iscander13

Member

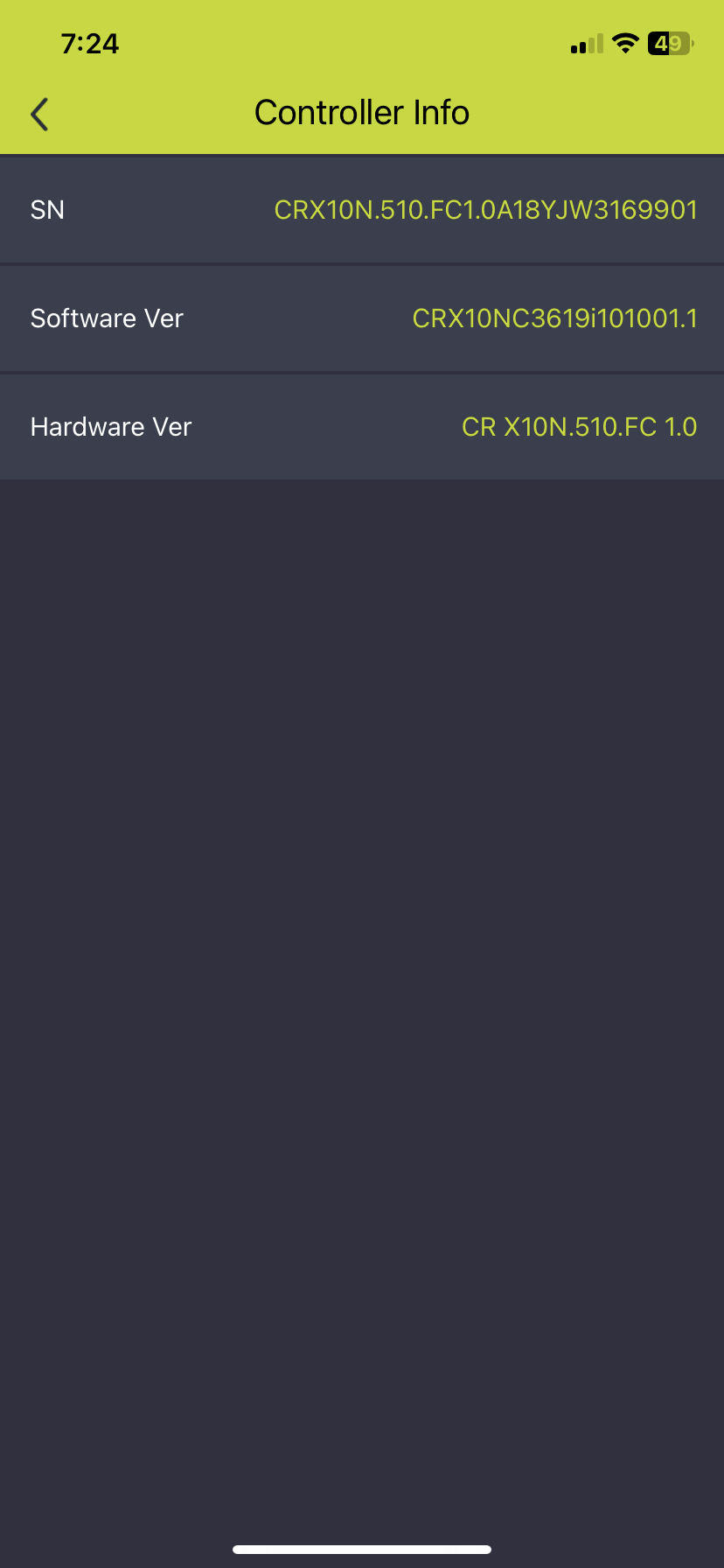

Hi. I have the same cutoffs on my engine. Only 700km on the ODO. Problems have occurred since the beginning of operation. In the beginning of operation the cutoffs were on light PASSes on flat surface. But now I have cutoffs on all levels. I have noticed that sometimes I get a lot of cutoffs when I ride a steep gravel road uphill. It looks like something is not well mounted inside and it's affecting the engine performance. I have hardware version FC 1.0 and software CRX10NC4814i101003.1. I am waiting for the BESST tool to change the software, but when I see the problem progressing in my motor, I don't think a software update will help me solve these issues. It seems to be a torque sensor problem. @patdam, is it difficult to replace the torque sensor by yourself?