You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bosch CX gen 4 chainring nut

- Thread starter WilkyWay

- Start date

I used this tool: 8.95eur

Fits perfectly.

and went from 36t to 34t:

www.bike-discount.de

www.bike-discount.de

Fits perfectly.

and went from 36t to 34t:

e*spec Steel Direct Mount Chainring Bosch CX Gen4

Features - e*thirteen e*spec Steel Direct Mount Chainring Chainring for 10-, 11- and 12-speed Chain line 52mm (Boost) M3 narrow-wide tooth profile eliminates chain noise and decreases overall system wear Product features...

www.bike-discount.de

www.bike-discount.de

Last edited:

Well, I lubed the chain yesterday and noticed that the chainring was loose!Used blue thread lock and it hasn’t moved since. No O ring.

To get home I put the bike into eMTB mode and placed as little pressure on the pedals as possible.

When home I took the crank off, followed by the nut. Cleaned all the threads on both the lockring nut and motor spindle. I could not use the nut again as normal as the first couple of threads had been damaged. I turned the nut around and tried it on and it was ok.

So at the moment I am using the same lockring back to front with a good amount of blue threadlock. Lets see how long this lasts.

Two new lockrings on order.

In my humble opinion chain ring nuts should not come loose ..period. Why is is this acceptable? To me way back in the 70’s 80’s wheels used to come off trucks…okay showing my age, but when was the last time you had to check your fly wheel bolts torque apart from when you may have replaced a clutch…

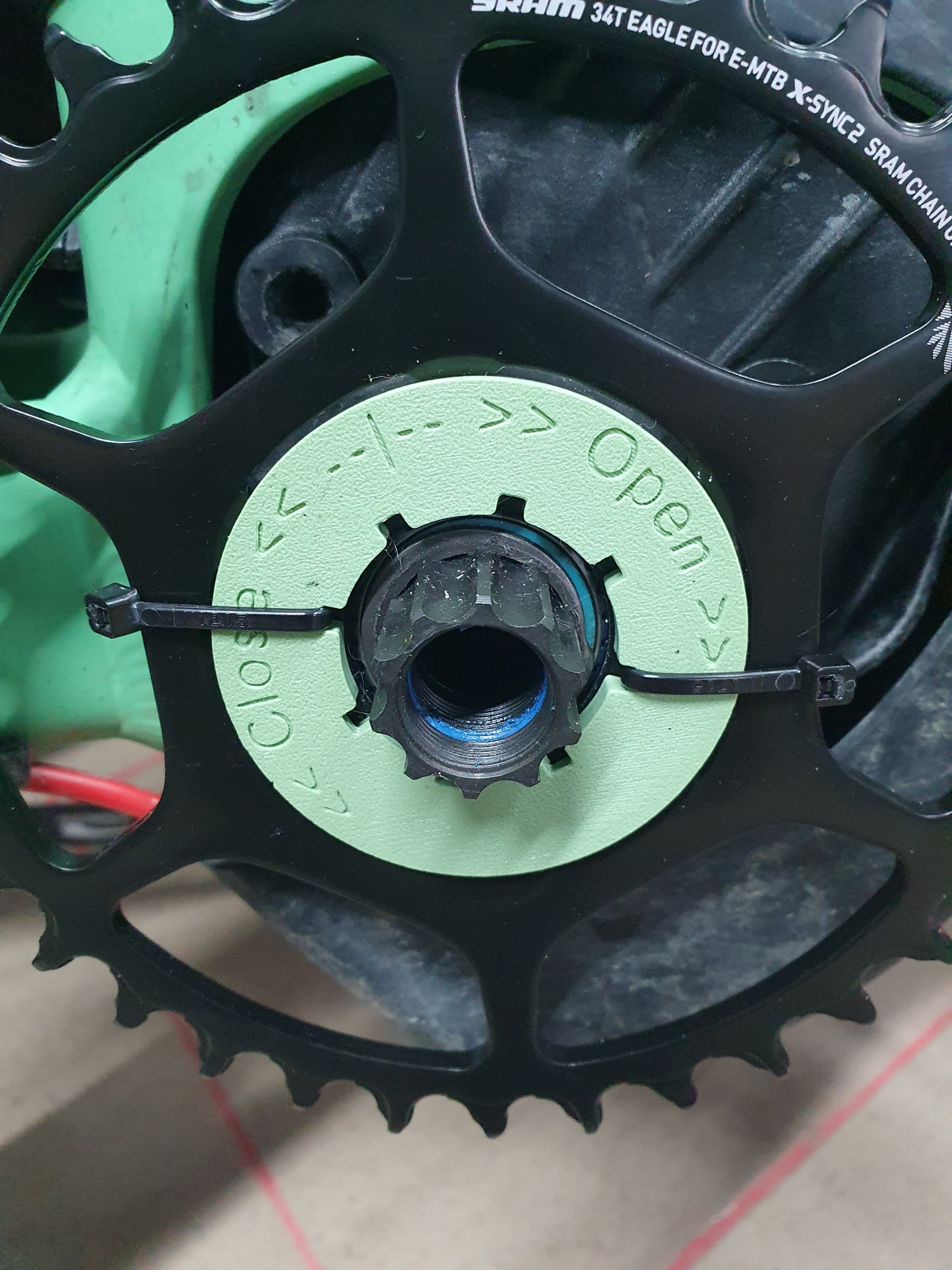

Brilliant!I have recently got a Cube Reaction Hybrid and the the chainring got completely loose (while riding) so I have designed and 3D printed this contraption.

Seems to be fine after 30km, worse case scenario it will act like a warning, zipties broken = time to re-tighten the locknut.

View attachment 107711 View attachment 107712

Are you willing to share the .stl file?

@Zaskar20 I was thinking of putting it (stl or actual part) up for sale but ditched the idea, mainly because I'm lazy  .

.

It only fits a Sram boost chainring because of the 6 mm offset makes a curve on the chainring where this slots in.

If you are interested (and have an Sram chainring) I'll put it up a 3D printing website and PM you the link.

Just out of curiosity how much would you be willing to pay for this STL / printed part?

It only fits a Sram boost chainring because of the 6 mm offset makes a curve on the chainring where this slots in.

If you are interested (and have an Sram chainring) I'll put it up a 3D printing website and PM you the link.

Just out of curiosity how much would you be willing to pay for this STL / printed part?

I have never seen anyone specifically state this but in my opinion that ring nut is single use only. The reason I say that is because it has a very short threaded length and yet is secured to a pretty high torque ( typically 25nm). In my opinion that means it relies on the threads being "spread" by that torque in order to gain maximum grip on the motor crank.....in other words the threads on the ring nut are sacrificial. Persoanlly I would use a new ring nut if I changed the chainring or if the existing ring nut came loose.

Why mess a bout? A new one for Bosch CX is c £8 ( BDU4XX 1270014085)

Why mess a bout? A new one for Bosch CX is c £8 ( BDU4XX 1270014085)

Last edited:

I don’t think so.I have never seen anyone specifically state this but in my opinion that ring nut is single use only.

The Bosch manual states to clean the ring nut threads, apply some grease and then re-mount the nut.

The CX motor crank is standard ISIS and the chainwheels to fit are all 3rd party with varying offsets and some with a recess for an O ring and some not. Bosch do however sell a lockring . Ensure threads are clean is always a good move on any fixing but apply grease on such a short amount of thread?? No reason, there will be little or not friction. Apply a little grease on the facing elements of the chainwheel and lockring OK but not the threads. ........... Never seen any manual from Bosch on fitting a chainwheel.....................give a link to the manual?I don’t think so.

The Bosch manual states to clean the ring nut threads, apply some grease and then re-mount the nut.

@Mikerb

Only the spline dimensions of the crank shaft are standard ISIS. The whole shaft construction including the threaded part to fix the spider/chainring is an integral part of the motor and proprietary Bosch. You buy the spidernut from Bosch and not from a crank or chainring manufacturer.

The threads are not sacrificial, but of course they can become worn out over time and multiple mountings just like any other screw or nut.

Check the manual here: Bosch 2020 Dealer Manual

Only the spline dimensions of the crank shaft are standard ISIS. The whole shaft construction including the threaded part to fix the spider/chainring is an integral part of the motor and proprietary Bosch. You buy the spidernut from Bosch and not from a crank or chainring manufacturer.

The threads are not sacrificial, but of course they can become worn out over time and multiple mountings just like any other screw or nut.

Check the manual here: Bosch 2020 Dealer Manual

I've published my little contraption on Printables (Printables) if anyone wants to print it and marvel at its genius

Ark

Active member

IF anyone in the UK wants to print it out then check your local libraries one likely has a 3d printer

I think officially they are called "maker spaces"

there's a list on a gov website but most the links seem dead and it's definetly out of date because my city centre library has one and it's not on the list

www.gov.uk

www.gov.uk

I think officially they are called "maker spaces"

there's a list on a gov website but most the links seem dead and it's definetly out of date because my city centre library has one and it's not on the list

Libraries and makerspaces

OK thanks......................page 116 to save other trawling through.@Mikerb

Only the spline dimensions of the crank shaft are standard ISIS. The whole shaft construction including the threaded part to fix the spider/chainring is an integral part of the motor and proprietary Bosch. You buy the spidernut from Bosch and not from a crank or chainring manufacturer.

The threads are not sacrificial, but of course they can become worn out over time and multiple mountings just like any other screw or nut.

Check the manual here: Bosch 2020 Dealer Manual

The manual details how to remove and install various components including the spider or DM chainwheel and yes it does say clean and lightly grease it but it does not specify anything with regard to re-use of the lockring, and in most cases that lockring will have been in place for a considerable period of time.........................or maybe it has come loose

Personally, I see no reason to apply grease since the main reasons to do so, on any fixing, are to prevent binding when trying to remove at a later date, and to ensure minimal friction which would make it more difficult to achieve the correct torque. The amount of thread is so small, neither is likely with the lockring, and grease could prevent the needed thread pitch friction to keep it secured given the relatively low torque setting.

I will stick to basic principles for fasteners however when it comes to whether a fastener is suitable for re use. My chainring typically outlasts chain changes and up to 3 cassette changes so £8 for a new lockring on top of the cost of a new DM chainring is my choice.................and I never had one comes loose. If I was forced to refit the existing lockring as an interim measure, I would use blue loctite ( and no grease!).

Last edited:

You wouldn’t need to clean the threads if you should use a new lockring.yes it does say clean and lightly grease it but it does not specify anything with regard to re-use of the lockring,

The chain ring nut is delivered with the motor and you would only need a new one when it’s broken or worn out.

On one of my bikes the lockring is nearly 10,000 km old and has outlived three chainrings without any signs of wear.

But if it makes you feel better just put a new one on with every new chainring. As you mentioned they don’t cost that much.

....well, as I said above....and regardless of advice in the Bosch manual...........I do not believe a lockring comprising so few threads needs or indeed should have grease applied.................neither should the lockring be re-used if changing the dm chainring/spider or if the lockring has come loose. Basic understanding of how a threaded fastener works in terms of thread pitch friction and a torque setting just below the shear point tells you that. If the torque setting was somewhat less...say 10nm........I would say it would need threadlock because it infers the thread of one or other ( maybe both) elements of the fastening, are too soft for a near sheer point torque. This fastener has, for the amount of thread involved a relative high torque setting of 25nm. So I would fit it without grease and without thread lock.In shock to see how many have lose lockrings. Same here on my cx smart after 250, fully lose. Makes me wonder if its an assembly issue due to the amount of grease or there is a more structural issue in how its mounted

nb ever wondered how many bike mechanics have a 2 way torque wrench!!

Last edited:

Agree with you, i have now also just cleaned the treahds from grease, and lucky enough to have a 2 way torque wrench myself. On the other end, never seen my LBS use one.

With my bike i noticed also the casette was not torqued to spec and same goes for the brake levers and stem.

With my bike i noticed also the casette was not torqued to spec and same goes for the brake levers and stem.

HORSPWR

E*POWAH Master

I'd just drill it and pin it and be done with it. 20 minutes and you could have it done!

I'd drill and tap a small threaded hole in the chainring in between one of the nut cutouts and fit a small socket head cap screw (and Loctite that), that nuts not going anywhere unless that cap screw comes out first!

I'd drill and tap a small threaded hole in the chainring in between one of the nut cutouts and fit a small socket head cap screw (and Loctite that), that nuts not going anywhere unless that cap screw comes out first!

Wilbur

Member

Thanks for the links.I used this tool: 8.95eur

Fits perfectly.

and went from 36t to 34t:

e*spec Steel Direct Mount Chainring Bosch CX Gen4

Features - e*thirteen e*spec Steel Direct Mount Chainring Chainring for 10-, 11- and 12-speed Chain line 52mm (Boost) M3 narrow-wide tooth profile eliminates chain noise and decreases overall system wear Product features...www.bike-discount.de

Tyjay

Active member

Quick question been given a cube with the lock ring on but no chainring on

so when I turn it clockwise to loosen it, it obviously spins the motor as theres nothing to stop it from spinning

its an oldish bike probably gen 1/2 motor said I’d have a look and get it working again but can’t do anything if I can’t removing locking ring

any Ideas what I can do there’s not much space between lock ring and frame

so when I turn it clockwise to loosen it, it obviously spins the motor as theres nothing to stop it from spinning

its an oldish bike probably gen 1/2 motor said I’d have a look and get it working again but can’t do anything if I can’t removing locking ring

any Ideas what I can do there’s not much space between lock ring and frame

Tyjay

Active member

thanksMight put the chainring on which you can then use to lock the crank with a stick/screwdriver etc & use an adjustable wrench or mole grips to loosen the lock ring. If you're careful you might even save it!

cant put the chainring back on

Iv tried a screwdriver between the lock ring and frame hopefully trying to jam the spindle from spinning but can’t get enough to stop it

Have to say bike has sat for over a year and was gonna be ”scrapped“ but I didn’t want to see that

If I had a third of the chainring it might fit in the gap and I could probably loosen it that way

but currently stuck for a more simple solution

Tyjay

Active member

It goes behind the lock ringWhy cant you put the chain ring back on?

chainnring then lock ring

but because the lockring has been put on the motor just spins so can’t remove it to put chainring on

proper stuck

Yes but the amount of space is the same just in reverse, so you could still put the chain ring on, use it to lock the crank and find a way to knock the lock ring loose eg. a screwdriver & hammer. A lock ring is about eight quid, so even sacrificing it shouldn't be an issue.

Get two of you on it, one to hold the chain ring still & wedged against the frame with something while you knock the lock ring off & it's job done.

Get two of you on it, one to hold the chain ring still & wedged against the frame with something while you knock the lock ring off & it's job done.

Tyjay

Active member

Appreciate the reply but there’s nothing to put the chainring on the lock ring is at the end of the threads so nothing to grab onto if u get what I’m sayingYes but the amount of space is the same just in reverse, so you could still put the chain ring on, use it to lock the crank and find a way to knock the lock ring loose eg. a screwdriver & hammer. A lock ring is about eight quid, so even sacrificing it shouldn't be an issue.

Get two of you on it, one to hold the chain ring still & wedged against the frame with something while you knock the lock ring off & it's job done.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 556K

- Messages

- 28,082

- Members

Latest articles

-

Santa Cruz Vala X0 review - a new approach to perfection?

The new Vala is Santa Cruz’ first attempt on a Bosch-powered emtb. Like...- Knut Nes

- 6 min read

- Views: 1K

- Reaction score: 5

- Comments: 4

-

A new standard for charging ebikes is coming? A quick interview with Bosch - charge2bike

I had a quick chat with dr Vikram Godbole about "charge2bike", a new...- Knut Nes

- 2 min read

- Views: 899

- Reaction score: 7

- Comments: 4