There was one shim washer between the case and one 6900ZZ that was in five pieces. This was replaced

Hi PoppyRex, thank you for posting your results. Can you please give more information or pictures of the shim washer replacement

There was one shim washer between the case and one 6900ZZ that was in five pieces. This was replaced

the shim washer was between the case and the bearing on the end of the large plastic gear. The shim washer is 21.8mm OD, 18.2mm ID ans 0.3mm thick.Hi PoppyRex, thank you for posting your results. Can you please give more information or pictures of the shim washer replacement

Question 3: There is a thin shim washer that sits between the engine case and the bearing on the the end of the black plastic bearing. If you look at the picture I posted you can make out a couple of pieces of the shim washer on the end of the bearing,covered in grease and grime.Bonjour from Strasbourg in Alsace, France.

I made my presentation here.

I have a Husqvarna GT2 now with a STePS E8000, and before with two E7000... with W013 + E010 .

The first one collapsed without merci after 1200 km, the second unit after 2500 km in Sweden.

An accu BT-E8010 à 504 Wh collapsed after 500 km, and my three other BT-E8010 have only 88% Restcapacity after~~ 52 loadcycles each.

The third drive unit, the E8000, has now 16077 km since the last change on 22. XII 2019.

I make never sprints, MTB and I am travelling to 99,99% with Eco High also in big hills with my trailor like a steamer and only on macadam.

But I think his further life of the E8000 could be shorter from now.

1) I hear the bearings like in a cyclical soft coffee mill only when I use Boost

2) If I stay beside my bike,

and I take with one hand a pedal through the frame and with the other the second one,

and if I push above and pull under, the crank has a play which makes also some clac-clac noise.

Congrats for this servicing thread !

I had also a very pleasant email thread with Peter Collard from Bearings Performance Line,

but I have also other questions about the spinning torque sensor and the day after rebuilding the drive unit...

Question 1: which kind of puller do you use to take away the several bearings. Can you give us pictures and references, please?

Question 2: you can read in a german forum pedelecofum.de a lot of disappointed users with error E010 after they rebuilt the drive unit

How ist it truelly?

Question 3 for @PoppyRex : I do not understand this thing with the washer. Can you give us a picture, please?

Question 4: grease, grease, grease... this point stays open in this thread.

View attachment 72347

View attachment 72353 .

I am ready with 5 sealed ball bearings,

and not only with 2. I think it is better.

Without these 3 only shielded I shall have no problem with grease, leakage or a not compatible grease mix there.

That is why I should only need one grease for the teeth. Am I right, so?

View attachment 72398

As Bearing Man, I am Peter Collard from Performance Line Bearings Just for the record, I did not "abandon the repair of Shimano motors" because of this reason. When we repair any motor, it works and we then guarantee our parts and work for 12 months. Because the failure rate of the Shimano motor with all sorts of software issues was so high (regardless if they had been worked on or not), meant the chance of a few failing at some point in the following 12 months of us having looked at it was relatively high. So occasionally we would get the call...Since you looked at my motor 8 months ago, it has packed up with fault code! And as we were the last people to touch the motor, we inevitably got the blame! If you have to buy a few new motors for people, that cost is unsustainable. The decision not to repair Shimano was also coupled with months of time spent in the early days, changing parts, testing, changing parts again, testing again! Got pretty sick of Shimano if I am honest. It was never a common motor compared to Bosch, Brose, Yamaha etc. so recouping any losses was just not possible and 3 years ago we just didn't have the resources to continue supporting this motor.Hej Hej friends.

I asked this evening @PeterMayer from eMax Tuning to read this page # 8.

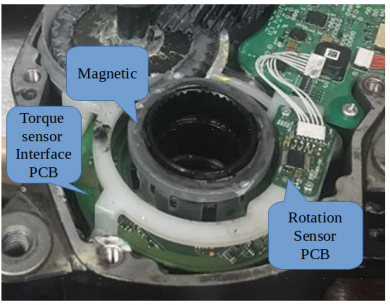

His answer is absolutely clear >> "We cannot remove the torque sensor without the large PCB, because the calibration data are stored there.

But anyway, if the sensor is removed with its small sensor PCB and the large motor PCB, it is imperative to redo its calibration.

This is also why Peter Collard of Performance Line Bearings has abandoned the repair of the STePS Shimano E8000."

The same is true in Germany for ebike-doktor.de

Obviously we don't read anything about "the day after".

Nor on the crankset which swings from right to left and vice versa.

These silences seem to be answers, even failures of the engine rebuild.

---------------

From what we read in the German thread, Shimano seems to be more open to replacing motors after the warranty has expired,

unlike the dying BT-E8010 accumolators immediately the day after they hit the market.

So, I hope I have only to change the two crank bearings or that the DU fails before or a little bit after the warranty expires.

May be used under a wide range of operating conditions offering very significant advantages over conventional lithium greases at high temperature or in the presence of water.

Looks good, eh!?Resists the formation of deposits caused by oxidation at high operating temperatures.

The World's largest electric mountain bike community.