Longfellow78

Active member

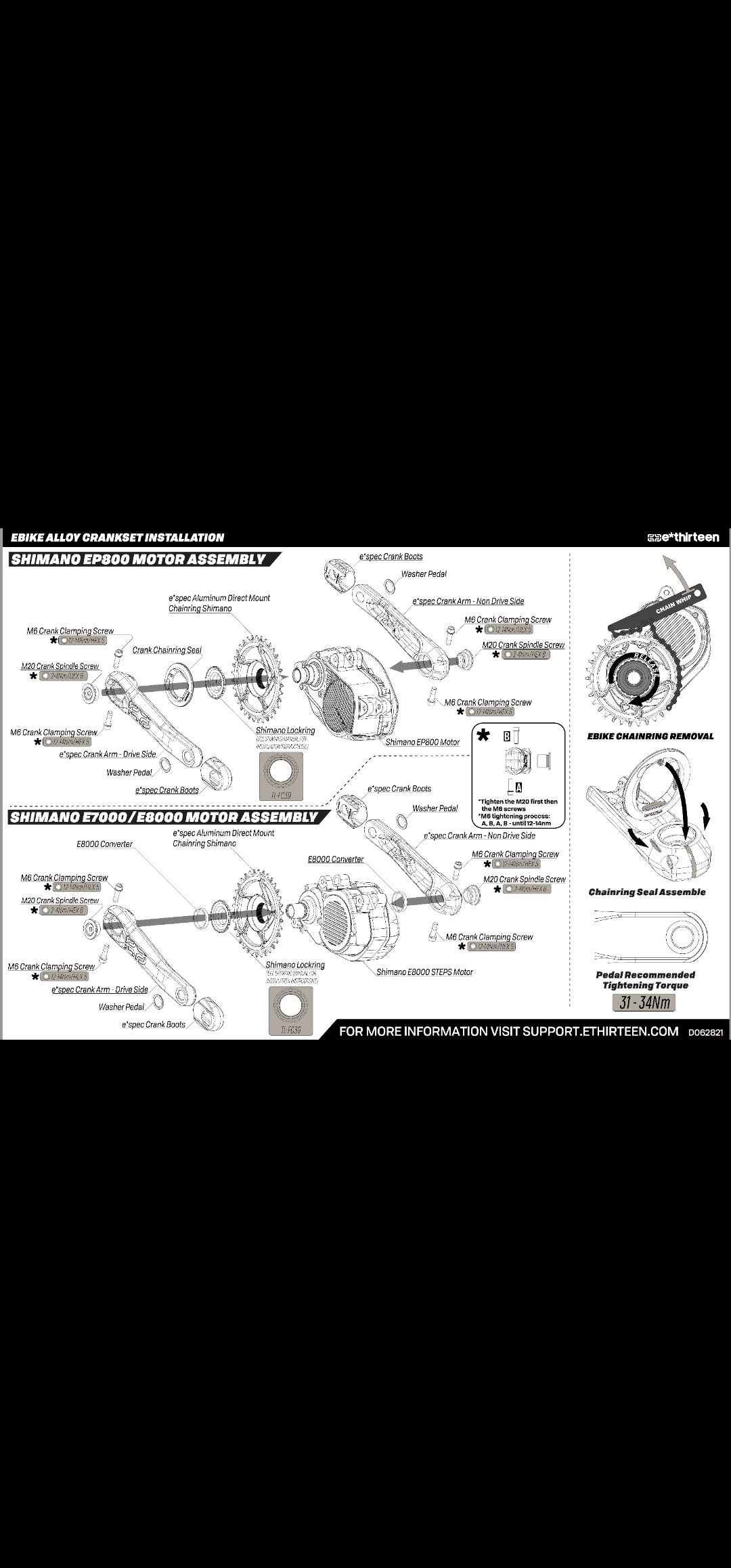

I've heard various things about the E*13 cranks and problems with the EP8.

But lots of threads and it's confusing. Please can someone in one post sum up the summary information for the noobs. Is there anything to add to below as is my understanding correct? Thanks.

1) As far as I read - there was a problem with the Carbon cranks falling off the top spec carbon bikes, which were replaced by Shimano with alloy cranks which was "supposed" to fix it.

2) Then there is a problem with the motor axle snapping because the pinch bolts were mounted the same side as a little hole in the motor axle, compressing and cracking it - the fix being to ensure that the motor hole is the opposite side to the pinch bolt, and that the pinch bolt is correctly torqued (don't know the torque amount) that the preload cap is correctly torqued (don't know the amount) and that blue threadlock is placed on the preload cap

3) That alloy cranks are falling off due to again incorrect torque and lack of threadlock as above.

Did I also read something about removing a rubber seal? Or was that to fit XT replacement cranks?

The root cause of this is that the cranks are not certified as compatible with shimano and that they are microscopically the wrong size, and if not tight enough they "walk" off the axle and cause all the above problems.

Any corrections or comments much appreciated, thanks.

But lots of threads and it's confusing. Please can someone in one post sum up the summary information for the noobs. Is there anything to add to below as is my understanding correct? Thanks.

1) As far as I read - there was a problem with the Carbon cranks falling off the top spec carbon bikes, which were replaced by Shimano with alloy cranks which was "supposed" to fix it.

2) Then there is a problem with the motor axle snapping because the pinch bolts were mounted the same side as a little hole in the motor axle, compressing and cracking it - the fix being to ensure that the motor hole is the opposite side to the pinch bolt, and that the pinch bolt is correctly torqued (don't know the torque amount) that the preload cap is correctly torqued (don't know the amount) and that blue threadlock is placed on the preload cap

3) That alloy cranks are falling off due to again incorrect torque and lack of threadlock as above.

Did I also read something about removing a rubber seal? Or was that to fit XT replacement cranks?

The root cause of this is that the cranks are not certified as compatible with shimano and that they are microscopically the wrong size, and if not tight enough they "walk" off the axle and cause all the above problems.

Any corrections or comments much appreciated, thanks.