You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Servicing - what should I be checking and when?

- Thread starter TommyC

- Start date

You will need oil for the fork. Not much but still. If you're in it for the long term, then buy a litre or so & then it's always on hand for when you need it. Essentially, if you stick to the recommended 50 hour servicing intervals, you'll be cleaning the internals, swapping the wiper seals & renewing the oil. Strictcly speaking, you should renew crush washers & fork seals but in reality, you'll find they nearly always need doing less often unless they're obviously damaged etc.

www.ridefox.com

www.ridefox.com

2022 Bath Oil Volume Chart | Bike Help Center | FOX

steve_sordy

Wedding Crasher

I bought an ordinary socket for my Fox 38 for a few pounds and ground it flat with a hand-held grinder. I was surprised how quick it was to do. Then I smoothed if off on some Emery cloth (but any 180-grit abrasive will do).Flat socket is for the air spring side , normal sockets can chew up the cap as there's very little to get a hold of ...........

Lay the emery cloth on a flat hard surface and then rub the socket across in a figure of eight motion. Turn the socket by 90 degrees or so every 30 seconds. Then remove any burrs inside and out; (they will be slight).

Only saved myself about a fiver, but it was the principle of the thing.

I bought one of these off ebay last yearI bought an ordinary socket for my Fox 38 for a few pounds and ground it flat with a hand-held grinder. I was surprised how quick it was to do. Then I smoothed if off on some Emery cloth (but any 180-grit abrasive will do).

Lay the emery cloth on a flat hard surface and then rub the socket across in a figure of eight motion. Turn the socket by 90 degrees or so every 30 seconds. Then remove any burrs inside and out; (they will be slight).

Only saved myself about a fiver, but it was the principle of the thing.

Comes in handy for all the different size nuts it's aluminium on the suspension top

Ark

Active member

and in an emergency if oil is dripping from that crush washer, some people literally make a temporary one out of a milk carton with a hole punch.You will need oil for the fork. Not much but still. If you're in it for the long term, then buy a litre or so & then it's always on hand for when you need it. Essentially, if you stick to the recommended 50 hour servicing intervals, you'll be cleaning the internals, swapping the wiper seals & renewing the oil. Strictcly speaking, you should renew crush washers & fork seals but in reality, you'll find they nearly always need doing less often unless they're obviously damaged etc.

Yep. Although I'm suggesting you can get away with quick & dirty servicing on forks, I tend to do shocks by the book as they're under way more pressure. Different discussion but MTB forks are a lousy design in general. They run out of lube & gobble up dirt in a matter of hours. We need to resurrect the upside down design, way better philosophy.

steve_sordy

Wedding Crasher

That's an interesting tool for sure!I bought one of these off ebay last year

Comes in handy for all the different size nuts it's aluminium on the suspension top

View attachment 137439

Can you really put 40Nm through that without damage?

That's what it's made for, haven't broken it yet but saying that I've tempted fateThat's an interesting tool for sure!

Can you really put 40Nm through that without damage?

I thought they were 28nmThat's an interesting tool for sure!

Can you really put 40Nm through that without damage?

steve_sordy

Wedding Crasher

That sounds like a correct figure to me. However, I remember clearly that it was 40Nm on the Pike that I first removed the top cap. I remember it because I thought it was a stupidly high figure. 40Nm is the same as for a bottom bracket or the cassette lock ring, but they well designed for the spanner/lock ring to get hold of, not thin alloy flats!I thought they were 28nm

I was bricking myself at my first attempt to remove the cap. It sure felt like it could have been 40Nm. I made no attempt to retighten it back to 40Nm, just to what felt to be "tight enough". But I slowly gained sag over the next few rides, so it wasn't tight enough! I didn't have a torque wrench big enough so I just increased the tightness a little bit. That stopped the leakage, but I have no idea how tight it was.

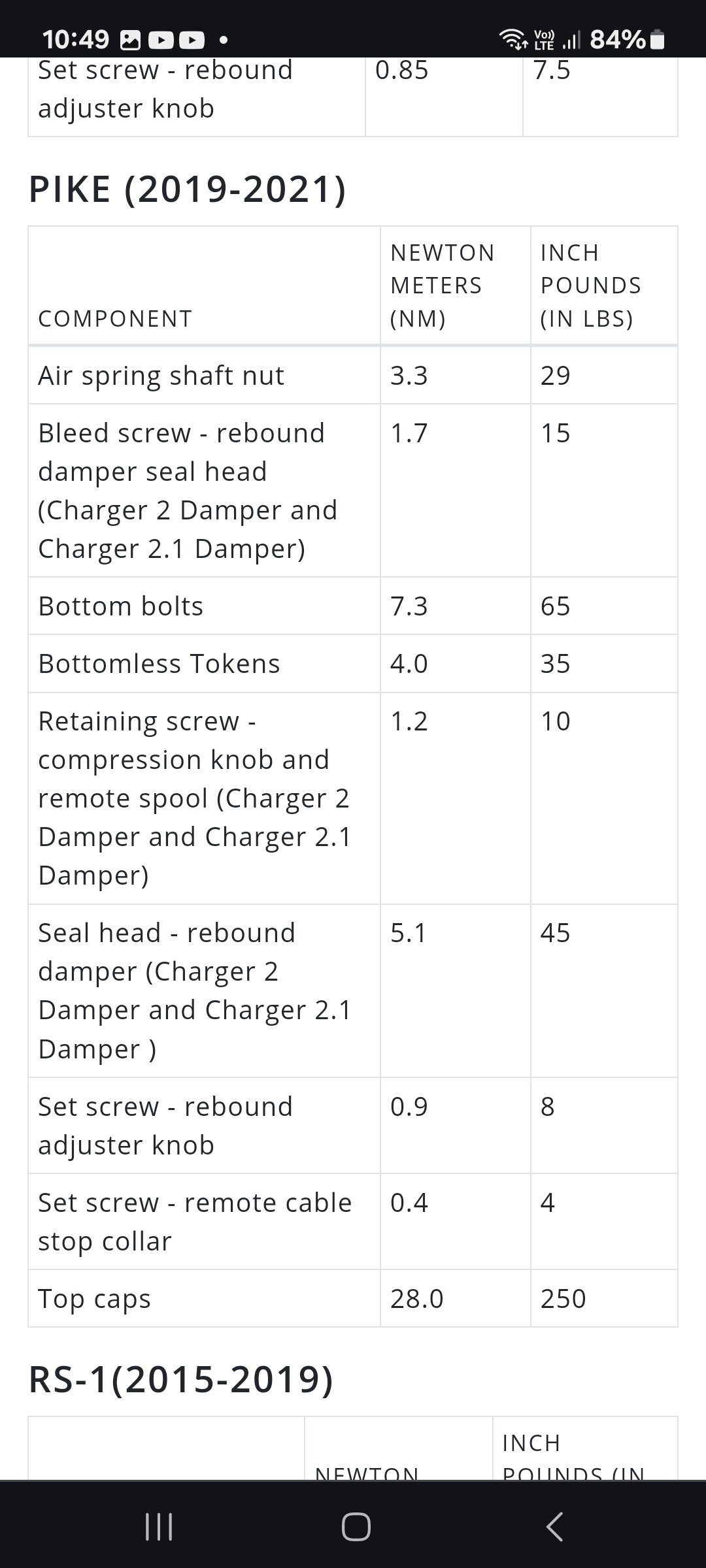

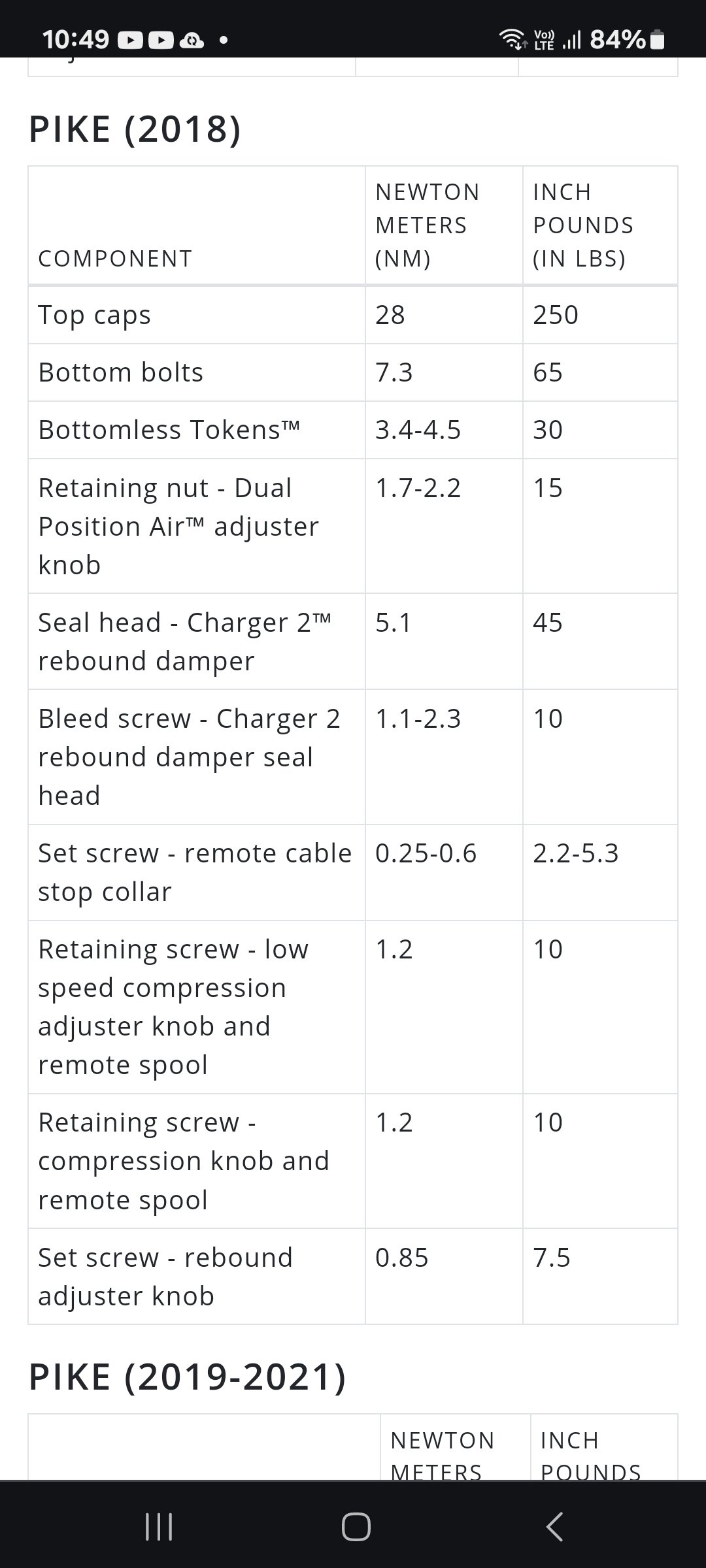

This is what I work from SteveThat sounds like a correct figure to me. However, I remember clearly that it was 40Nm on the Pike that I first removed the top cap. I remember it because I thought it was a stupidly high figure. 40Nm is the same as for a bottom bracket or the cassette lock ring, but they well designed for the spanner/lock ring to get hold of, not thin alloy flats!

I was bricking myself at my first attempt to remove the cap. It sure felt like it could have been 40Nm. I made no attempt to retighten it back to 40Nm, just to what felt to be "tight enough". But I slowly gained sag over the next few rides, so it wasn't tight enough! I didn't have a torque wrench big enough so I just increased the tightness a little bit. That stopped the leakage, but I have no idea how tight it was.

Pretty much the same for most of the forks

That's why I bought that thing with all the sizes on it, saves grinding down socketsWell I only have 27mm sockets and need 26mm. I reckon I’ll end just using an adjustable spanner and going FT.

steve_sordy

Wedding Crasher

That is a risk too far for me. I reckon the top cap has such small flats that all six flats are required to loosen them. Two flats is 2/3 too few.Well I only have 27mm sockets and need 26mm. I reckon I’ll end just using an adjustable spanner and going FT.

I’m a plumber. A 6” Bahco adjustable is like an extension of my arm! I’d get it off and back on no problem. Just not sure I’d torque it up enough without marking it.

- Thread starter

- #50

steve_sordy

Wedding Crasher

- Thread starter

- #52

So the bike is almost back together. Rear shock is serviced, although it didn’t look like it needed it. Those white washer are a pain in the arse! Frame is back together and motor/electrics back in. Rear wheel has had new wheel bearings and I’ve just topped up the tubeless sealant. It was done over a year ago but it’s also never been topped up and I read cleaning the old stuff out is messy!

Just the forks to go but I’ve hit a problem. I can’t get the air spring out. I know, I didn’t need to take it out, I was just being nosy, but now the air spring has pushed back and is stuck. Now I have the circlip out of the bottom, can I just put some air in the top again and pop it out?

Just the forks to go but I’ve hit a problem. I can’t get the air spring out. I know, I didn’t need to take it out, I was just being nosy, but now the air spring has pushed back and is stuck. Now I have the circlip out of the bottom, can I just put some air in the top again and pop it out?

I take it the threaded rod decided to loose itself in the lowersSo the bike is almost back together. Rear shock is serviced, although it didn’t look like it needed it. Those white washer are a pain in the arse! Frame is back together and motor/electrics back in. Rear wheel has had new wheel bearings and I’ve just topped up the tubeless sealant. It was done over a year ago but it’s also never been topped up and I read cleaning the old stuff out is messy!

Just the forks to go but I’ve hit a problem. I can’t get the air spring out. I know, I didn’t need to take it out, I was just being nosy, but now the air spring has pushed back and is stuck. Now I have the circlip out of the bottom, can I just put some air in the top again and pop it out?

Just pump it up very slowly and it should work it's way back out

Jus put a cloth over the end to catch it

- Thread starter

- #54

It came out by hand in the end as I was scared to put too much pressure in there! Some air definitely helped though.I take it the threaded rod decided to loose itself in the lowers

Just pump it up very slowly and it should work it's way back out

Jus put a cloth over the end to catch it

Forks are back on the bike but the damper side wouldn’t torque up as the damper just spins? Will keep an eye on it to see if it leaks.

Only put in fresh oil in the end. Seals and crush washers all looked good so will keep the ones I bought for another day.

Forks are back on the bike but the damper side wouldn’t torque up as the damper just spins? Will keep an eye on it to see if it leaks.

Only put in fresh oil in the end. Seals and crush washers all looked good so will keep the ones I bought for another day.

The rod where it comes out the bottom? Yeah, they're like that. Sometimes you can tighten them to the torque you want, sometimes they spin a little. Do what you can, and hope for the best. I've never had one come apart.

I'm a cheapskate do the same thing with my seals and crush washers. Reusing them once or twice has never been a problem.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 559K

- Messages

- 28,287

- Members

Latest articles

-

2025 Canyon Spectral:ONfly CF Ltd review

We were quite surprised to read about the new lightweight Canyon...- Knut Nes

- 7 min read

- Views: 847

- Comments: 1

-

Santa Cruz Vala X0 review - a new approach to perfection?

The new Vala is Santa Cruz’ first attempt on a Bosch-powered emtb. Like...- Knut Nes

- 6 min read

- Views: 10K

- Reaction score: 6

- Comments: 20