Hey guys, I’m taking delivery of a spanking new Cube Stereo tomorrow. I’m like a kid at Christmas! Not sure I’ll sleep tonight!

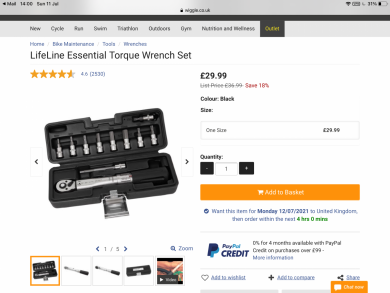

I’ve bought some carbon bars that I want to add before riding the bike, is it necessary to use a torque wrench or can I just be careful not to tighten them too much when fitting?

If anyone has any experience with this I’d be very grateful for your thoughts.

Cheers.

I’ve bought some carbon bars that I want to add before riding the bike, is it necessary to use a torque wrench or can I just be careful not to tighten them too much when fitting?

If anyone has any experience with this I’d be very grateful for your thoughts.

Cheers.