Rod B.

Well-known member

After submitting Part # 1 and Part # 2 of the tech series on Shimano brakes, I realized I had not included anything on checking your Shimano brake rotor for minimum thickness or signs of uneven rotor wear.

You can review Part # 1 and Part # 2 in the series here:

www.emtbforums.com

www.emtbforums.com

www.emtbforums.com

www.emtbforums.com

So, how do you know if your brake rotor is too worn or has worn unevenly?

Unevenly worn brake rotor indicators:

You may encounter an issue with your brakes in which no matter how much you clean the brake pads, your brakes will begin squealing after a hard downhill run. You may also experience a grip/release/grip severe brake juddering when hard braking. Despite you making several attempts at cleaning the pads, the squealing or juddering continues. When this occurs, you should pay careful attention to your brake pads by examining the surface of the brake pads for signs of an uneven wearing brake rotor.

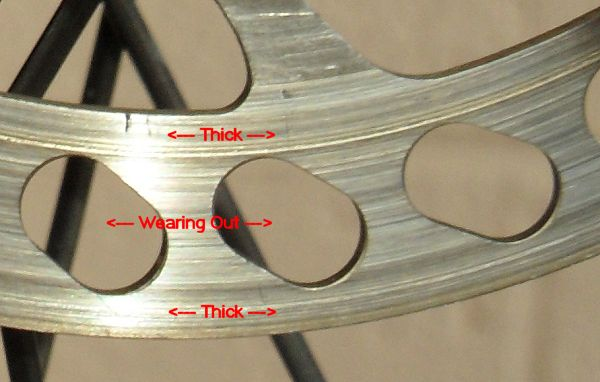

Occasionally, a brake rotor will develop uneven wear indicated by high and low channels on the braking surface of the rotor. Why this occurs may be attributed to many things including, rotor design, weight of the rider, extended hard braking on long downhill runs, use of metallic brake pads, or possibly a set of defective brake pads with hard spots in the braking compound. Uneven rotor wear will significantly reduce braking capacity and cause severe brake squeal.

If you see bands of discolored stripping on your brake pad surfaces, this is an indicator of an uneven brake rotor.

Uneven wear and channels developing on surface of brake rotor

Example of uneven wear on a SRAM Centerline rotor

Example of uneven channels/braking surface starting to develop on a Shimano brake rotor.

You can continue riding on the pads and rotor. However, the uneven rotor wear and brake squealing will gradually become worse with time. You will also experience a reduced braking capacity similar in manner to brake fade after a long downhill run.

An uneven brake rotor cannot be repaired. To do so, would require removal of too much material from the brake rotor. Buying a new set of brake pads will also not correct the problem and will ruin the new brake pads. The only successful remedy is to replace the defective brake rotor and brake pads with new components. Yes, that sucks...

Worn brake rotors:

Every brake manufacturer, including Shimano, sets a maximum wear limit on their brake rotors. Seen is a picture of a 203mm, Shimano RT-MT800 brake rotor. Depicted in laser etched writing is the abbreviated term "203mm Min. TH=1.5." This means the 203mm brake rotor has a "Minimum" rotor thickness of 1.50mm. Shimano brake rotors when brand new measure 1.80 millimeters thick. Therefore, when the rotor has been worn down to a thickness of 1.50 millimeters, it has reached the end of it's service life and should be replaced.

Some will say you can exceed minimum rotor thickness and still be safe. This may be true however, how far do you want to take the rotor down? What's safe? The minimum rotor thickness provided by Shimano seems like a safe bet.

As a rotor gradually exceeds minimum thickness, all sorts of things begin to happen. An overly thin brake rotor will heat up quickly, leading to brake fade or rotor failure. Because of the reduced rotor thickness, the pistons must move the brake pads further outwards to engage the rotor. When you couple a worn rotor with a set of worn brake pads, you'll start experiencing a spongy brake lever and the need to pump the brake lever to engage the brakes. My thoughts are this...the cost of a rotor isn't worth a broken body and time off your bike because of an injury caused by brake failure or loss of braking performance. It's just not worth it.

Not my picture....Damn....."Coming in Hot!"

Tools needed to check rotor thickness:

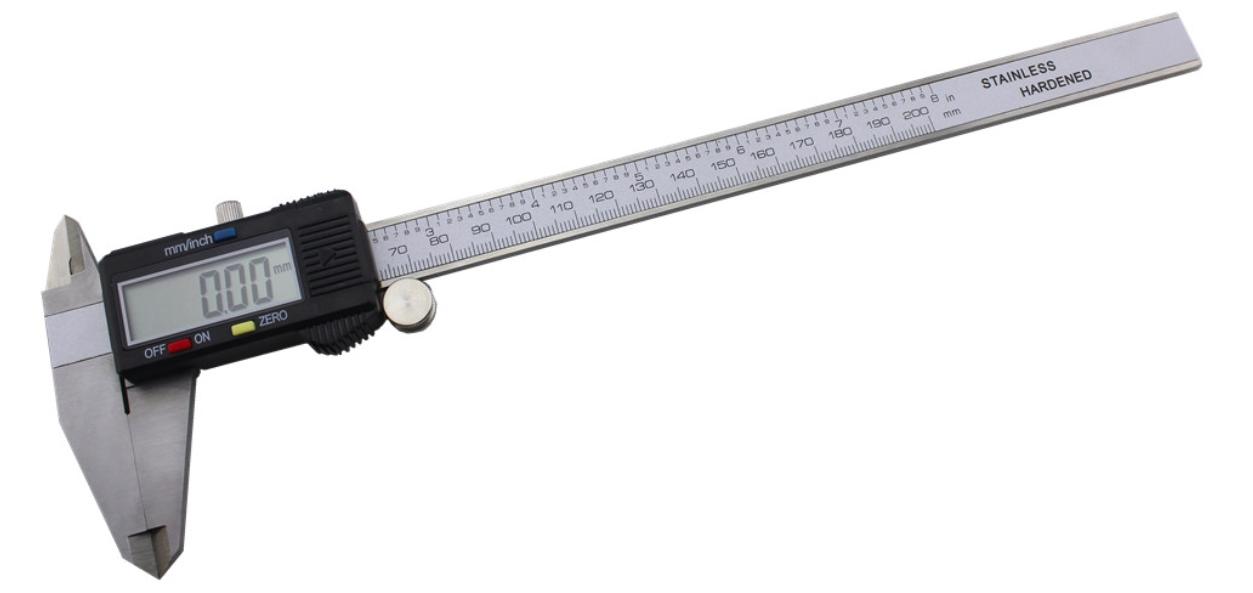

To check you rotor's thickness, you will need a device such as a Vernier Caliper or Micrometer to accurately measure rotor thickness. A device that measures in metric units, i.e. millimeters is preferable. Some calipers come with a dial gauge and others with a digital display. A digital display is easier to read if you are not familiar with how to use a dial gauge to take measurements. Vernier calipers and micrometers can be readily purchased at a reasonable price on Amazon. Note that micrometers tend to be more expensive than Vernier calipers.

Vernier caliper with digital display.

Micrometer with digital display

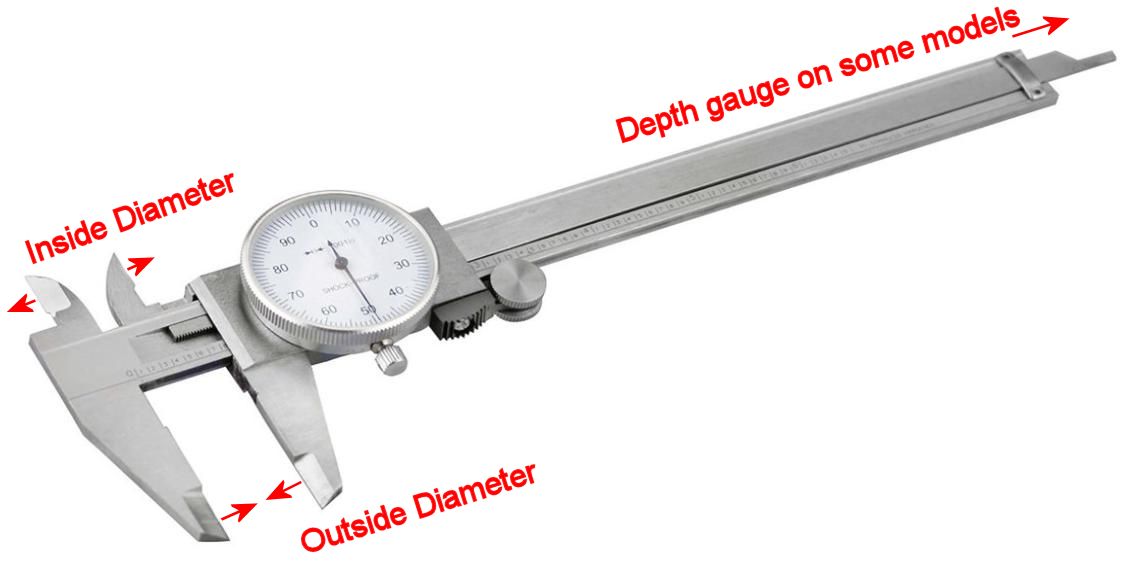

The Vernier caliper is a very handy measuring tool especially for measuring sag on your front fork or rear shock. I use the "Inside Diameter" portion of the tool to measure sag. The Vernier caliper is also an exceptionally handy tool for use around the home and in the shop. Seen in the photograph below is a Vernier caliper with dial. Vernier calipers can measure inside diameter, outside diameter and if equipped, depth of a bore.

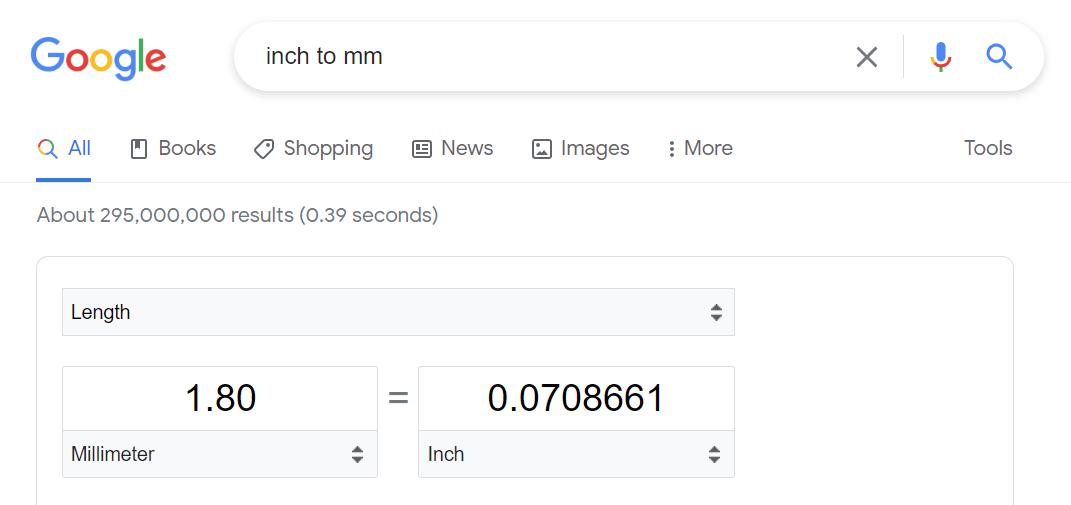

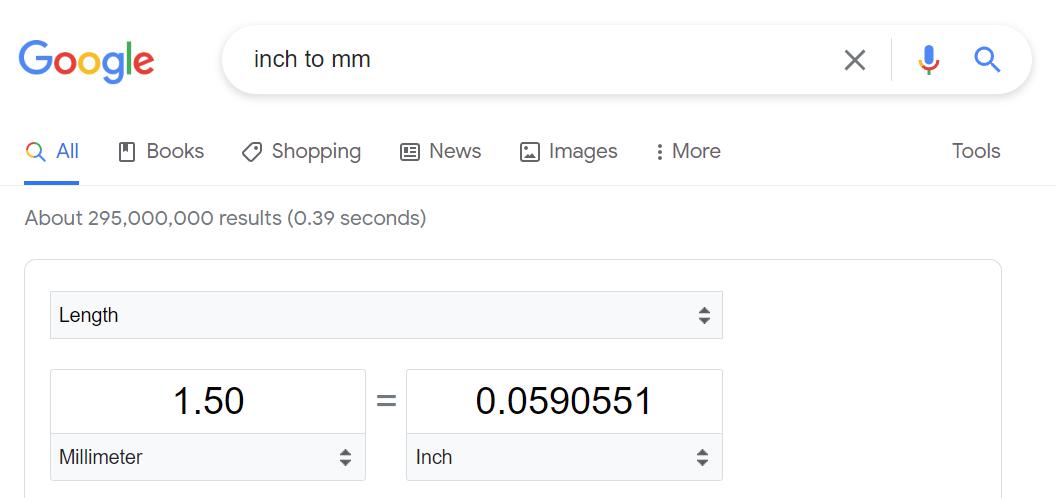

Vernier calipers sold in the United States typically will measure in imperial units. If you do have an imperial type Vernier caliper you can use it to measure rotor thickness, but you will need to convert the Imperial measurement to Metric units. This can be easily done by using an Inch to Metric conversion chart such as what's found on Google.

Shimano rotors are 1.80mm thick when new. 1.80 Millimeters equates to 0.070 inches.

1.50mm is the minimum rotor thickness recommended by Shimano. 1.50 Millimeters equates to 0.059 inches.

To measure your rotor's thickness, you need to measure only the area of the rotor where the brake pad makes contact. Insure that you do not inadvertently place a part of the caliper on a portion of the rotor that is 1.80mm thick and not used for braking. This obviously will throw your measurement off. Also make sure no grit is present on the rotor when you take the measurement.

If the measuring device that you use measures in metric units, then the process is simple. The thickness of the rotor cannot measure less than 1.50mm. If it does, the rotor has reached the end of it's service life and should be replaced.

Here is a YouTube video on how to use and read a metric unit, Vernier caliper. The graphics are a bit much, however the video is an excellent tutorial.

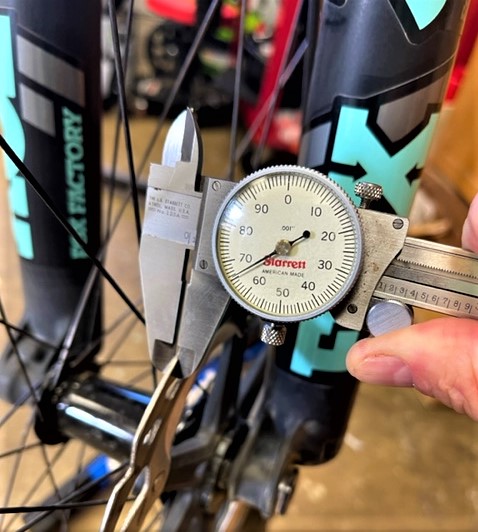

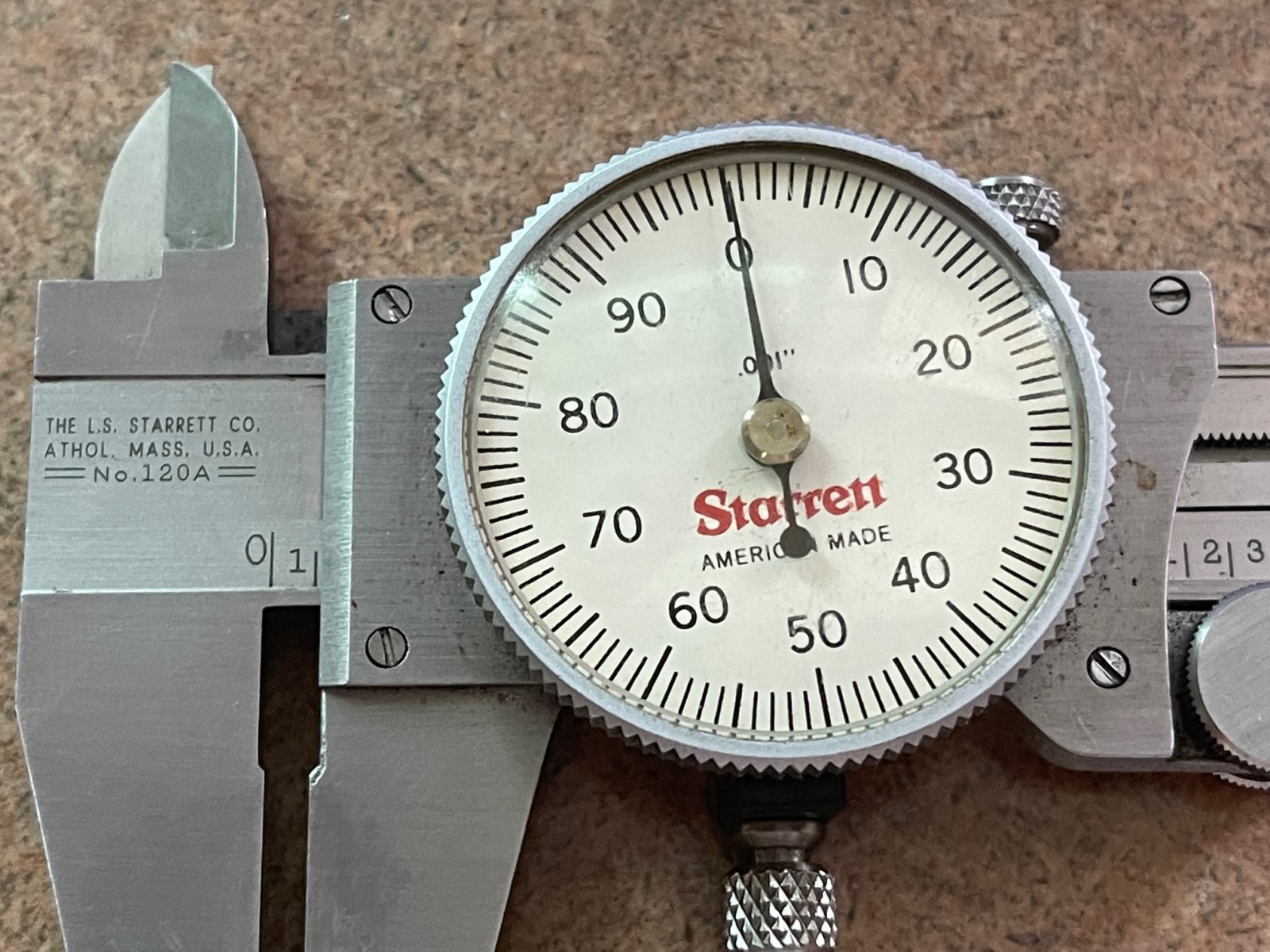

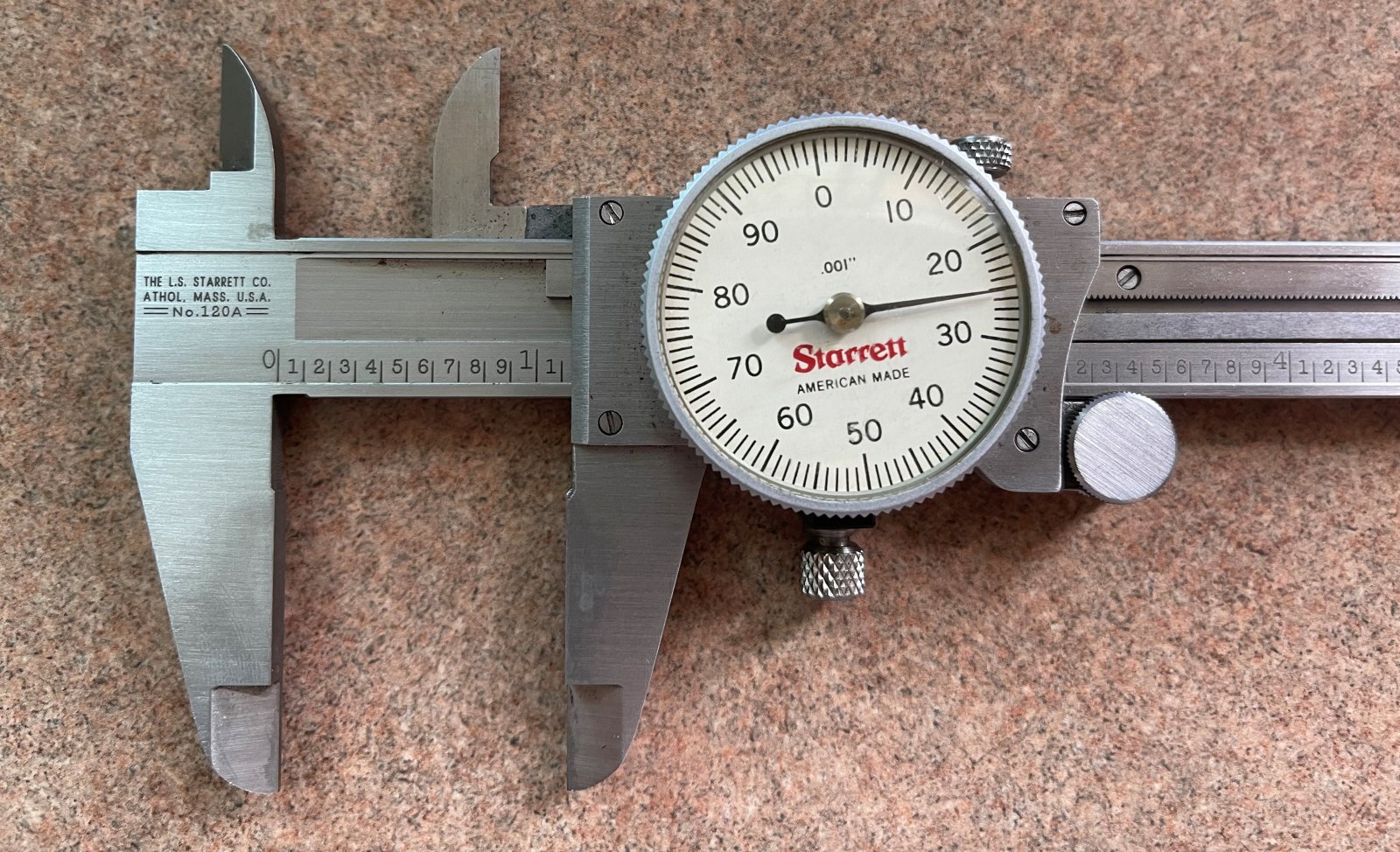

Seen in the picture below, I am using a Starrett brand Vernier caliper which measures in "Imperial Units" and has a dial gauge. I am using it to measure the front rotor on my Rise. Note that I am only measuring the area of the rotor where the brake pads make contact and not any area of the rotor that is 1.80mm thick.

Let's pay particular attention to the dial. All Shimano brake rotors new measure 1.80mm. If the rotor were brand new, the needle would point to 70 on the dial, which is 0.70 inches and converted to metric is 1.80mm.

If the needle were pointing at 59 on the dial, which is 0.059 inches and converts to 1.50mm, this would indicate the rotor has reached minimum thickness and should be replaced.

In the photograph, the dial's needle is pointing at 66, which is 0.066 inches. 0.066 converted to metric is 1.67mm. This indicates my front rotor is at approximately 60% of it's service life.

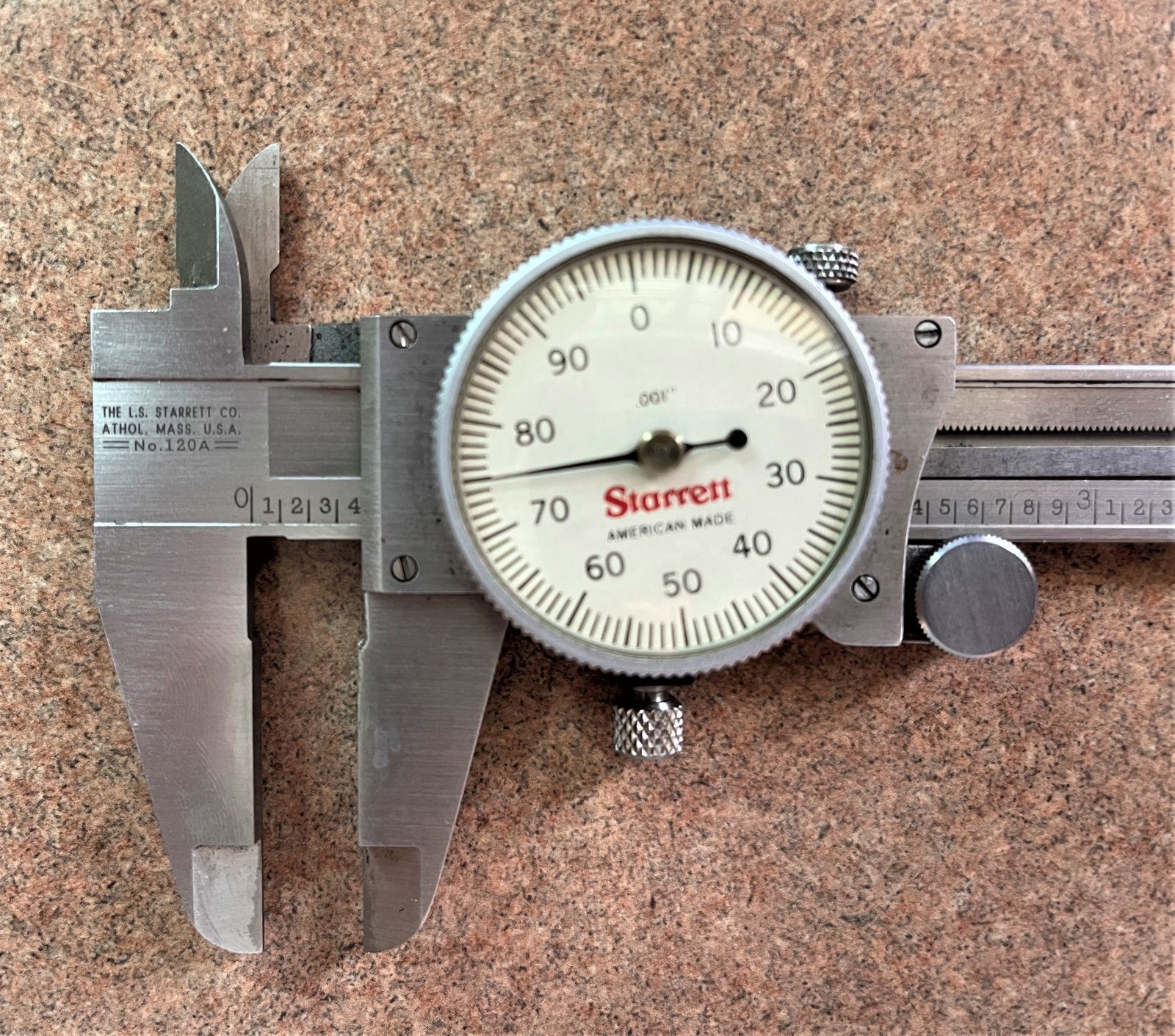

In the picture below I am measuring my rear brake rotor. The needle is pointing at 64 or 0.064 inches. 0.064 converted to metric is 1.62mm. This indicates my rear rotor is at approximately 50% of it's service life.

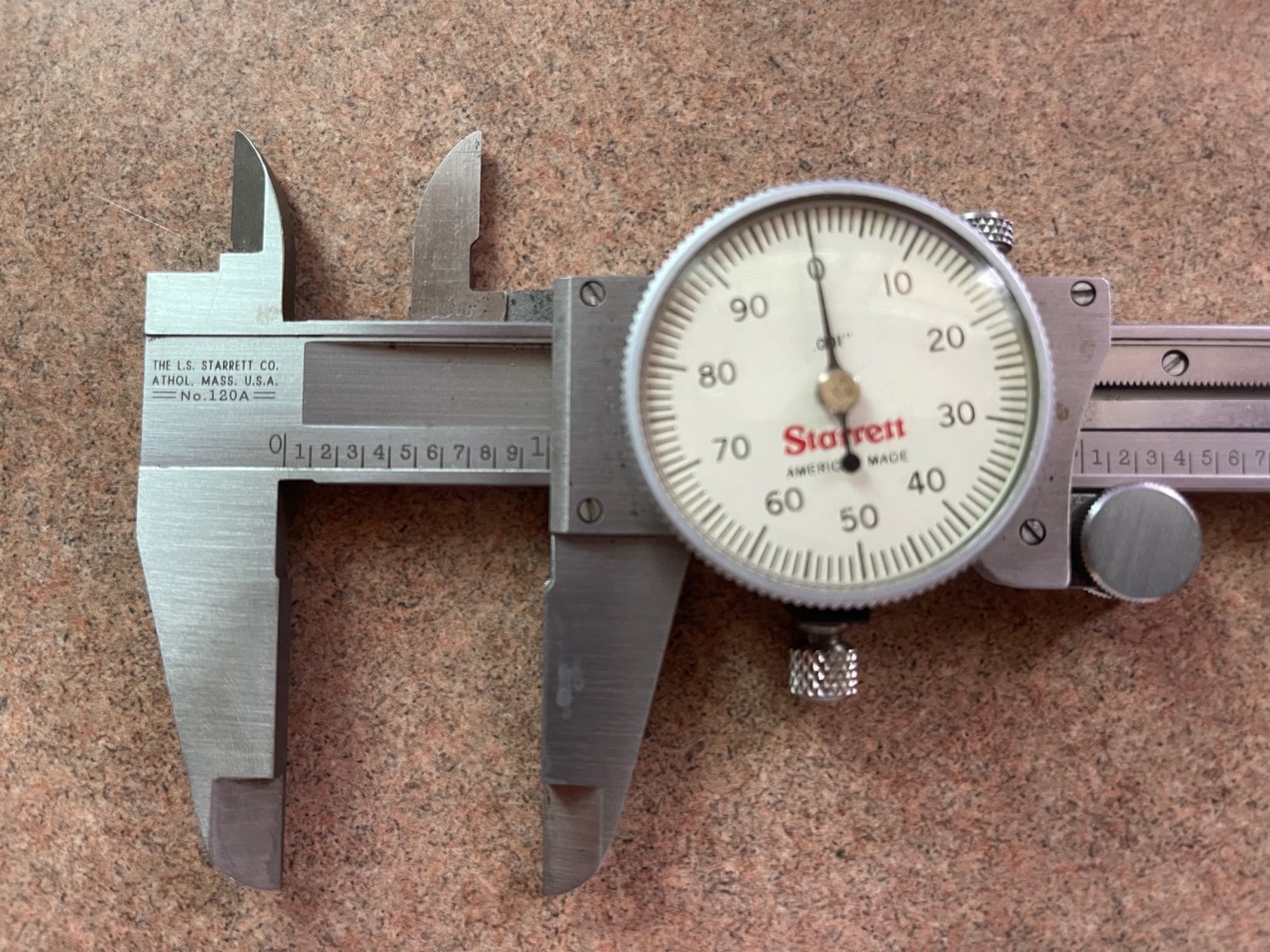

Below is a picture of me measuring across the braking and non braking areas of the brake rotor. This has thrown off the thickness measurement. When measuring the rotor, be sure to measure only the braking area of the rotor. I would like to add that this is not the correct way to take a measurement with a Vernier caliper. I was trying to squeeze the caliper closed with one hand while at the same time take the shot with my phone in the other hand.

I hope your find this article useful. Let's ride....

Note: I received a message after posting the above article in regards to reading an Imperial unit, Vernier caliper with dial. I've edited the post and below I've attached pictures to help you better understand how to read an imperial unit, dial gauge, Vernier caliper.

I'm not a rocket scientist, machinist, nor a mathematical engineer. I like to ride mountain bikes, that's it..... If I screw the pooch on a term or something, don't shoot me. There are many YouTube videos which also offer tutorials on the use of a Vernier caliper or Micrometer.

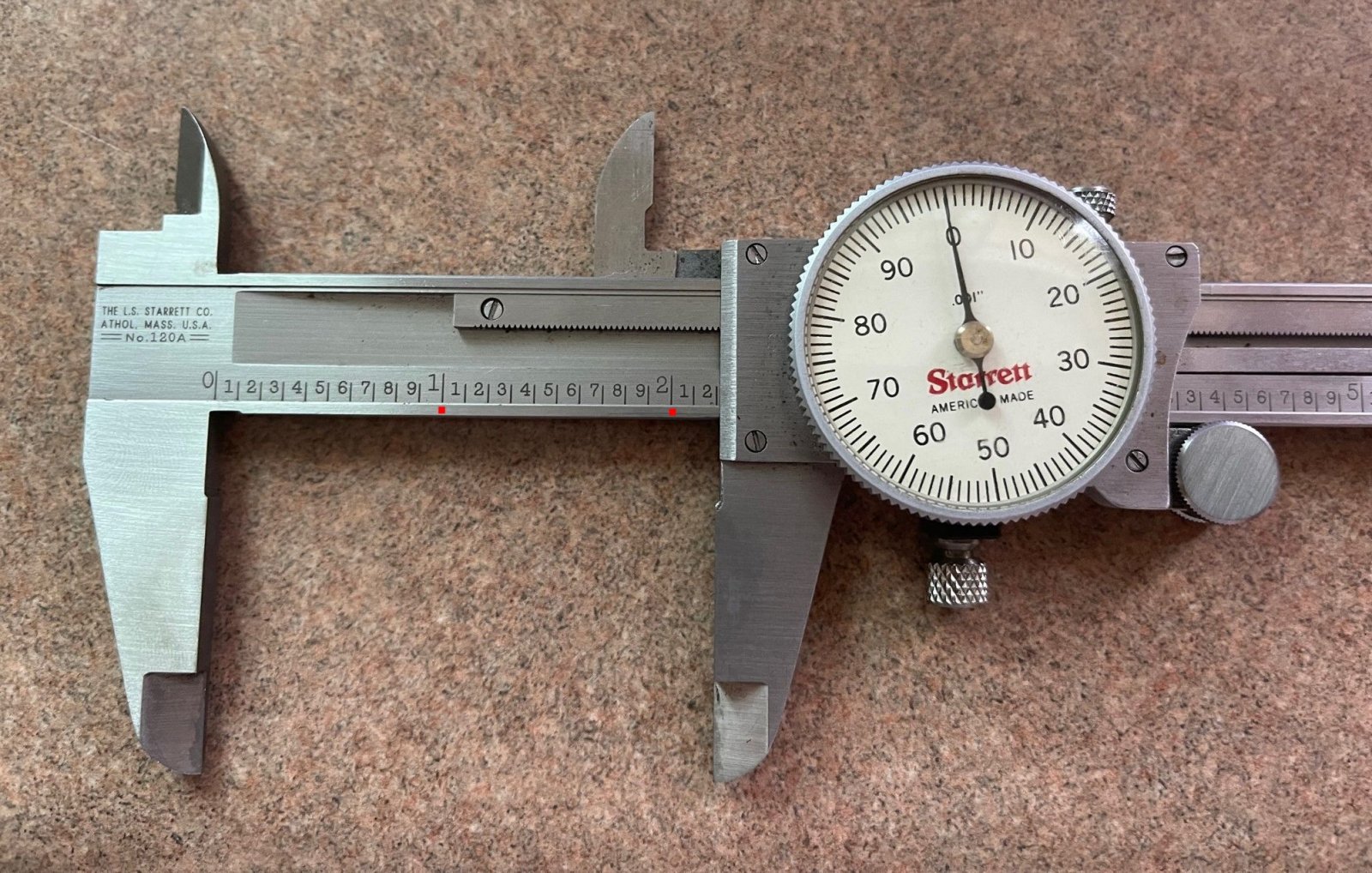

An imperial unit Vernier caliper has one inch values. The size of the Vernier caliper will dictate how many one inch values it has. My Starrett Vernier has six, one inch values. Each one inch value is divided into 10 increments.

With your Vernier fully closed, the needle should be centered on zero. You can reset and manually adjust the dial to center on zero by loosening the adjustment knob. Once the dial has been centered on "0", tighten the adjustment knob (Seen near the 50 on the dial) to lock the dial in place. The knob seen near the ten on the dial, locks the caliper slide in place so you can retain your measurement after it has been taken. The large knob at the 35 position on the dial allows you to advance or retract the slide using your thumb.

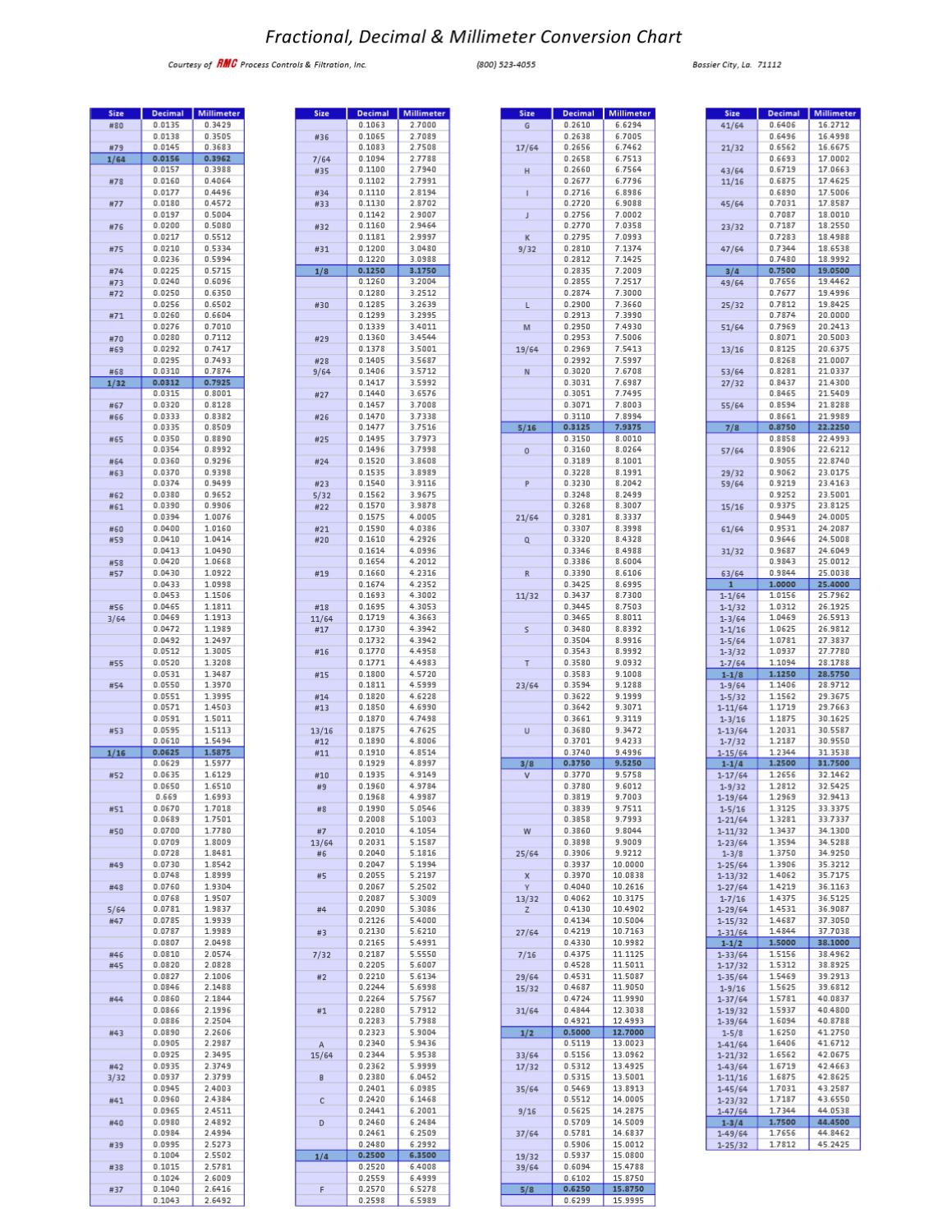

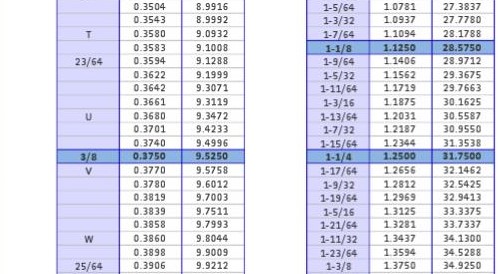

My Starrett Vernier caliper measures in decimal "0000." You can convert the decimal measurement to inch or metric equivalent via conversion charts which can easily be found on the internet. The chart below displays imperial and metric drill bit size, inch, metric and decimal equivalents.

Seen in the picture below, I have placed the caliper's slide on "1" the first increment, within the first one inch value. The dial is on zero. The decimal reading would thus be 0.100. If the caliper slide was on "2" the second increment in the one inch value and the dial were on zero, the decimal reading would be 0.200.

In the picture below, the slide is slightly past the "1" increment but not yet to the "2" increment. The needle is pointing to "50" on the dial. The decimal reading would thus be 0.150. If the needle were pointing at "70", the decimal reading would be 0.170 and so forth.

In the next example, the needle is past the "3" increment but not quite to the "4". The needle is pointing to "75" on the dial. The decimal reading would thus be 0.375. If you cross reference the 0.375 decimal reading to the above conversion chart, you find 0.375 is 3/8th of a inch or 9.52 millimeters.

3/8th's of an inch is 0.375

Okay, let's step it up a notch. In the photograph below, the slide is on the one inch marker. The needle on the dial is pointing to zero. Thus the decimal reading is 1.000. If you cross reference 1.000 on the conversion chart you'll find 1.000 equals one inch or 25.40 millimeters.

In the below picture, the slide is past the one inch value and past the "1" increment but not to the "2" increment. The needle on the dial is pointing to "25." The decimal reading would thus be 1.125. If you reference 1.125 in the conversion chart you will find this equals 1 1/8th inch or 28.57 millimeters.

Okay, one final picture. In the below picture the slide is past the two inch value. The slide is at the "5" increment within the two inch value. The needle is pointing to zero on the dial. The decimal reading is thus 2.500. The equates to 2.5 inches or 63.5 millimeters.

A Vernier caliper is an extremely helpful tool. I use mine to accurately set sag on my Fox front fork and rear shock. A Vernier caliper can be useful in determining the size of a bolt, thickness of a steerer tube, depth of a bore or the inside diameter, outside diameter and width of an unmarked cartridge bearing. I very much recommend one for your tool box.

You can review Part # 1 and Part # 2 in the series here:

Part # 1: Shimano Brake System Service - EMTB Forums

This will be a two part technical article discussing Shimano braking system components, how to service your Shimano brakes and brake system modification on your Rise. Part # 1 will discuss basic maintenance on your Shimano brakes. I am not a professional mechanic but I do enjoy working on...

www.emtbforums.com

www.emtbforums.com

PART # 2: SHIMANO BRAKE SYSTEM – Orbea Rise Brake System Modification

This technical article is the second installment in a two part series on Shimano brake systems. Refer to “Part # 1: Shimano Brake System Service”, for information on bleeding and servicing Shimano brakes and brake pad compounds...

So, how do you know if your brake rotor is too worn or has worn unevenly?

Unevenly worn brake rotor indicators:

You may encounter an issue with your brakes in which no matter how much you clean the brake pads, your brakes will begin squealing after a hard downhill run. You may also experience a grip/release/grip severe brake juddering when hard braking. Despite you making several attempts at cleaning the pads, the squealing or juddering continues. When this occurs, you should pay careful attention to your brake pads by examining the surface of the brake pads for signs of an uneven wearing brake rotor.

Occasionally, a brake rotor will develop uneven wear indicated by high and low channels on the braking surface of the rotor. Why this occurs may be attributed to many things including, rotor design, weight of the rider, extended hard braking on long downhill runs, use of metallic brake pads, or possibly a set of defective brake pads with hard spots in the braking compound. Uneven rotor wear will significantly reduce braking capacity and cause severe brake squeal.

If you see bands of discolored stripping on your brake pad surfaces, this is an indicator of an uneven brake rotor.

Uneven wear and channels developing on surface of brake rotor

Example of uneven wear on a SRAM Centerline rotor

Example of uneven channels/braking surface starting to develop on a Shimano brake rotor.

You can continue riding on the pads and rotor. However, the uneven rotor wear and brake squealing will gradually become worse with time. You will also experience a reduced braking capacity similar in manner to brake fade after a long downhill run.

An uneven brake rotor cannot be repaired. To do so, would require removal of too much material from the brake rotor. Buying a new set of brake pads will also not correct the problem and will ruin the new brake pads. The only successful remedy is to replace the defective brake rotor and brake pads with new components. Yes, that sucks...

Worn brake rotors:

Every brake manufacturer, including Shimano, sets a maximum wear limit on their brake rotors. Seen is a picture of a 203mm, Shimano RT-MT800 brake rotor. Depicted in laser etched writing is the abbreviated term "203mm Min. TH=1.5." This means the 203mm brake rotor has a "Minimum" rotor thickness of 1.50mm. Shimano brake rotors when brand new measure 1.80 millimeters thick. Therefore, when the rotor has been worn down to a thickness of 1.50 millimeters, it has reached the end of it's service life and should be replaced.

Some will say you can exceed minimum rotor thickness and still be safe. This may be true however, how far do you want to take the rotor down? What's safe? The minimum rotor thickness provided by Shimano seems like a safe bet.

As a rotor gradually exceeds minimum thickness, all sorts of things begin to happen. An overly thin brake rotor will heat up quickly, leading to brake fade or rotor failure. Because of the reduced rotor thickness, the pistons must move the brake pads further outwards to engage the rotor. When you couple a worn rotor with a set of worn brake pads, you'll start experiencing a spongy brake lever and the need to pump the brake lever to engage the brakes. My thoughts are this...the cost of a rotor isn't worth a broken body and time off your bike because of an injury caused by brake failure or loss of braking performance. It's just not worth it.

Not my picture....Damn....."Coming in Hot!"

Tools needed to check rotor thickness:

To check you rotor's thickness, you will need a device such as a Vernier Caliper or Micrometer to accurately measure rotor thickness. A device that measures in metric units, i.e. millimeters is preferable. Some calipers come with a dial gauge and others with a digital display. A digital display is easier to read if you are not familiar with how to use a dial gauge to take measurements. Vernier calipers and micrometers can be readily purchased at a reasonable price on Amazon. Note that micrometers tend to be more expensive than Vernier calipers.

Vernier caliper with digital display.

Micrometer with digital display

The Vernier caliper is a very handy measuring tool especially for measuring sag on your front fork or rear shock. I use the "Inside Diameter" portion of the tool to measure sag. The Vernier caliper is also an exceptionally handy tool for use around the home and in the shop. Seen in the photograph below is a Vernier caliper with dial. Vernier calipers can measure inside diameter, outside diameter and if equipped, depth of a bore.

Vernier calipers sold in the United States typically will measure in imperial units. If you do have an imperial type Vernier caliper you can use it to measure rotor thickness, but you will need to convert the Imperial measurement to Metric units. This can be easily done by using an Inch to Metric conversion chart such as what's found on Google.

Shimano rotors are 1.80mm thick when new. 1.80 Millimeters equates to 0.070 inches.

1.50mm is the minimum rotor thickness recommended by Shimano. 1.50 Millimeters equates to 0.059 inches.

To measure your rotor's thickness, you need to measure only the area of the rotor where the brake pad makes contact. Insure that you do not inadvertently place a part of the caliper on a portion of the rotor that is 1.80mm thick and not used for braking. This obviously will throw your measurement off. Also make sure no grit is present on the rotor when you take the measurement.

If the measuring device that you use measures in metric units, then the process is simple. The thickness of the rotor cannot measure less than 1.50mm. If it does, the rotor has reached the end of it's service life and should be replaced.

Here is a YouTube video on how to use and read a metric unit, Vernier caliper. The graphics are a bit much, however the video is an excellent tutorial.

Seen in the picture below, I am using a Starrett brand Vernier caliper which measures in "Imperial Units" and has a dial gauge. I am using it to measure the front rotor on my Rise. Note that I am only measuring the area of the rotor where the brake pads make contact and not any area of the rotor that is 1.80mm thick.

Let's pay particular attention to the dial. All Shimano brake rotors new measure 1.80mm. If the rotor were brand new, the needle would point to 70 on the dial, which is 0.70 inches and converted to metric is 1.80mm.

If the needle were pointing at 59 on the dial, which is 0.059 inches and converts to 1.50mm, this would indicate the rotor has reached minimum thickness and should be replaced.

In the photograph, the dial's needle is pointing at 66, which is 0.066 inches. 0.066 converted to metric is 1.67mm. This indicates my front rotor is at approximately 60% of it's service life.

In the picture below I am measuring my rear brake rotor. The needle is pointing at 64 or 0.064 inches. 0.064 converted to metric is 1.62mm. This indicates my rear rotor is at approximately 50% of it's service life.

Below is a picture of me measuring across the braking and non braking areas of the brake rotor. This has thrown off the thickness measurement. When measuring the rotor, be sure to measure only the braking area of the rotor. I would like to add that this is not the correct way to take a measurement with a Vernier caliper. I was trying to squeeze the caliper closed with one hand while at the same time take the shot with my phone in the other hand.

I hope your find this article useful. Let's ride....

Note: I received a message after posting the above article in regards to reading an Imperial unit, Vernier caliper with dial. I've edited the post and below I've attached pictures to help you better understand how to read an imperial unit, dial gauge, Vernier caliper.

I'm not a rocket scientist, machinist, nor a mathematical engineer. I like to ride mountain bikes, that's it..... If I screw the pooch on a term or something, don't shoot me. There are many YouTube videos which also offer tutorials on the use of a Vernier caliper or Micrometer.

An imperial unit Vernier caliper has one inch values. The size of the Vernier caliper will dictate how many one inch values it has. My Starrett Vernier has six, one inch values. Each one inch value is divided into 10 increments.

With your Vernier fully closed, the needle should be centered on zero. You can reset and manually adjust the dial to center on zero by loosening the adjustment knob. Once the dial has been centered on "0", tighten the adjustment knob (Seen near the 50 on the dial) to lock the dial in place. The knob seen near the ten on the dial, locks the caliper slide in place so you can retain your measurement after it has been taken. The large knob at the 35 position on the dial allows you to advance or retract the slide using your thumb.

My Starrett Vernier caliper measures in decimal "0000." You can convert the decimal measurement to inch or metric equivalent via conversion charts which can easily be found on the internet. The chart below displays imperial and metric drill bit size, inch, metric and decimal equivalents.

Seen in the picture below, I have placed the caliper's slide on "1" the first increment, within the first one inch value. The dial is on zero. The decimal reading would thus be 0.100. If the caliper slide was on "2" the second increment in the one inch value and the dial were on zero, the decimal reading would be 0.200.

In the picture below, the slide is slightly past the "1" increment but not yet to the "2" increment. The needle is pointing to "50" on the dial. The decimal reading would thus be 0.150. If the needle were pointing at "70", the decimal reading would be 0.170 and so forth.

In the next example, the needle is past the "3" increment but not quite to the "4". The needle is pointing to "75" on the dial. The decimal reading would thus be 0.375. If you cross reference the 0.375 decimal reading to the above conversion chart, you find 0.375 is 3/8th of a inch or 9.52 millimeters.

3/8th's of an inch is 0.375

Okay, let's step it up a notch. In the photograph below, the slide is on the one inch marker. The needle on the dial is pointing to zero. Thus the decimal reading is 1.000. If you cross reference 1.000 on the conversion chart you'll find 1.000 equals one inch or 25.40 millimeters.

In the below picture, the slide is past the one inch value and past the "1" increment but not to the "2" increment. The needle on the dial is pointing to "25." The decimal reading would thus be 1.125. If you reference 1.125 in the conversion chart you will find this equals 1 1/8th inch or 28.57 millimeters.

Okay, one final picture. In the below picture the slide is past the two inch value. The slide is at the "5" increment within the two inch value. The needle is pointing to zero on the dial. The decimal reading is thus 2.500. The equates to 2.5 inches or 63.5 millimeters.

A Vernier caliper is an extremely helpful tool. I use mine to accurately set sag on my Fox front fork and rear shock. A Vernier caliper can be useful in determining the size of a bolt, thickness of a steerer tube, depth of a bore or the inside diameter, outside diameter and width of an unmarked cartridge bearing. I very much recommend one for your tool box.

Last edited: