------------------------------------

EDIT 2/21/2019 - Hey it's me JD from the future (2 months after this first post). I wanted to add a little info here on how you can obtain your own set of gears that is 3d printed by Shapeways so I created a quick Wordpress site with some info:

Guide to the LSS

In there is information about the latest design, links to purchasing, and installation instructions (or if you just want direct links, here is the LSS and LSSDT). Anyway, I still encourage you to read this entire thread as it provides a ton of information on the development, prototype feedback and reviews of the kit. Enjoy.

-----------------------------------

I've only had my 2019 Turbo Levo a few weeks but already felt the need for speed. I do a decent amount of road riding with my bike (at $7k, it's my do-it-all bike) and felt the 20 mph speed limit was a little too limiting. However, I don't want to mess with firmware changes that could brick my bike or cause warranty issues. I also had a number of requirements:

1) Must be 100% mechanical (no software changes)

2) Must be easily reversible (less than 5 min)

3) Must not have any re-wiring of the bike/sensors

4) Keep speed limit at around 28 mph.

In California Class 3 electric bikes w/ 28 mph speed limiters are legal on the roads, so If I made such a device I would be reasonably within the law when riding on the road. When riding on trails I do not need more than 20mph.

My wife thought I was crazy as I sat staring at my bike for like 30 minutes at a time lost in concentration for thinking about the best way to do it. Fortunately I'm good with CAD and have several 3d printers so once the inspiration for a planetary gear set came to mind, I was off designing...

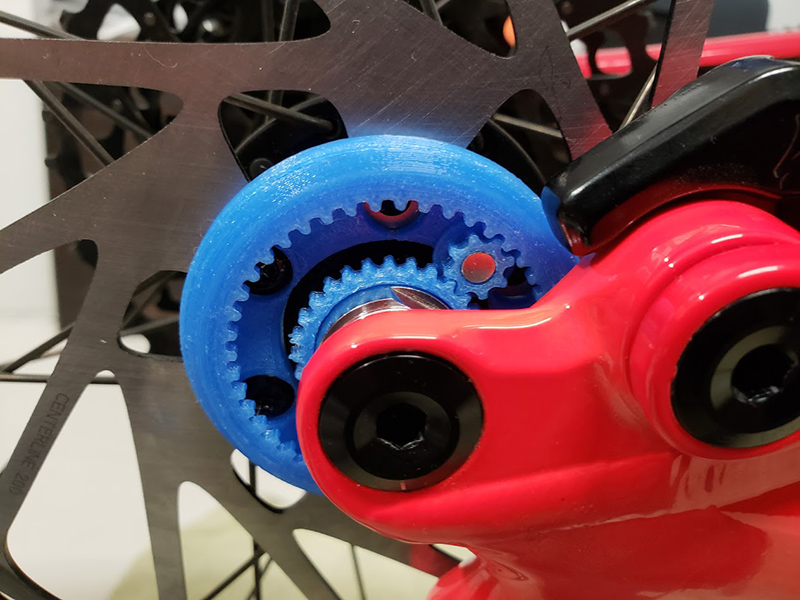

A few days later (and several failed iterations) I had prototype 3 installed on the bike (ignore the ugly blue color, it will be stealth black eventually):

Little did I know at this point it would take 13 more prototypes before I got it working to my satisfaction. Since this post is getting sort of long I'll stop here and call it Part I. If you guys are interested I can do more posts and continue the detailed information on the design/troubleshooting and final outcome (spoiler: it's awesome).

Obligatory info:

Please read about the electric bike laws in your country: Electric bicycle laws - Wikipedia

EDIT 2/21/2019 - Hey it's me JD from the future (2 months after this first post). I wanted to add a little info here on how you can obtain your own set of gears that is 3d printed by Shapeways so I created a quick Wordpress site with some info:

Guide to the LSS

In there is information about the latest design, links to purchasing, and installation instructions (or if you just want direct links, here is the LSS and LSSDT). Anyway, I still encourage you to read this entire thread as it provides a ton of information on the development, prototype feedback and reviews of the kit. Enjoy.

-----------------------------------

I've only had my 2019 Turbo Levo a few weeks but already felt the need for speed. I do a decent amount of road riding with my bike (at $7k, it's my do-it-all bike) and felt the 20 mph speed limit was a little too limiting. However, I don't want to mess with firmware changes that could brick my bike or cause warranty issues. I also had a number of requirements:

1) Must be 100% mechanical (no software changes)

2) Must be easily reversible (less than 5 min)

3) Must not have any re-wiring of the bike/sensors

4) Keep speed limit at around 28 mph.

In California Class 3 electric bikes w/ 28 mph speed limiters are legal on the roads, so If I made such a device I would be reasonably within the law when riding on the road. When riding on trails I do not need more than 20mph.

My wife thought I was crazy as I sat staring at my bike for like 30 minutes at a time lost in concentration for thinking about the best way to do it. Fortunately I'm good with CAD and have several 3d printers so once the inspiration for a planetary gear set came to mind, I was off designing...

A few days later (and several failed iterations) I had prototype 3 installed on the bike (ignore the ugly blue color, it will be stealth black eventually):

Little did I know at this point it would take 13 more prototypes before I got it working to my satisfaction. Since this post is getting sort of long I'll stop here and call it Part I. If you guys are interested I can do more posts and continue the detailed information on the design/troubleshooting and final outcome (spoiler: it's awesome).

Obligatory info:

Please read about the electric bike laws in your country: Electric bicycle laws - Wikipedia

Last edited: