Rod B.

Well-known member

Thank you to those who have contributed their experiences thus far to make this article better.

I service the linkage, i.e. remove the linkage, axles, inspect, clean and lubricate the bearings about every six months on my Rise. The pivot bearings have held up nicely. Very wet or powdery dirt conditions, or frequent bike washings will dry out the Orbea factory grease lubricating the axles. I remove and lubricate the upper and lower pivot axles every two months.

Here is a great YouTube video on removal and replacement of frame pivot bearings should it become necessary during your inspection.

Let's Begin:

You may notice your Rise has started to make an irritating creaking noise while riding. The creaking noise will sound very similar to a creaking seat post or saddle. The sound will start out small, but become progressively worse. You may also notice the smooth and plush suspension feeling the bike had when new is gone.

In most circumstances, there is nothing wrong with your rear shock, or the seat post or saddle rail clamps. The creaking noise you hear is caused by a pivot axle needing grease or the upper linkage arms have loosened and moved on the upper axle splines. The stiff suspension may possibly be attributed to dirty pivot linkage and bearings requiring a cleaning and service. I cover servicing the lower pivot axle assembly in a separate tech article.

www.emtbforums.com

www.emtbforums.com

Before you begin taking you bike linkage apart, consider buying a pivot bearing kit from Orbea. If during the inspection process you do encounter a bad bearing, you won't be caught short handed trying to source a new bearing.

The upper pivot axle is made out of aluminum and rides upon two steel bearings mounted in the frame. The fit between the bearings and the axel is a close tolerance fit. The axle does not have a seal to keep dirt or water from working between the bearing race and axle. Dry powdery conditions or exposure to water will wash lubrication from the axle area. If the axle runs dry of lubrication, creaking and wear on the axle's aluminum shoulders will occur. This leads to sloppy rear linkage and replacement of the splined axle if wear is excessive.

Each linkage arm is held in place with a single pinch bolt. Many Rise owners have experienced a problem with linkage arm slippage on the splined axle. When this occurs, the linkage arms open up and play develops. The side to side axle play will cause a creaking noise as it shifts on the bearings. If you feel the rear end sway or flex sideways during cornering, a loose linkage arm may be the culprit. If you experience this issue, check the upper axle. There should be no axle visible between the frame and inside of the linkage arm. There should also be no side to side lateral play in the axle assembly. If you are experiencing an issue with the linkage arms slipping on the axle, I highly suggest buying Loctite 638 cylindrical retaining compound. Loctite 638 works similar to Loctite thread locker. It will keep the splined axle mated securely to the linkage arms and create a firm attachment.

Bearings:

Bearings used on the Rise are manufactured by Enduro. They have a black oxide finish which inhibits corrosion. The Enduro bearings on the Rise are a "LLU" and "Max" design.

"LLU" indicates a bearing that has a full contact, dual lip seal, which rides in a groove on the inner race. This type of seal is good at keeping contaminants out of the bearing.

"Max" is a term used by Enduro. It refers to the absence of an inner bearing retainer. By removing the bearing retainer, Enduro is able to pack the Maximum amount of ball bearings into the bearing.

Cross section of a typical bearing with inner nylon bearing retainer

Cross section of Enduro LLU Max bearing. Note the absence of the nylon retainer

The Cleaning Process:

Because the pivot bearings are mounted in the frame and linkage arm, you will only have access to one side of the bearing. I like to use a spray cleaner to forcibly clean and dissolve the old grease from the bearing. I've found Maxima chain cleaner works well to dissolve old bearing grease. It's safe to use on rubber, metal and carbon fiber components. If you don't have access to a spray detergent cleaner, WD40 also works well at dissolving grease.

Seal Removal:

After you have cleaned the exterior of the bearing, linkage arm and frame. You will need to remove the bearing's outer rubber seal. I use a hobby knife like what's pictured below. Any razor or thin blade will work. You want to be careful and not cut or bend the seal during the removal process. To remove the seal, insert the tip of the razor slightly between the outer bearing race and the edge of the seal. Gently pry up. You may have to free up the seal in several places to get it to pop up.

The rubber seal on cartridge bearings has an inner and outer side. The inner side of the seal which faces the ball bearings, will have an exposed metal grove to accommodate the bearings. The picture below depicts the inner side of a bearing seal with the groove.

Bearing Inspection:

Pivot bearings typically only rotates a few degrees. Because of this, only a few of the ball bearings consistently take the brunt of impact force. Those few ball bearings will eventually develop flat spots which hinders smooth rotating suspension.

After you have fully cleaned the bearing, rotate it with your fingers. Feel for a bumpy rough feeling. If the bearing is hard to rotate or exhibits a rough feeling, the bearing will need replacement.

Note: You may get a rough or bumpy feeling if the grease is dry or grit has gotten into the bearing and contaminated the grease. Therefore, it's important to fully clean the bearing before checking for bearing flat spots or ease of movement. A good bearing will rotate smoothly and easily.

Bearing Grease:

The type of grease you use, will depend on your riding environment. Enduro recommends three types of lubricants for the Enduro bearings on your Rise. They are:

1. Mobil XHP 222

2. Almagard 3752

3. CRC Marine (Stalube Product #SL3120)

www.endurobearings.com

www.endurobearings.com

When greasing the bearing pivot points and hardware, try not to over grease. Excess grease will accumulate in the pivot points, attract dirt and cause linkage stiction which we don't want.

To grease a bearing, take a dab of grease with your finger and begin pushing the grease into the bearing. Work your way around the circumference of the bearing. Do not completely pack the bearing solid with grease. You want lubrication, but you also want easy bearing movement after the seal has been re-installed.

Install the rubber seal on the bearing, smooth rubber side out, groove side of seal inwards. Lightly push the seal into place with the pad of your thumb. It should install easily. If you push hard or use your fingernails to push the seal into place. You will bend and deform the seal. After seal installation, wipe off excess grease from the bearing surfaces to prevent dirt accumulation.

Here is an excellent YouTube video on greasing bearings:

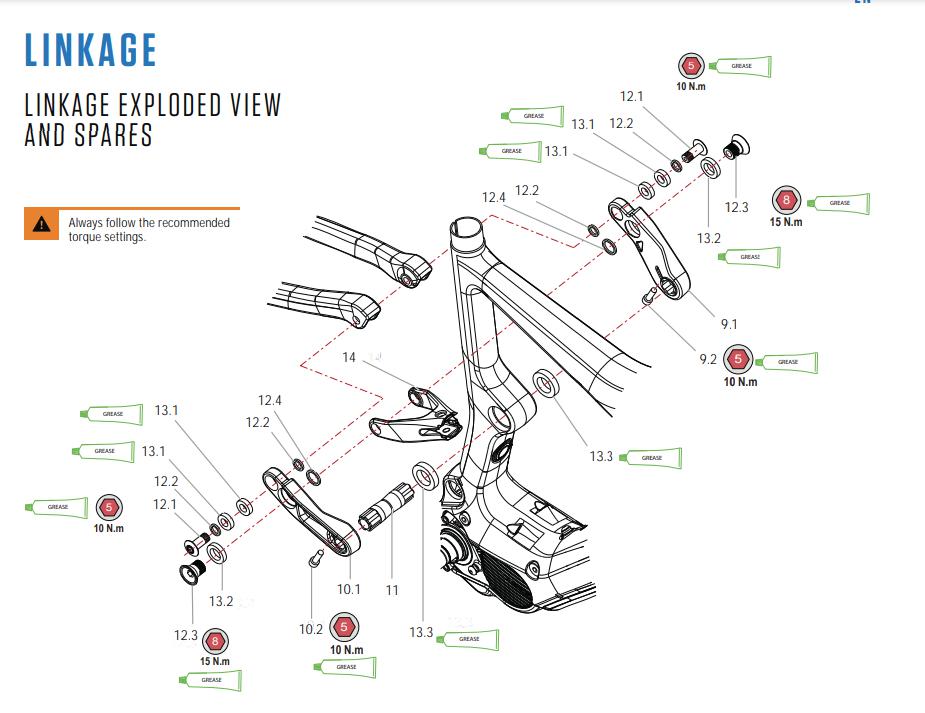

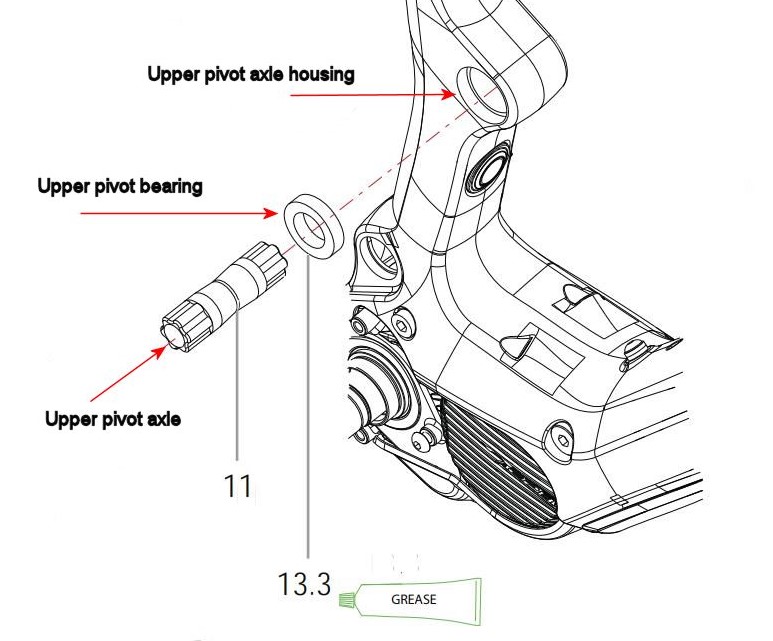

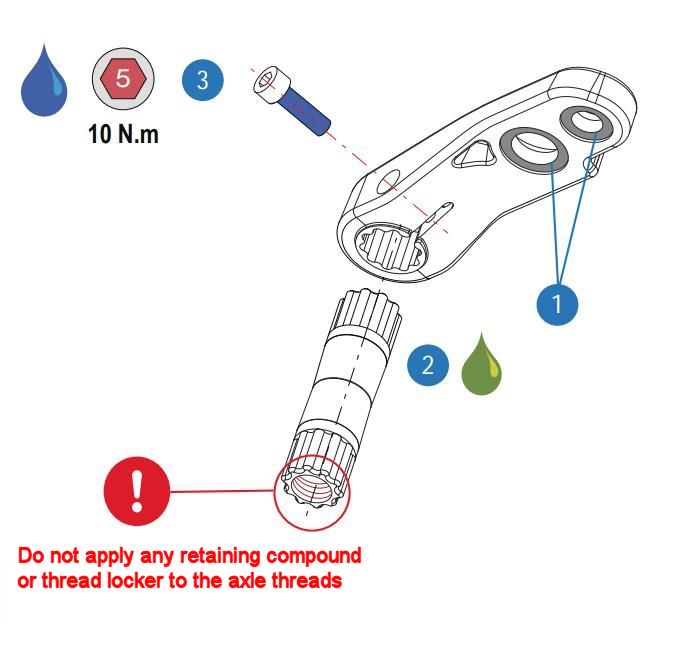

Orbea Rise diagram showing the upper axle pivot linkage, areas requiring grease, and hardware torque settings

Tools:

The Rise linkage screws can easily be deformed or scratched. Because of this, I like to use hex sockets to remove and install the linkage. I find they tend to cause less damage than a "T" handle hex wrench.

If you don't own a torque wrench, consider buying one. Without a torque wrench, it's very easy to over or under tighten a bolt, or possibly damage a carbon fiber frame by over tightening a bolt.

When shopping for a torque wrench, buy a torque wrench which reads in Newton Meters. Bike specs are typically listed in Newton Meters. Lastly, buy a torque wrench that has a low torque range i.e. 1 to 20 N.m. A torque wrench which reads 1 to 200 N.m. won't be as accurate at the lower torque settings used on bicycles, i.e. 4 or 6 N.m.

Pro Bike Tool on Amazon has a nice 1-20 Nm, 1/4" drive torque wrench that comes with hex and Torx sockets for $75.

Upper Axle and Linkage Removal & Installation:

When I do a full service cleaning and lubrication, I like to do the upper pivot linkage separately from the lower main pivot axle. You can remove the upper and lower pivot assembly all at once, however you'll have to contend with a loose chain stay flopping about. Lastly, if I am just greasing the upper axle, I do a shortcut disassembly by leaving the shock in place and I just remove the upper linkage arms and axle for greasing. I am providing a full blown and in depth disassembly of the linkage. I leave it up to you to decide which method or shortcut in the procedure you wish to do.

