Has anyone dropped the motor on an e160RS ? I have an aluminium bash guard ( the one someone on this site makes) which bolts into the frame tube at the front and has a strong velcro pad at the back.

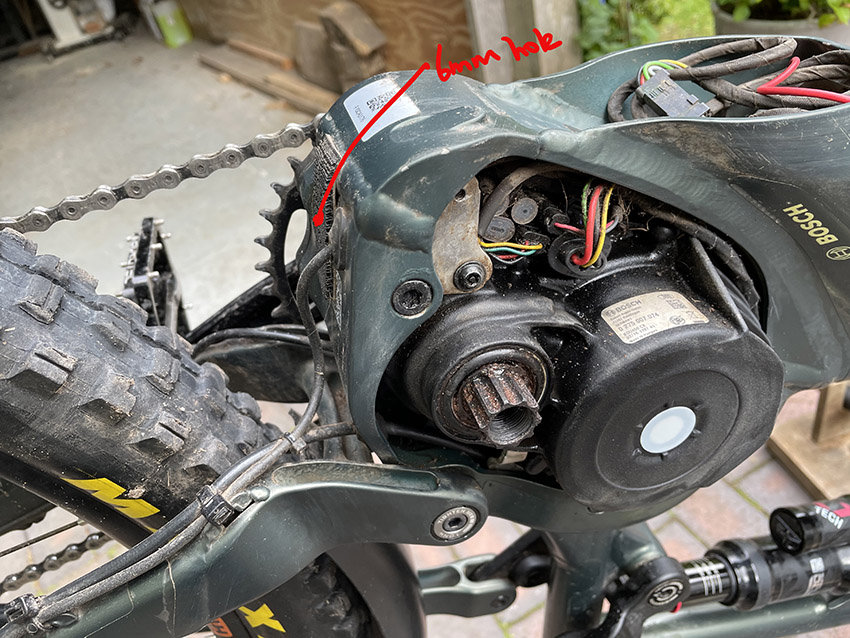

It keeps popping off at the back when it clips a log or something. I was thinking of drilling a 6mm hole, tapping and securing with a bolt into the frame or a

threaded rivet. Has anyone done this and do you know what's behind the frame to be drilled ?

threaded rivet. Has anyone done this and do you know what's behind the frame to be drilled ?

It keeps popping off at the back when it clips a log or something. I was thinking of drilling a 6mm hole, tapping and securing with a bolt into the frame or a