Does it let you change the motor settings ?I have the ver 3 vitus display and my phone is on android 14 and go+ works perfectly but it wont work with go something to do with the bluetooth version i think but go+ is very good for adjusting the motor settings, as far as you can with an app

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bafang m510

- Thread starter Puschtrale

- Start date

iscander13

Member

I have a v3 display, with a fresh version of android and GO+ tells me "operation failed"Can you not do it with go+?

iscander13

Member

what SW do you have on v3 display?I have the ver 3 vitus display and my phone is on android 14 and go+ works perfectly but it wont work with go something to do with the bluetooth version i think but go+ is very good for adjusting the motor settings, as far as you can with an app

Dado

Well-known member

Hard to say, dont understand to that labelling.BTW: what's the latest firmware version for the DSP 245 v2?

Have these. 2 of them are with custom brand startup animation.

Karamba!

Member

Are those for v2 or v3?Hard to say, dont understand to that labelling.

Have these. 2 of them are with custom brand startup animation.

View attachment 135560

Dado

Well-known member

Also the one with 3.0 in a name is possible to flash to v2 display.Are those for v2 or v3?

Karamba!

Member

What's new in them, do they bring any new functionality ot fix?Also the one with 3.0 in a name is possible to flash to v2 display.

Dado

Well-known member

I can not see much. Some new languages, no new themes.What's new in them, do they bring any new functionality ot fix?

Karamba!

Member

Thanks DadoI can not see much. Some new languages, no new themes.

Not sure, it has the vitus flash screen but as far as i can tell ver 2 is bluetooth 5.0 and ver 3 is 5.1what SW do you have on v3 display?

Cant see any other reason why bafang go wont connect to ver 3 only the later bafang go+ will connect

Hi Petr, i have also Leader Fox (Acron precisely) with M510, but i have no such behaviour as you are describing here, mine is buttery smooth even when peddaling low. Although i have different software version. My first motor died after like 100km, controller stopped working, but they send me a new motor unit.Hello everyone. I have a new bike. Leader fox with bafang m510 and LG 36V battery. I have a terrible on-off issue once pedaling lightly. Leader Fox suggested a new motor but the seller is sending me besst tool and firmware to flash. I want to flash the FW first as it is difficult to send the whole bike via post to them.

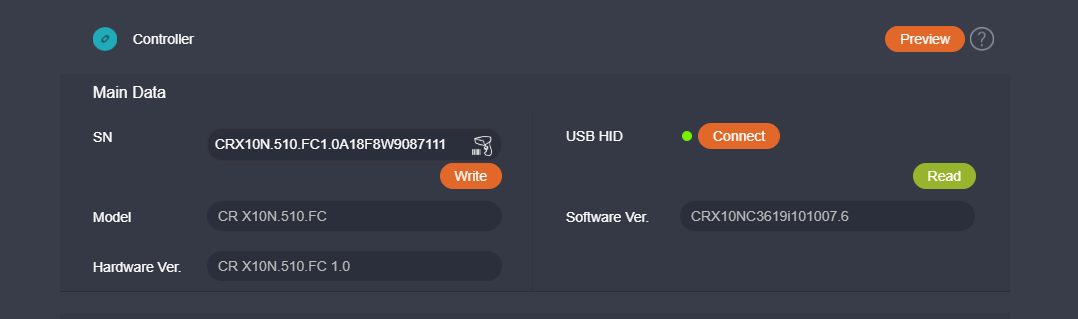

Can somebody tell me if my actual FW version is old or not?

And can somebody assist me while I try to flash my bike? Maybe @Dado if you find some time it would be great.

Thank you all. BR Petr

View attachment 134925 View attachment 134926

Hi,

I just rolled the dice on a 'dead' e-mythique. Thanks to everyone here for all the information so far, especially @Zimmerframe and @Dado for everything in the public, and also any/all of the information in the open source project on github.

Thanks to that, i've been able to acquire a compatible charger, trick the bike into powering on and identify the first issue with the display and keypad.

The 245 controller has weak (or no) pullups on the button inputs from what I can tell, which is causing phantom button presses, resulting in both the error 05 and 35. I threw together a little board with some switches and 10k's to 3v3 and the controller now behaves correctly, no faults or errors. Might at some point turn it into an inline fix for any E-mythiques presenting this fault that are no longer able to get support from CRC/Wiggle.

The 245 Controller also has no 120R termination resistor on the CAN. Not a gamechanger, but i'm a lot happier with one in place. I've started to generate a CAN DBC file for it, mainly out of curiosity as I don't think it really has any utility beyond what can be done with presumably the K1 devices or BESST.

I do have a few questions that might be answered elsewhere, although i have looked, so I would appreciate if anyone can help.

1. Compared to the E8000, the cranks are very stiff, I can hang a 1kg water bottle off the pedal when the crank is at 3 o'clock without it moving. Is this normal, or should I dig a little deeper?

2. What is your torque signal with no load? Mine is at 760ish mv, and when putting the bike into a mode, it tries to go on it's own. Hanging the 1kg bottle on the bike puts it at around 790mv, and I can get it up past 3000mv with bodyweight. It appears to be working, but uncalibrated.

3. Are each firmware version unique to the hardware configuration and battery configuration?

4. I read on another thread that someone replaced the display on a Vitus with an alternative model (I can't remember which), but doing so lost the calibration for the motor, even when returning to the stock display. At some point I would like to get rid of the display in favour of an E181, am I likely to reach the same fate? (and with a BESST or K1, can I backup my settings and load them in when the alternative part is fitted?)

Finally, I've been continuing to risk purchasing from Chiggle, as such I have a number of spares including cranks, cables, top and bottom battery mounts, displays, speed sensors, and even managed to snag a 2nd battery. If anyone does have an issue that can't be resolved by Aliexpress, send me a message. I don't really want to hoard, but at the same time I'm trying to prepare for zero support.

Edit: Also, if you have a 245 and think the display is plastic, allowing you to remove the pcb, be careful, it's glass, and glued to the LCD. If you break it you'll also break the screen. Part is: Here for a replacement 30pin 1.9" 170x320 LCD, then you'll need a small rectangle of plexi to cover it.

I just rolled the dice on a 'dead' e-mythique. Thanks to everyone here for all the information so far, especially @Zimmerframe and @Dado for everything in the public, and also any/all of the information in the open source project on github.

Thanks to that, i've been able to acquire a compatible charger, trick the bike into powering on and identify the first issue with the display and keypad.

The 245 controller has weak (or no) pullups on the button inputs from what I can tell, which is causing phantom button presses, resulting in both the error 05 and 35. I threw together a little board with some switches and 10k's to 3v3 and the controller now behaves correctly, no faults or errors. Might at some point turn it into an inline fix for any E-mythiques presenting this fault that are no longer able to get support from CRC/Wiggle.

The 245 Controller also has no 120R termination resistor on the CAN. Not a gamechanger, but i'm a lot happier with one in place. I've started to generate a CAN DBC file for it, mainly out of curiosity as I don't think it really has any utility beyond what can be done with presumably the K1 devices or BESST.

I do have a few questions that might be answered elsewhere, although i have looked, so I would appreciate if anyone can help.

1. Compared to the E8000, the cranks are very stiff, I can hang a 1kg water bottle off the pedal when the crank is at 3 o'clock without it moving. Is this normal, or should I dig a little deeper?

2. What is your torque signal with no load? Mine is at 760ish mv, and when putting the bike into a mode, it tries to go on it's own. Hanging the 1kg bottle on the bike puts it at around 790mv, and I can get it up past 3000mv with bodyweight. It appears to be working, but uncalibrated.

3. Are each firmware version unique to the hardware configuration and battery configuration?

4. I read on another thread that someone replaced the display on a Vitus with an alternative model (I can't remember which), but doing so lost the calibration for the motor, even when returning to the stock display. At some point I would like to get rid of the display in favour of an E181, am I likely to reach the same fate? (and with a BESST or K1, can I backup my settings and load them in when the alternative part is fitted?)

Finally, I've been continuing to risk purchasing from Chiggle, as such I have a number of spares including cranks, cables, top and bottom battery mounts, displays, speed sensors, and even managed to snag a 2nd battery. If anyone does have an issue that can't be resolved by Aliexpress, send me a message. I don't really want to hoard, but at the same time I'm trying to prepare for zero support.

Edit: Also, if you have a 245 and think the display is plastic, allowing you to remove the pcb, be careful, it's glass, and glued to the LCD. If you break it you'll also break the screen. Part is: Here for a replacement 30pin 1.9" 170x320 LCD, then you'll need a small rectangle of plexi to cover it.

Last edited:

Torque signal with no load is normally about 750 or 760, so sounds like yours is correct.Hi,

I just rolled the dice on a 'dead' e-mythique. Thanks to everyone here for all the information so far, especially @Zimmerframe and @Dado for everything in the public, and also any/all of the information in the open source project on github.

Thanks to that, i've been able to acquire a compatible charger, trick the bike into powering on and identify the first issue with the display and keypad.

The 245 controller has weak (or no) pullups on the button inputs from what I can tell, which is causing phantom button presses, resulting in both the error 05 and 35. I threw together a little board with some switches and 10k's to 3v3 and the controller now behaves correctly, no faults or errors. Might at some point turn it into an inline fix for any E-mythiques presenting this fault that are no longer able to get support from CRC/Wiggle.

The 245 Controller also has no 120R termination resistor on the CAN. Not a gamechanger, but i'm a lot happier with one in place. I've started to generate a CAN DBC file for it, mainly out of curiosity as I don't think it really has any utility beyond what can be done with presumably the K1 devices or BESST.

I do have a few questions that might be answered elsewhere, although i have looked, so I would appreciate if anyone can help.

1. Compared to the E8000, the cranks are very stiff, I can hang a 1kg water bottle off the pedal when the crank is at 3 o'clock without it moving. Is this normal, or should I dig a little deeper?

2. What is your torque signal with no load? Mine is at 760ish mv, and when putting the bike into a mode, it tries to go on it's own. Hanging the 1kg bottle on the bike puts it at around 790mv, and I can get it up past 3000mv with bodyweight. It appears to be working, but uncalibrated.

3. Are each firmware version unique to the hardware configuration and battery configuration?

4. I read on another thread that someone replaced the display on a Vitus with an alternative model (I can't remember which), but doing so lost the calibration for the motor, even when returning to the stock display. At some point I would like to get rid of the display in favour of an E181, am I likely to reach the same fate? (and with a BESST or K1, can I backup my settings and load them in when the alternative part is fitted?)

Finally, I've been continuing to risk purchasing from Chiggle, as such I have a number of spares including cranks, cables, top and bottom battery mounts, displays, speed sensors, and even managed to snag a 2nd battery. If anyone does have an issue that can't be resolved by Aliexpress, send me a message. I don't really want to hoard, but at the same time I'm trying to prepare for zero support.

Swapping a display shouldn't affect the motor settings. I swapped to a v3 and go+ wiped all my motor settings. Seen this a few times now, it doesn't always read the motor settings and replaces everything with zeros instead.

Waynemarlow

E*POWAH Master

Mike, you maybe better looking over on Bafang M500/M600 thread where there are a couple of very knowledgable guys on there ( CiDi for one ) who have already logged the CAN signals. They may be able to save you considerable time.I've started to generate a CAN DBC file for it, mainly out of curiosity as I don't think it really has any utility beyond what can be done with presumably the K1 devices or BESST.

There are number of replacement screens, have a look at 20.55£ 45% OFF|Bicycle Display Bafang | Bafang Bbs 02 Display | Bafang Bbs01 Display - Dz41 Bbs0102 03 - Aliexpress is the one Neeko used. I have one and not using it if you want a repalcement.

The older M600 keypad will also fit, not quite as tactile but quite bash resistant, I've already broken one of the DPC245 keypads ( caught it on a fence post going through a gate ). They can be purchased off AliExpress.

Last edited:

Having same issues and error codes 36 and 05. Does this DZ41 plug and play with the 510 FC2.0 because it looks exactly what i'd like coming from the Bosch Purion.Mike, you maybe better looking over on Bafang M500/M600 thread where there are a couple of very knowledgable guys on there ( CiDi for one ) who have already logged the CAN signals. They may be able to save you considerable time.

There are number of replacement screens, have a look at 20.55£ 45% OFF|Bicycle Display Bafang | Bafang Bbs 02 Display | Bafang Bbs01 Display - Dz41 Bbs0102 03 - Aliexpress is the one Neeko used. I have one and not using it if you want a repalcement.

The older M600 keypad will also fit, not quite as tactile but quite bash resistant, I've already broken one of the DPC245 keypads ( caught it on a fence post going through a gate ). They can be purchased off AliExpress.

Waynemarlow

E*POWAH Master

Not actually sure as I bought it in and stuck it on the shelf as a spare as I had eyesight problems with the older DPC242, I'll have a look in the next couple of days.Having same issues and error codes 36 and 05. Does this DZ41 plug and play with the 510 FC2.0 because it looks exactly what i'd like coming from the Bosch Purion.

I think Neeko had a vid of it but I can only find the short clip Quick Peak of the DZ41 display (CANBus) hooked up to the Dengfu E10v1. He's stating its on his M600 so I guess it should run on the M510.

Dengfu E22 Frame Thread

Just in case, here is the instructions for the DZ41 display 👍🏿

Last edited:

vikino1

Active member

I use DZ 41 on the M500, it's really just a basic display, but it's enough for normal driving.

I ordered this display:

You can change max. speed and wheel circumference after entering the code and has quite a lot of functions.

Page Not Found - Aliexpress.com

I ordered this display:

You can change max. speed and wheel circumference after entering the code and has quite a lot of functions.

Page Not Found - Aliexpress.com

Last edited:

Dado

Well-known member

Seeing quite a high failure of buttons very quick... How hard is to put there proper buttons.

Anyone have any tips on how to get the nut loose, that holds the chainring spider on the spindle?

I got the tool from Bafang with the 4 teeth, but just bent the teeth without any budge of the nut.

Now printed a tool that fits on the nut, but so hard to hold against with a chain tool.

Feels like a lot more than the 35Nm of torque that is indicated on the nut.

Any tips?

Youtube videos for taking the motor apart always start after this has already been removed.

I got the tool from Bafang with the 4 teeth, but just bent the teeth without any budge of the nut.

Now printed a tool that fits on the nut, but so hard to hold against with a chain tool.

Feels like a lot more than the 35Nm of torque that is indicated on the nut.

Any tips?

Youtube videos for taking the motor apart always start after this has already been removed.

I assume you know its a left hand thread?Anyone have any tips on how to get the nut loose, that holds the chainring spider on the spindle?

I got the tool from Bafang with the 4 teeth, but just bent the teeth without any budge of the nut.

Now printed a tool that fits on the nut, but so hard to hold against with a chain tool.

Feels like a lot more than the 35Nm of torque that is indicated on the nut.

Any tips?

Youtube videos for taking the motor apart always start after this has already been removed.

Yes, well I assumed it as the arrow shows to the right with 35 NmI assume you know its a left hand thread?

Err ok to the right loosens it to the left tightens it at least it does on my m510Yes, well I assumed it as the arrow shows to the right with 35 Nm

I only mention it cos it caught me out for a bit

Hope you get it undone

adam271226

New Member

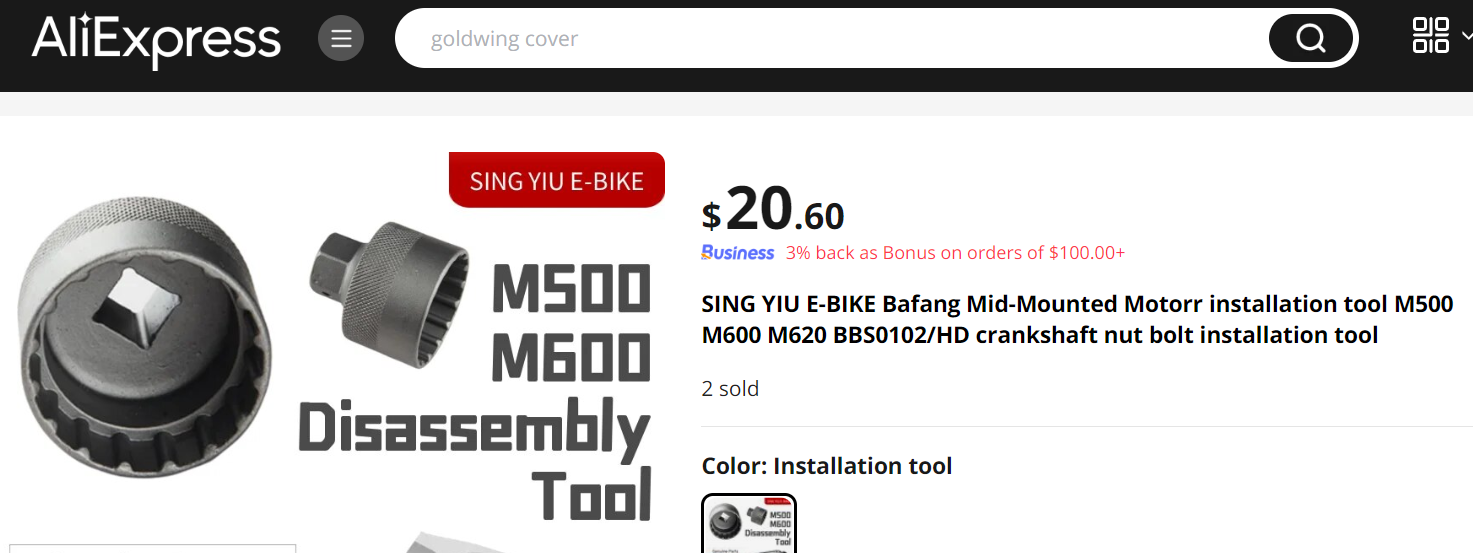

If motor is installed in the frame with wheel and chain still on you can use a helper to hold the the wheel as you apply firm force down (so tool does not slip) and to the right to loosen. Use of a penetrating oil (Kroil Penetrant) 5-10 minutes before you start may help. I used impact gun to loosen chairing nut on several bikes that were "stuck" but since I have been applying very small amount of anti-seize compound on threads I have not had a problem . I use a tool received from aliexpress for this job with slight modification. Tool has semi-rounded edge and I found that it would slip so I ground the end of the socket flat. Attached is a picture of the unmodified tool as example but I think this tool can be purchased on other websites (faster delivery, if nothing else).Anyone have any tips on how to get the nut loose, that holds the chainring spider on the spindle?

I got the tool from Bafang with the 4 teeth, but just bent the teeth without any budge of the nut.

Now printed a tool that fits on the nut, but so hard to hold against with a chain tool.

Feels like a lot more than the 35Nm of torque that is indicated on the nut.

Any tips?

Youtube videos for taking the motor apart always start after this has already been removed.

Those tips sound great. I am just installing the spare motor I bought (to buy some time to fix the other one), but I'll give the penetrating oil another go and especially I will try that tool.

Main problem at the moment is the original Bafang tool bends eben with little force used and that cuts off the whole process right at the start.

The tool only lists M500 and M600, but I'm guessing the nut on the M510 has the same measurements.

Thanks a lot for the advice.

Main problem at the moment is the original Bafang tool bends eben with little force used and that cuts off the whole process right at the start.

The tool only lists M500 and M600, but I'm guessing the nut on the M510 has the same measurements.

Thanks a lot for the advice.

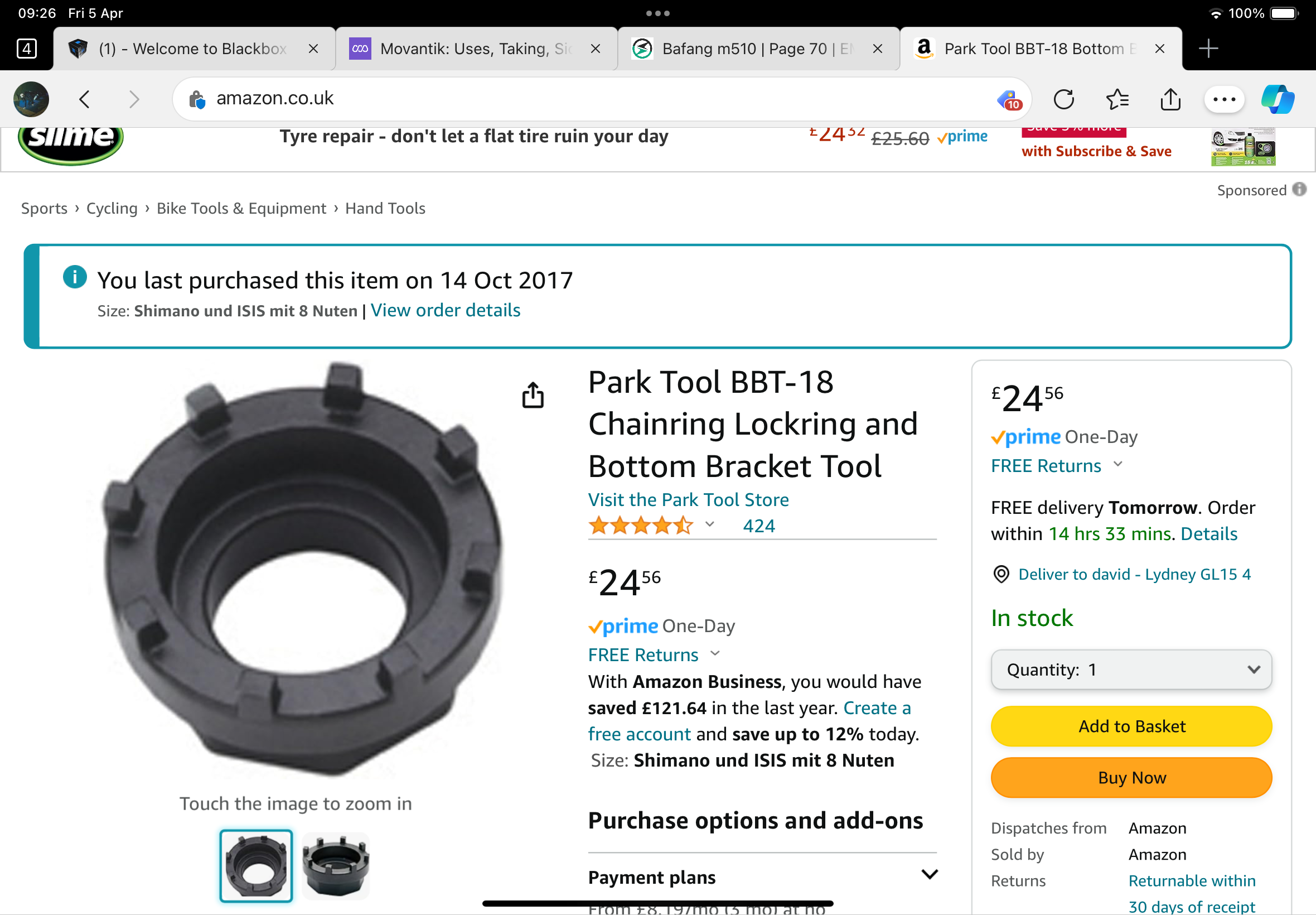

Thanks, this tool looks more like it would fit. I'll see what the Amazon version looks like, but might go for the original.I use this from parktool but there is cheaper on amazon but its worth saying again it is a LEFT HAND THREAD and rember the tool has to fit over the axle the one pictured above wont

View attachment 137581

i noted that if you take the chain ring off by undoing the 4 bolts holding it on the spider then you can take one of the motor mounting bolts out, then then put it through the spider back into the motor mounting hole. this will lock it solid. or use a chain whip and cable tie it to the chain stay. i didn't actually try both methods at the same time.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 577K

- Messages

- 29,401

- Members