Richardsuperstar

New Member

I have a Trek Rail 9 which like many has the usual creaks and clicks.

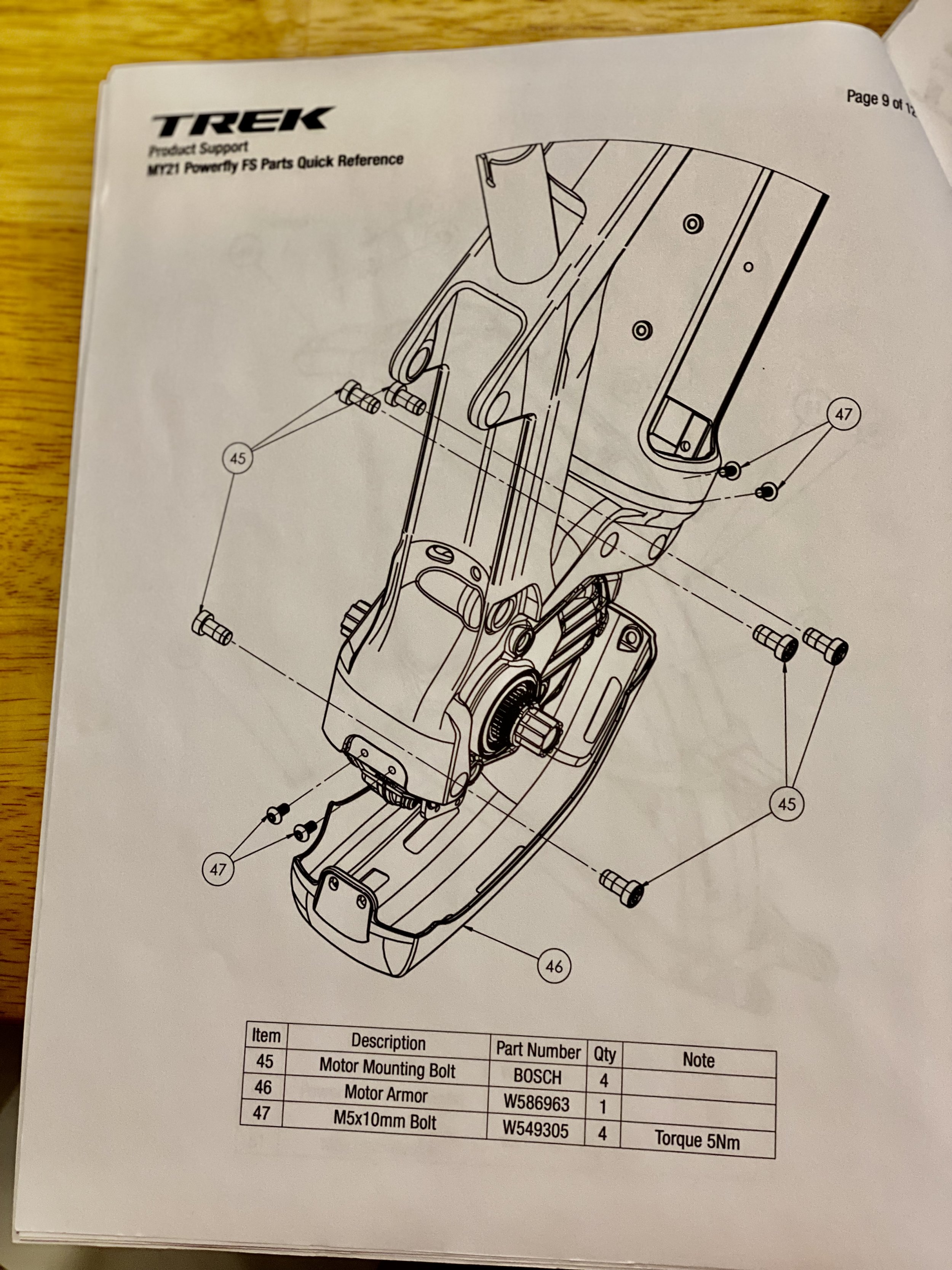

I think i have narrowed mine down to the mounting plates on the motor. There appears to be 8 Torx T25 bolts holding these plates to the main motor one of which seems to have come loose and the others dont seem to be that tight.

The question is though how tight do these need to be. I found a maintenance manual on here for Bosch motors which states these plates are secured up to 11nm but that seems pretty much for what I believe is a M5 thread.

Other than that I can't find any other info other than the main 6 that holf the motor to the frame.

So any ideas much appreciated.

I think i have narrowed mine down to the mounting plates on the motor. There appears to be 8 Torx T25 bolts holding these plates to the main motor one of which seems to have come loose and the others dont seem to be that tight.

The question is though how tight do these need to be. I found a maintenance manual on here for Bosch motors which states these plates are secured up to 11nm but that seems pretty much for what I believe is a M5 thread.

Other than that I can't find any other info other than the main 6 that holf the motor to the frame.

So any ideas much appreciated.