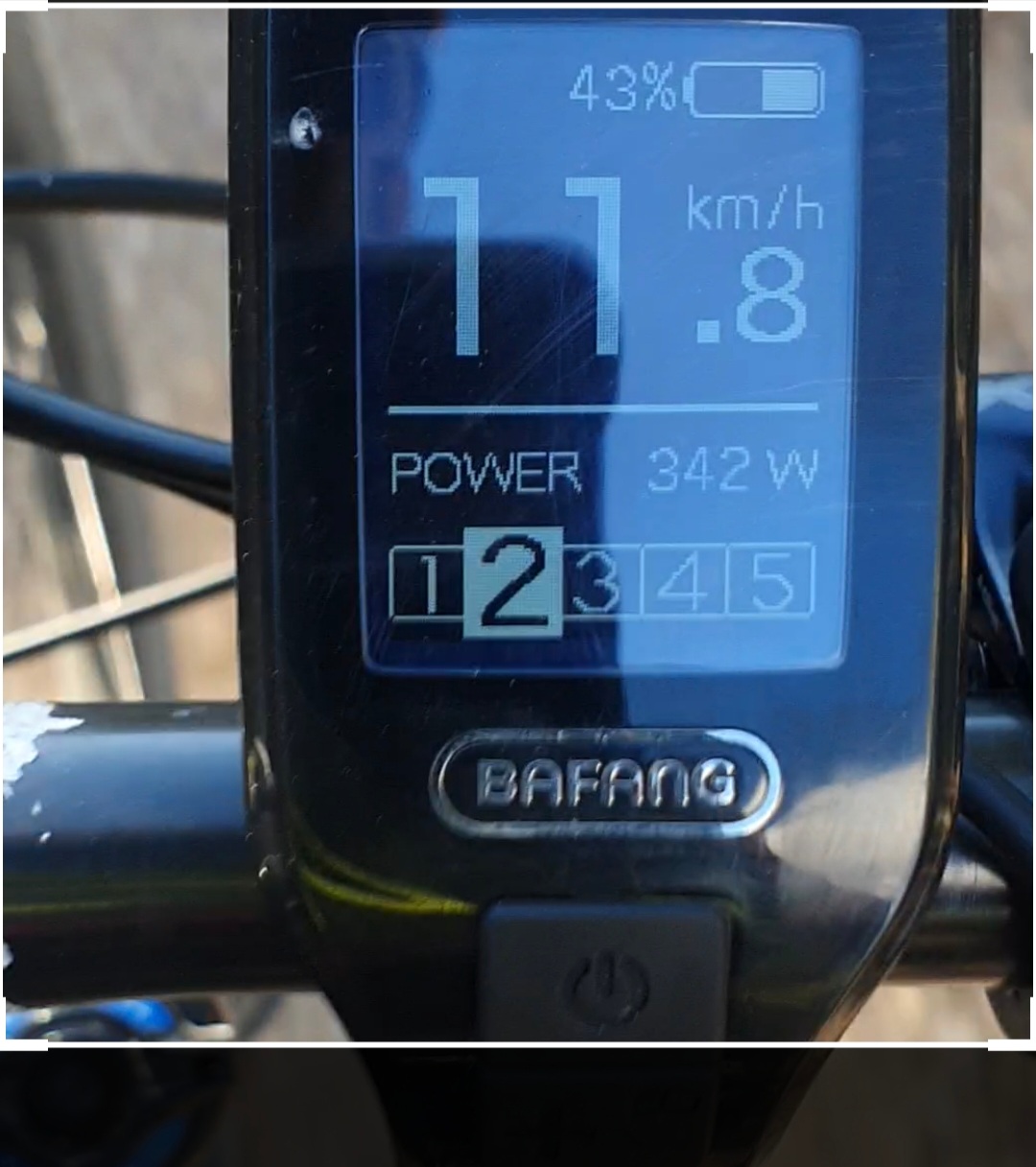

Hello, I have a new m500 and although it seems strange to some, I have a lot of power at levels 1 (150-180w), 2(200-280w) and 3( +300w) constant power are not power peaks

I have not reached levels 4 and 5.

I don't know if it's normal, I asked the seller and he tells me that I have a good engine.

I can climb trails at 10% on level 1 almost effortlessly and if I put level 2 it's like 1% on the non-powered bike. I bought the bafang bft04 motor and battery and when I got the seller I contacted to tell me that the motor was 48v not 43v like bafang batteries and he gave me the 43v firmware Now I have the motor at 43v the same as the battery.

I have this firmware CRX10NC4313i142012.9-28-2230-20220415.bin

I have not reached levels 4 and 5.

I don't know if it's normal, I asked the seller and he tells me that I have a good engine.

I can climb trails at 10% on level 1 almost effortlessly and if I put level 2 it's like 1% on the non-powered bike. I bought the bafang bft04 motor and battery and when I got the seller I contacted to tell me that the motor was 48v not 43v like bafang batteries and he gave me the 43v firmware Now I have the motor at 43v the same as the battery.

I have this firmware CRX10NC4313i142012.9-28-2230-20220415.bin