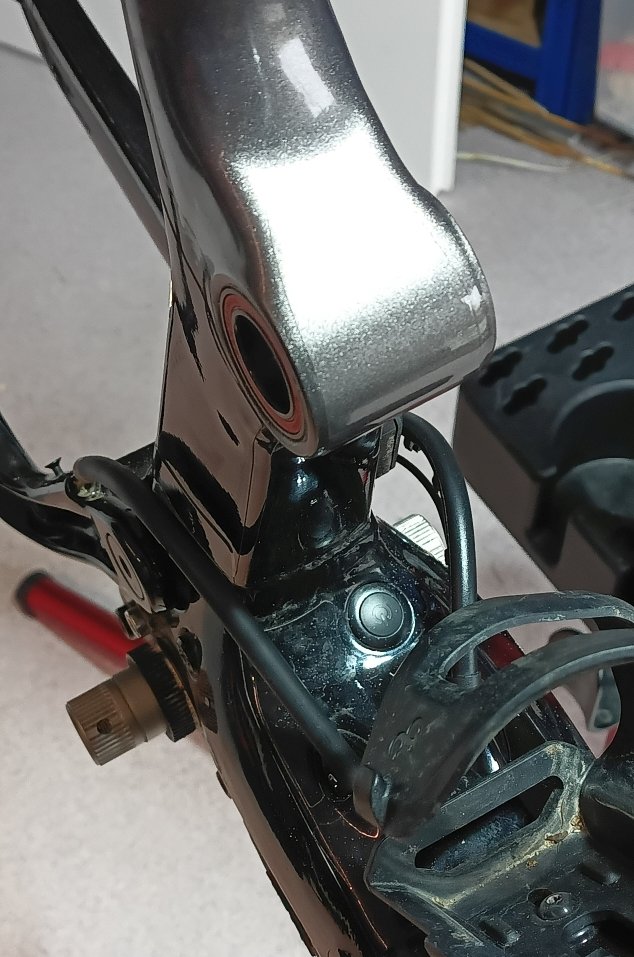

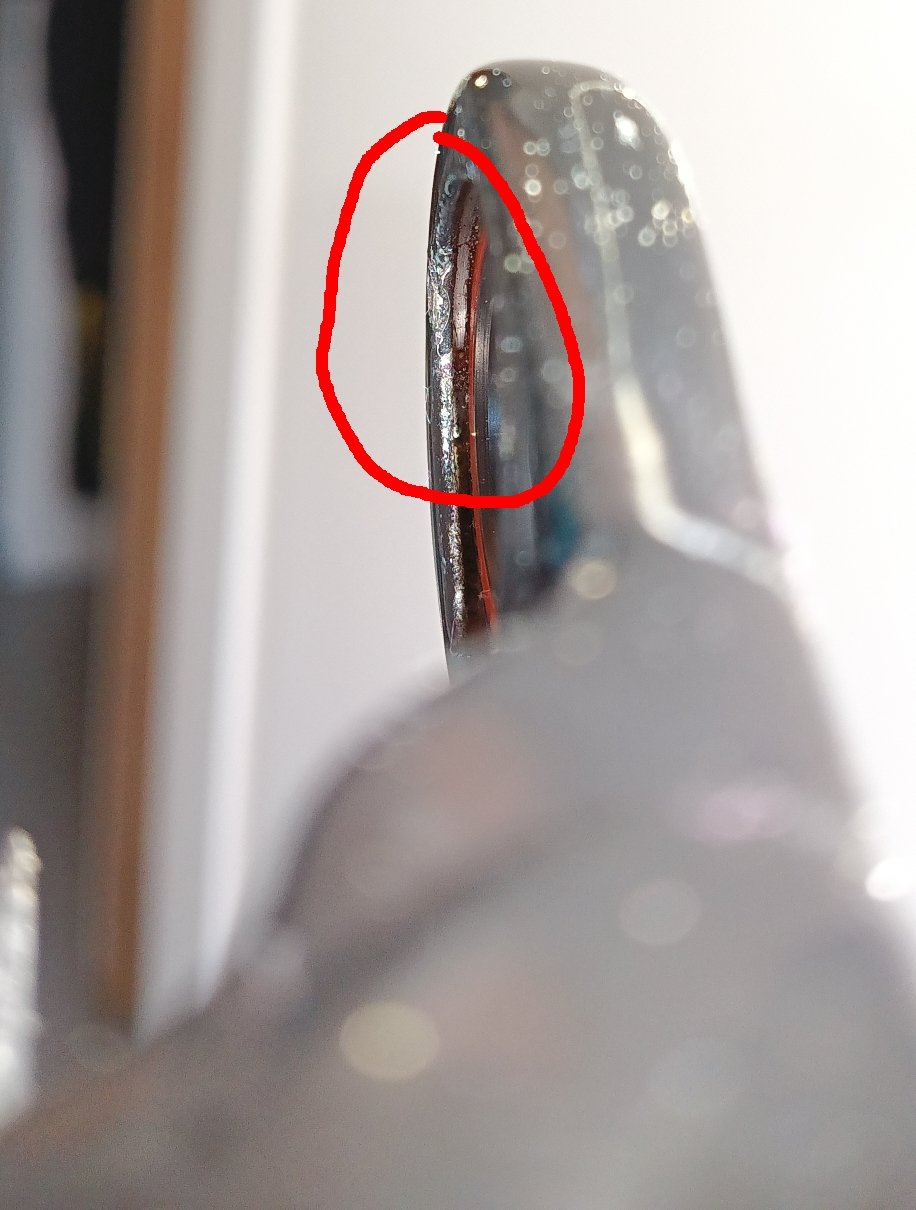

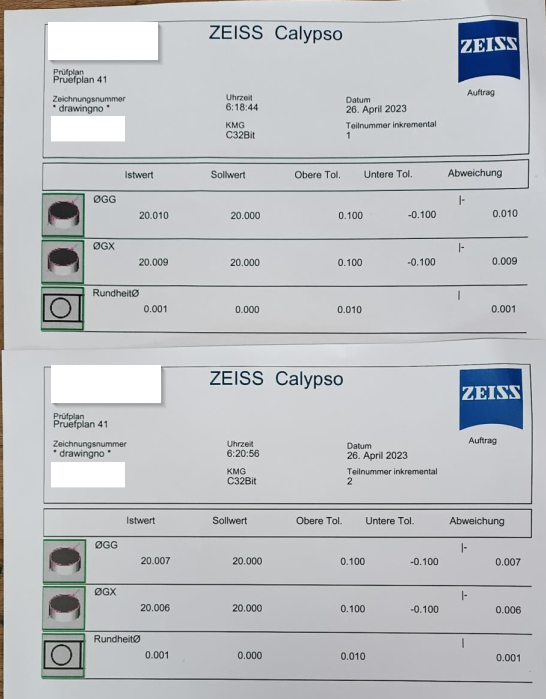

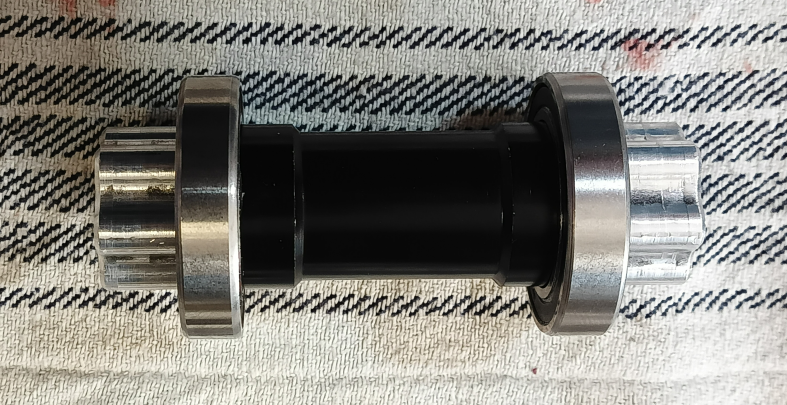

I’ve had the same issues (Orbea Rise M10). Started with a cracking sound. I thought it was the rear chain/seatstay bearings. However located it to rear hub a RF vault. Cleaned, pawls and ratchet. No change but actually got worse the next ride. Could hear it just rocking bike with rear brake on. Took to LBS (JE James who have been brilliant). Said they’d had a few of issues with this hub. Returned to Silverfish, RF distributed in UK. Sent out a new hub. Got it today.They said it wasn’t the actual drive mechanism but the hub itself. Not exactly sure what. Apparently some of the hubs had a bonded body which worked loose. I only got 760miles out of it. Temped to sell on and get a DTSwiss 350.

FYI RF also warrantied my wheel, and they chose to provide a complete new wheel, not just a new hub. Didn't get any specific details as to the problem. Can't fault the service, it's great when a company stands behind their productsI tried the PTFE fix, but no joy for me. If you do try it, make sure it doesn’t get anywhere near your brake rotor. I removed mine.

I will update here once I hear what RF say.