freerider85

Member

Hi guys I need help with my levo motor issue .

One day bike just simply stopped working ,battery turn on but there was no assistance at all .

When I started searching for issue (motor was completely invisible in blevo an MC no communication ).

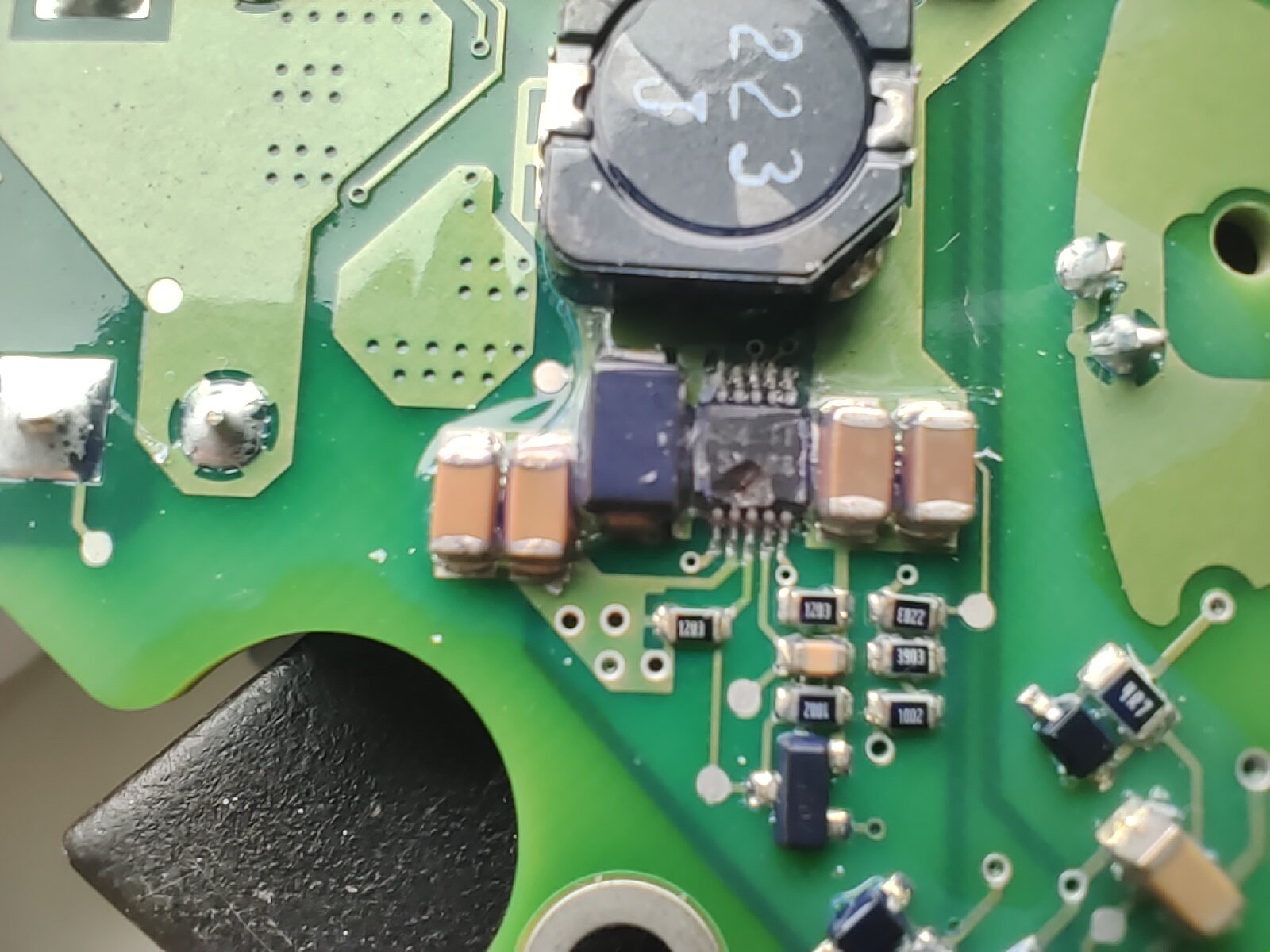

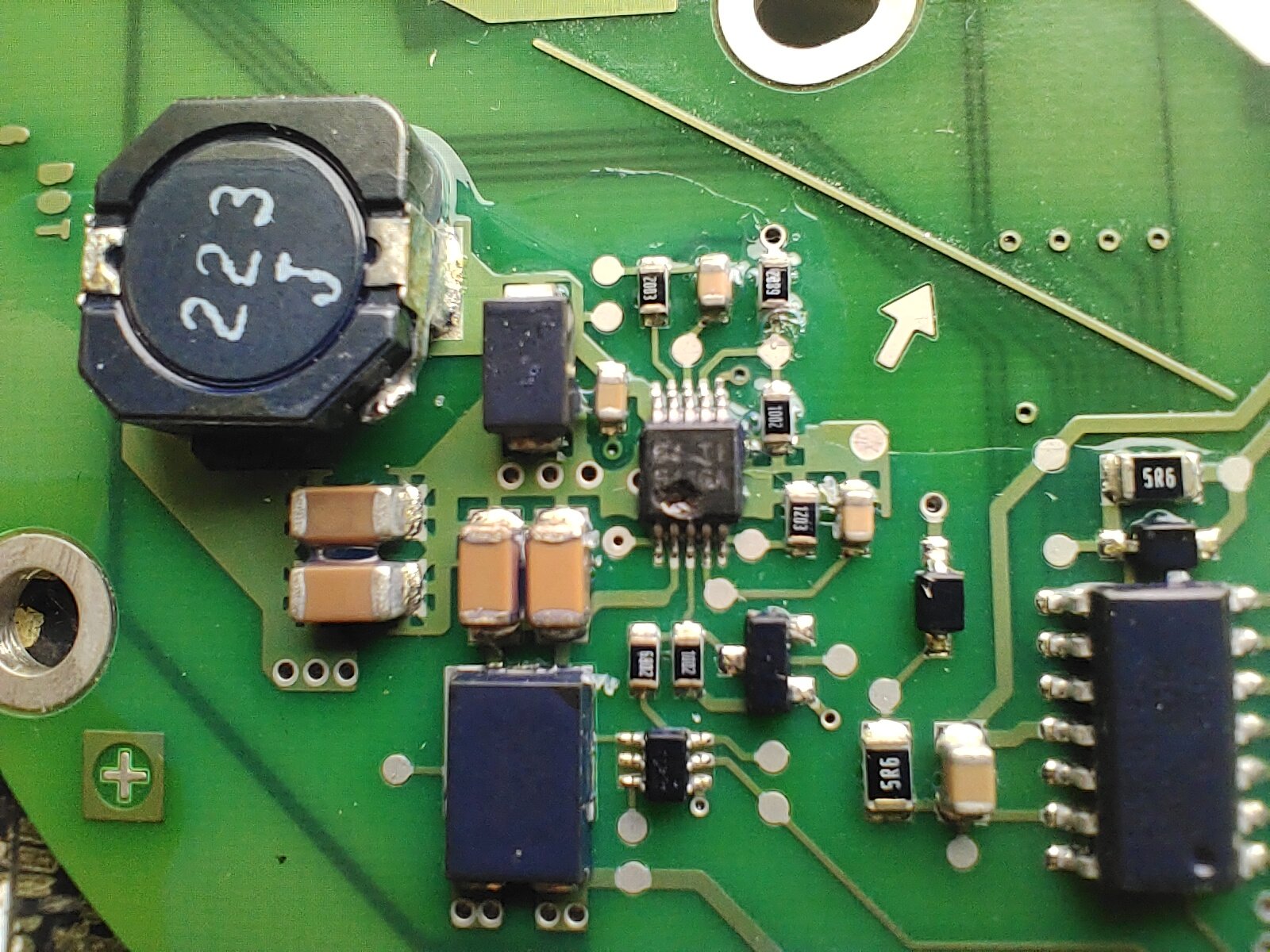

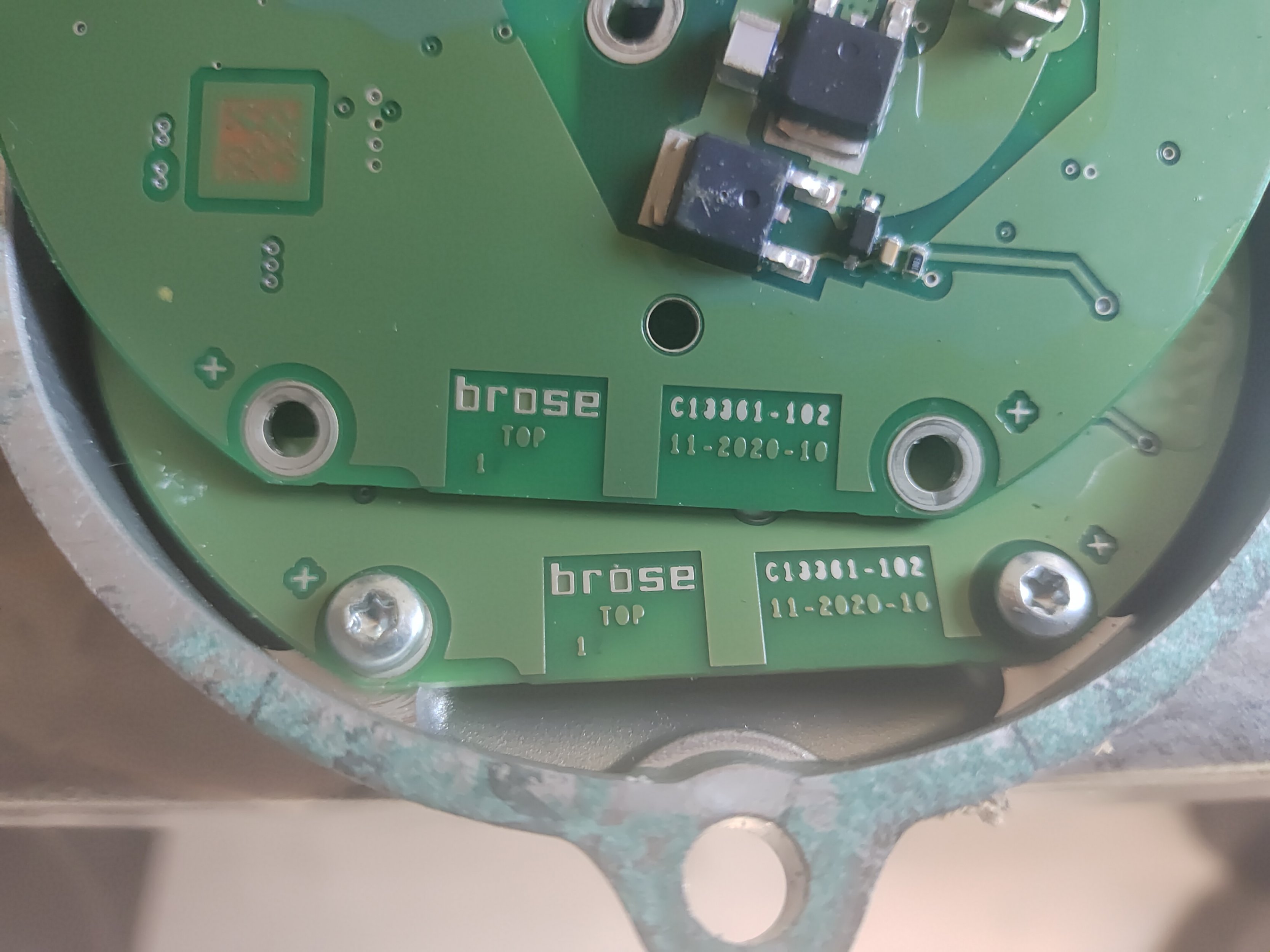

After disassembly I discovered couple parts on motor board (ic's) were burned .

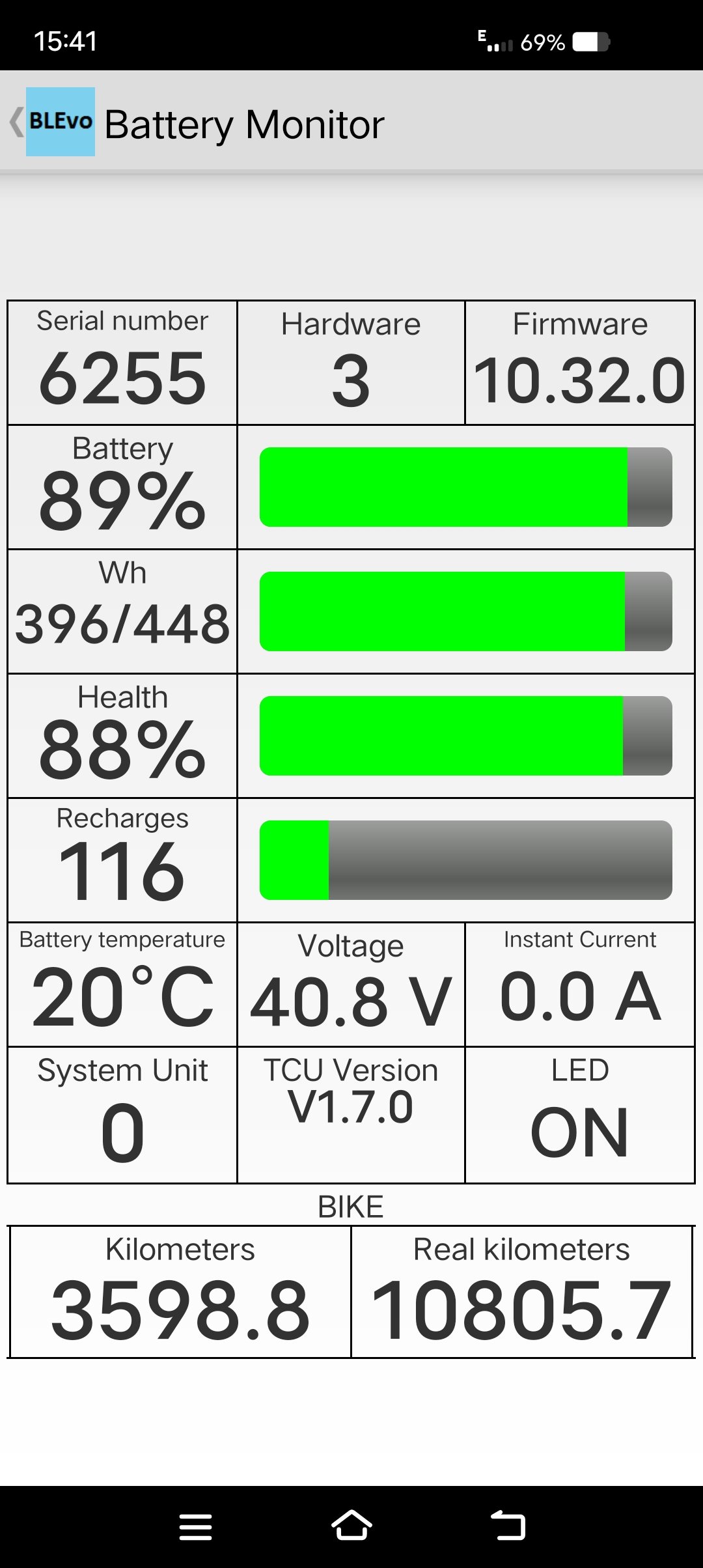

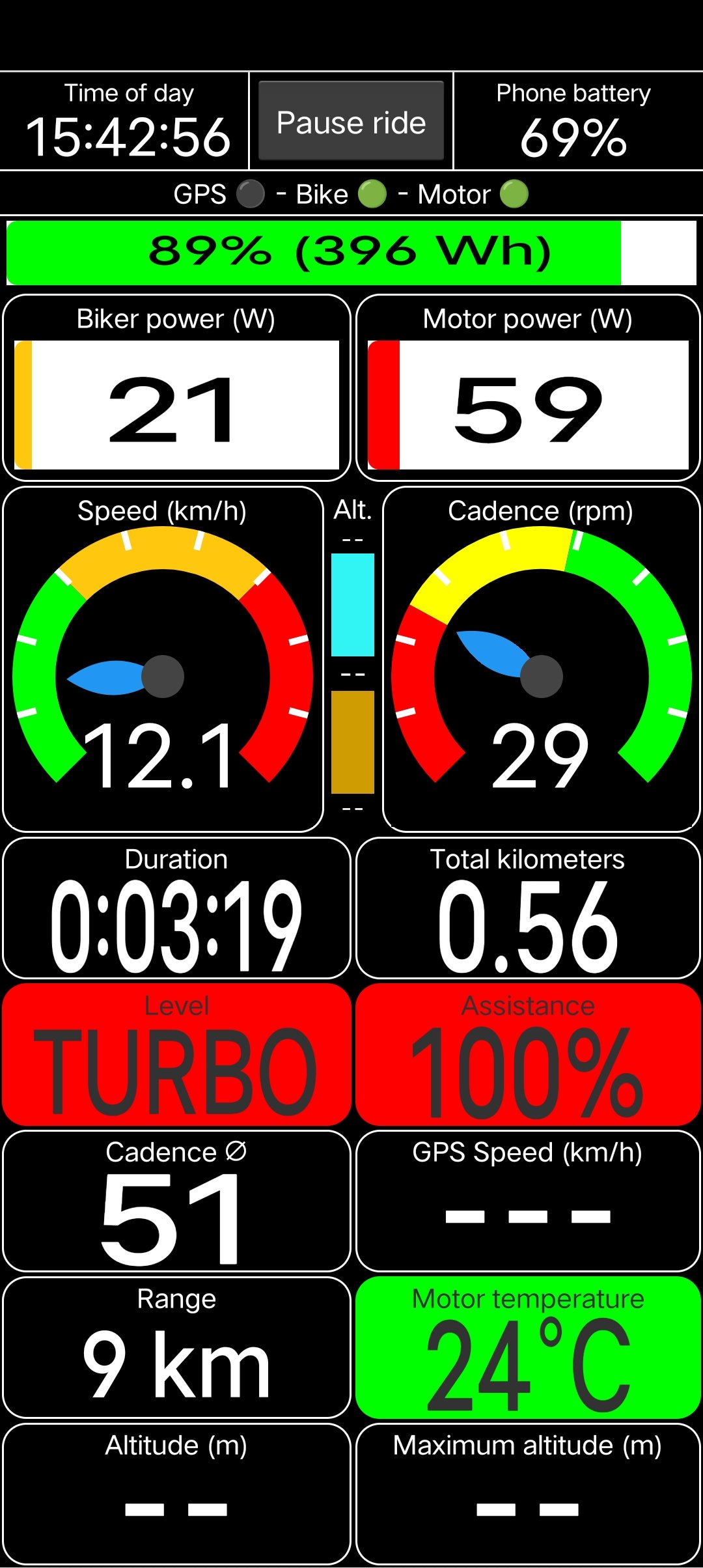

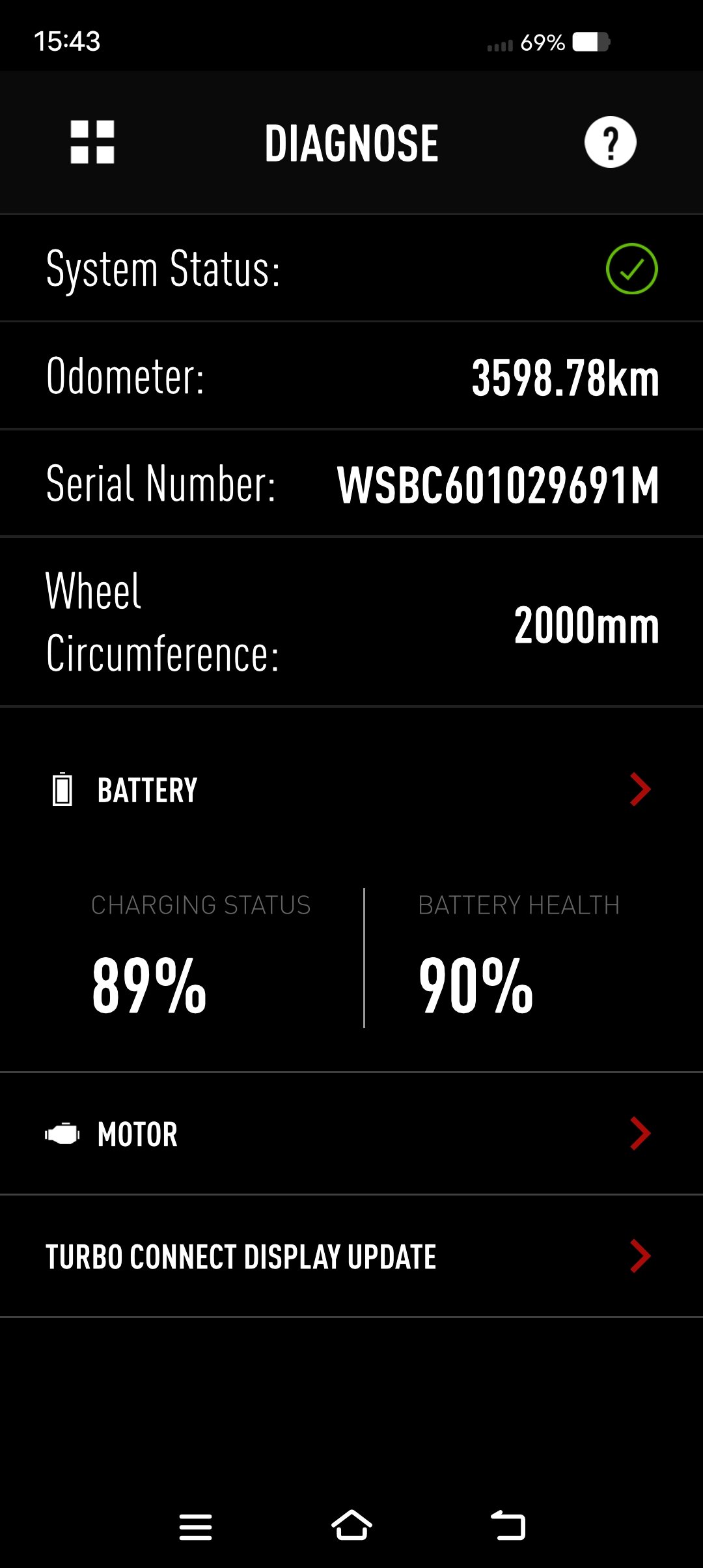

So I got my self new/used motor PCB .Now I can see motor serial # and all sensors are working in app I ca see even battery current when pedal .

BUT MOTOR IT SELF IS STILL DEATH NO ASSISTANCE. I already checked every sensor even made better connection for torque sens. pickup ring as is not very good from factory . I checked 100 times cable from battery and ring every wire with voltmeter all connections are good (power/data) .

Last thing is probably firmware is it possible battery and new motor board is not compatible due different firmware versions ? .

Now I'm just stranded thinking of buying new analog frame and ditch levo use just parts from it because new motor is too expensive and my battery is also old .

Any help appreciated

One day bike just simply stopped working ,battery turn on but there was no assistance at all .

When I started searching for issue (motor was completely invisible in blevo an MC no communication ).

After disassembly I discovered couple parts on motor board (ic's) were burned .

So I got my self new/used motor PCB .Now I can see motor serial # and all sensors are working in app I ca see even battery current when pedal .

BUT MOTOR IT SELF IS STILL DEATH NO ASSISTANCE. I already checked every sensor even made better connection for torque sens. pickup ring as is not very good from factory . I checked 100 times cable from battery and ring every wire with voltmeter all connections are good (power/data) .

Last thing is probably firmware is it possible battery and new motor board is not compatible due different firmware versions ? .

Now I'm just stranded thinking of buying new analog frame and ditch levo use just parts from it because new motor is too expensive and my battery is also old .

Any help appreciated

Last edited: