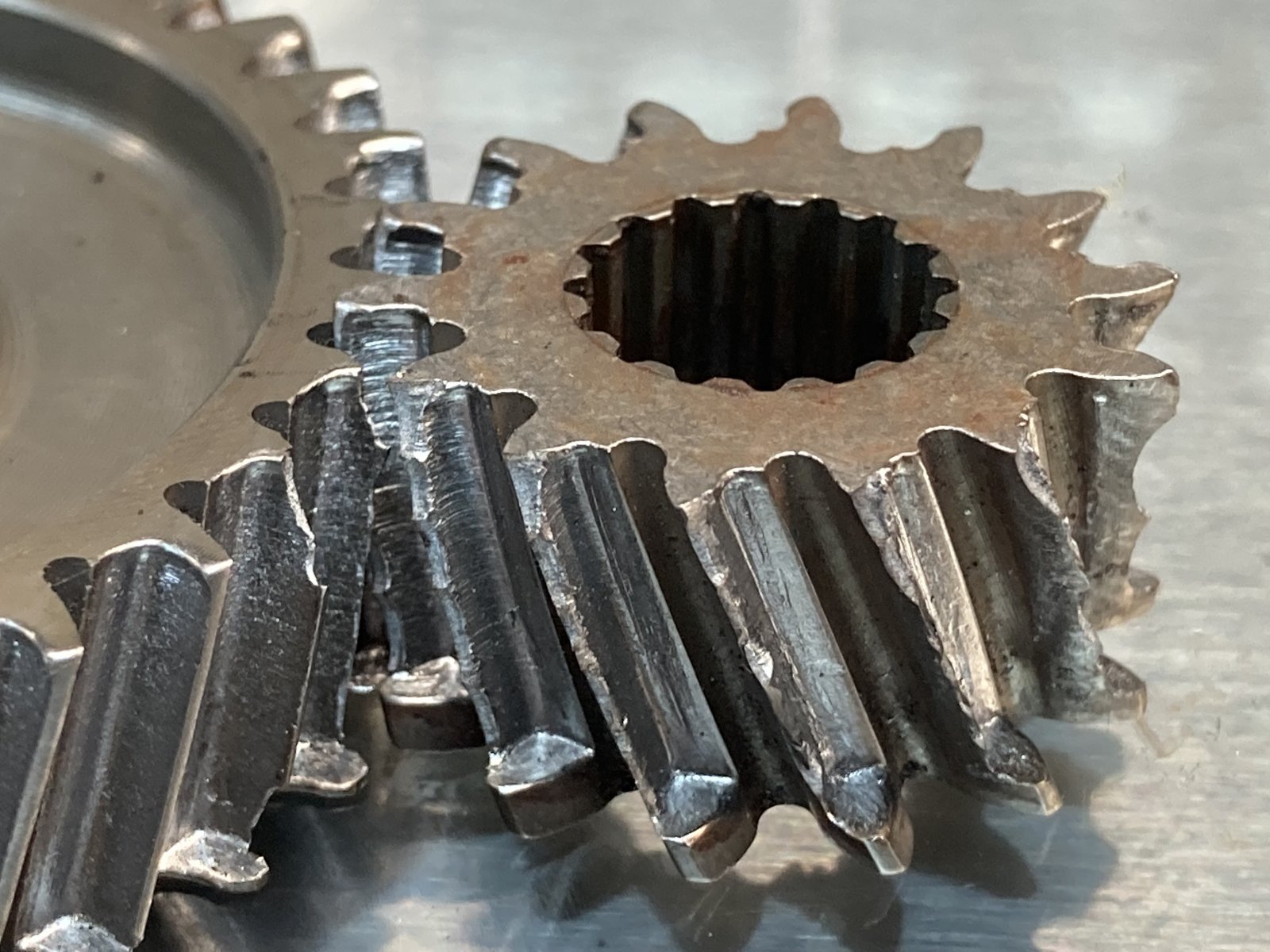

We get a lot of motors in the workshop where the owner has gone with the old adage... I'll fix it when it breaks! Unfortunately, with an ebike motor once a different noise is noticed coming from the motor, it's already costing you more money every pedal stroke!

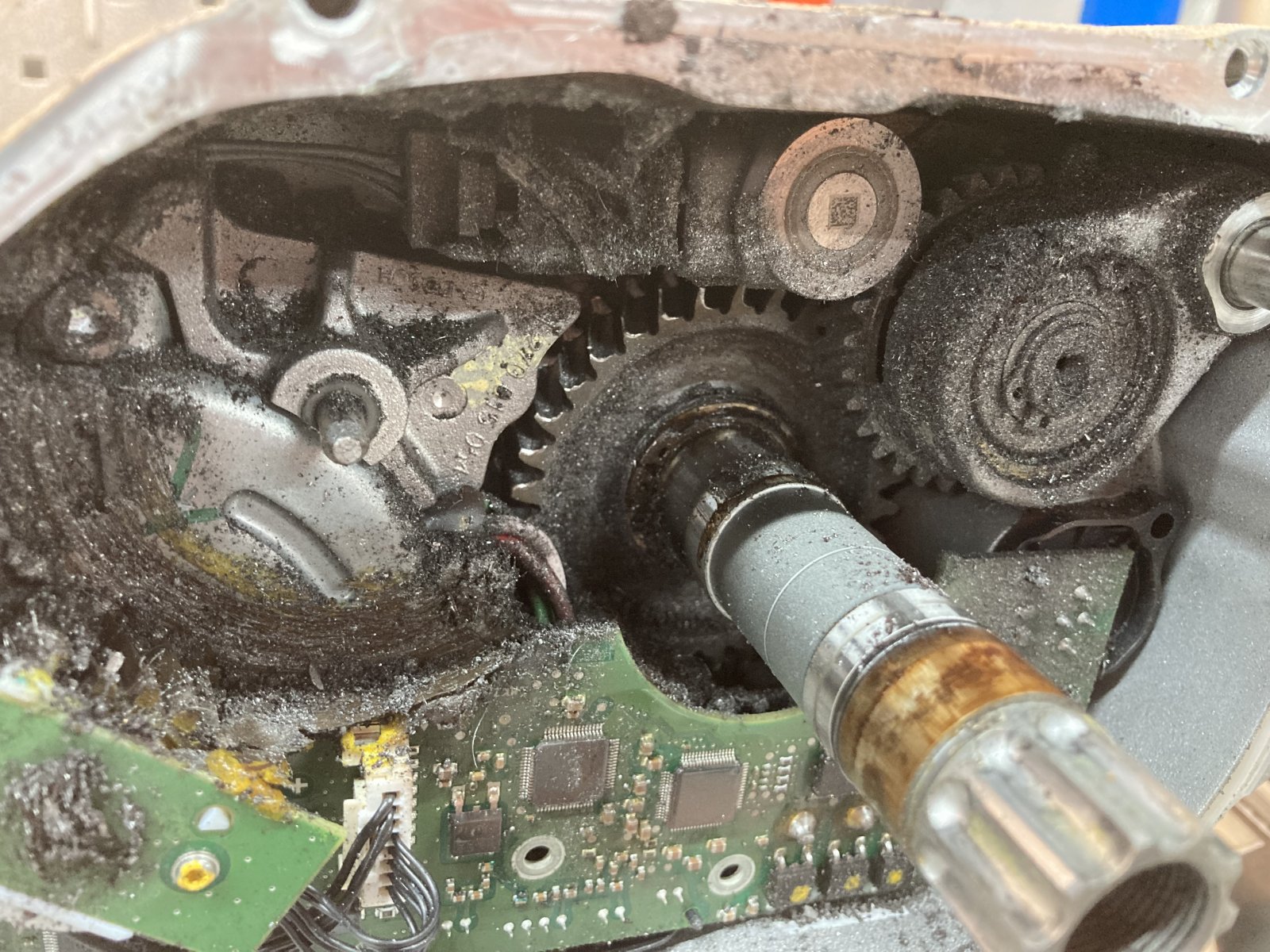

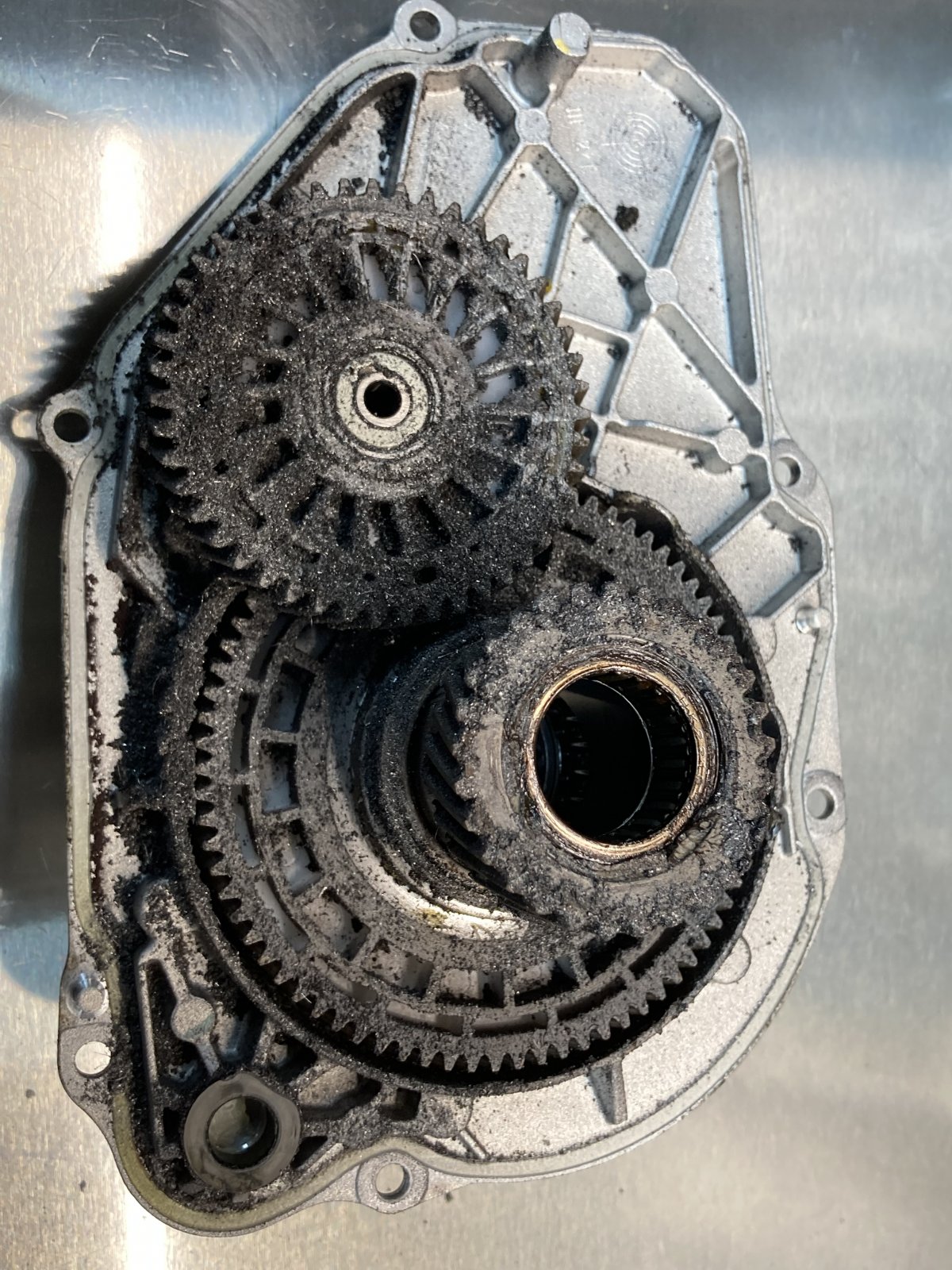

However, some people try and push the envelope, just that little bit too far! Don't be this guy!

However, some people try and push the envelope, just that little bit too far! Don't be this guy!