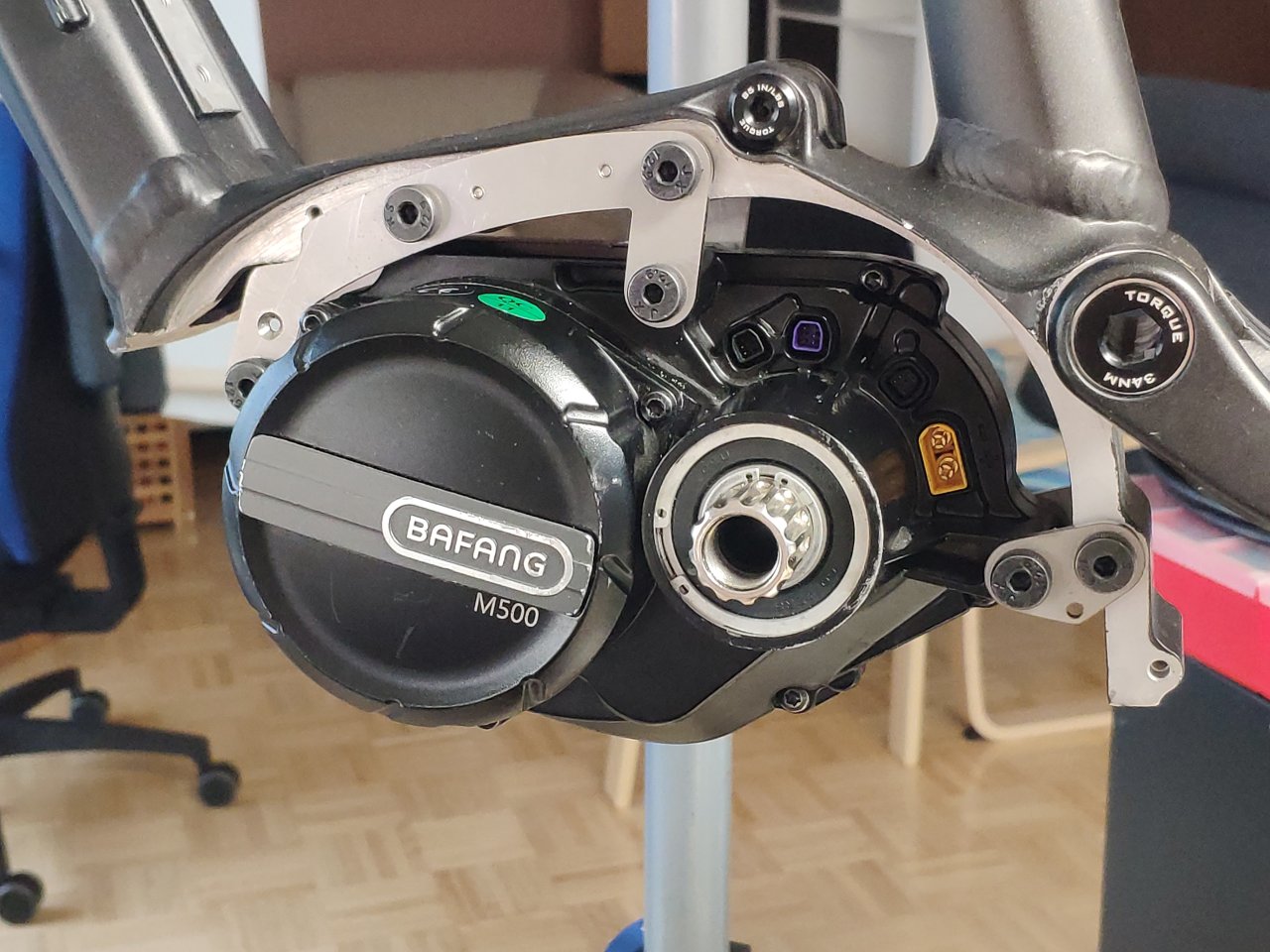

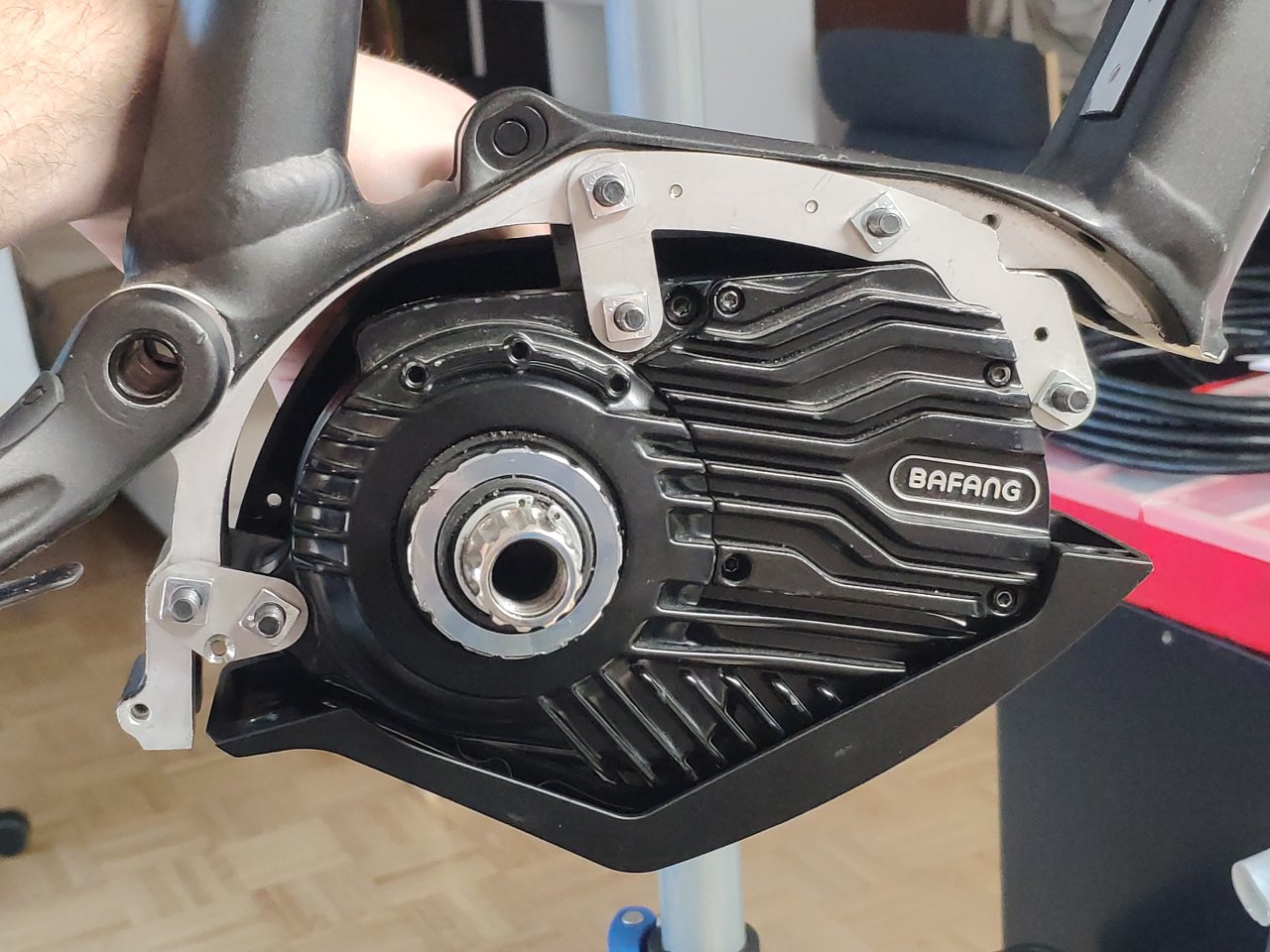

Hi everyone, after a few days of active development I can finally ditch the Bosch Performance Line motor and fit a Bafang M560. I have designed matching 3D printed parts that fit the "standard rounding" that Bosch frame manufacturers used until 2017/2018. The steel and 3D printed parts adapt from Bosch to Bafang so that the supplied Bafang cover (MD G521.B) and the Bafang bashguard (BG G521.B) can also be easily mounted with the original screws. I will also be designing 3D printed parts for the "A version" (MD G521.A cover and BG G521.A bashguard). The motor has been positioned in CAD so that both versions can be fitted with the appropriate adaptations.

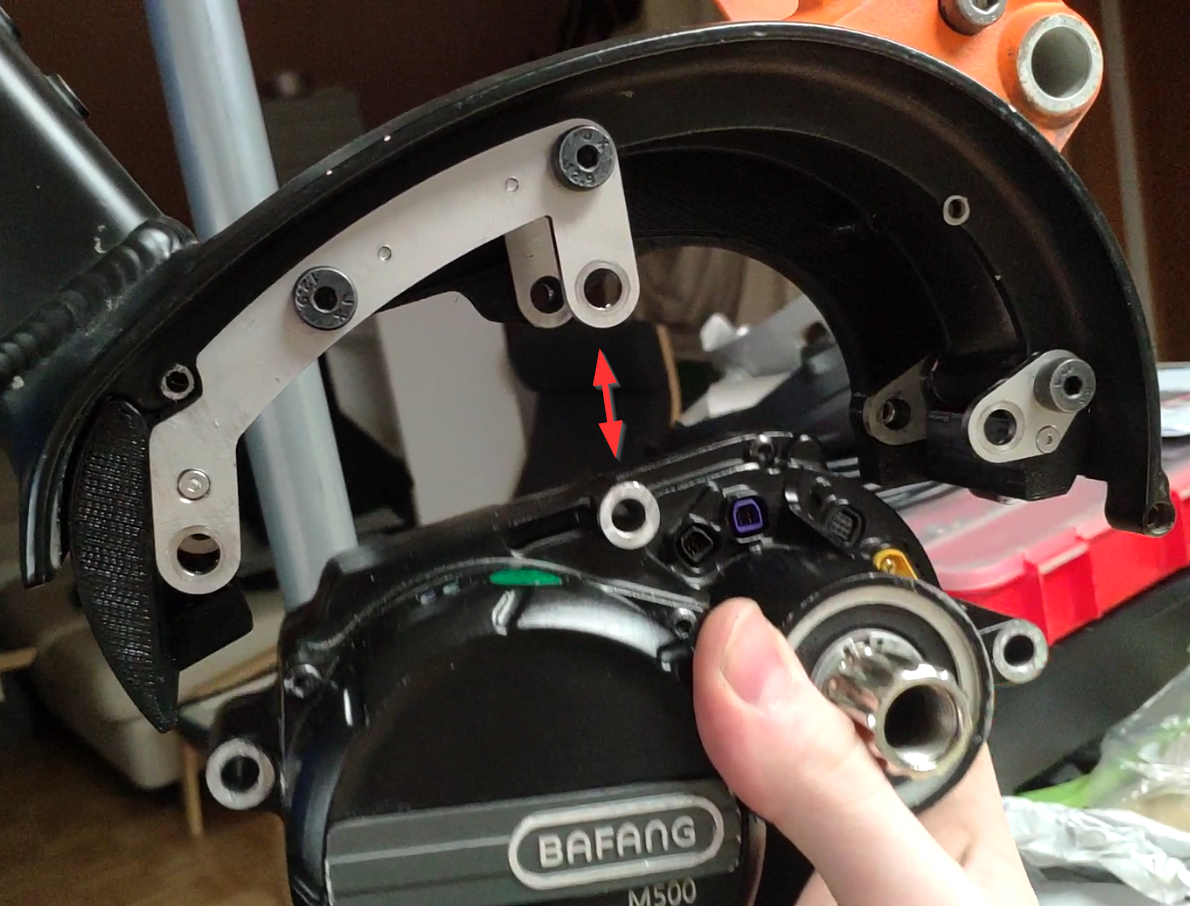

The kit has been designed so that it can remain fitted if the motor needs to be removed for maintenance. It is bolted on with M6 shoulder bolts and 4 additional M3*8mm Torx bolts, which are identical to the Bafang bolts supplied for the cover (marked red in the picture below). The M4 screws for mounting the bashguard have the same hexagon socket as the shoulder screws.

I also reused two of the three Bosch screws (marked in yellow). All in all, you only need the following tools for assembly: Torx 10 (3D print connector, cover), Torx 20 (Bosch screws) and 4mm square (bashguard and shoulder screws). I may replace the Bosch screws with Torx 10 and threads in the plates to optimise further.

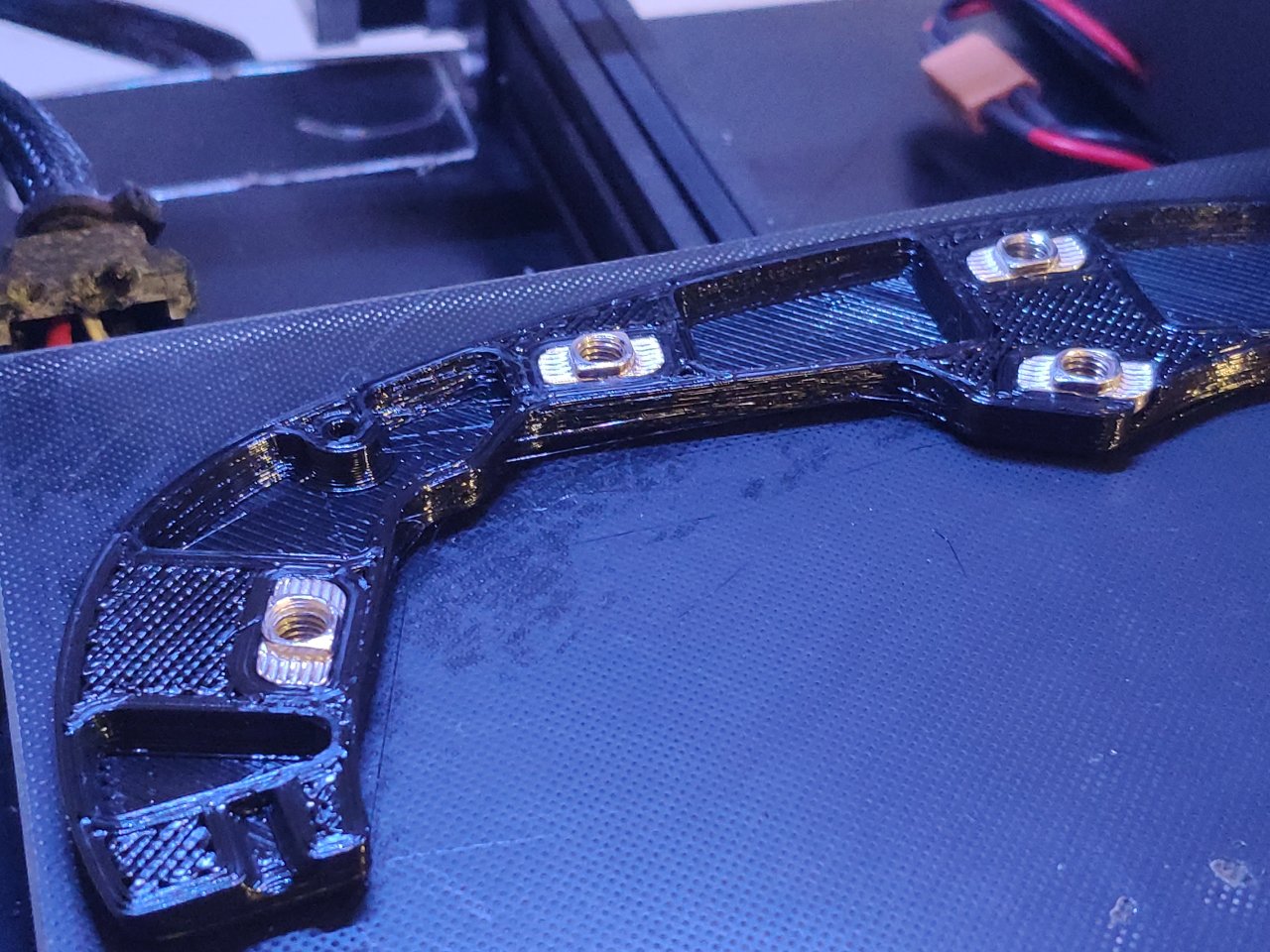

Yes, I use 3D printing (PETG) to attach an ebike motor. However, the important components are bolted to the frame using shoulder bolts and 3mm V2A steel plates. In the longer term, the plastic parts are to be replaced by parts made of carbon/fibreglass-reinforced material. Injection moulding would be ideal, but there has to be enough interest first... T-slot nuts are integrated into the 3D print as threads on the opposite side. To do this, you pause the print, insert the nuts and then simply continue printing:

