Michail

New Member

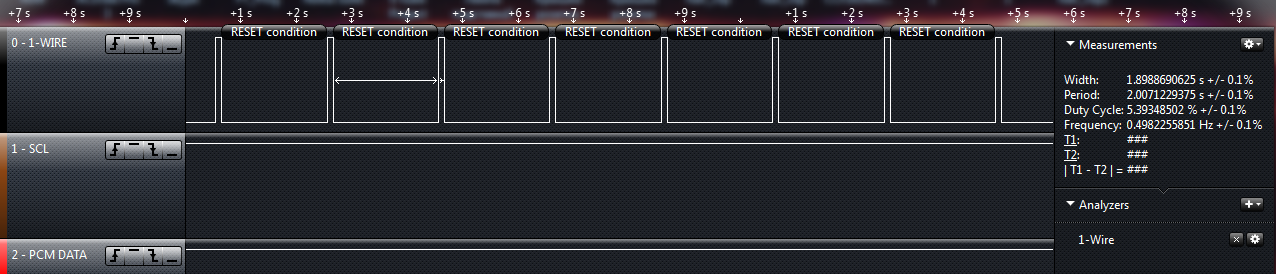

Good afternoon. I had the opportunity to repair the charger from Focus 03/18. The problem was that I did not want to charge below 10% on batteries and low ambient temperature. The forum said this. Having studied the circuitry of a 4 amp charger, I found many flaws up to the soldered components on the board. Charging itself is simple in circuit design, it is very simple to start and check the jumper, but the microcontroller monitors the 3-pin and many are mistaken that the logic level is there, this data bus is not compatible with the standard (the EnergyBus connector itself), maybe it's 1-wire or serial. Bicycle authorization is simple, the charger needs to get data on the battery capacity, temperature on it, and the service status of the BMS via the bus. Charging problems are caused by the drift of the SMD resistor values in the battery voltage test circuit, when the power output relay is turned on, there is interference (contact bounce), replaced the relay with a better one and shunt the winding and relay contacts with 2 ceramic capacitors. Perhaps the interference from the relay greatly affects the operation of the microcontroller, which controls 3 pins. The fact that the manufacturer changed the battery to the place of charging in this is the logic, perhaps in the new battery there is a different sensor and an algorithm for reading and calibrating data from the sensor, and after that the charger starts to charge normally, receiving normal data on the bus. It was possible to solve the problem with charging, it charges at least 1%, I did not check the temperature. Perhaps the software itself microcontroller watching for 3 pin does not work correctly. I will write after lengthy tests about more specific results.