You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bosch Gen4 Seal Service & Grease up

- Thread starter RustyMTB

- Start date

Peaky Rider

E*POWAH Master

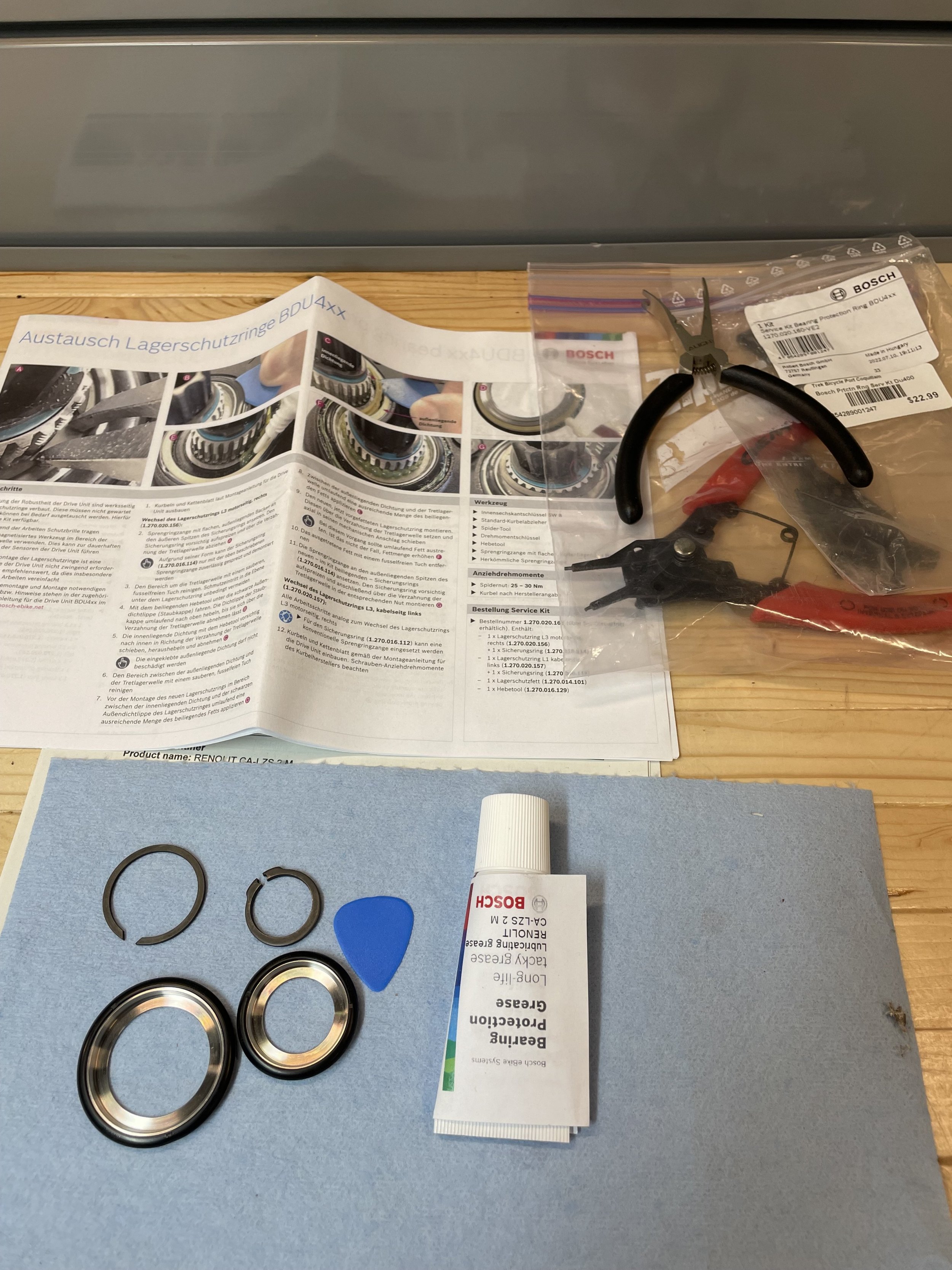

Well, they look like the original snap rings in Rusty's video, not the circlips shown in the adverts.. Pity, I found similar ones in a Bontrager freehub and had great fun (not) piddling them out with a pick, not a plectrum, and a watchmaker's screwdriver.Freshly delivered from James and one of each circlips

View attachment 122779

I've probably taken hundreds of those clips out whilst working in the motor trade. I just use a flat screwdriver and prize one side out then run the screwdriver round underneath and out it should pop. Assuming you can get to it! I've not looked yet but it's only a spring clip and should hardly be a challenging task.

They are hard to find. I have some laying around from a service set of the bosch gen 2 motor. They are the same size but don't fit as the rub against the seal while fitting

You could, I suppose use a set of verns to measure the drive side circlip & find an alternative with better ends. A circlip should last the life of the bike after all.

- Thread starter

- #36

IME it rotates in its groove, so at least two hands are needed & you have to take into account not damaging the chainring thread on the crank spindle. It's not insurmountable by any means but they could easily have designed it better.I've probably taken hundreds of those clips out whilst working in the motor trade. I just use a flat screwdriver and prize one side out then run the screwdriver round underneath and out it should pop. Assuming you can get to it! I've not looked yet but it's only a spring clip and should hardly be a challenging task.

IME it rotates in its groove, so at least two hands are needed & you have to take into account not damaging the chainring thread on the crank spindle. It's not insurmountable by any means but they could easily have designed it better.

It sounds like a clueless designer has been let loose on the cad software

I've just done my seals and found on that drive shaft circlip that the ordinary circlip pliers open the clip enough to ease out with a small screwdriver.

What I find strange is that neither Bosch or anyone else has not prized the bearing outer seals off and put grease where it's actually needed, in the bearing!

I used the rubber seal to push the grease in on the none drive side, and did that about four times.

The drive side has more room and you can use your thumb to get the grease into the bearing.

What I find strange is that neither Bosch or anyone else has not prized the bearing outer seals off and put grease where it's actually needed, in the bearing!

I used the rubber seal to push the grease in on the none drive side, and did that about four times.

The drive side has more room and you can use your thumb to get the grease into the bearing.

Did you remove the bearing seal cover? Or was that the way you discovered it? Can/would you use the supplied grease for the bearings?I've just done my seals and found on that drive shaft circlip that the ordinary circlip pliers open the clip enough to ease out with a small screwdriver.

What I find strange is that neither Bosch or anyone else has not prized the bearing outer seals off and put grease where it's actually needed, in the bearing!

I used the rubber seal to push the grease in on the none drive side, and did that about four times.

The drive side has more room and you can use your thumb to get the grease into the bearing.

View attachment 123927 View attachment 123928 View attachment 123929 View attachment 123930 View attachment 123931 View attachment 123932

I’m about to install the seal kit and I’ll probably inspect or regrease the bearings if possible.

First off,sling that plectrum it's useless

When you have removed the seals the bearing outer is visible.

I used a Stanley knife blade to gently tease the outer seal off.

Then use some brake cleaner on a rag and use a thin screwdriver to get the bearing clean.

On the left side I kept on filling with grease and used the seal cover to push the grease into the bearing.

Don't press that hard that you end up refitted the seal until you think there's enough grease in the bearing.

Just use your thumb on the drive side.

And yes it's the same grease.

When you have removed the seals the bearing outer is visible.

I used a Stanley knife blade to gently tease the outer seal off.

Then use some brake cleaner on a rag and use a thin screwdriver to get the bearing clean.

On the left side I kept on filling with grease and used the seal cover to push the grease into the bearing.

Don't press that hard that you end up refitted the seal until you think there's enough grease in the bearing.

Just use your thumb on the drive side.

And yes it's the same grease.

I always open bearings and regrease them.You've gone deeper than me. Good work, would be interested in seeing the results next time you're in there, given you've opened a sealed bearing cover.

Bearings only need a little grease to work properly; provided they're not contaminated they're probably ok.

I changed the non-drive side seal on my bike today and the old seal was already torn so good timing for this thread.

I did notice that there's significant lateral movement of the motor shaft when the crankarm and circlip are removed - is that normal?

I changed the non-drive side seal on my bike today and the old seal was already torn so good timing for this thread.

I did notice that there's significant lateral movement of the motor shaft when the crankarm and circlip are removed - is that normal?

Not really. I didn't measure the movement but it was something like 5mm lateral. I'll see if there's the same movement when I do the other side tomorrow and measure the play.Not in my experience. Has it had a few pedal strikes along the way?

Installed the drive side motor seal yesterday. I should have took more pics but I got caught up in the entire process along with a bit of head-scratching.

Once I was able to remove cir-clip the old seal-ring came out fairly easy. There was some old grease remaining which I cleaned up and carefully inspected. I now had access to the seal cover on the bearing.

I made several attempts to carefully remove the hard rubber cover from the bearing without success. The technique for removal was described here but I became worried that I could be doing damage to that seal or open up a can of worms. Therefore I could not visually inspect the bearings or condition (grease).

I cleaned the area and liberally re-greased with the provided grease. Reinstalled the new cir-clip then re-torqued , regreased, and added blue lock tight to the castle nut. Disassembled and regreased the magnetic peddles also.

The entire process took a few hours probably because it was my first time replacing the motor seals and I gave everything a good cleaning and re-greasing. I may regret not accessing the bearings but they felt good and I could not see any issues (water ingress or wear).

Before.

After

Now to tackle the non-driveside motor seal.

Once I was able to remove cir-clip the old seal-ring came out fairly easy. There was some old grease remaining which I cleaned up and carefully inspected. I now had access to the seal cover on the bearing.

I made several attempts to carefully remove the hard rubber cover from the bearing without success. The technique for removal was described here but I became worried that I could be doing damage to that seal or open up a can of worms. Therefore I could not visually inspect the bearings or condition (grease).

I cleaned the area and liberally re-greased with the provided grease. Reinstalled the new cir-clip then re-torqued , regreased, and added blue lock tight to the castle nut. Disassembled and regreased the magnetic peddles also.

The entire process took a few hours probably because it was my first time replacing the motor seals and I gave everything a good cleaning and re-greasing. I may regret not accessing the bearings but they felt good and I could not see any issues (water ingress or wear).

Before.

After

Now to tackle the non-driveside motor seal.

Non-drive side motor seals; Full of confidence I tackled this seal this morning. Fairly easy except for fitting the cir-clip pliers…but eventually got them to work. I still didn’t open the hard rubber bearing cover but again the bearing looked/felt okay. AND…took some amateur pics of the process.

Fairly straightforward and squished in lots of the Bosch lubricant. Greased up the peddle shaft while I was at it.

Anyone need a guitar pick?

Fairly straightforward and squished in lots of the Bosch lubricant. Greased up the peddle shaft while I was at it.

Anyone need a guitar pick?

I’d be happy with thirty five minutes.Next time you'll do it in thirty minutes all in.Might be useful to clean up the excess grease as it will trap all the dirt first time out.

Good little preventative maintenance for a reasonable price. The excess grease was all cleaned up once the final torques were applied. I can’t believe that the crank bolts need 50nm…

Peaky Rider

E*POWAH Master

Are the crank bolts definitely 50 nm? I'll need a three foot long bar to get to that spec.

50nm was all I could find when I did a search. 50 is possible but you really need to hold onto the crank. Seems kinda high though.Are the crank bolts definitely 50 nm? I'll need a three foot long bar to get to that spec.

bazxa

Member

30nm on the nut

Peaky Rider

E*POWAH Master

Just got round to doing the seals on my two year old, 3000 mile Rail Bosch motor and I was surprised just how clean and well greased the old seals had kept the bearings.

The leaflet that came with the new seals said "these do not require maintenance", perhaps they had a point, at least in my case.

The leaflet that came with the new seals said "these do not require maintenance", perhaps they had a point, at least in my case.

Last edited:

Bought a used 2021 Cube Reaction Pro with 3500km travelled and checked the drive side seal - still had some grease but I cleaned and regreased anyway. This cheap bike will go camping so I can leave the Rise at home......... and you can never have too many bikes anyway right?

P.S. For torque on the chainring nut, firm with purple loctite is working fine for me. I don't think it needs to be wrenched up to 50nm.

P.S. For torque on the chainring nut, firm with purple loctite is working fine for me. I don't think it needs to be wrenched up to 50nm.

Last edited:

Rain just gets depressing. If I lived in the UK I imagine there would be a lot of winter holidays in Southern Europe.Oh to live somewhere it isn't pissing down constantly

The torque on the chainring nut, or castle nut, is more important than the crank bolt imo. The castle nut was only 20-25nm (I think?) and I applied a small amount of blue lock-tite to the threads. (Counter-clockwise).P.S. For torque on the chainring nut, firm with purple loctite is working fine for me. I don't think it needs to be wrenched up to 50nm.

As mentioned in here the crank bolt only needs 30mm. I could only find 50nm torque for the crank bolt which seemed excessive to me. 30nm makes more sense.

oscarbravo

New Member

The splined shaft is running against the inner race of the main bearing so what stops water ingress at that metal to metal gap?Bought a used 2021 Cube Reaction Pro with 3500km travelled and checked the drive side seal - still had some grease but I cleaned and regreased anyway. This cheap bike will go camping so I can leave the Rise at home......... and you can never have too many bikes anyway right?

P.S. For torque on the chainring nut, firm with purple loctite is working fine for me. I don't think it needs to be wrenched up to 50nm.

View attachment 127135

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 571K

- Messages

- 29,038

- Members

Latest articles

-

The new Whyte Kado – an existing design with a new price?

Don’t get me wrong, the Kado isn’t an old bike. It’s a brand-new model...- Knut Nes

- 2 min read

- Views: 2K

- Reaction score: 2

- Comments: 4

-

Pinion Motor Gearbox: What’s It Really Like?

Introduction The Nicolai S16 is a long-travel enduro eMTB that...- Rob Rides EMTB

- 5 min read

- Views: 4K

- Reaction score: 16

- Comments: 10