You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

STEPS E8000 Motor Service

- Thread starter SmokeyBear

- Start date

Hey guys,

I’m pretty good with mechanics and electronics as I do many different repairs myself - from cars to mobile phones (even inc. microsoldering). I’d like to check my 700km E8000 motor inside - got some clicking/ticking noise (3 clicks per revolution) only when pedalling with motor assistance off, no weird noises tho when motor is running under load or without a chain in a walk mode - smooth as butter. Maybe some needle bearings needs regressing or replacing? While the whole procedure looks fairly straightforward and simple to me what worries me A LOT is that i saw a few posts from people who just happen to open their motors finding out later that it throws some e10 errors!?! Apparently no cables etc has been torn apart… I can’t understand for life why by simply taking something apart it breaks afterwards - can somebody please explain me that phenomenon and if there is any specific alignment of SOMETHING in there that must be preserved ? Many thanks in advance!

I’m pretty good with mechanics and electronics as I do many different repairs myself - from cars to mobile phones (even inc. microsoldering). I’d like to check my 700km E8000 motor inside - got some clicking/ticking noise (3 clicks per revolution) only when pedalling with motor assistance off, no weird noises tho when motor is running under load or without a chain in a walk mode - smooth as butter. Maybe some needle bearings needs regressing or replacing? While the whole procedure looks fairly straightforward and simple to me what worries me A LOT is that i saw a few posts from people who just happen to open their motors finding out later that it throws some e10 errors!?! Apparently no cables etc has been torn apart… I can’t understand for life why by simply taking something apart it breaks afterwards - can somebody please explain me that phenomenon and if there is any specific alignment of SOMETHING in there that must be preserved ? Many thanks in advance!

Yeah i have no clue either. Ive opened my motor 6 or 7 times and never had the issue.

Maybe something that was calibrated gets out of spec after disassembly? Perhaps it has something to do with splitting the crank axle in 2 pieces, which my motor didnt allow because it is glued together. See post:

www.emtbforums.com

www.emtbforums.com

Maybe something that was calibrated gets out of spec after disassembly? Perhaps it has something to do with splitting the crank axle in 2 pieces, which my motor didnt allow because it is glued together. See post:

STEPS E8000 Motor Service

Updating the list: 1 x 6808 2rs Sealed Ball bearing 40x52x7mm 1 x 6805 2rs Sealed Ball Bearing 25x37x7mm 3 x 6900 ZZ Shielded Ball Bearing 10x22x6mm 1 x 6000 ZZ Shielded Ball Bearing 10x26x8mm 1 x K25x29x10 Needle Roller Cage Assembly 1 x K25x29x17 Needle Roller Cage Assembly Mike: Thanks for...

Hi @cream

First, thanks for your work and troubleshooting on these motors. I have a few questions to you - I’ve got one of these e8000 with E010 right at the boot (no access to the computer menu etc) it just starts right off with beeping and the error code displayed.

1. I wonder if the main PCB initialise cadence or torque sensor right at the boot which in case of lack of communication could throw such an error at this point and stop boot up procedure?

2. If I would disconnect from the main PCB: cadence sensor ribbon (tiny pcb), wireless transmitter (ring pcb) and maybe one more ribbon from engine hall sensor would the whole thing boot (given that there is no problem on the main PCB)?

I’m just trying to narrow down the problem and see what’s “not needed” at least to get the display booting to the menu…

3. There is no water ingress signs inside and everything else looks really good. Is there any way of telling which exact error (to pinpoint the problem) I’m dealing with without the genuine shimano PC dongle (Sm-pce1/2)?

Many thanks in advance!

First, thanks for your work and troubleshooting on these motors. I have a few questions to you - I’ve got one of these e8000 with E010 right at the boot (no access to the computer menu etc) it just starts right off with beeping and the error code displayed.

1. I wonder if the main PCB initialise cadence or torque sensor right at the boot which in case of lack of communication could throw such an error at this point and stop boot up procedure?

2. If I would disconnect from the main PCB: cadence sensor ribbon (tiny pcb), wireless transmitter (ring pcb) and maybe one more ribbon from engine hall sensor would the whole thing boot (given that there is no problem on the main PCB)?

I’m just trying to narrow down the problem and see what’s “not needed” at least to get the display booting to the menu…

3. There is no water ingress signs inside and everything else looks really good. Is there any way of telling which exact error (to pinpoint the problem) I’m dealing with without the genuine shimano PC dongle (Sm-pce1/2)?

Many thanks in advance!

Last edited:

Hi! Anyone know a service company in Italy for e8000 motors?

Mine has 9800km on it, from 2018. Suddenly came quite draggy and ofc heats up a lot. Drag is more on boost and less on eco. Also, engine freewheel started to stick simultaneously, and is basically not working at boost(cranks keep spinning), eco is still rideable. This appeared quite suddenly half way down a trail.

Mine has 9800km on it, from 2018. Suddenly came quite draggy and ofc heats up a lot. Drag is more on boost and less on eco. Also, engine freewheel started to stick simultaneously, and is basically not working at boost(cranks keep spinning), eco is still rideable. This appeared quite suddenly half way down a trail.

@Bearing Man I can not send you a PM as I’m too new here, so this is the only way to ask you…

I’ve got my 700km e8000 motor opened and it looks pretty new inside- the grease is white, no signs of water ingress inside. I’d like to add some grease as I feel like there could be a bit more in there but here is some problem in choosing which one to get as some of them are hard to source and also there is lots different of options in this thread which confuses me…

The question is simple:

If this were your personal motor which one you’d add in there (i don’t really want to remove the original grease)?

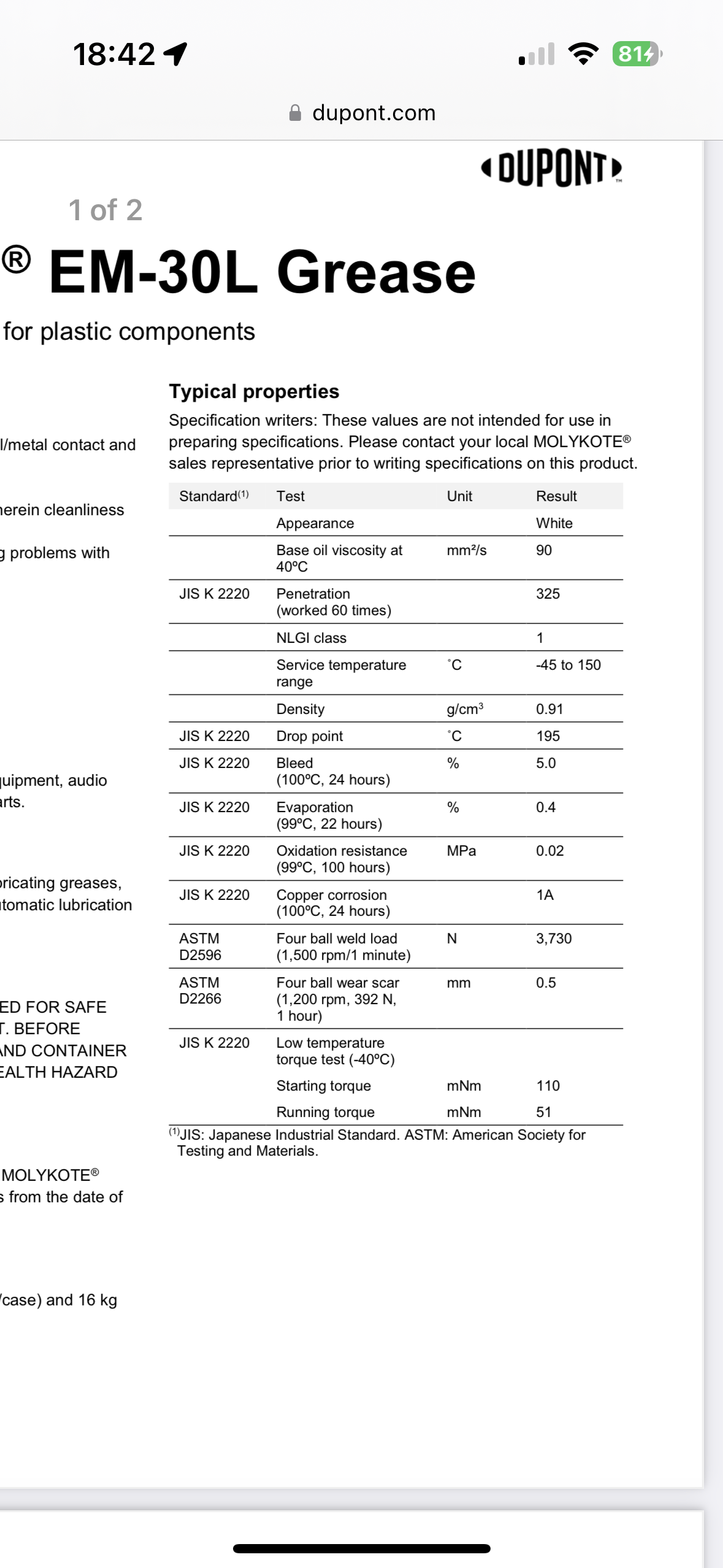

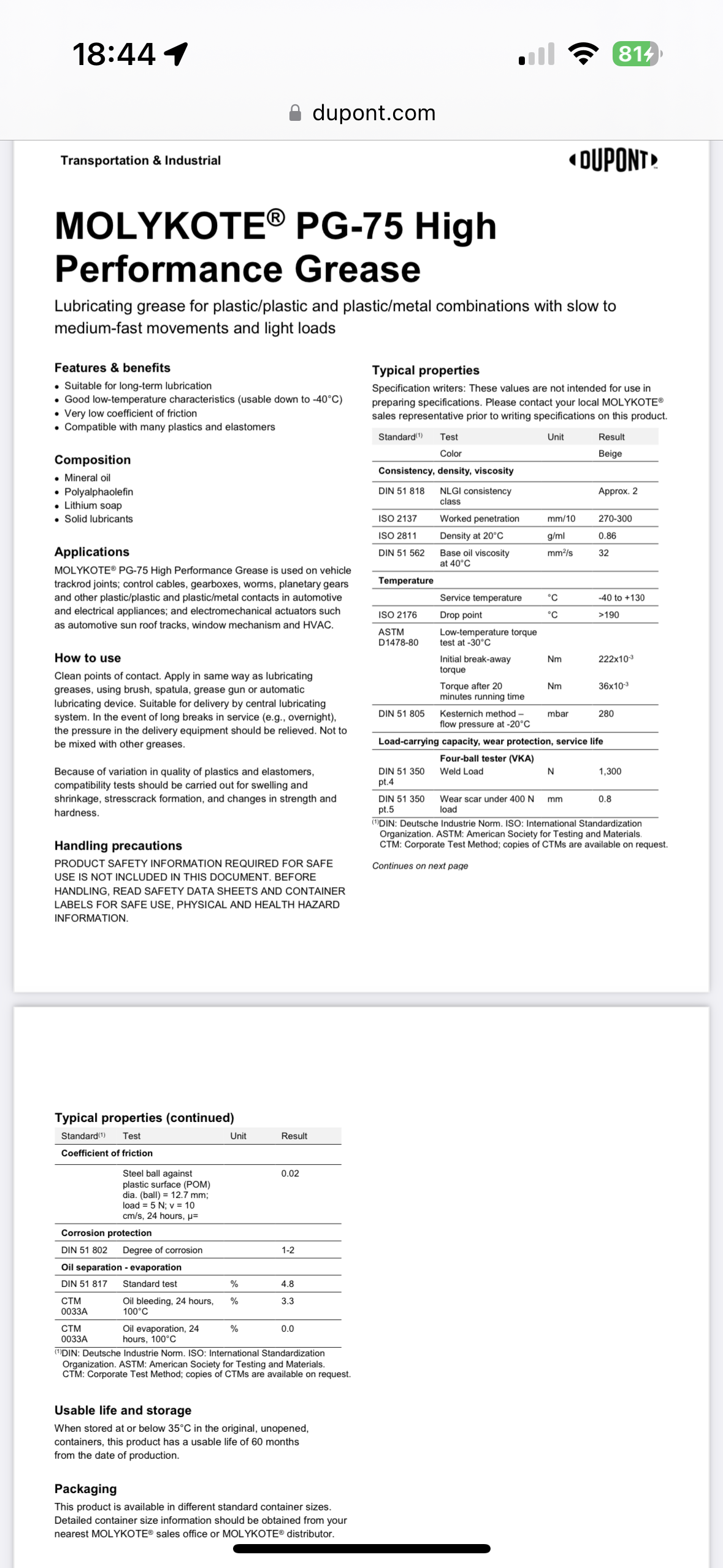

1. PG-75 - i know that’s not the one of your choice which is kinda good because this one is hard to source and rather pricey…

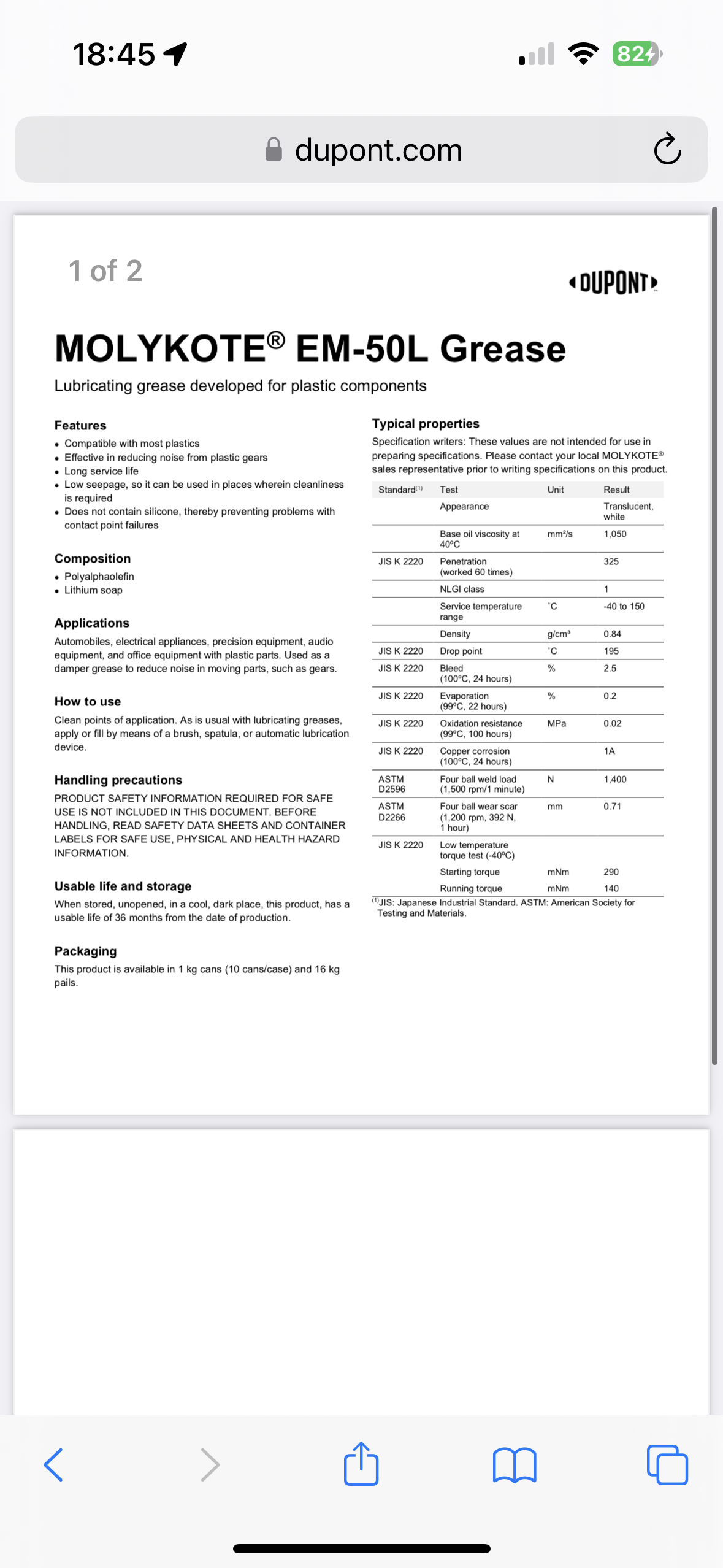

2. EM-50L - easier to source, not that pricey as above.

3. EM-30L - the one i can get without any hassle, is this any good for my application or I should lean towards EM-50L more?

4. Any other contender?

As for Roller bearings/clutch: Shell Gadus S2 V100 2 , will it be good enough or shall I not bother?

I’d like to order this and close my motor asap and put my bike back together. I will appreciate your input. Many thanks in advance!

I’ve got my 700km e8000 motor opened and it looks pretty new inside- the grease is white, no signs of water ingress inside. I’d like to add some grease as I feel like there could be a bit more in there but here is some problem in choosing which one to get as some of them are hard to source and also there is lots different of options in this thread which confuses me…

The question is simple:

If this were your personal motor which one you’d add in there (i don’t really want to remove the original grease)?

1. PG-75 - i know that’s not the one of your choice which is kinda good because this one is hard to source and rather pricey…

2. EM-50L - easier to source, not that pricey as above.

3. EM-30L - the one i can get without any hassle, is this any good for my application or I should lean towards EM-50L more?

4. Any other contender?

As for Roller bearings/clutch: Shell Gadus S2 V100 2 , will it be good enough or shall I not bother?

I’d like to order this and close my motor asap and put my bike back together. I will appreciate your input. Many thanks in advance!

Last edited:

@Bearing Man I can not send you a PM as I’m too new here, so this is the only way to ask you…

I’ve got my 700km e8000 motor opened and it looks pretty new inside- the grease is white, no signs of water ingress inside. I’d like to add some grease as I feel like there could be a bit more in there but here is some problem in choosing which one to get as some of them are hard to source and also there is lots different of options in this thread which confuses me…

The question is simple:

If this were your personal motor which one you’d add in there (i don’t really want to remove the original grease)?

1. PG-75 - i know that’s not the one of your choice which is kinda good because this one is hard to source and rather pricey…

2. EM-50L - easier to source, not that pricey as above.

3. EM-30L - the one i can get without any hassle, is this any good for my application or I should lean towards EM-50L more?

4. Any other contender?

As for Roller bearings/clutch: Shell Gadus S2 V100 2 , will it be good enough or shall I not bother?

I’d like to order this and close my motor asap and put my bike back together. I will appreciate your input. Many thanks in advance!

I am sorry PeGaZ, as I have stated several times throughout this thread. I cannot recommend a grease for this motor. Shimano do use a couple of different greases throughout the motor and no one currently knows what these greases are? If I say one on here that does not work for the rest of the motors life, I will be in trouble. (Even if I say it's for my own motor).

If I ever do find out, here is where I will post it first!

Cheers, I got your point but now my only option is to scrape the remainings off the sides and put everything together - not great either…I am sorry PeGaZ, as I have stated several times throughout this thread. I cannot recommend a grease for this motor. Shimano do use a couple of different greases throughout the motor and no one currently knows what these greases are? If I say one on here that does not work for the rest of the motors life, I will be in trouble. (Even if I say it's for my own motor).

If I ever do find out, here is where I will post it first!

h.h.

New Member

Hello,

I'm new here, but I've already read a lot here. I am in the process of repairing my wife's engine. She has a Rossignol with Steps E8000 motor. At 11000km, or thereabouts, the bottom bracket has gone, including damage to the motor housing. I've replaced all the bearings except for one, I've repaired the motor housing with 2 components, but now I have a problem: how do I get the large sealing ring (35x45x4 mm) back in? I just don't know how to get it back in without breaking it. Can anyone give me a tip? Thank you very much!

I'm new here, but I've already read a lot here. I am in the process of repairing my wife's engine. She has a Rossignol with Steps E8000 motor. At 11000km, or thereabouts, the bottom bracket has gone, including damage to the motor housing. I've replaced all the bearings except for one, I've repaired the motor housing with 2 components, but now I have a problem: how do I get the large sealing ring (35x45x4 mm) back in? I just don't know how to get it back in without breaking it. Can anyone give me a tip? Thank you very much!

Last edited:

shep

New Member

Hello,

I'm new here, but I've already read a lot here. I am in the process of repairing my wife's engine. She has a Rossignol with Steps E8000 motor. At 11000km, or thereabouts, the bottom bracket has gone, including damage to the motor housing. I've replaced all the bearings except for one, I've repaired the motor housing with 2 components, but now I have a problem: how do I get the large sealing ring (35x45x4 mm) back in? I just don't know how to get it back in without breaking it. Can anyone give me a tip? Thank you very much!

STEPS E8000 Motor Service

I've just serviced my E8000 motor and replaced some bearings, it's now working quietly and smoothly like new. If anyone needs any advice, I've got the bearing numbers and some pictures to help see what goes where. Gimme a shout if you are stuck.

Strindberg

Active member

I wrote ~~ 50 comments or more about servicing and afterfun with E8000

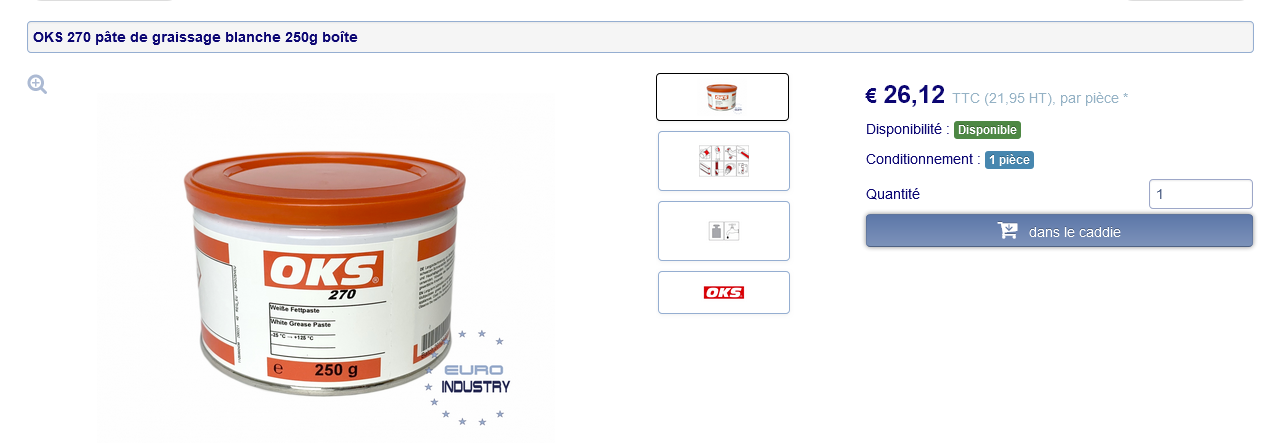

Here about grease, I used OKS 270 >>> STEPS E8000 Motor Service

and here >>> STEPS E8000 Motor Service

scroll-up and -down to see and follow

here >>> Shimano E8000 (and EP8) re-greasing and Range improvement

and here >>> STEPS E8000 Motor Service

and here >>> STEPS E8000 Motor Service

Here about grease, I used OKS 270 >>> STEPS E8000 Motor Service

and here >>> STEPS E8000 Motor Service

scroll-up and -down to see and follow

here >>> Shimano E8000 (and EP8) re-greasing and Range improvement

and here >>> STEPS E8000 Motor Service

and here >>> STEPS E8000 Motor Service

That OKS 270 looks good on paper but it’s even harder to get and even more expensive then Molykote! Seems way better then the glorified pg75. I’m no expert on lubricants but read a lot in the past few days. PG75 is for slow/medium fast movements and LIGHT! loads and it’s NOT fully synthetic…Compared to other contenders it’s got pretty low weld load at 1300N (higher =better) and quite high wear scar at 0.8mm (lower=better)… I found something that looks better on a paper also from molykote and it’s EM-30L: higher temp rage, weld load=3730N and scar= 0.5mm, it’s suitable for plastics, metals, rubber and it’s white! I think this is what I’m going to use on mineI wrote ~~ 50 comments or more about servicing and afterfun with E8000

Here about grease, I used OKS 270 >>> STEPS E8000 Motor Service

and here >>> STEPS E8000 Motor Service

scroll-up and -down to see and follow

here >>> Shimano E8000 (and EP8) re-greasing and Range improvement

and here >>> STEPS E8000 Motor Service

and here >>> STEPS E8000 Motor Service

View attachment 128692

“…MOLYKOTE® EM-30L grease is a premium quality lubricant that meets a range of requirements for the lubrication of plastic-plastic, plastic-metal and rubber-metal interfaces. MOLYKOTE® EM-30L is well suited for low to medium speed motion and medium to heavy duty applications…”

There is one Polish guy who made almost a scientific research on various greases for ebike power train that are easily accessible on our market

(use google translatator if you’re interested- i don’t have to because this is my native language

Basically he claims that every fully synthetic grease or the one that contains PTFG is suitable for plastics even if it’s not mentioned in the specs. This is his list of candidates for polyamide gears in our motors:

1. Mobilith SHC 1000 special - gray/black, highest weld load at 6030N.

2. Mobil SHC Polyrex 462 - white, 4000N Weld load, good water isolation.

3. Mobilith SHC 100 - red.

4. Molycote G 4500/1,

Anyways, use your common sense and do your own lesson as I’m not recommending anything here. I’m just adding to the debate whether pg75 is the really the best choice for this application…

Last edited:

Strindberg

Active member

Not expensive for our purpose: 26,- € >>> 250 grammes

euro-industry.com

euro-industry.com

And you can also use this OKS 270 grease when you overhaul the bike's fork.

I'm sure you have dealers for the industry in your neighbourhood.

Industrie

Railway engineering

Municipal technology

Steel industry

Rubber and plastics processing

Logistics

Paper and packaging industry

Chemical industry

Shipbuilding and marine engineering

Plant and mechanical engineering (tools)

Glass and foundry industry

OKS 270 pâte de graissage blanche 250g boîte - achat en ligne | Euro Industry

OKS 270 pâte de graissage blanche 250g boîte

And you can also use this OKS 270 grease when you overhaul the bike's fork.

I'm sure you have dealers for the industry in your neighbourhood.

Industrie

- Ingénierie ferroviaire

- Technologie municipale

- Industrie sidérurgique

- Transformation de caoutchouc et de plastique

- Logistique

- Industrie du papier et de l'emballage

- Industrie chimique

- Construction navale et ingénierie maritime

- Usines et génie mécanique (outil)

- Industrie du verre et de la fonderie

Railway engineering

Municipal technology

Steel industry

Rubber and plastics processing

Logistics

Paper and packaging industry

Chemical industry

Shipbuilding and marine engineering

Plant and mechanical engineering (tools)

Glass and foundry industry

Last edited:

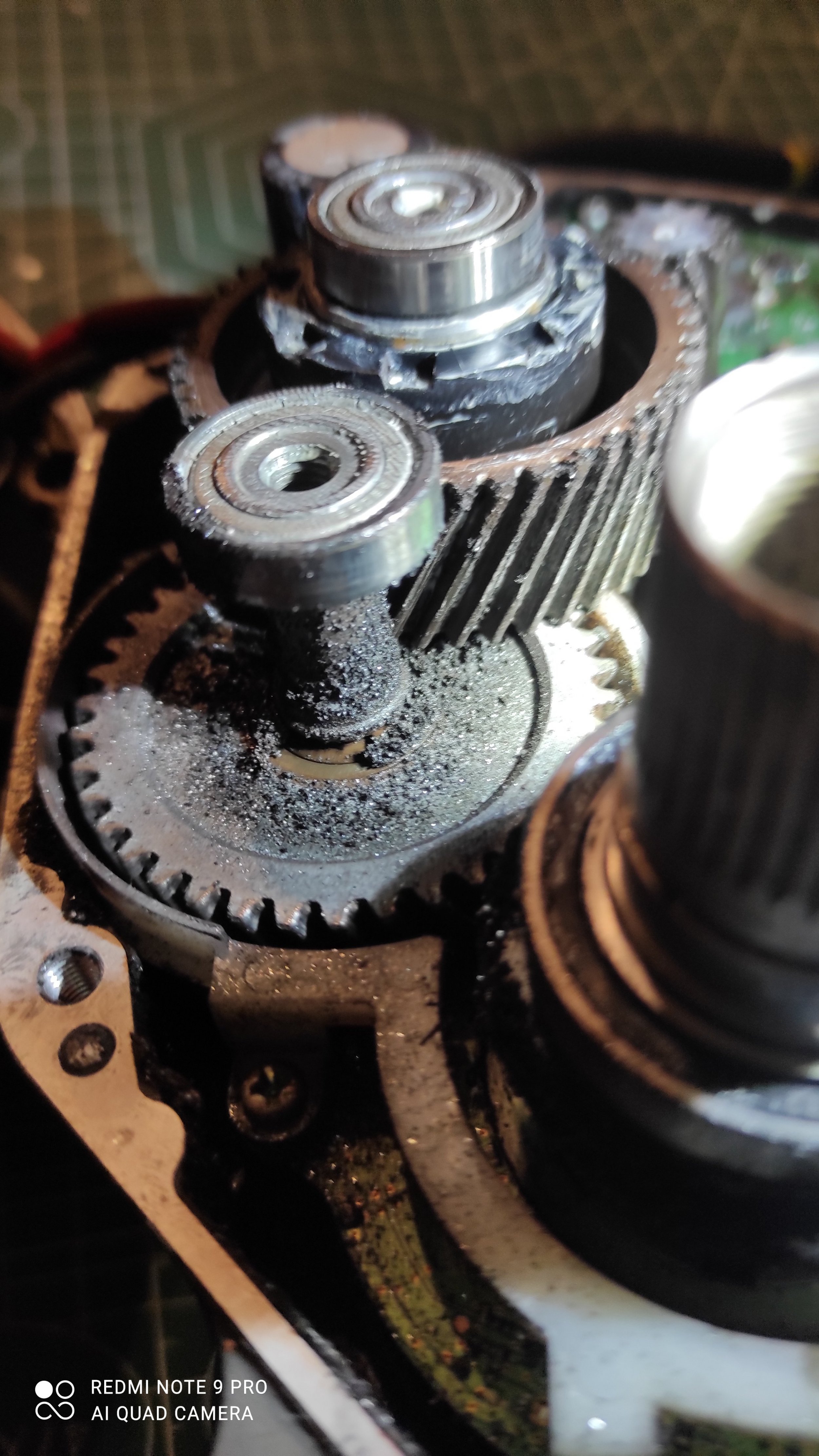

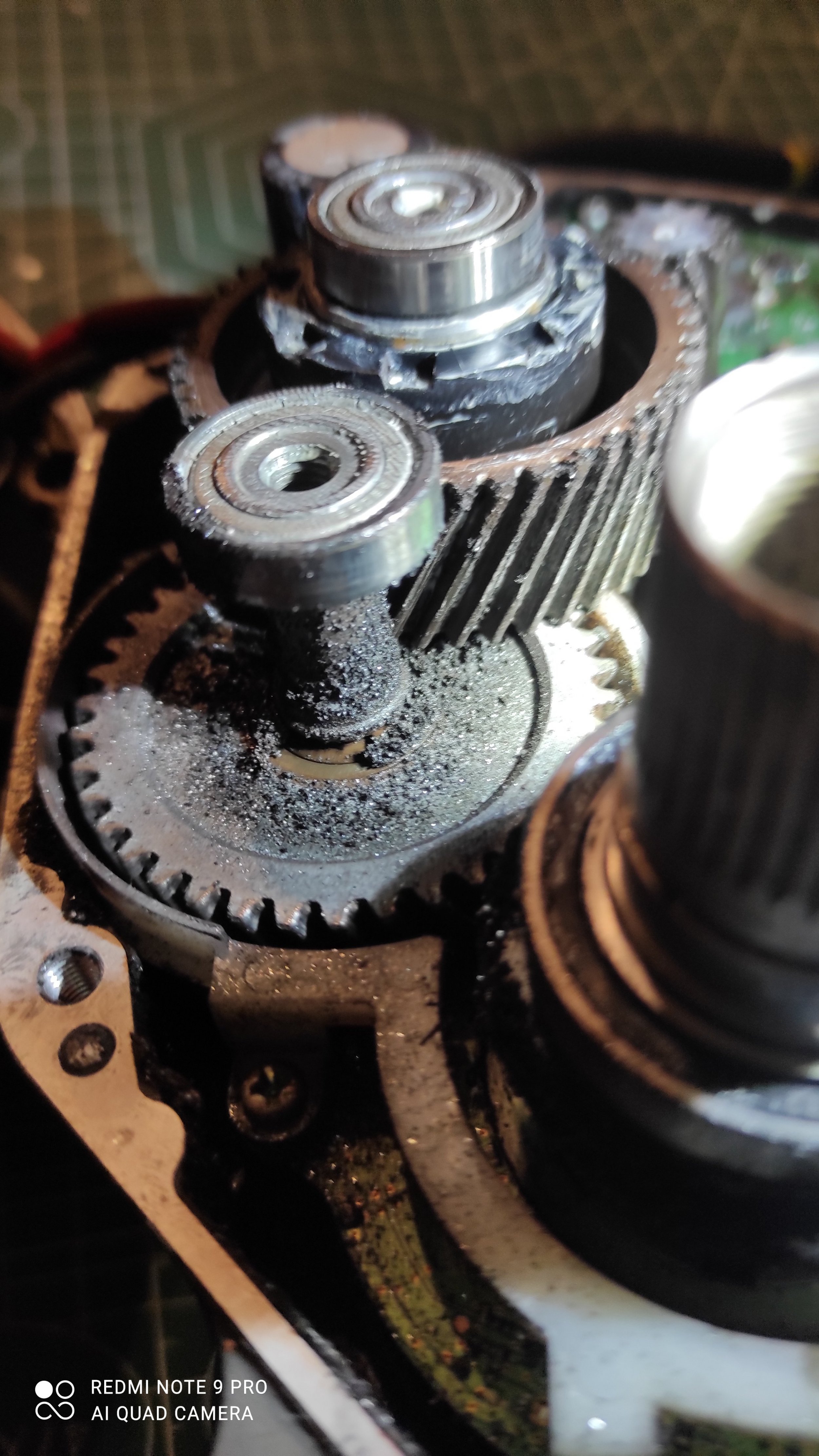

@Spiff @S13 - different height of big metal sprockets therory.

There was a discussion regarding grinding noise, burned grease and some theory that one design is better over the other.

I’ve opened 2 motors:

1. Early one 2017 - 3 clutches, big metal sprocket has height around 8.4mm

2. Later model - 2 clutches, metal sprocket is around 9.4mm so 1mm thicker.

My theory:

Technically higher (9.4mm) gear seen on later models should be better as the area of contact is larger therefore smaller forces are being passed onto the teeth, less friction but on the other hand it reduces the clearance between the top of the plastic gear.

2. Maybe grinding and grease burning has nothing to do with clearance or gear size? Maybe it’s the way motor is being used? Please note that bearing that holds the shaft with metal/plastic cog assy is mounted right on the motor’s housing so it takes all the heat it generates and passing it onto the small metal cog which suffers the most. Maybe earlier design (3rd clutch system) was better as since there was “more metal” inside the cog which helped in pulling away all that heat from the smaller metal sprocket underneath? Later on they’ve removed the 3rd clutch so now everything goes into the gear itself causing grease degradation? Maybe gear size has nothing to do in this case?

I have swapped big metal gear assembly from the older motor and put into then new one (2clutches) - it was riding nicely and quietly.

I’m just wondering if putting the thicker gear to 3 clutch design motor OR thinner into 2 clutch design can be a bad idea?

There was a discussion regarding grinding noise, burned grease and some theory that one design is better over the other.

I’ve opened 2 motors:

1. Early one 2017 - 3 clutches, big metal sprocket has height around 8.4mm

2. Later model - 2 clutches, metal sprocket is around 9.4mm so 1mm thicker.

My theory:

Technically higher (9.4mm) gear seen on later models should be better as the area of contact is larger therefore smaller forces are being passed onto the teeth, less friction but on the other hand it reduces the clearance between the top of the plastic gear.

2. Maybe grinding and grease burning has nothing to do with clearance or gear size? Maybe it’s the way motor is being used? Please note that bearing that holds the shaft with metal/plastic cog assy is mounted right on the motor’s housing so it takes all the heat it generates and passing it onto the small metal cog which suffers the most. Maybe earlier design (3rd clutch system) was better as since there was “more metal” inside the cog which helped in pulling away all that heat from the smaller metal sprocket underneath? Later on they’ve removed the 3rd clutch so now everything goes into the gear itself causing grease degradation? Maybe gear size has nothing to do in this case?

I have swapped big metal gear assembly from the older motor and put into then new one (2clutches) - it was riding nicely and quietly.

I’m just wondering if putting the thicker gear to 3 clutch design motor OR thinner into 2 clutch design can be a bad idea?

Well we can only guess what motivated Shimano to change the design. However the grinding and misalignment problem of those gears is seen with both the early model and the later model.

I personally think they shouldn't have used helical cut gears, because of the axial force involved that pushes the motor clutch mechanism out of alignment. And when that happens, you get more friction, grease displacement, grease failure etc... And yes the heat of the motor nearby doesnt help either.

Maybe they should have used a double cut helical gear (or herringbone) or at least stabilized the clutch mechanism with an additional needle bearing to handle the axial forces.

Which of the 2 designs is better? I dont know. My later 2019 model started to fail after ~5000km. And ive now swapped the gear set to the older design type (with the 3rd clutch inside). Its holding up for now, but im not actively using the E8000 any more.

Thankfully i now have a dyname 4.0 motor that has none of these problems (all gears and clutches can be cleaned, greased and replaced from the outside).

If you can at least regrease the E8000 gears every 2500km or so, it should be able to last quite a bit longer.

I personally think they shouldn't have used helical cut gears, because of the axial force involved that pushes the motor clutch mechanism out of alignment. And when that happens, you get more friction, grease displacement, grease failure etc... And yes the heat of the motor nearby doesnt help either.

Maybe they should have used a double cut helical gear (or herringbone) or at least stabilized the clutch mechanism with an additional needle bearing to handle the axial forces.

Which of the 2 designs is better? I dont know. My later 2019 model started to fail after ~5000km. And ive now swapped the gear set to the older design type (with the 3rd clutch inside). Its holding up for now, but im not actively using the E8000 any more.

Thankfully i now have a dyname 4.0 motor that has none of these problems (all gears and clutches can be cleaned, greased and replaced from the outside).

If you can at least regrease the E8000 gears every 2500km or so, it should be able to last quite a bit longer.

Hello,

In the E8000 motor, my metal helical gear is broken.

Where can I find it.

Sorry for my broken English, I'm French.

View attachment 135442

Your English is better than my French, so no apology required!

Best bet would be to try and source one from a broken E8000 motor from eBay or similar?

There will be motors out there with electronics or the plastic gears that are useless, but the metal gear intact, asking any sellers the question would be crucial.

Otherwise, perhaps pick up a refurbished or new motor if the bike it is fitted to is a ‘keeper’, and then your old motor will have some spares to potentially keep it going?

There is a poland guy in a facebook group who sells repaired E8000 and EP8 at fair prices.

www.facebook.com

www.facebook.com

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

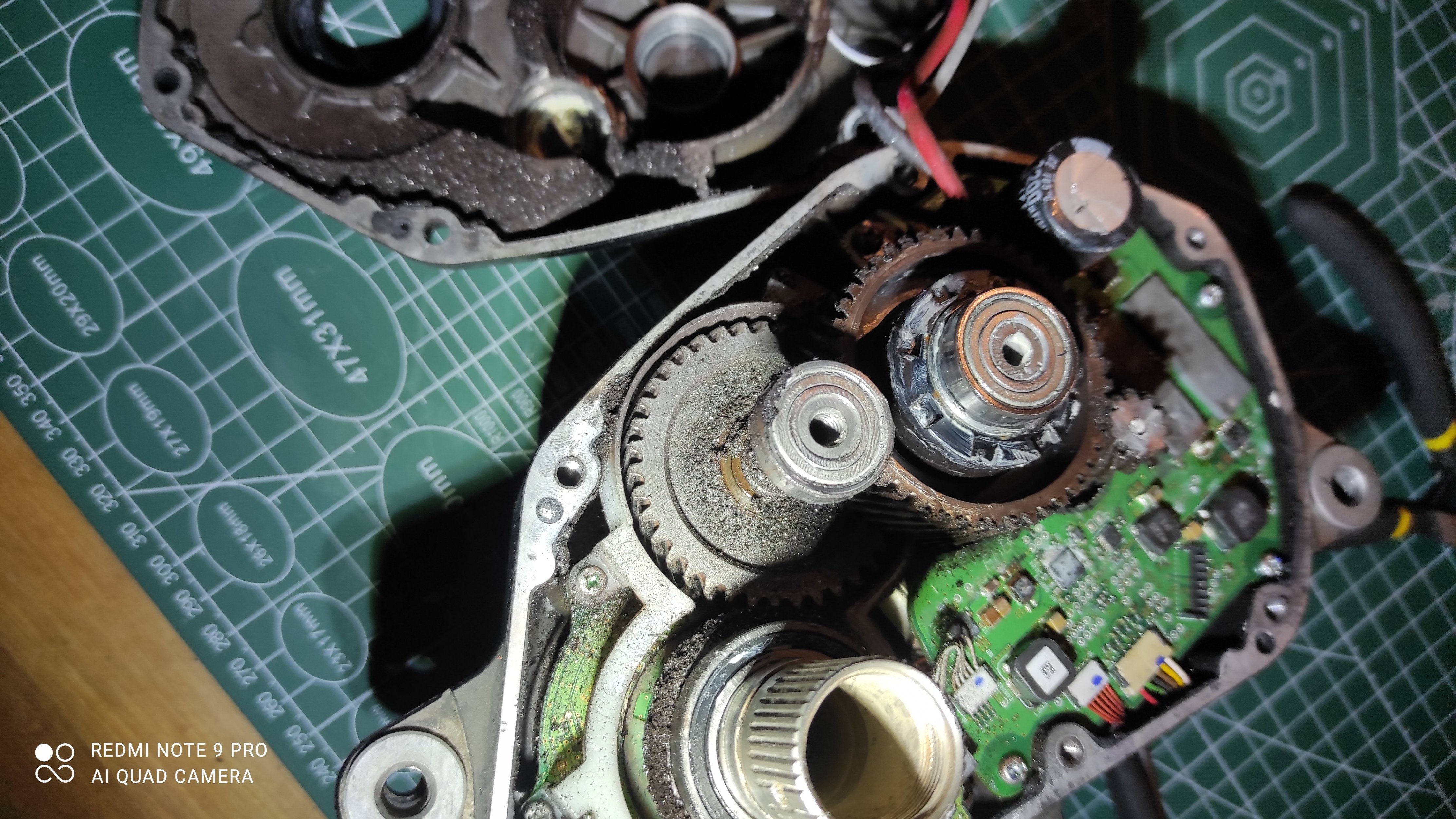

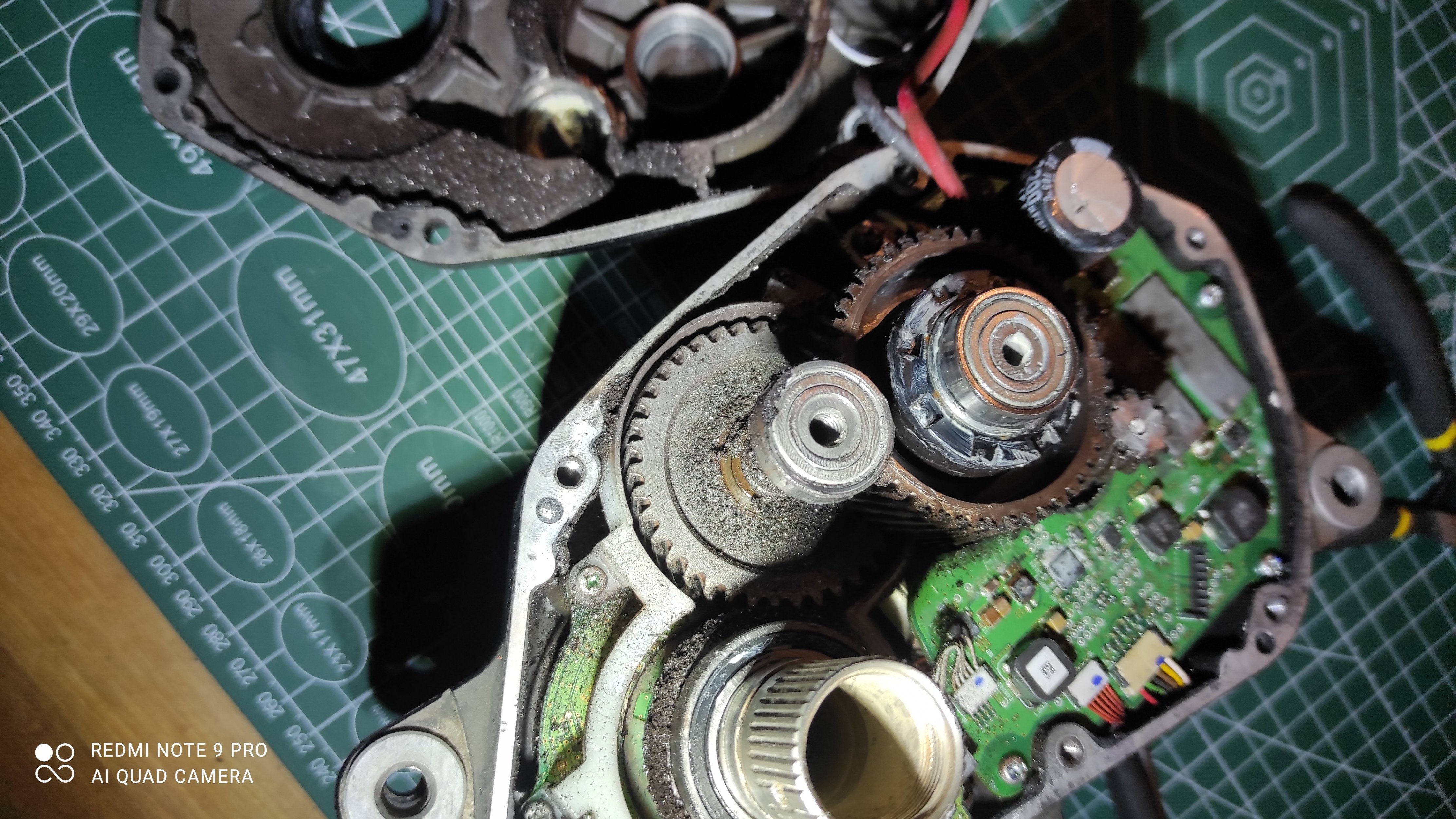

My friend's e8000 broke down and as it was out of warranty he took it over to me, to see what could be done. I have previous Bafang motor servicing experience, and I have agreed to check.

When I opened the motor it was trashed inside and full of grime. The previous mechanic who replaced bearings didn't use any silicone and the motor was in horrible state.

I have managed to take it apart completely and found that the first clutch bearing connecting to rotor failed. I have found a replacement for it and it's on its way.

Now here's the issue though. I was trying to take out the crank shaft out and didn't succeed. So I had to unplug both cadence and torque sensor stationary boards. I then mashed to take out the shaft with the torque sensor assembly.

Not being fully familiar with Shimano I have assumed that there might be a bearing inside and decided to take out the shaft which was pretty stuck. Inthe end I did maybe to press it out. But that has resulted in the plastic portion of the sensor flying off and both ribbons got loose. Luckily both remained intact. I have then assembled it back, but lost track of orientation and I am not sure if they are plugged in the right sockets.

My questions are the following:

1. How do I determine the correct orientation of the plastic bit in relation to the metal sleeve?

2. Is there a hack how to calibrate torque sensor by adjusting magnet position?

3. Will flashing new firmware recalibrate the torque sensor.

Currently I don't have the bike here and new gear is on its way, so can't really test. But the more I am reading about it, the more worried I am becoming

When I opened the motor it was trashed inside and full of grime. The previous mechanic who replaced bearings didn't use any silicone and the motor was in horrible state.

I have managed to take it apart completely and found that the first clutch bearing connecting to rotor failed. I have found a replacement for it and it's on its way.

Now here's the issue though. I was trying to take out the crank shaft out and didn't succeed. So I had to unplug both cadence and torque sensor stationary boards. I then mashed to take out the shaft with the torque sensor assembly.

Not being fully familiar with Shimano I have assumed that there might be a bearing inside and decided to take out the shaft which was pretty stuck. Inthe end I did maybe to press it out. But that has resulted in the plastic portion of the sensor flying off and both ribbons got loose. Luckily both remained intact. I have then assembled it back, but lost track of orientation and I am not sure if they are plugged in the right sockets.

My questions are the following:

1. How do I determine the correct orientation of the plastic bit in relation to the metal sleeve?

2. Is there a hack how to calibrate torque sensor by adjusting magnet position?

3. Will flashing new firmware recalibrate the torque sensor.

Currently I don't have the bike here and new gear is on its way, so can't really test. But the more I am reading about it, the more worried I am becoming

Messy

New Member

Hi. Basically if you moved any of the parts on main shaft (magnet, PCB that is rotating together with the shaft or the whole plastic assembly on which the round board together with the magnet is sitting) you are buried.My friend's e8000 broke down and as it was out of warranty he took it over to me, to see what could be done. I have previous Bafang motor servicing experience, and I have agreed to check.

When I opened the motor it was trashed inside and full of grime. The previous mechanic who replaced bearings didn't use any silicone and the motor was in horrible state.

I have managed to take it apart completely and found that the first clutch bearing connecting to rotor failed. I have found a replacement for it and it's on its way.

Now here's the issue though. I was trying to take out the crank shaft out and didn't succeed. So I had to unplug both cadence and torque sensor stationary boards. I then mashed to take out the shaft with the torque sensor assembly.

Not being fully familiar with Shimano I have assumed that there might be a bearing inside and decided to take out the shaft which was pretty stuck. Inthe end I did maybe to press it out. But that has resulted in the plastic portion of the sensor flying off and both ribbons got loose. Luckily both remained intact. I have then assembled it back, but lost track of orientation and I am not sure if they are plugged in the right sockets.

My questions are the following:

1. How do I determine the correct orientation of the plastic bit in relation to the metal sleeve?

2. Is there a hack how to calibrate torque sensor by adjusting magnet position?

3. Will flashing new firmware recalibrate the torque sensor.

Currently I don't have the bike here and new gear is on its way, so can't really test. But the more I am reading about it, the more worried I am becoming

View attachment 136153 View attachment 136154 View attachment 136155 View attachment 136156 View attachment 136157

Sorry to say, but the only place that can calibrate your torque sensor is Shimano assembly line, and they do not accept any motors for repair.

Therefore if after assembly your motor will pop Error 010, just simply give up. You will waste your time trying to position the PCB's/magnet together and chance to success are leaning towards zero.

Sorry to give you that info, but Shimano is way overcomplicated/ unserviceable compared to any other brand like Brose, Yamaha, Bosch etc...

Its totally different level of 'being careful' while working on Shimano compared to any other motor...

@TeoElFeo may I ask what mileage is the motor and at what stage service was done to that motor?

Hi, this issue turned into a problem. I tries to fit EP8, but the shape is just a tiny bit different and it does not fit on a 2018 Pivot Shuttle. The top of the engine hits an internal shape in the frame (a main pivot thread insert, so no filing here..)Hi! Anyone know a service company in Italy for e8000 motors?

Mine has 9800km on it, from 2018. Suddenly came quite draggy and ofc heats up a lot. Drag is more on boost and less on eco. Also, engine freewheel started to stick simultaneously, and is basically not working at boost(cranks keep spinning), eco is still rideable. This appeared quite suddenly half way down a trail.

I'm a bit desperate, since I plan on going to Finale in a few weeks, I'm already in Italy with my camper. I'll be in Maritime Alpes for the next two weeks, if anyone has a spare around there, or knows a shop, I'd be happy to buy a E8000.

I would like to know how much crank free play is too much on an E8000 motor.

Mine currently has 2K miles, and runs fine. I have noticed slop in the crank pinion however.

There is no end play on the shaft. But I can hear it , feel it, and see it when I grasp the pedals in both hands and test for free play.

My instincts are that this free play is not good, and will lead to further wear.

Forgive me not reading all the pages and asking..?!>!

edit- just to add- much was recently made about the E-Bike Performance Centre on social media ( Frequently Asked Questions & Answers - eBike Motor Centre (Performance Line Bearings) )

....and yet it doesnt appear that they mention Shimano beyond having the brand name plastered on their web pages...Does anyone know, or have experience with these service techs respect Shimano motors..?

grtzzz

Tim

Mine currently has 2K miles, and runs fine. I have noticed slop in the crank pinion however.

There is no end play on the shaft. But I can hear it , feel it, and see it when I grasp the pedals in both hands and test for free play.

My instincts are that this free play is not good, and will lead to further wear.

Forgive me not reading all the pages and asking..?!>!

edit- just to add- much was recently made about the E-Bike Performance Centre on social media ( Frequently Asked Questions & Answers - eBike Motor Centre (Performance Line Bearings) )

....and yet it doesnt appear that they mention Shimano beyond having the brand name plastered on their web pages...Does anyone know, or have experience with these service techs respect Shimano motors..?

grtzzz

Tim

Last edited:

Hi @Beatn1K, I am the owner of the much spoken about Ebike Motor Centre, and hopefully I can answer some of your questions here.I would like to know how much crank free play is too much on an E8000 motor.

Mine currently has 2K miles, and runs fine. I have noticed slop in the crank pinion however.

There is no end play on the shaft. But I can hear it , feel it, and see it when I grasp the pedals in both hands and test for free play.

My instincts are that this free play is not good, and will lead to further wear.

Forgive me not reading all the pages and asking..?!>!

edit- just to add- much was recently made about the E-Bike Performance Centre on social media ( Frequently Asked Questions & Answers - eBike Motor Centre (Performance Line Bearings) )

....and yet it doesnt appear that they mention Shimano beyond having the brand name plastered on their web pages...Does anyone know, or have experience with these service techs respect Shimano motors..?

grtzzz

Tim

With regards play in the crankshaft. There should be no discernible play radially or up and down if you like. However, if you are holding the very end of the crank arm and physically pulling it back and forth, the tiniest bit of play will be exaggerated. Try just moving it gently back and forth toward and away from the bike and see if any movement is visible. If not, don't worry. Then drop the chain off the front chainring and turn the crank forward and backwards by hand and listen to the motor. There should be no harsh rumble or "bad wheel bearing" kind of noise.

We have to mention Shimano on our site because we try and support people with bearings and parts for these motors. It is very sad that we had to make the decision to stop repairing Shimano motors. This had to be done because Shimano are the only main motor manufacturer that will not currently talk to us, or supply us any software or information.

This means that if we repair a Shimano motor, we can't test it, delete any error codes, or set up an exchange motor with the correct parameter's for the bike.

We have just applied again! for a Shimano account and software, and so far again we have been ignored! I can only ask everyone who reads this post to email Shimano and ask them to help us a little so we may help everyone a lot! We have over 30 partners worldwide who could stop this worry and expense for Shimano owners overnight. But unless Shimano talk to us, nothing will change.

Hello Sir !Hi @Beatn1K, I am the owner of the much spoken about Ebike Motor Centre, and hopefully I can answer some of your questions here.

With regards play in the crankshaft. There should be no discernible play radially or up and down if you like. However, if you are holding the very end of the crank arm and physically pulling it back and forth, the tiniest bit of play will be exaggerated. Try just moving it gently back and forth toward and away from the bike and see if any movement is visible. If not, don't worry. Then drop the chain off the front chainring and turn the crank forward and backwards by hand and listen to the motor. There should be no harsh rumble or "bad wheel bearing" kind of noise.

We have to mention Shimano on our site because we try and support people with bearings and parts for these motors. It is very sad that we had to make the decision to stop repairing Shimano motors. This had to be done because Shimano are the only main motor manufacturer that will not currently talk to us, or supply us any software or information.

This means that if we repair a Shimano motor, we can't test it, delete any error codes, or set up an exchange motor with the correct parameter's for the bike.

We have just applied again! for a Shimano account and software, and so far again we have been ignored! I can only ask everyone who reads this post to email Shimano and ask them to help us a little so we may help everyone a lot! We have over 30 partners worldwide who could stop this worry and expense for Shimano owners overnight. But unless Shimano talk to us, nothing will change.

Thanks for taking the time to reply here..... I since found the recommended bearings set for my motor on your web pages....

I see how difficult it is to make sense of "how long is a piece of string ?" but appreciate your efforts and input.

Perhaps the recent video feature has spooked me. I have some experience fettling motorcycles, and Im pretty sure the bearings' radial slop is a lot more than barely discernible. Although the bearings arent especially noisey, I cant judge how much of that sound is the motor. Its silent rotating in reverse.

I wish Shimano would support their customers more too. Of course, their dealer network is far and wide but their attitude to the serviceability of their products will eventually come round to damage their reputation in my opinion. I agree, they should own it and support service centers like yours.

Expensive tech that doesnt go the distance will generate bad feeling amongst their customer base. I imagine their accountants think they have it covered!?!?

Im happy to ping an email at their customer services to that effect. Afterall, I have a barely used bike with an over priced paperweight in the middle !!!lol

fingers crossed common sense prevails

Tim

brw0513

Member

Hi Bearing Man. Do you have an email address for Shimano? I'd be happy to send them an email.We have just applied again! for a Shimano account and software, and so far again we have been ignored! I can only ask everyone who reads this post to email Shimano and ask them to help us a little so we may help everyone a lot! We have over 30 partners worldwide who could stop this worry and expense for Shimano owners overnight. But unless Shimano talk to us, nothing will change.

I bought a set of bearings for my EP-8000 through your Australia distributor - and fitted the easiest ones to get to myself. My preference would have been to send the motor away for a more thorough service including seals and re-greasing. If Shimano won't come to the party, then my next eMTB will be powered by something more long term owner friendly.

It's ludicrous an eMTB motor can't be fully serviced outside of warranty.

There is no email address that I have been able to find for Shimano ebike in Japan, not even a form to send, but you can find country contacts forms here: CONTACT SHIMANO | SHIMANO BIKE-AUSTRALIA We have been emailing the UK import suppliers, but this has proved fruitless so far!

When you look at the size of Shimano, you will get some idea of the futility of any sort of campaign. Locations|SHIMANO Corporate Site

However, the bike manufacturers should be more willing to listen when customers tell them they would be reluctant to buy another one of their bikes if fitted with a Shimano motor. State the reason as Shimano do not support repair of their product and this is not acceptable or sustainable.

And the bike manufacturers will have a much louder voice than any of us.

When you look at the size of Shimano, you will get some idea of the futility of any sort of campaign. Locations|SHIMANO Corporate Site

However, the bike manufacturers should be more willing to listen when customers tell them they would be reluctant to buy another one of their bikes if fitted with a Shimano motor. State the reason as Shimano do not support repair of their product and this is not acceptable or sustainable.

And the bike manufacturers will have a much louder voice than any of us.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 556K

- Messages

- 28,085

- Members

Latest articles

-

Santa Cruz Vala X0 review - a new approach to perfection?

The new Vala is Santa Cruz’ first attempt on a Bosch-powered emtb. Like...- Knut Nes

- 6 min read

- Views: 1K

- Reaction score: 5

- Comments: 4

-

A new standard for charging ebikes is coming? A quick interview with Bosch - charge2bike

I had a quick chat with dr Vikram Godbole about "charge2bike", a new...- Knut Nes

- 2 min read

- Views: 944

- Reaction score: 7

- Comments: 4