It has been said that re-greasing the motor improves the range, so I am going to explain my findings.

In my case, I opened the E8000 motor with 7500Km (I have another motor with 7500Km), I checked that no water had ever entered, the bearings are fine and without rust and they spin smoothly, so I only re-greased:

* For plastic-metal gears I used Molikote PG-75.

* For the crankshaft needle bearings I used White Lithium grease

* For the seals of the bottom bracket, I used Motorex green grease that improves the sealing.

Once this was done, I closed the motor and then I tested it on a 40Km and 400m route that I had done in May before re-greasing the Motor, and I was very surprised by the difference in power usage before and after greasing:

* May 13, 2023 with the motor before greasing, power usage was 210Wh.

* July 29, 2023 with the motor after greasing, power usage was 164Wh

Doing the calculations, it turns out that the ungreased motor uses 28% more power than the greased one. As the temperature was cooler in May and in August we were over 30º, it is even possible that at equal temperature the improvement in autonomy is higher than this 28%.

When this motor is good and does not fail with the famous E010, it is a very nice motor and with this little maintenance that is very easy to do, its life and autonomy improve a lot. But Shimano says that the motors do not need maintenance and that they are a consumable and that when there is a problem with it we have to spend €1,300 and change it for a new one. Probably, this is one of the reasons for the low sale of Shimano powered bikes.

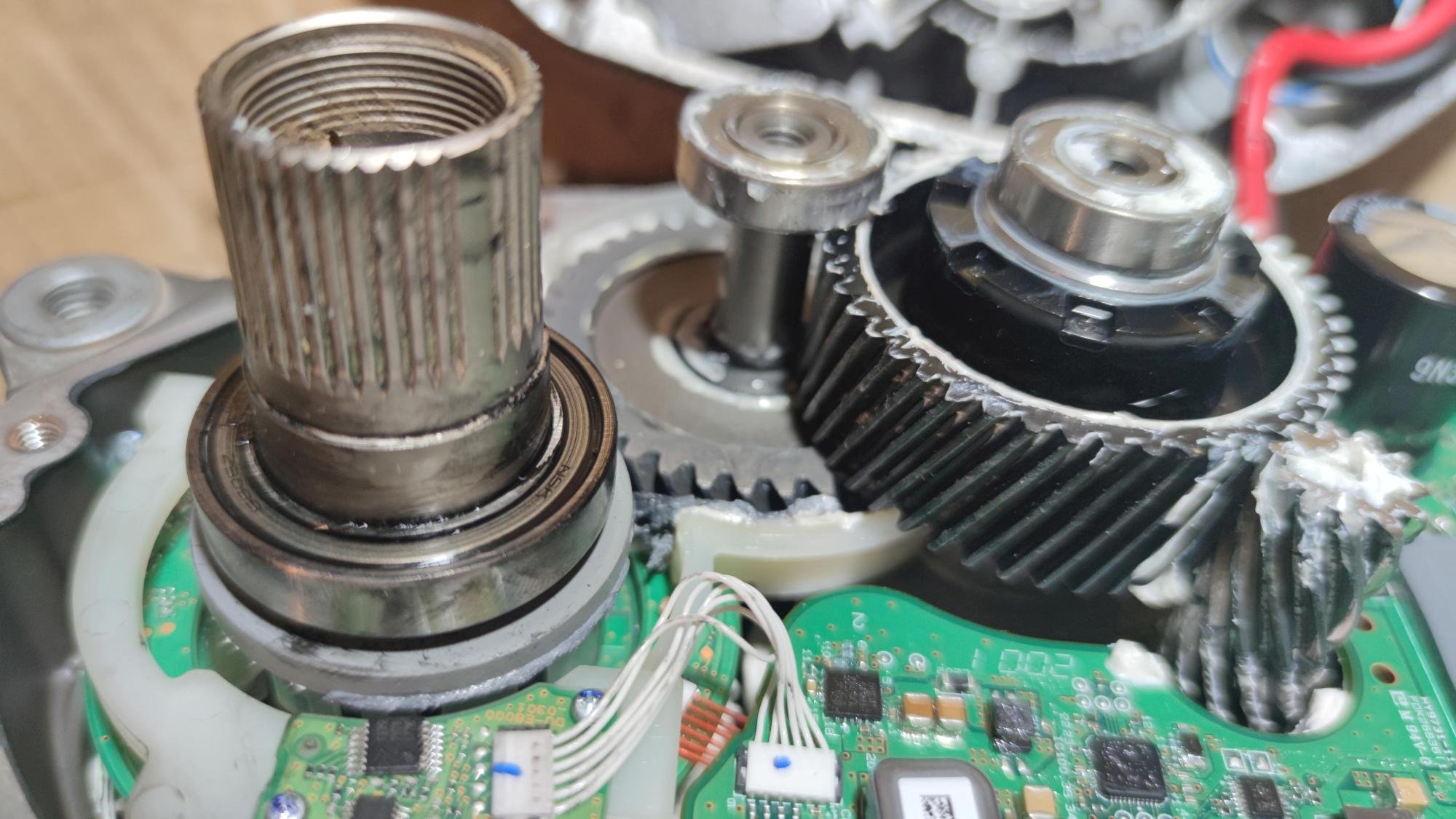

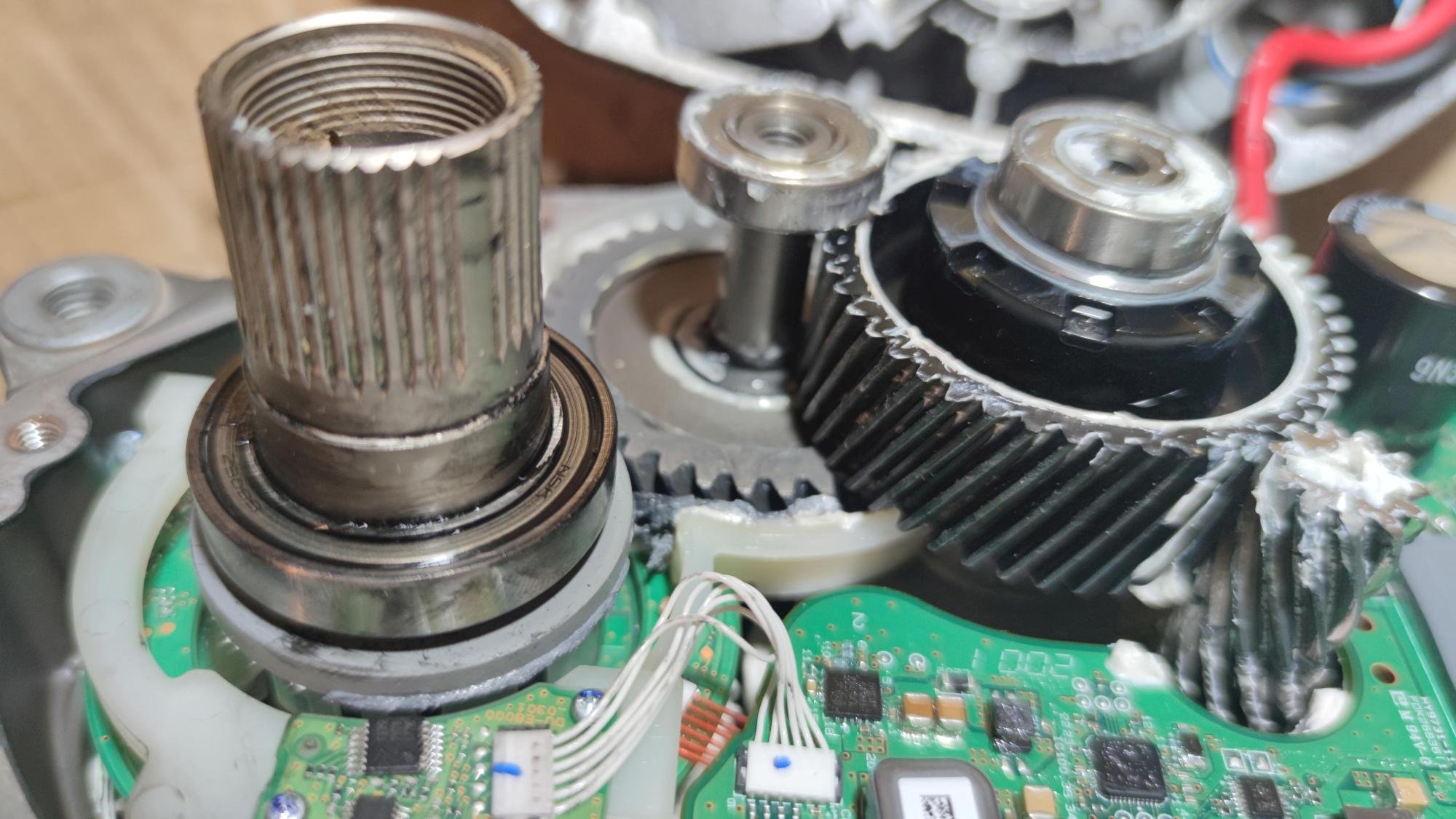

In the photos you can see how dry the gear teeth were, and in the last one how they were after greasing.

In my case, I opened the E8000 motor with 7500Km (I have another motor with 7500Km), I checked that no water had ever entered, the bearings are fine and without rust and they spin smoothly, so I only re-greased:

* For plastic-metal gears I used Molikote PG-75.

* For the crankshaft needle bearings I used White Lithium grease

* For the seals of the bottom bracket, I used Motorex green grease that improves the sealing.

Once this was done, I closed the motor and then I tested it on a 40Km and 400m route that I had done in May before re-greasing the Motor, and I was very surprised by the difference in power usage before and after greasing:

* May 13, 2023 with the motor before greasing, power usage was 210Wh.

* July 29, 2023 with the motor after greasing, power usage was 164Wh

Doing the calculations, it turns out that the ungreased motor uses 28% more power than the greased one. As the temperature was cooler in May and in August we were over 30º, it is even possible that at equal temperature the improvement in autonomy is higher than this 28%.

When this motor is good and does not fail with the famous E010, it is a very nice motor and with this little maintenance that is very easy to do, its life and autonomy improve a lot. But Shimano says that the motors do not need maintenance and that they are a consumable and that when there is a problem with it we have to spend €1,300 and change it for a new one. Probably, this is one of the reasons for the low sale of Shimano powered bikes.

In the photos you can see how dry the gear teeth were, and in the last one how they were after greasing.

Last edited: