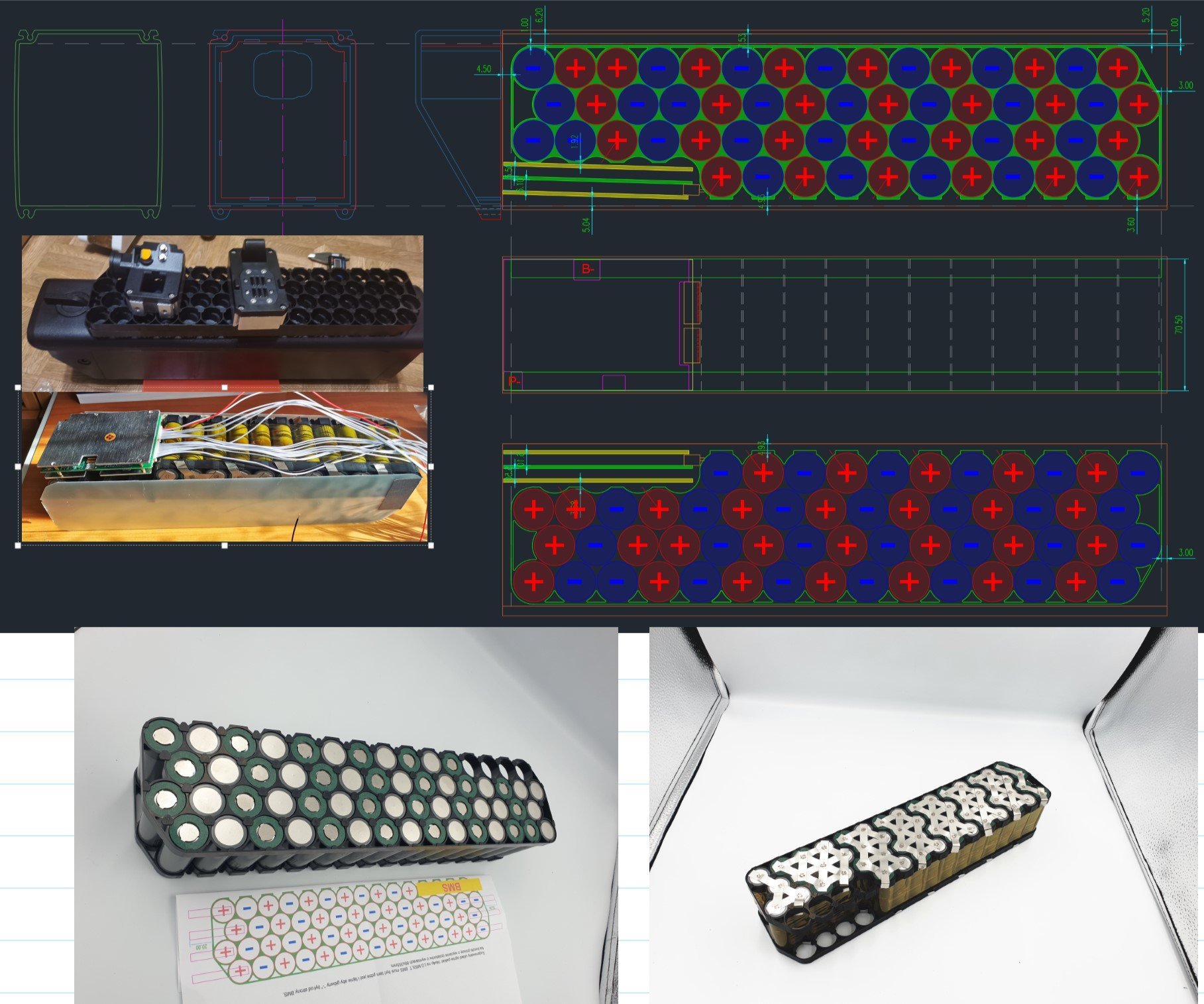

E55 FRAME+ MOTOR + BATTERY KIT

DENGFU E55 Frame is a AM mountain E-bike carbon frame, with BAFANG M620 1000W 48V Gear sensor motor and 48V 20Ah 960Wh / 52V 20Ah 1040Wh Lithium-ion battery.

www.dengfubike.com

www.dengfubike.com

Last edited: