Long story short, I have a spare motor that doesn’t work. I had no idea why.

Curious to know I dived in.

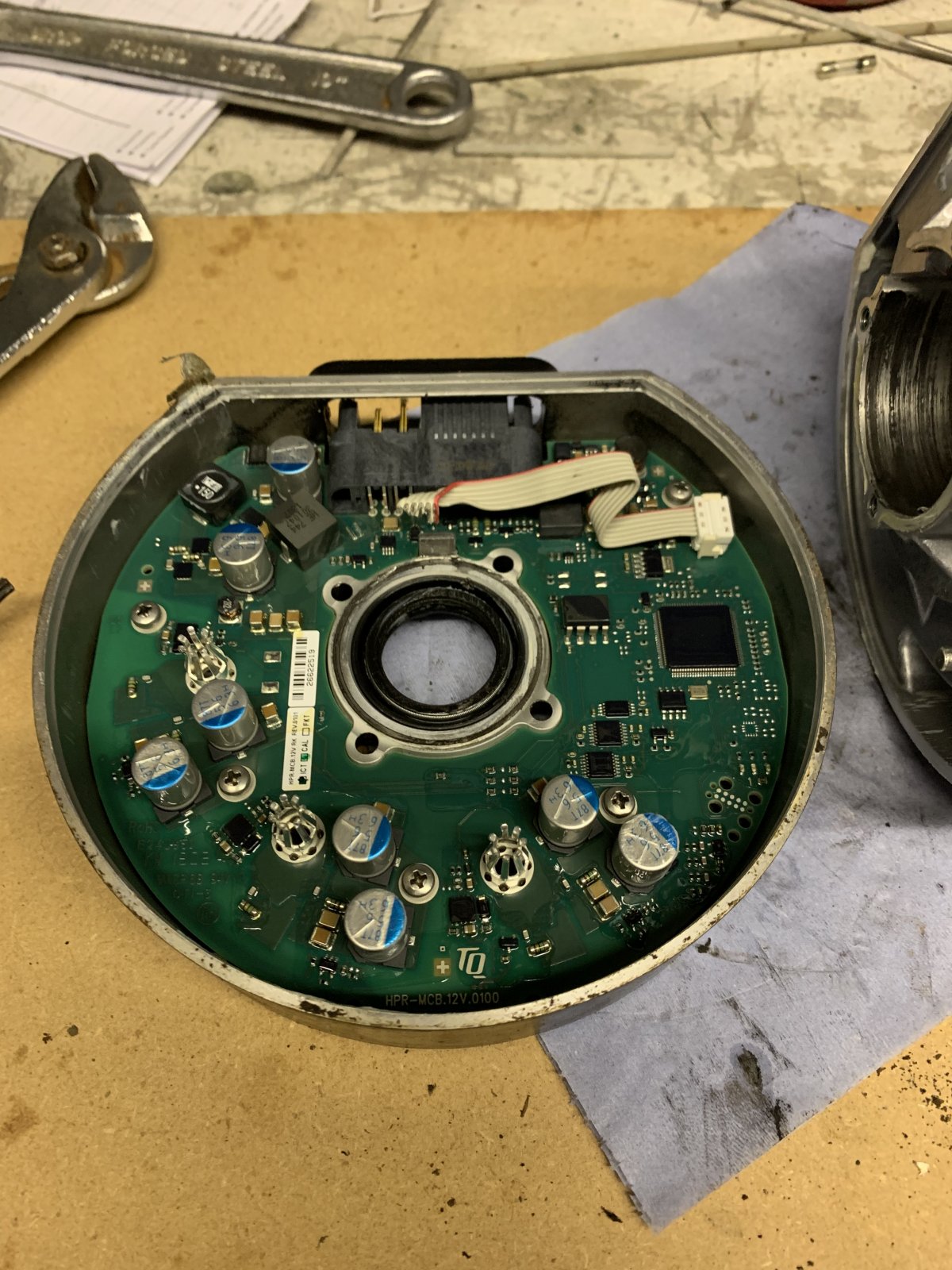

Easy enough to open. Two sides. The drive side and the electronics side.

The e side is just the 4 torx screws around the centre. Once removed the black section can be pulled off. It’s not immediately easy as it’s held in place by an O ring and the centre seal around the crank. Jiggle it push/pull/tap and it will pop off.

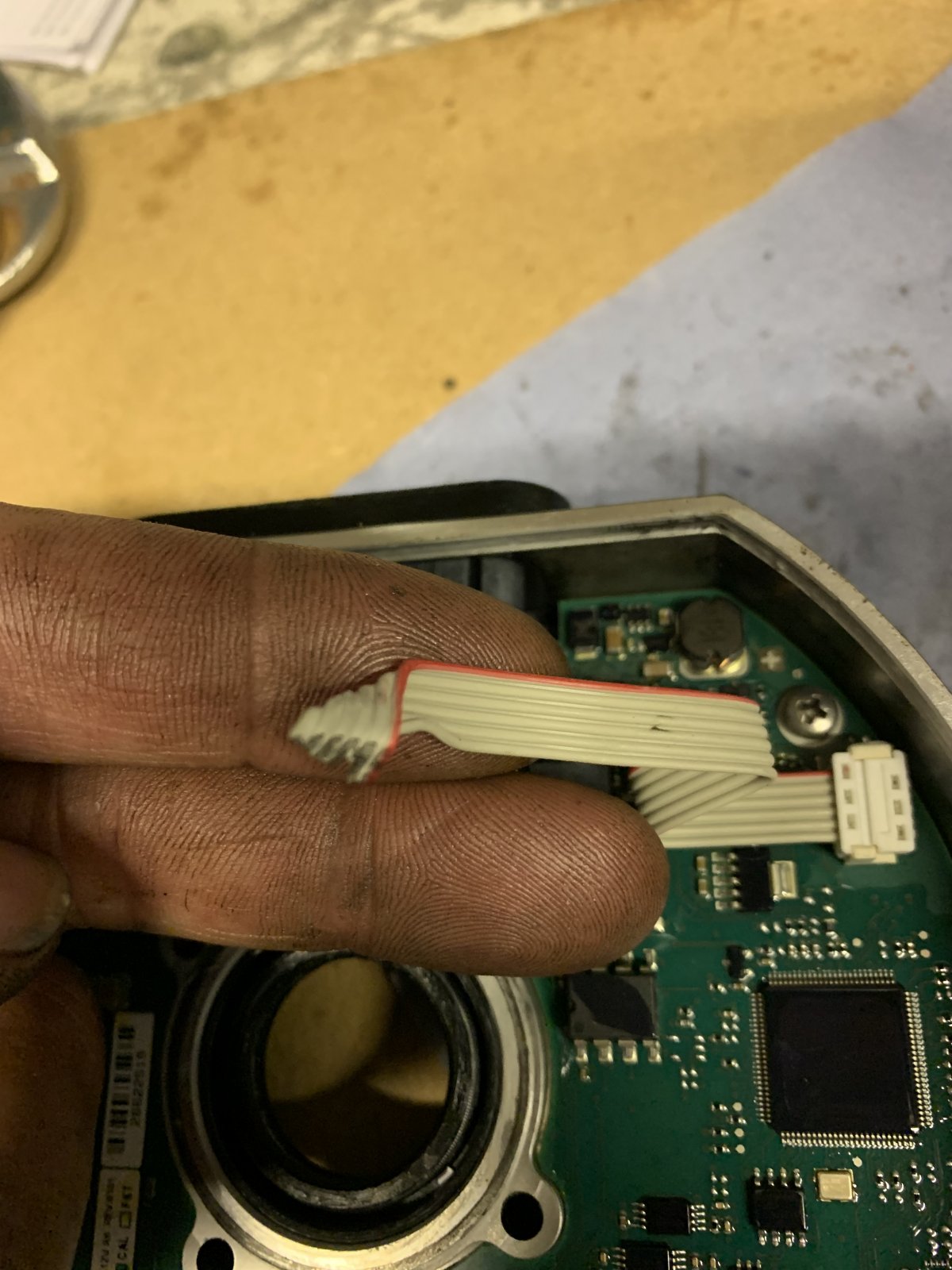

This is where I discovered the problem. It looks as if the ribbon cable connecting the pcb to the torque sensor has been sheared.

Once this side of the motor is open the crank assy can be tapped out from the other side.

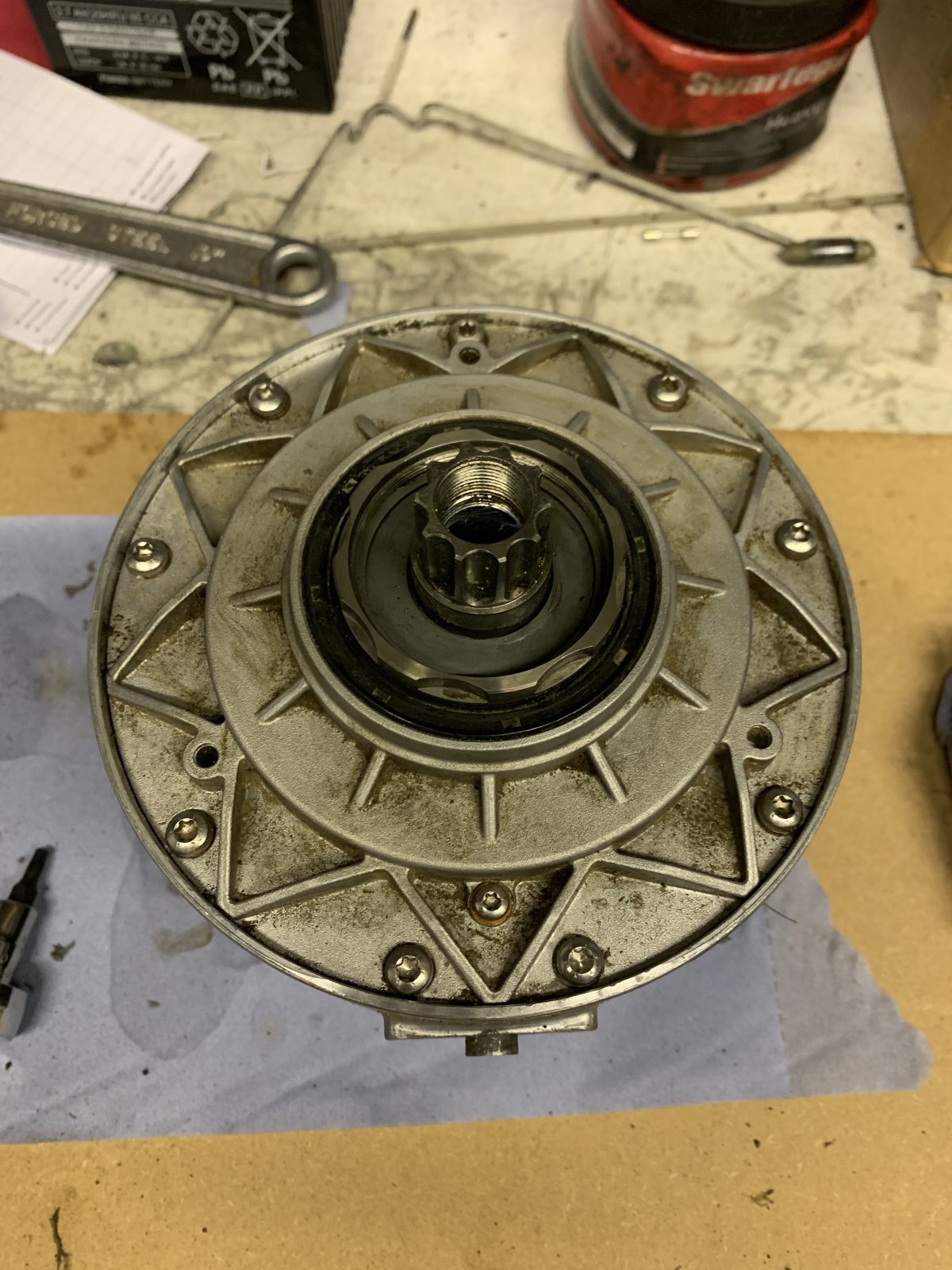

Removing the opposite side is a bit more tricky. Remove the 9 (I think?) torx screws and copper washers. Once out it’s a cast of gripping the ribs of the casting and pulling it free. Again the central seal creates friction and again, watch out for the big O ring around the edge.

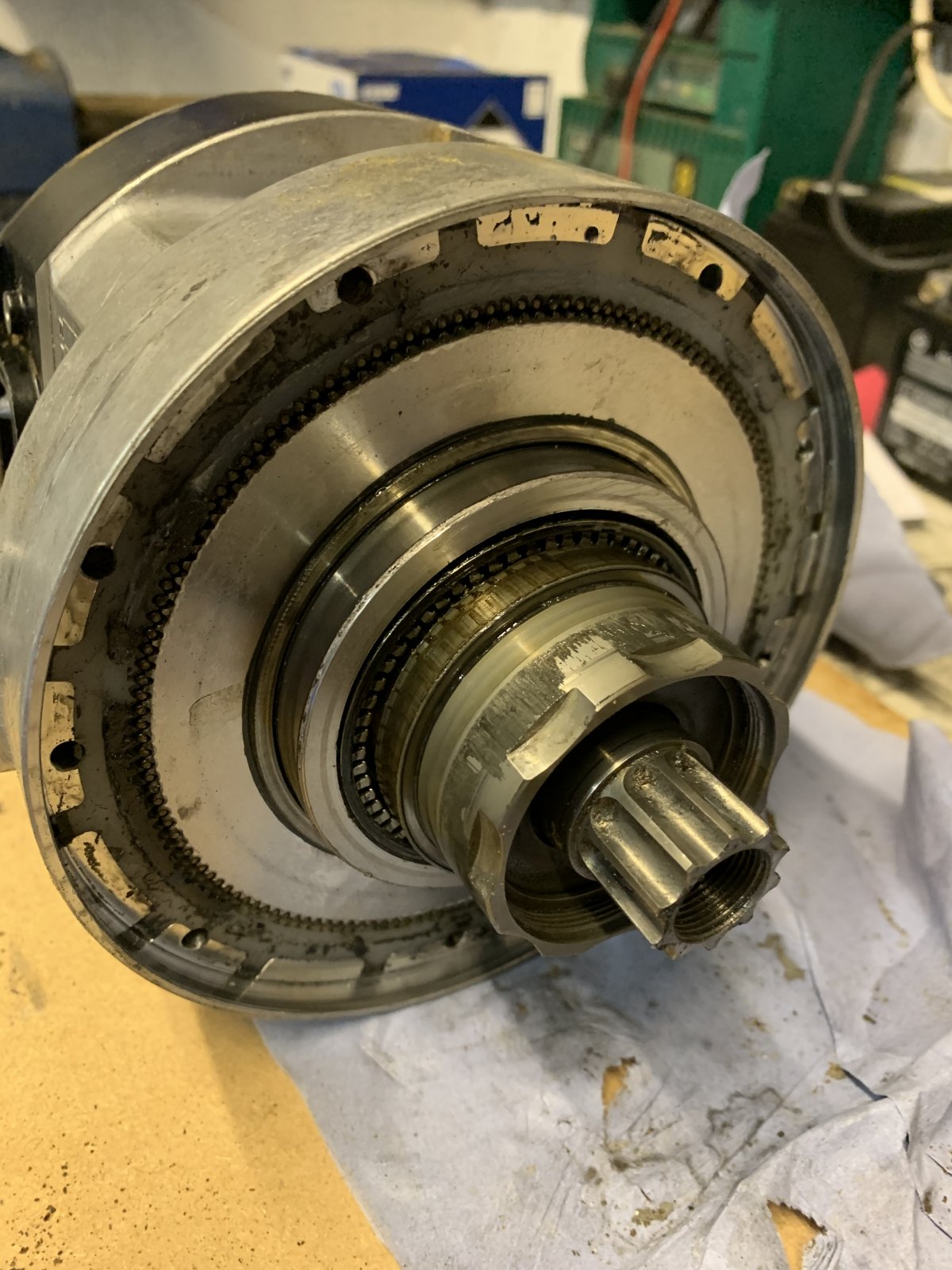

Once off you have access to the drive unit, the sprag clutch and the bearings.

All of the internals look perfect with zero evidence of water or dirt ingress.

Now I just have to source a new crank assy with torque/cadence sensor or repair the ribbon cable.

Curious to know I dived in.

Easy enough to open. Two sides. The drive side and the electronics side.

The e side is just the 4 torx screws around the centre. Once removed the black section can be pulled off. It’s not immediately easy as it’s held in place by an O ring and the centre seal around the crank. Jiggle it push/pull/tap and it will pop off.

This is where I discovered the problem. It looks as if the ribbon cable connecting the pcb to the torque sensor has been sheared.

Once this side of the motor is open the crank assy can be tapped out from the other side.

Removing the opposite side is a bit more tricky. Remove the 9 (I think?) torx screws and copper washers. Once out it’s a cast of gripping the ribs of the casting and pulling it free. Again the central seal creates friction and again, watch out for the big O ring around the edge.

Once off you have access to the drive unit, the sprag clutch and the bearings.

All of the internals look perfect with zero evidence of water or dirt ingress.

Now I just have to source a new crank assy with torque/cadence sensor or repair the ribbon cable.