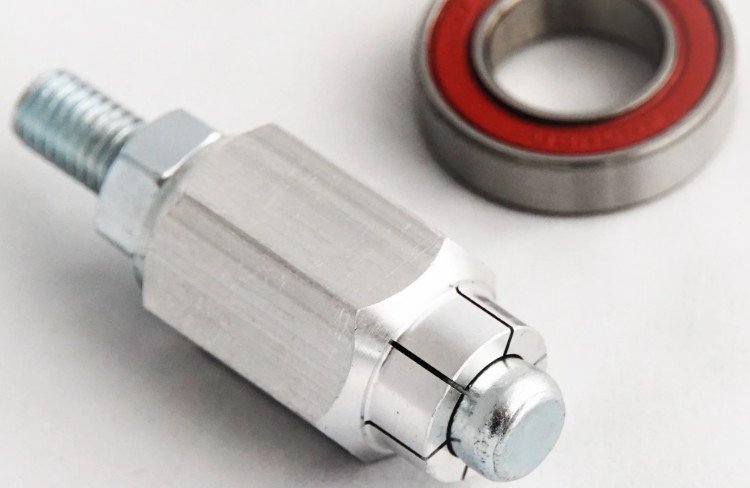

2 years on and a tad over 5200ks the bearings are shot, we'll they were junk to begin with, anyhow I've replaced them all apart from the double bearing that sits on the end of the chainstay, these bearings are 63801, they sit back to back, so you can't press them out as I have every tool for the job, and a blind bearing puller hasn't worked either, does anyone or has someone managed to get these out, if so how please..

Thanks in advance

Thanks in advance