flightrisk86

Member

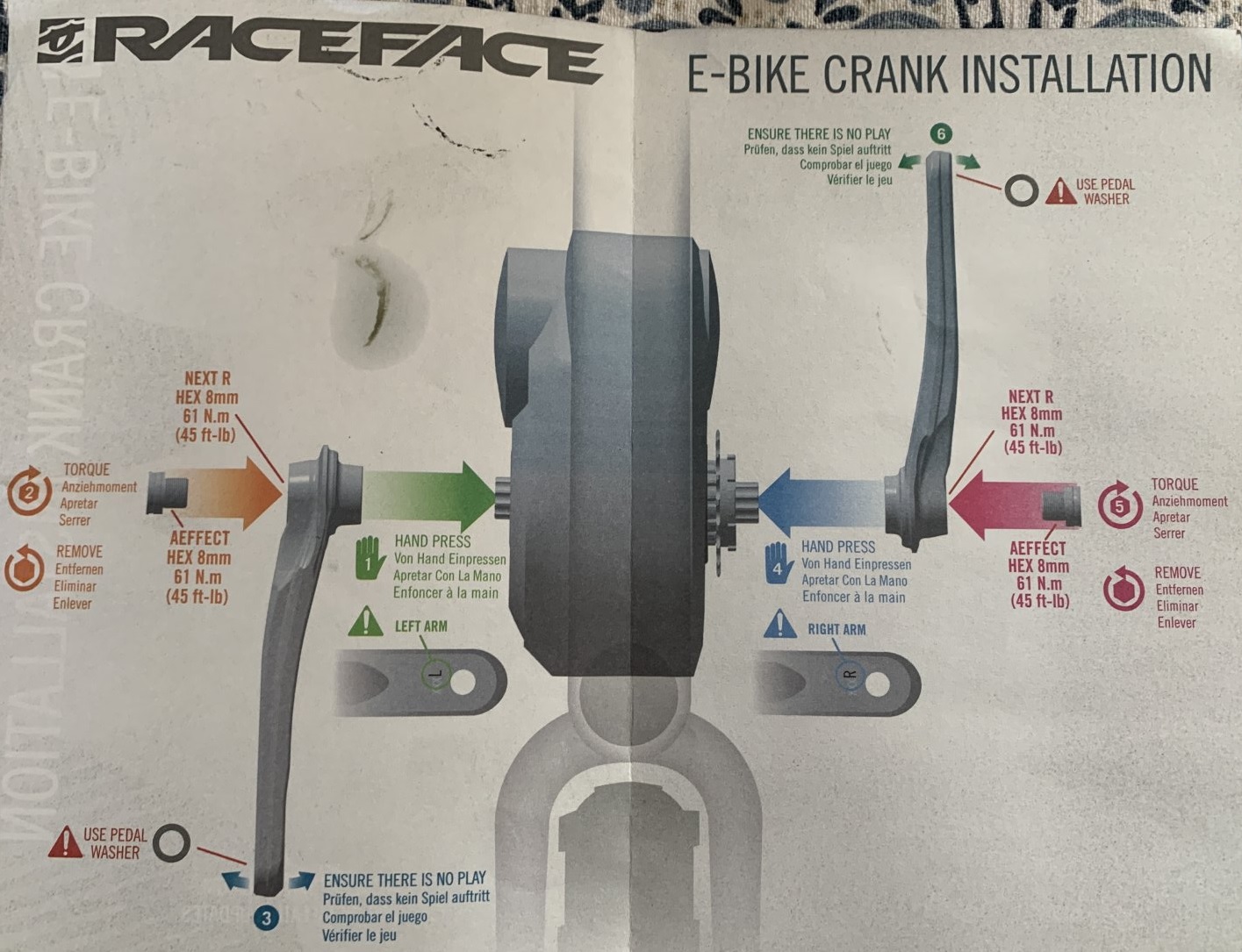

RaceFace Cranks

Yeah, cranks on both sides cw tighten ccw loosen. It's the pedals that have opposite threadsI saw that, but it makes me thing both sides are right hand threads.?

Yes, they're both right-hand thread.I saw that, but it makes me thing both sides are right hand threads.?

I did the same thing and swapped to160mm e13 Crankarms but just torqued by feel and never had them come loose. Interesting that ur driveside was the wobbly side as its usually the non drive side falling off. I did have the original 165mm ND side fall off once.I installed 160mm aluminum e*spec arms on my Rail 9.7. At the end of my first ride (~24 miles), the driveside arm was wobbly loose while the non-driveside arm bolt was just in need of tightening. I contacted e*thirteen to inform them of the situation, stating I had used the original installation instructions as guidence with 40Nm applied to the hardware. They wanted to confirm I applied grease to the spindle and then suggested moving up to 45Nm torque for the bolts. I put the higher amount of torque to the hardware, added some paint lines for visual reference and all seems to be fine now after additional ride time.

Just curious if this is happening. Thanks

The World's largest electric mountain bike community.