vman

Active member

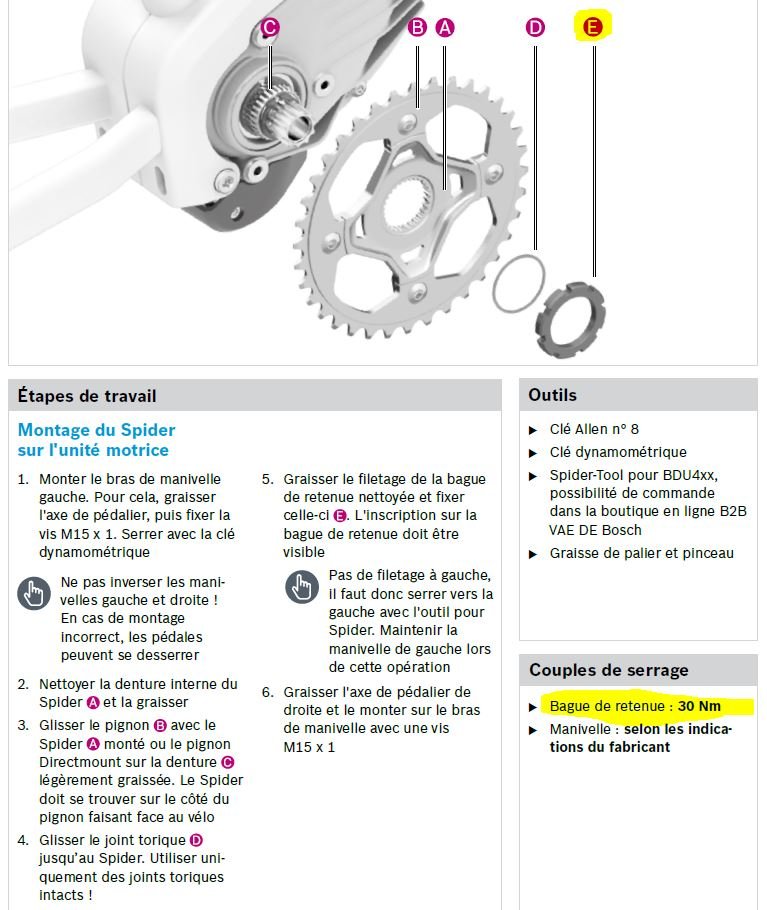

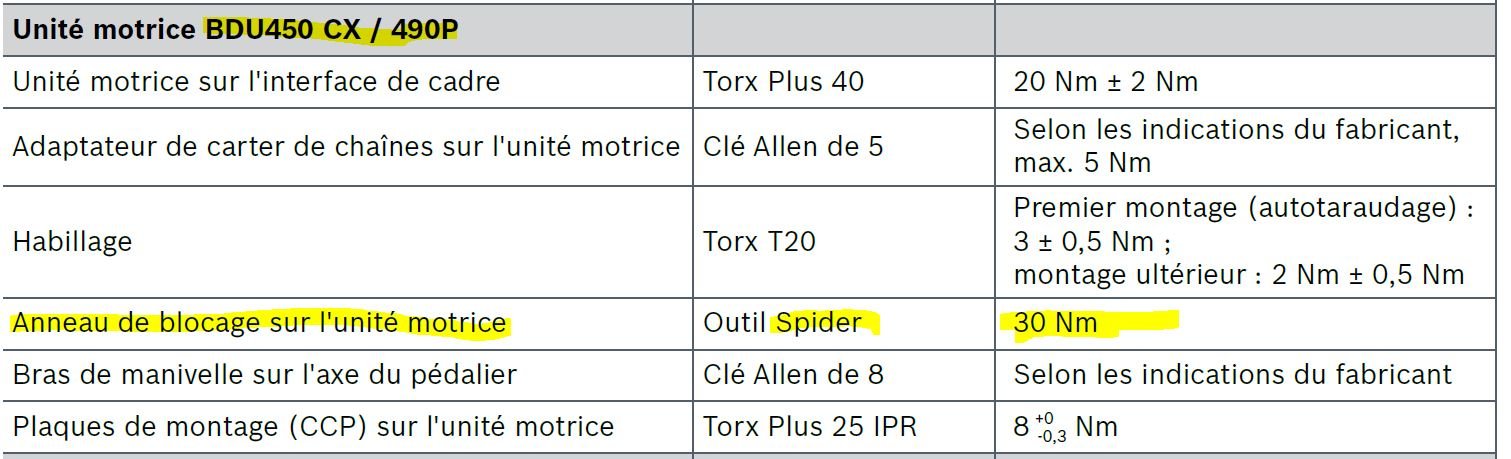

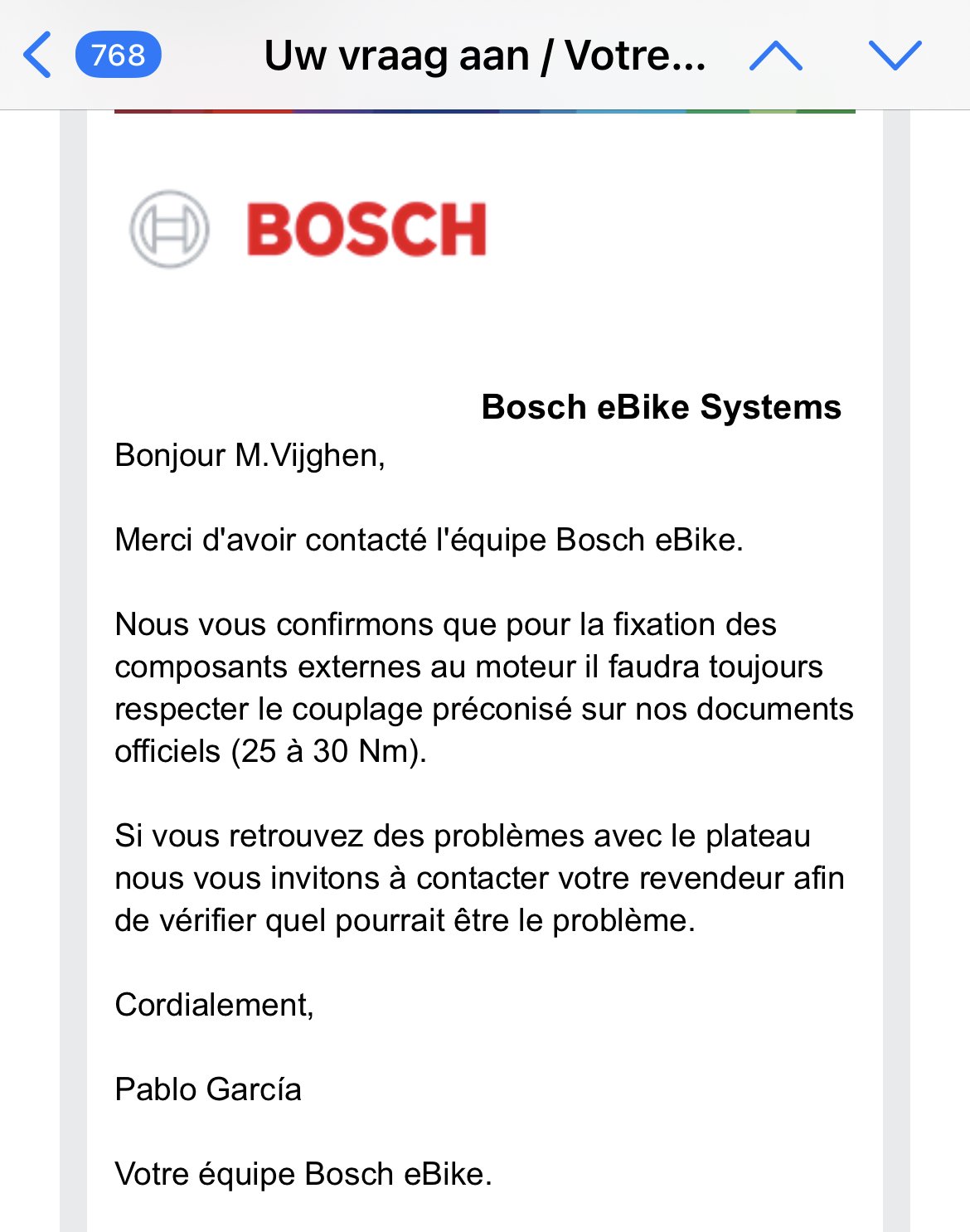

After following Bosch instructions (grease don't loctite) the chain ring lockring nut to 25 to 30 NM and having it fall off 3 times I was pretty annoyed and about to start looking into drilling it out and using safety wire. I even went to the local Trek Dealer and had them torque it down in case my torque wrench was to blame. Most local Trek dealers just state the Torque is 25 to 30 NM (as printed on the part) - when you call Bosch if you are lucky you will get someone who will read an outdated manual and confirm the old torque spec. However, what Bosch consumer support and most Trek folks don't know is a Technical Service Bulletin was issued by Bosch that stated the spec on the lockring is actually 40 NM to 45 NM. When my wife and I dropped both chain rings while riding on vacation, thankfully we found a local mechanic who actually cared about solving the problem and informed me of the change in torque spec - he torqued the lockrings on both our Trek Rails to 45 NM and so far after 300 miles they have not moved.

V

V