T-slot nuts are integrated into the 3D print as threads on the opposite side. To do this, you pause the print, insert the nuts and then simply continue printing:

The kit has a very minimalist design, which means that the plates can always remain the same and only the connectors need to be adapted to the frame contour. Example of this Trek Powerfly FS 7 from 2016 (exactly this model). Here the hole spacing fits, but the contour has been adapted by the manufacturer, which means that the standard round fairing would not fit easily:

The contours therefore differ in some cases, which means that the hole spacing may fit, but the contour may not. If you want to try it, I have a few plates left:

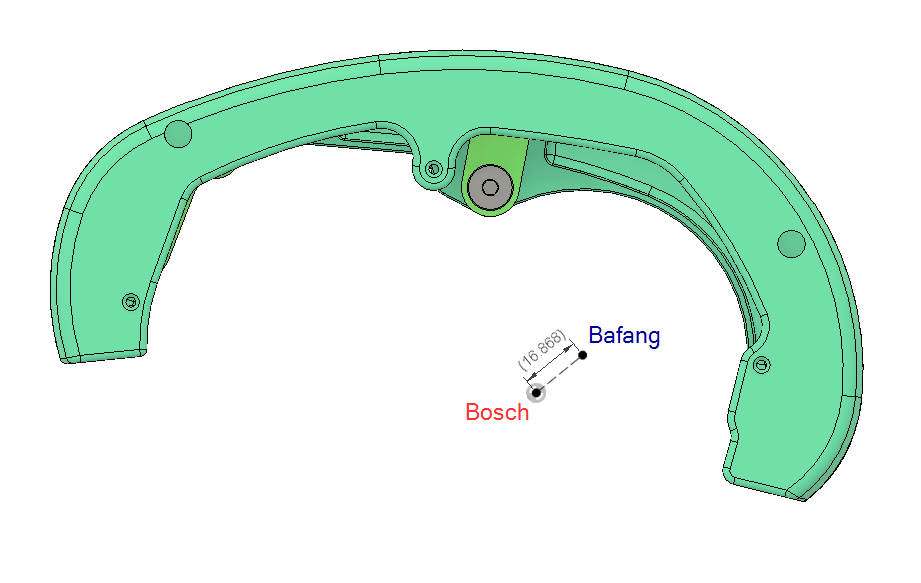

The offset to the centre of the bottom bracket of the original Bosch motor mount is approximately 16.87mm towards the centre of the frame:

The kit has been designed so that it can remain fitted if the motor needs to be removed for maintenance. It is bolted on with M6 shoulder bolts and 4 additional M3*8mm Torx bolts, which are identical to the Bafang bolts supplied for the cover (marked red in the picture below). The M4 screws for mounting the bashguard have the same hexagon socket as the shoulder screws.

I also reused two of the three Bosch screws (marked in yellow). All in all, you only need the following tools for assembly: Torx 10 (3D print connector, cover), Torx 20 (Bosch screws) and 4mm square (bashguard and shoulder screws). I may replace the Bosch screws with Torx 10 and threads in the plates to optimise further.

Yes, I use 3D printing (PETG) to attach an ebike motor. However, the important components are bolted to the frame using shoulder bolts and 3mm V2A steel plates. In the longer term, the plastic parts are to be replaced by parts made of carbon/fibreglass-reinforced material. Injection moulding would be ideal, but there has to be enough interest first...

The kit has a very minimalist design, which means that the plates can always remain the same and only the connectors need to be adapted to the frame contour. Example of this Trek Powerfly FS 7 from 2016 (exactly this model). Here the hole spacing fits, but the contour has been adapted by the manufacturer, which means that the standard round fairing would not fit easily:

The contours therefore differ in some cases, which means that the hole spacing may fit, but the contour may not. If you want to try it, I have a few plates left:

The offset to the centre of the bottom bracket of the original Bosch motor mount is approximately 16.87mm towards the centre of the frame:

Last edited: