Rod B.

Well-known member

This is Part Two in a two part series on servicing the Rise pivot bearings and linkage. Part Two will discuss servicing the Rise's lower main pivot axle and bearings. If possible, please read Part One before continuing with this article.

In Part One, "Orbea Rise - Upper Linkage Axle and Bearing Service" I discuss:

After you've been riding your Rise for awhile, you may notice your Rise has started to make a creaking noise while riding. The sound will sound similar to a creaking seat post or seat. You may also notice that the rear suspension may begin to feel stiff and not as plush as it used to be. You may question your shock/settings due to the stiffness in the suspension. In most circumstances, there is nothing wrong with your rear shock, the seat post or saddle rail clamp. The stiff suspension and or creaking noise may be attributed to a upper or lower pivot axle, linkage arms and or bearings in need of cleaning and lubrication.

Like many things on a bike, the pivot linkage needs the occasional bit of love. As a personal rule, I like to full service clean, inspect and lube the suspension linkage on my bikes every six months. I grease the upper and lower pivot axles every few months. This keeps noises to a minimum and the suspension functioning smoothly. You don't want to skip servicing the suspension linkage on your bike, it will make a good bit of difference in how your bike performs. Depending upon the frequency of your rides, distance covered, the riding climate and type of terrain your ride, you may only need to service your linkage once a year, or you may need to do it more frequently than every six months.

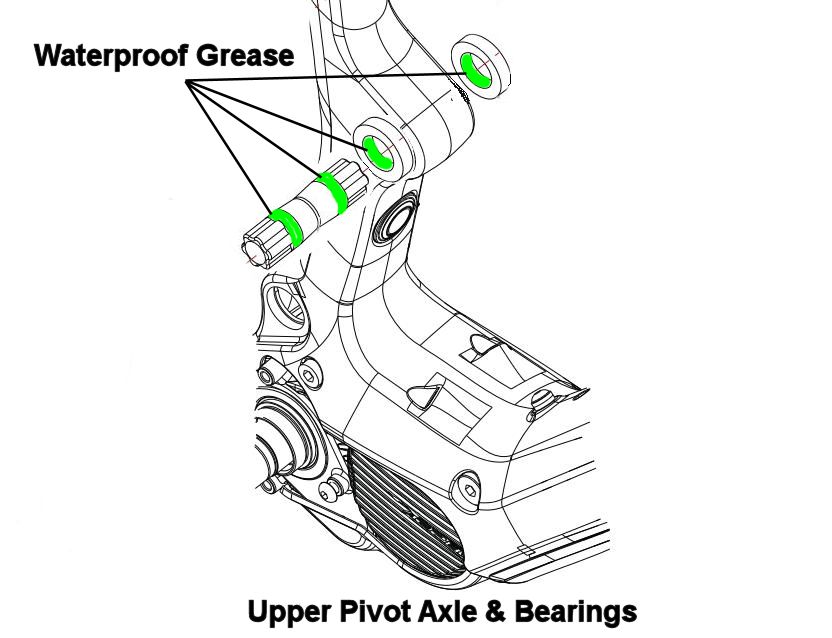

It’s important to keep in mind that the upper and lower pivot axles on the Rise do not have any seals or O rings which prevent water or dust from working its way into where the alloy axle contacts and rides upon the steel bearings. I’ve found that if the bike is exposed to frequent moisture or powdery dust, it will eventually wash out or dry up the pivot axle grease. Depending upon which axle runs dry of lubrication, it will start making a creaking noise caused by the alloy axle rubbing on the steel pivot bearing races. As I stated before, the noise will sound exactly the same as a seat post or saddle creaking. It’s also been my experience the upper pivot axle needs to be lubricated more frequently than the lower pivot axle.

To determine the condition of your rear suspension, place the bike in a bike stand. Remove the rear wheel. Wrap a soft rag around the front area your rear shock. Remove the shock's front mounting bolt. Lower the shock down so that it rests on the downtube. The rag will protect the paint.

With your hands, slowly raise and lower the rear triangle. With your ears listen for noise as you move the triangle up and down. There should be no grinding, grittiness, or squeaking noise. With your fingers, feel for resistance in the movement, any stiff spots, as you rotate the triangle. The movement should be smooth and easy. If you encounter noise and or, resistance, then your linkage needs service.

In most instances during disassembly and inspection, you will find the pivot bearings on your Rise will be fine. You will only need to clean and re-lubricate the exterior contact points where the bearing touches bolts, linkage arm and or the axle.

Occasionally, you will come across a pivot bearing that is frozen or stiff to spin. This may be because the bearing has flat spots, dirt has contaminated the bearing grease and or, water has worked past the bearing seal and rusted the steel bearing components. Stiff bearings will cause your Rise suspension to perform like an overinflated rear shock and your bike will track poorly on rough terrain.

If you encounter a frozen or hard to spin pivot bearing, you will need to determine why the bearing isn't functioning. To do this, remove the bearing's outer seal, fully clean the bearing, and inspect it for function. If after cleaning, the bearing spins freely without any bumpy or rough feeling, then all you will need to do is re-lubricate the bearing. If after cleaning the bearing does not spin easily, or exhibits a rough feeling, then the bearing will need to be replaced.

Enduro recommends the following greases for the bearings used on the Rise:

www.endurobearings.com

www.endurobearings.com

I do not cover replacing the pivot bearings in this tech series. While it's not too difficult to replace a pivot bearing, it does require some mechanical skill and a few specialized tools. If you don't know what you are doing, you can easily damage the frame where the bearing inserts, the paint, or the new bearing itself by improper installation. If you do not possess the mechanical skills or tools to replace a pivot bearing, I recommend taking your Rise to your local bike shop and have the bearings replaced.

Here are several good YouTube videos on servicing a pivot bearing and also the removal and replacement of pivot bearings should you wish to do the work yourself.

The Lower Main Pivot Assembly:

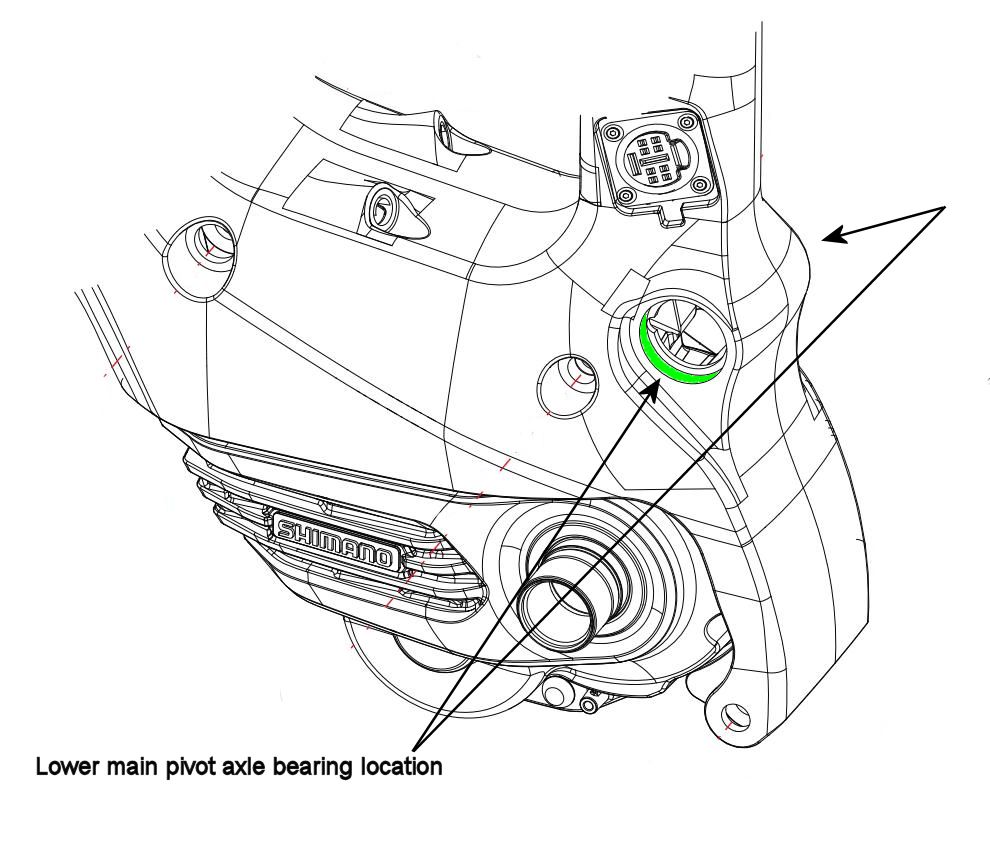

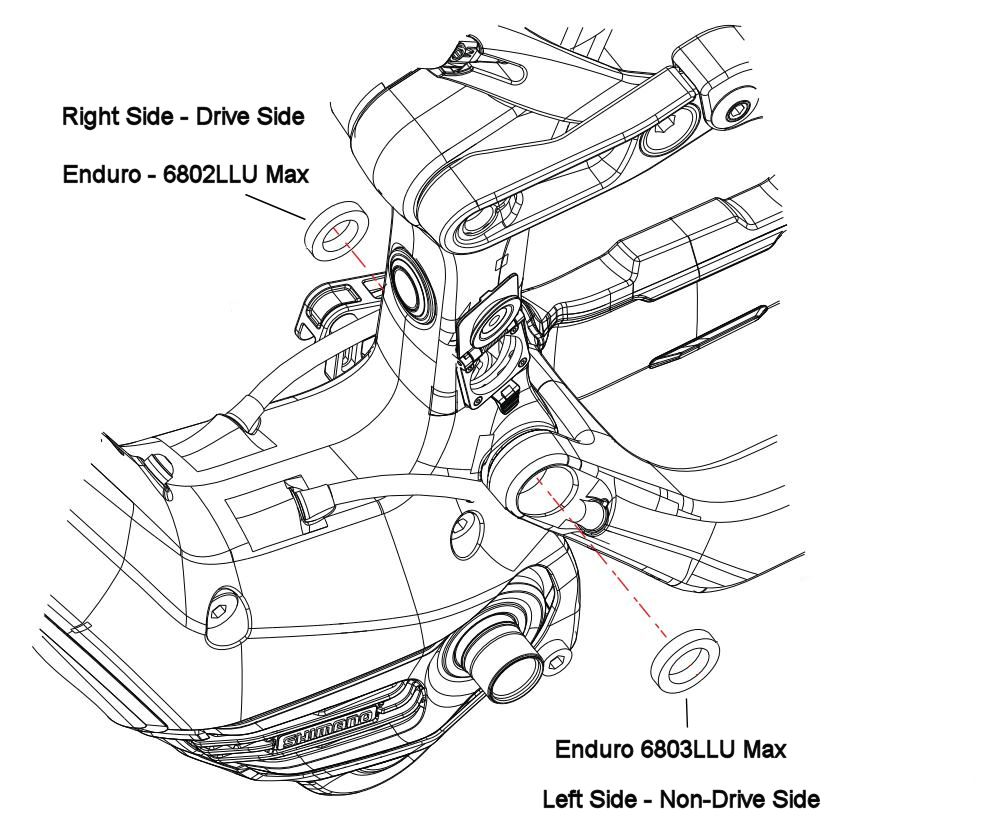

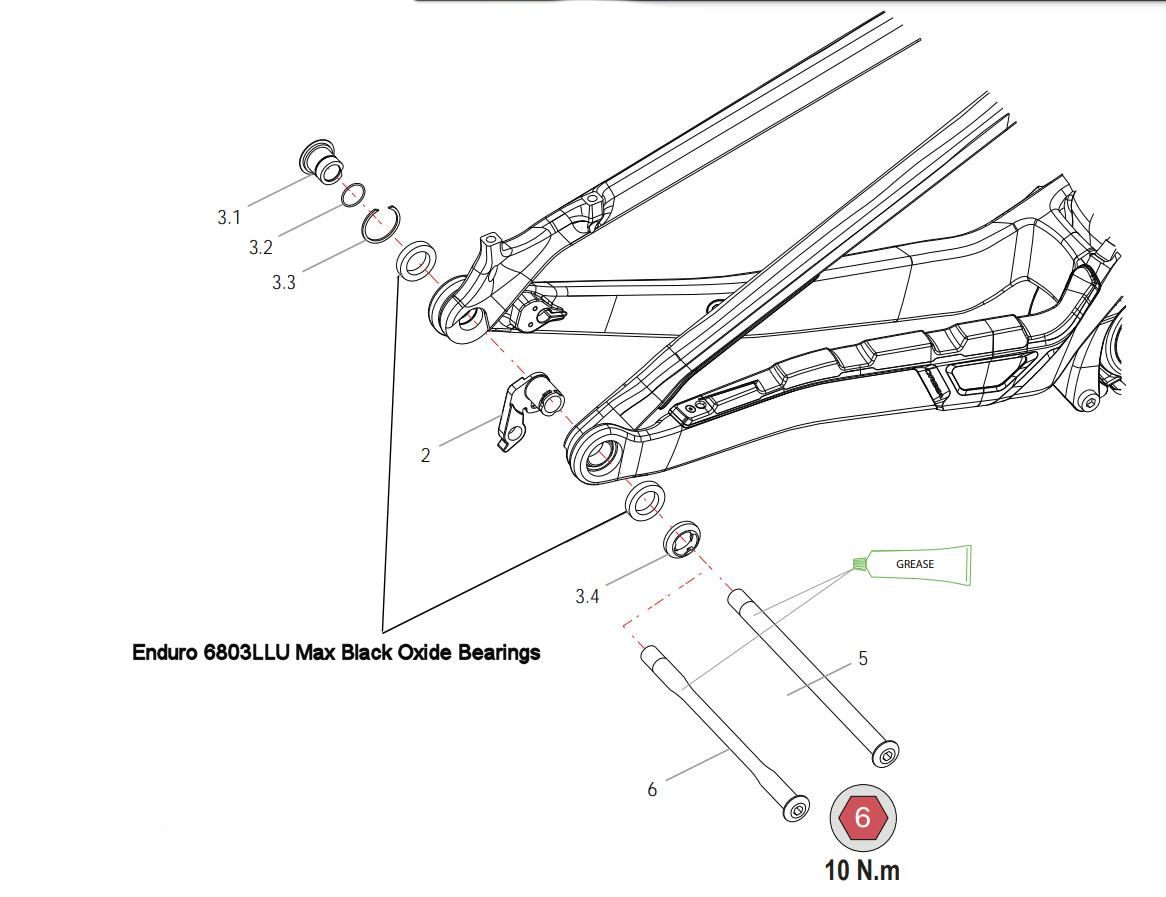

The lower main pivot axle bearing assembly consists of two Enduro bearings which are housed in the main frame. The two bearings differ in size. The left, non-drive side of the frame, uses is an Enduro 6803LLU Max BOSL (Black Oxide Coating) bearing. The right, drive side of the frame, uses an Enduro 6802LLU Max BOSL bearing.

Note: "LLU" refers to the seal design used on the bearing, which is a "Dual Lip" and "Full Contact" seal. This is one of the better designs at keeping contaminants out of the bearing. "Max" refers to the absence of an inner bearing retainer and allows room for the "Maximum" amount of bearings to be installed in the bearing. Refer to Part One in my series for further explanation on "LLU" and "Max" terminology.

The Lower Main Pivot Axle Assembly:

You have the option of removing the upper and lower linkage and allow the rear triangle to hang off the bike of the bike. Or, as I personally like to do, remove and replace the upper and lower pivot sections one at a time as separate procedures. Either way will work.

How the lower main pivot axle functions:

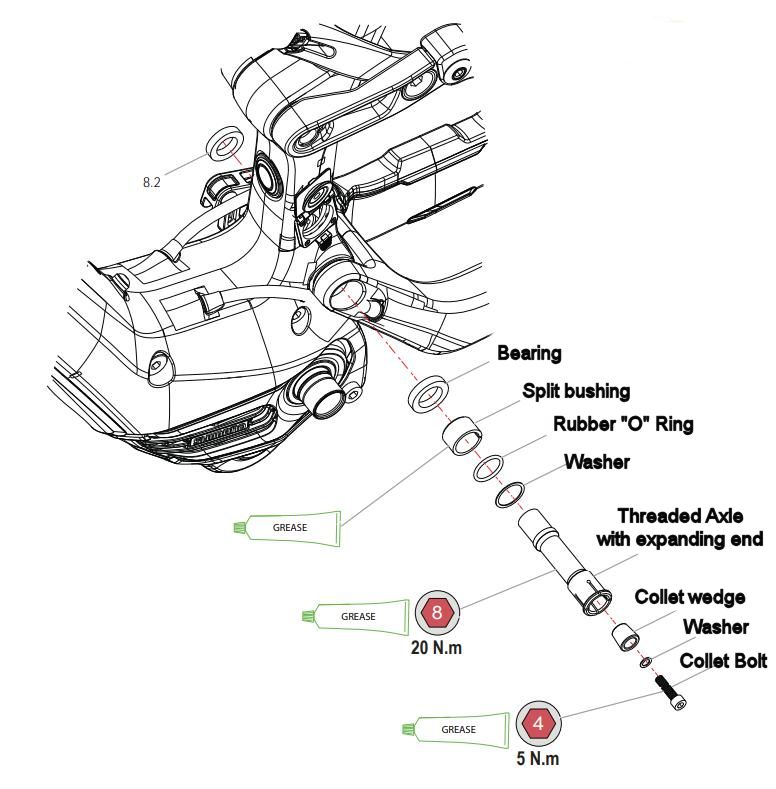

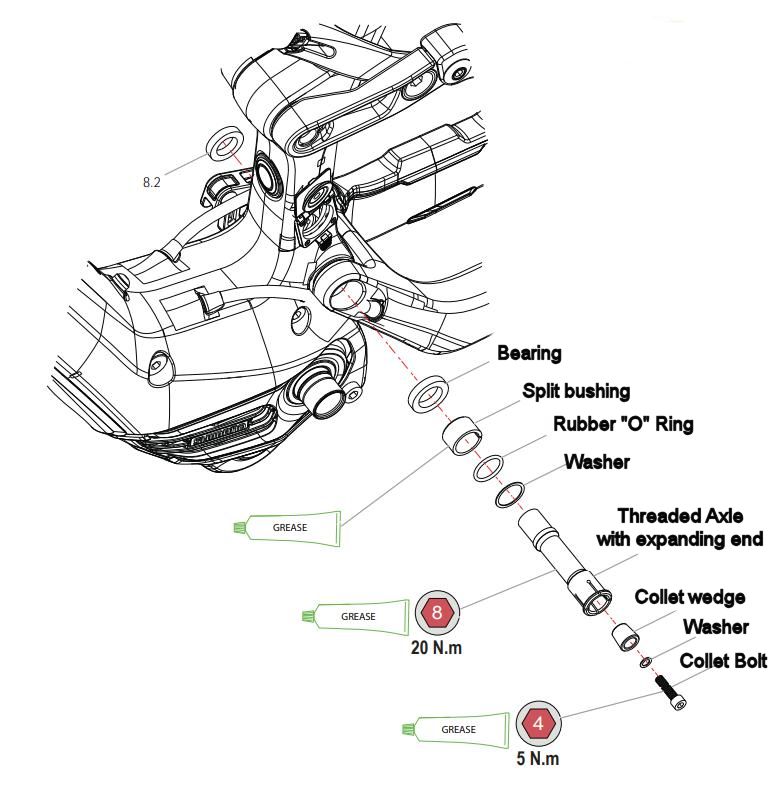

The Orbea Rise, Blue Paper diagram below details the lower pivot axle assembly and grease points. Also listed are the proper torque settings.

How it all works:

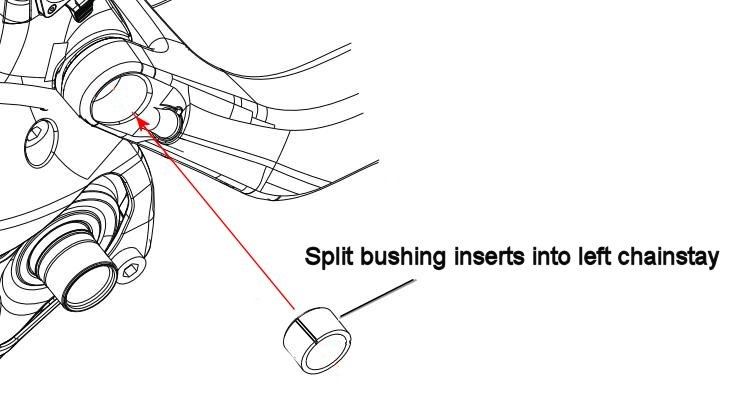

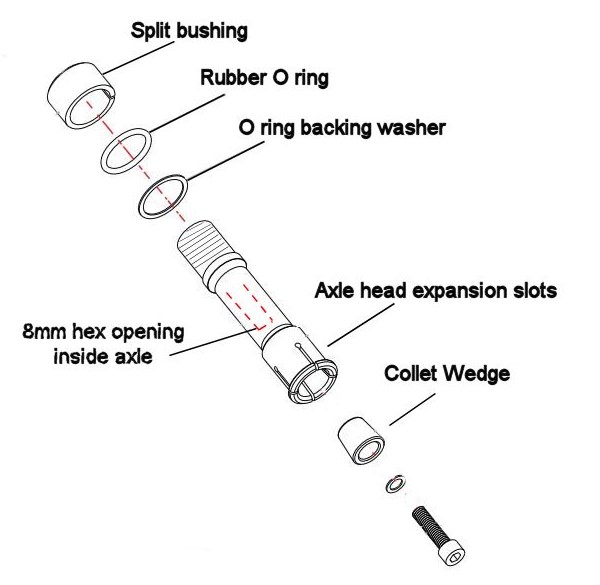

A split bronze bushing is inserted into the opening located on the left, "non-drive" chain stay. The lower pivot axle is threaded on one end and machined on the inside to accept an 8mm hex wrench. The axle is inserted through the bushing, the left chain stay, through the two frame pivot bearings and threaded into the right, drive side chain stay. A 8mm hex driver is used to tighten the axle to the correct torque setting.

The axle is prevented from backing out due to the split bushing and collet wedge. After the axle has been threaded into the chain stay, the collet wedge and collet wedge bolt are threaded into the end of the axle. As the collet wedge is tightened, it expands the head of the axle outward, which in turn expands the split bushing and locks the axle in place. Some mad engineering going on here.....

Lower Main Pivot Axle Service Procedure:

1. Place your Rise in a bike stand. Remove the rear wheel.

2. Wrap a rag around the front of the rear shock to cushion it. Remove the from shock mounting bolt. Lower the front of the shock until it rests on the downtube.

3. Using a hex driver, remove the collet bolt from the lower pivot axle. Remove the collet wedge from the axle.

4. On the left, non-drive side of the motor a black rubber routing tube which will hinder removal of the axle. The routing tube is used to route the rear brake hose from above the motor to the rear triangle. Clipped to the bottom of the routing tube is the small speed sensor wire coming from the rear triangle speed sensor to the motor.

Right and left routing tubes

In order to remove the axle, the left side routing tube will need to be folded slightly out of the way. Don't go crazy with the folding, you don't want to damage the brake hose. You want to fold it over just enough to be able to remove the axle.

The speed sensor wire is attached to the routing tube and held in place via small press fit rubber clamps molded into the bottom of the routing tube. Unclip the speed sensor wire from the clamps. Push excess brake hose from the rear caliper towards the routing tube in order to add slack in the brake hose at the routing tube. Pull up on the routing tube and out of it's mounting holes in the frame. Fold the routing tube slightly over and out of the way. Unthread the axle and remove it.

5. After removing the axle, you will see a split bushing located on the left (Non-Drive) side of the swing arm where the axle is inserted into the triangle. Remove the bushing.

6. With the axle removed, you can now lower or raise the rear triangle out of the way enough to inspect the lower pivot bearings. If the bearings spin easily and smoothly, you need only wipe the surface of the bearings to remove dirt and grime and place a small dab of grease on the inner part of the bearing where the axle will contact it.

If the bearings are rough or hard to spin, remove the rubber seal and clean the bearings. If after cleaning the bearings they still spin roughly or are hard to spin, you should replace the bearing(s). If the bearings spin freely after cleaning, repack the bearings with grease and reinstall the rubber seal with the correct side facing the ball bearings. Wipe excess grease from the bearing and bike frame using a towel.

5. Clean the lower pivot axle, all hardware, the triangle where the axle is threaded and where the bushing is inserted.

Lower pivot assembly installation

1. Apply a small dab of grease to the inside of the lower pivot bearings races mounted in the frame.

2. Apply a light film grease to the inside of the split bushing. Insert the bushing into it's housing on the left side of the rear triangle.

3. Apply a small amount of grease to the the threaded end of the axle and the shoulders of the axle where the axle will ride on the frame pivot bearings.

4. Lift or lower the rear triangle into position so it lines up with the bearings. Fold the brake hose guide tube out of the way and Insert the lower pivot axle into the bushing and through the bearings. Thread the axle into the right, drive side rear triangle insert using an 8mm hex driver, torque the axle to 20 N.m.

5. Insert the black rubber routing hose back into the holes in the frame and reattach the speed sensor wire to the guide tube clamps. Pull the brake hose back out of the rear triangle and to it's original position at the rear caliper.

6. Insert the collet wedge into the axle. Apply a film of grease on the collet wedge bolt and thread into place. Tighten the collet bolt to 5 N.m. Orbea does not specify thread locker for the axle or collect wedge bolt.

7. Rotate the rear triangle up and down and insure it moves freely and smoothly and without any side to side play.

8. Cheers.....you've completed the lower pivot axle linkage.

Rear Seat Stay Bearings:

Two Enduro 6803LLU Max, black oxide pivot bearings are located at the end of the chain and seat stay triangle. The pivot bearings facilitate a slight pivot movement between the chain and seat stays at the rear triangle. They do not see a lot of movement, but are important in maintaining rear triangle stability.

They will occasionally need to be examined for play or lack of function, and lubricated.

In Part One, "Orbea Rise - Upper Linkage Axle and Bearing Service" I discuss:

- Upper linkage disassembly and reassembly.

- Pivot bearing inspection and type of Enduro bearings used on the Rise.

- How to remove a bearing seal, clean the bearing and re-lubricate the bearing.

- Bearing greases recommended by Enduro.

After you've been riding your Rise for awhile, you may notice your Rise has started to make a creaking noise while riding. The sound will sound similar to a creaking seat post or seat. You may also notice that the rear suspension may begin to feel stiff and not as plush as it used to be. You may question your shock/settings due to the stiffness in the suspension. In most circumstances, there is nothing wrong with your rear shock, the seat post or saddle rail clamp. The stiff suspension and or creaking noise may be attributed to a upper or lower pivot axle, linkage arms and or bearings in need of cleaning and lubrication.

Like many things on a bike, the pivot linkage needs the occasional bit of love. As a personal rule, I like to full service clean, inspect and lube the suspension linkage on my bikes every six months. I grease the upper and lower pivot axles every few months. This keeps noises to a minimum and the suspension functioning smoothly. You don't want to skip servicing the suspension linkage on your bike, it will make a good bit of difference in how your bike performs. Depending upon the frequency of your rides, distance covered, the riding climate and type of terrain your ride, you may only need to service your linkage once a year, or you may need to do it more frequently than every six months.

It’s important to keep in mind that the upper and lower pivot axles on the Rise do not have any seals or O rings which prevent water or dust from working its way into where the alloy axle contacts and rides upon the steel bearings. I’ve found that if the bike is exposed to frequent moisture or powdery dust, it will eventually wash out or dry up the pivot axle grease. Depending upon which axle runs dry of lubrication, it will start making a creaking noise caused by the alloy axle rubbing on the steel pivot bearing races. As I stated before, the noise will sound exactly the same as a seat post or saddle creaking. It’s also been my experience the upper pivot axle needs to be lubricated more frequently than the lower pivot axle.

To determine the condition of your rear suspension, place the bike in a bike stand. Remove the rear wheel. Wrap a soft rag around the front area your rear shock. Remove the shock's front mounting bolt. Lower the shock down so that it rests on the downtube. The rag will protect the paint.

With your hands, slowly raise and lower the rear triangle. With your ears listen for noise as you move the triangle up and down. There should be no grinding, grittiness, or squeaking noise. With your fingers, feel for resistance in the movement, any stiff spots, as you rotate the triangle. The movement should be smooth and easy. If you encounter noise and or, resistance, then your linkage needs service.

In most instances during disassembly and inspection, you will find the pivot bearings on your Rise will be fine. You will only need to clean and re-lubricate the exterior contact points where the bearing touches bolts, linkage arm and or the axle.

Occasionally, you will come across a pivot bearing that is frozen or stiff to spin. This may be because the bearing has flat spots, dirt has contaminated the bearing grease and or, water has worked past the bearing seal and rusted the steel bearing components. Stiff bearings will cause your Rise suspension to perform like an overinflated rear shock and your bike will track poorly on rough terrain.

If you encounter a frozen or hard to spin pivot bearing, you will need to determine why the bearing isn't functioning. To do this, remove the bearing's outer seal, fully clean the bearing, and inspect it for function. If after cleaning, the bearing spins freely without any bumpy or rough feeling, then all you will need to do is re-lubricate the bearing. If after cleaning the bearing does not spin easily, or exhibits a rough feeling, then the bearing will need to be replaced.

Enduro recommends the following greases for the bearings used on the Rise:

Grease and Lubricants

I do not cover replacing the pivot bearings in this tech series. While it's not too difficult to replace a pivot bearing, it does require some mechanical skill and a few specialized tools. If you don't know what you are doing, you can easily damage the frame where the bearing inserts, the paint, or the new bearing itself by improper installation. If you do not possess the mechanical skills or tools to replace a pivot bearing, I recommend taking your Rise to your local bike shop and have the bearings replaced.

Here are several good YouTube videos on servicing a pivot bearing and also the removal and replacement of pivot bearings should you wish to do the work yourself.

The Lower Main Pivot Assembly:

The lower main pivot axle bearing assembly consists of two Enduro bearings which are housed in the main frame. The two bearings differ in size. The left, non-drive side of the frame, uses is an Enduro 6803LLU Max BOSL (Black Oxide Coating) bearing. The right, drive side of the frame, uses an Enduro 6802LLU Max BOSL bearing.

Note: "LLU" refers to the seal design used on the bearing, which is a "Dual Lip" and "Full Contact" seal. This is one of the better designs at keeping contaminants out of the bearing. "Max" refers to the absence of an inner bearing retainer and allows room for the "Maximum" amount of bearings to be installed in the bearing. Refer to Part One in my series for further explanation on "LLU" and "Max" terminology.

The Lower Main Pivot Axle Assembly:

You have the option of removing the upper and lower linkage and allow the rear triangle to hang off the bike of the bike. Or, as I personally like to do, remove and replace the upper and lower pivot sections one at a time as separate procedures. Either way will work.

How the lower main pivot axle functions:

The Orbea Rise, Blue Paper diagram below details the lower pivot axle assembly and grease points. Also listed are the proper torque settings.

How it all works:

A split bronze bushing is inserted into the opening located on the left, "non-drive" chain stay. The lower pivot axle is threaded on one end and machined on the inside to accept an 8mm hex wrench. The axle is inserted through the bushing, the left chain stay, through the two frame pivot bearings and threaded into the right, drive side chain stay. A 8mm hex driver is used to tighten the axle to the correct torque setting.

The axle is prevented from backing out due to the split bushing and collet wedge. After the axle has been threaded into the chain stay, the collet wedge and collet wedge bolt are threaded into the end of the axle. As the collet wedge is tightened, it expands the head of the axle outward, which in turn expands the split bushing and locks the axle in place. Some mad engineering going on here.....

Lower Main Pivot Axle Service Procedure:

1. Place your Rise in a bike stand. Remove the rear wheel.

2. Wrap a rag around the front of the rear shock to cushion it. Remove the from shock mounting bolt. Lower the front of the shock until it rests on the downtube.

3. Using a hex driver, remove the collet bolt from the lower pivot axle. Remove the collet wedge from the axle.

4. On the left, non-drive side of the motor a black rubber routing tube which will hinder removal of the axle. The routing tube is used to route the rear brake hose from above the motor to the rear triangle. Clipped to the bottom of the routing tube is the small speed sensor wire coming from the rear triangle speed sensor to the motor.

Right and left routing tubes

In order to remove the axle, the left side routing tube will need to be folded slightly out of the way. Don't go crazy with the folding, you don't want to damage the brake hose. You want to fold it over just enough to be able to remove the axle.

The speed sensor wire is attached to the routing tube and held in place via small press fit rubber clamps molded into the bottom of the routing tube. Unclip the speed sensor wire from the clamps. Push excess brake hose from the rear caliper towards the routing tube in order to add slack in the brake hose at the routing tube. Pull up on the routing tube and out of it's mounting holes in the frame. Fold the routing tube slightly over and out of the way. Unthread the axle and remove it.

5. After removing the axle, you will see a split bushing located on the left (Non-Drive) side of the swing arm where the axle is inserted into the triangle. Remove the bushing.

6. With the axle removed, you can now lower or raise the rear triangle out of the way enough to inspect the lower pivot bearings. If the bearings spin easily and smoothly, you need only wipe the surface of the bearings to remove dirt and grime and place a small dab of grease on the inner part of the bearing where the axle will contact it.

If the bearings are rough or hard to spin, remove the rubber seal and clean the bearings. If after cleaning the bearings they still spin roughly or are hard to spin, you should replace the bearing(s). If the bearings spin freely after cleaning, repack the bearings with grease and reinstall the rubber seal with the correct side facing the ball bearings. Wipe excess grease from the bearing and bike frame using a towel.

5. Clean the lower pivot axle, all hardware, the triangle where the axle is threaded and where the bushing is inserted.

Lower pivot assembly installation

1. Apply a small dab of grease to the inside of the lower pivot bearings races mounted in the frame.

2. Apply a light film grease to the inside of the split bushing. Insert the bushing into it's housing on the left side of the rear triangle.

3. Apply a small amount of grease to the the threaded end of the axle and the shoulders of the axle where the axle will ride on the frame pivot bearings.

4. Lift or lower the rear triangle into position so it lines up with the bearings. Fold the brake hose guide tube out of the way and Insert the lower pivot axle into the bushing and through the bearings. Thread the axle into the right, drive side rear triangle insert using an 8mm hex driver, torque the axle to 20 N.m.

5. Insert the black rubber routing hose back into the holes in the frame and reattach the speed sensor wire to the guide tube clamps. Pull the brake hose back out of the rear triangle and to it's original position at the rear caliper.

6. Insert the collet wedge into the axle. Apply a film of grease on the collet wedge bolt and thread into place. Tighten the collet bolt to 5 N.m. Orbea does not specify thread locker for the axle or collect wedge bolt.

7. Rotate the rear triangle up and down and insure it moves freely and smoothly and without any side to side play.

8. Cheers.....you've completed the lower pivot axle linkage.

Rear Seat Stay Bearings:

Two Enduro 6803LLU Max, black oxide pivot bearings are located at the end of the chain and seat stay triangle. The pivot bearings facilitate a slight pivot movement between the chain and seat stays at the rear triangle. They do not see a lot of movement, but are important in maintaining rear triangle stability.

They will occasionally need to be examined for play or lack of function, and lubricated.

Last edited: