Hey Guys,

Been lurking for a long time here and really hats off you @megabobra & @Koekie for what you've done.

Quick question as I am an absolute electrician newbie. I see that the Mega system is really suited for rim magnets and rotor magnets. @Sander mentioned to a few others with a spoke magnet (like myself) that the 3rd party chip systems are the way to go as the Mega is not for this type. But I fear the risk of the error buying this.

My Question:

Is there no way that the Mega can be jimmy rigged to fit the spoke magnet system?

It just seems like the Mega really is the most reliable way as you're simply changing the input to the sensor and not messing with any internal circuitry...Or is this just the sad truth where I must get a chip box and take a risk?

...Also anyone tried the new Volspeed V4 for Smart system that got released last month? Don't Volspeed tend to outperform Speedbox somewhat for previous motors?

Thank you again and appreciate the hard work you guys are doing for clueless hopefuls like myself.

-M

Hi M,

Thanks for the kind words. There have been a few people with a similar question to yours. Yes, I believe the Mega will work with a traditional speed sensor setup and magnet on the disc or spoke. But sorry, I can't confirm it as I simply don't have a bike to try it on.

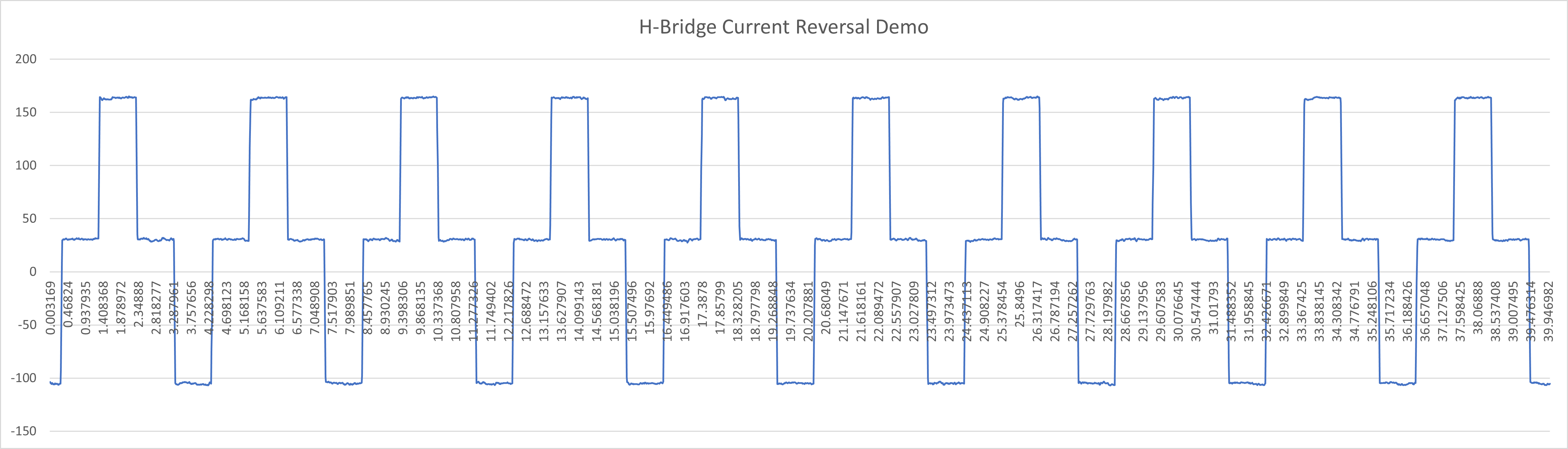

The setup would be a bit unconventional, but simply put, you would be removing the existing speed sensor and replacing it with the senor feeding the Mega. Then, tuck the original speed sensor somewhere up in the frame with the Mega's electromagnet up against it. You'll then be using the mega to trigger the existing speed sensor. Really it's the same arrangement as the Mega is intended for, just with the speed sensor sitting externally rather than within the motor housing.

Frankly I'd be surprised if it didn't work as I suspect the standard speed sensors are just a simple reed switch that don't much about the magnetic field placement and strength. But again, I can't confirm.

You would have see the info in this thread about building a small batch of Mega's. Once I receive all the components, I'll send one of these to someone locally who has a bike with a standard speed sensor and test out my theory above. If it works OK, then it should open the door to most motors - wouldn't it be nice to have a universal, open-source derestrictor all bikes regardless of brand/motor