1) Place your Rise in a bike stand. Remove the rear axle and wheel to unweight the rear triangle.

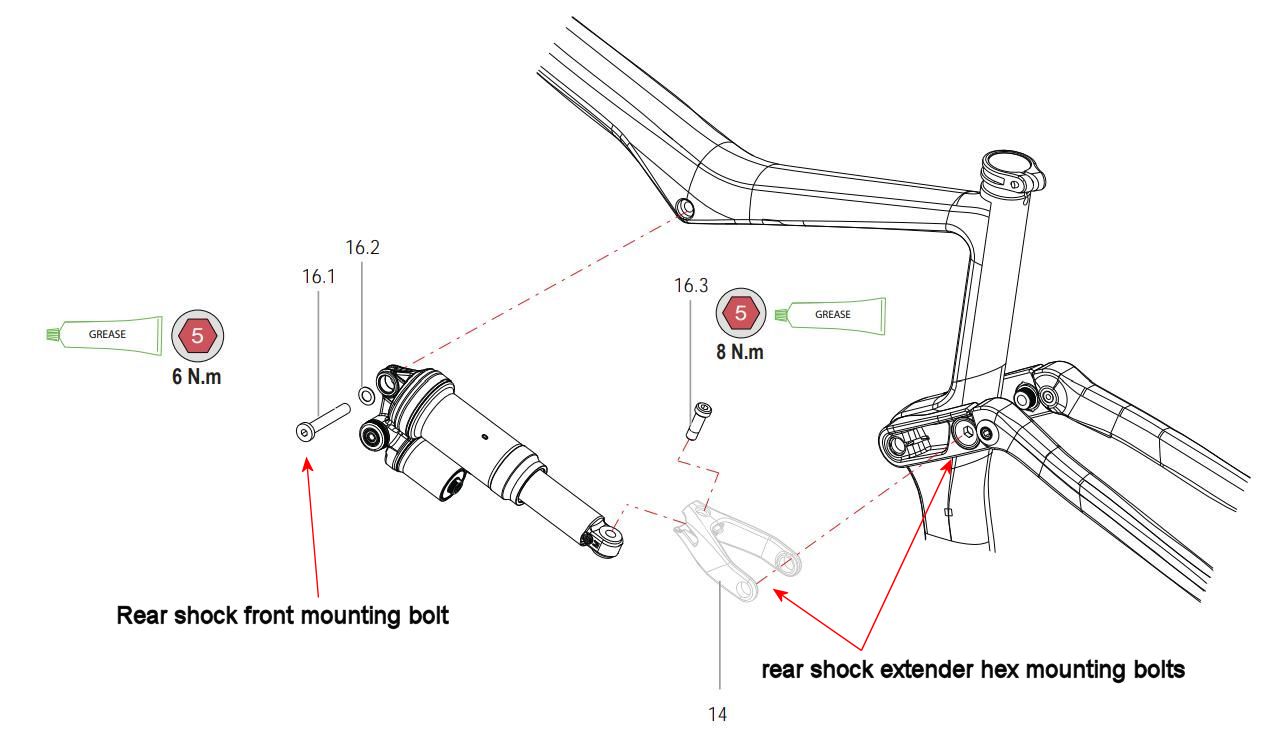

2) Wrap a rag around the front portion of the rear shock. Using a hex wrench/driver, remove the front shock mounting bolt. The rag will prevent the shock from dropping down and damaging the paint on the downtube.

With the front of the rear shock removed, move the rear triangle up and down to see if you can feel or hear binding, grinding etc. This will give you an idea of what condition your pivot linkage is in.

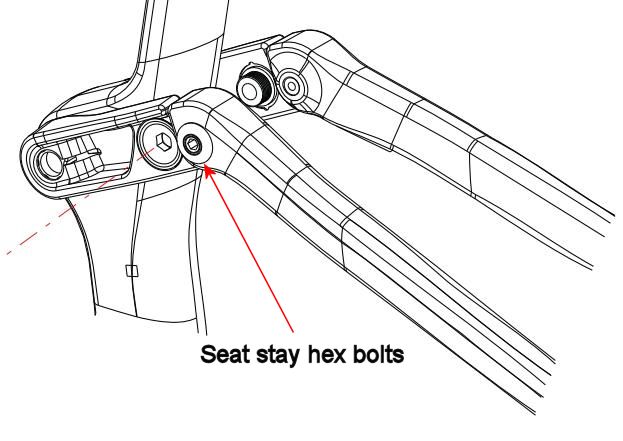

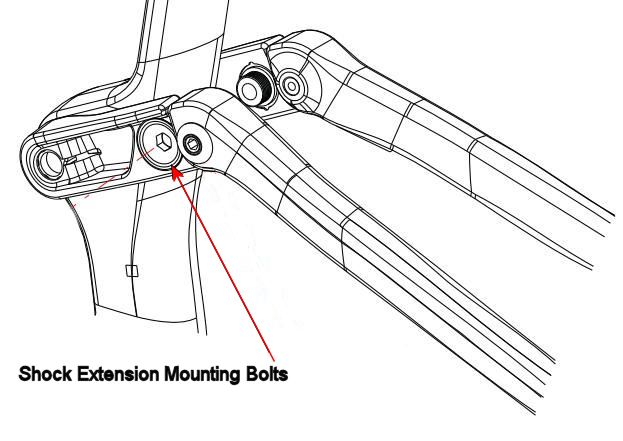

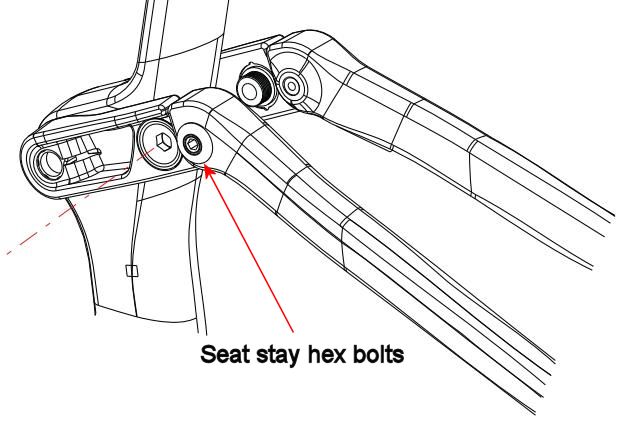

3) Remove the right/left seat stay hex bolts where they attach to the linkage arms.

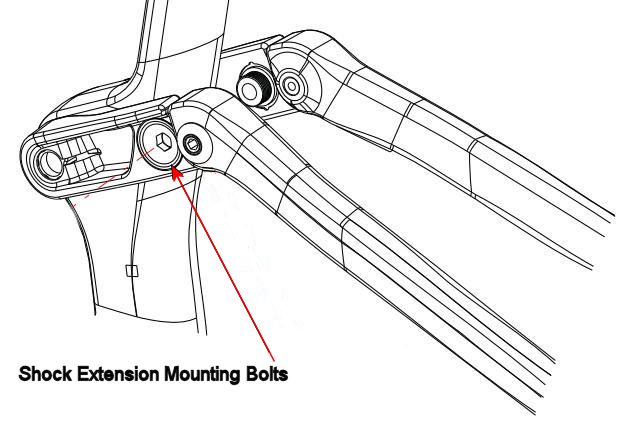

4) Remove the right/left rear shock extender hex bolts where they attach to the linkage arms.

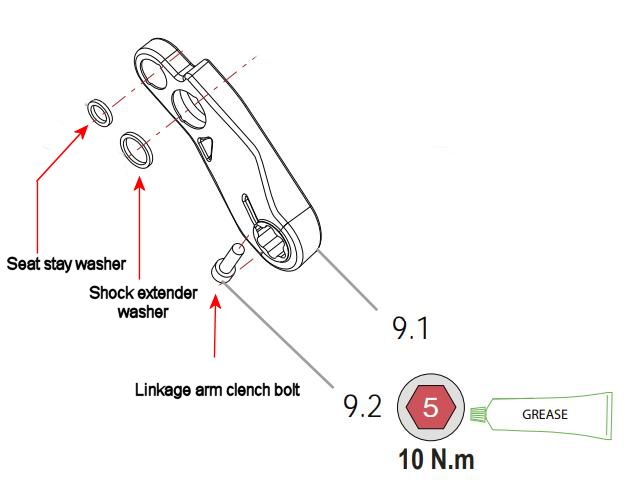

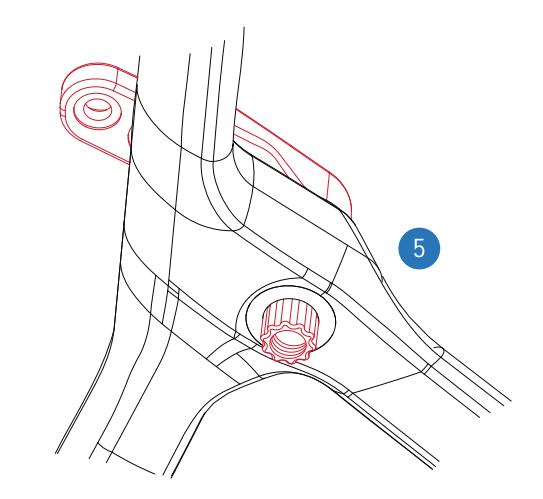

5) Remove the right and left pinch (Clench) bolts located on the bottom side of the linkage arms.

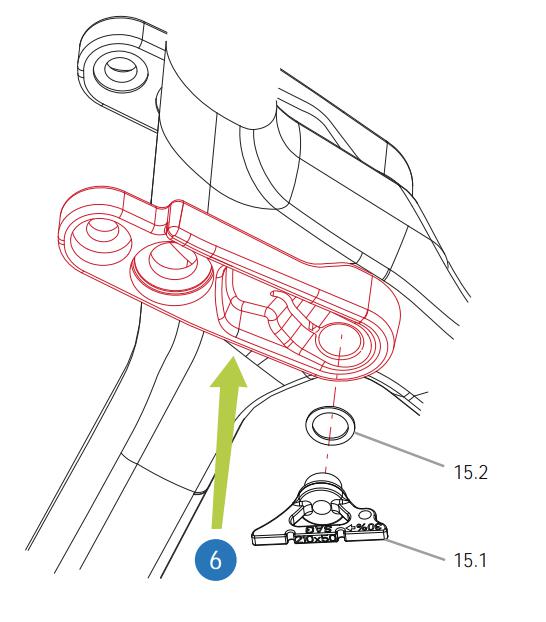

6) Six spacer washers are used in the upper suspension linkage. Two large spacer washers are used for the shock extender. They mount on the inner side of the linkage arm. Four smaller spacer washers are used for the seat stay. They mount on the inner and outer sides of the linkage arms. They may fall out, don't lose them.

7) After both pinch bolts have been removed, pull the seat stay arms away from the linkage and remove each linkage arm from the upper axle. The arms easily come off. Sometimes rocking the arms or a gentle tapping with a soft rubber mallet helps.

8) With the linkage arms removed, the upper axle will be exposed in the frame. Rotate the axle to see if it is binding or hard to remove. This will give you a general idea of what condition your upper pivot frame bearings are in.

9) The upper axle is threaded on one side to accept an Orbea pre-load tool. Your bike may come with the axle threads facing to the left side. The Rise Blue Paper requests the threaded axle side be located on the right, drive side.

10) With a rubber mallet, gently tap the upper axle out of the frame bearing assembly. The axle has a tight fit and will not easily slide out of the bearings. A soft rubber mallet and a soft wood dowel may be required to fully release the axle. Be very careful not to deform or mar the aluminum axle.

11) After the upper linkage assembly has been removed, begin the cleaning process. I like to place the dirty items on a towel. As I clean, I transfer the cleaned hardware to an adjacent clean towel.

Reinstallation:

Note: Because the axles are not sealed, water can wash out the grease lubricating the axle. If you wash your bike frequently or ride in wet and muddy conditions you should use a waterproof grease. I like Schaeffer's 219 SynForce Green which is a synthetic waterproof grease. It holds up extremely well in wet conditions or frequent bike washings. I also like that it's a "Green" grease with low aquatic toxicity and won't contaminate waterways during stream crossings.

1) With the upper linkage hardware and bearings cleaned and lubricated, you can begin the upper re-assembly.

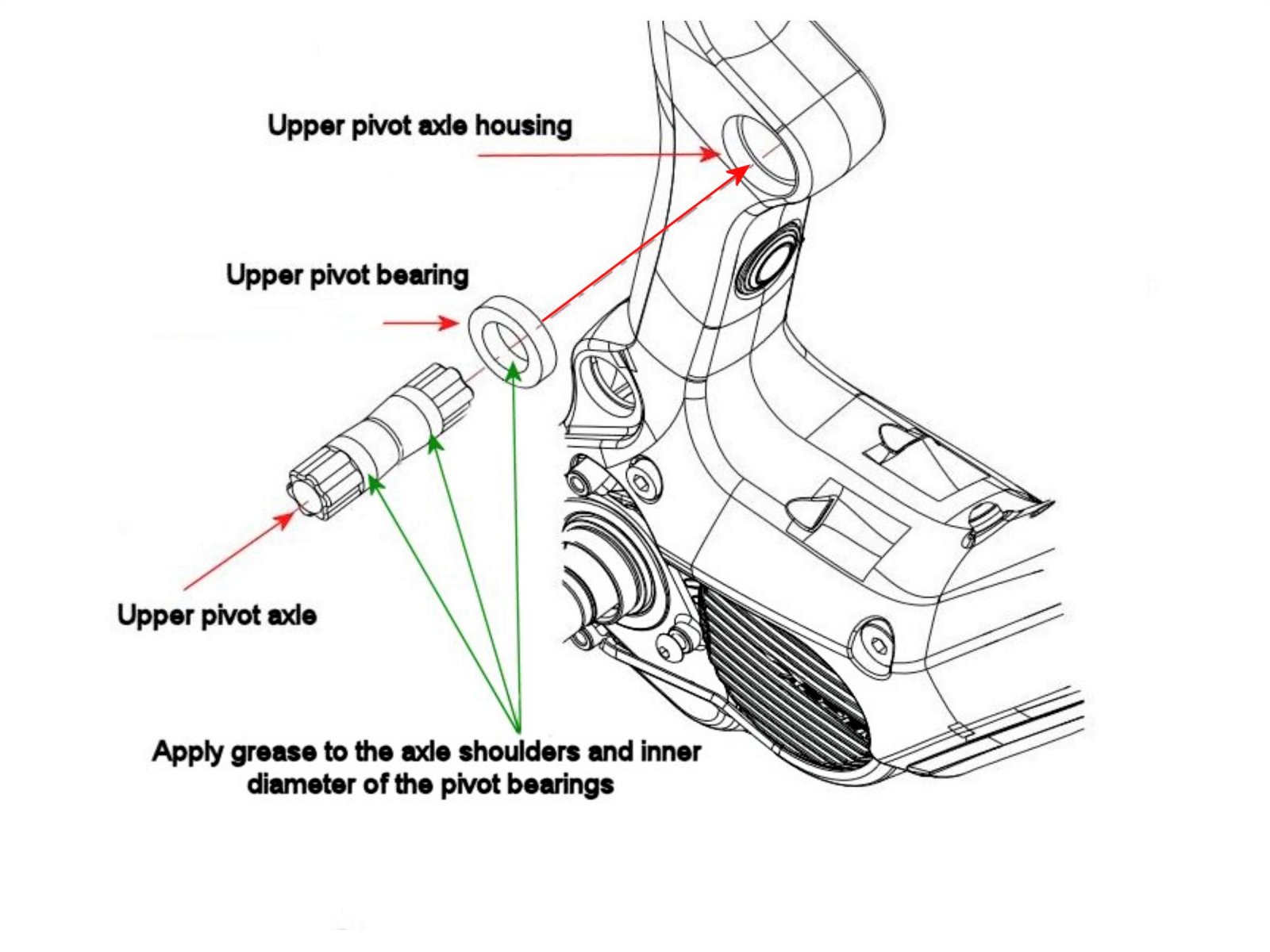

2) Apply a liberal amount of grease around the inside race of the two axle bearings mounted in the frame. Apply Loctite 638 or similar to the splines on the left non-threaded side of the axle and also inside the splined interface on the left linkage arm. I use my finger to spread the retaining compound around to insure full coverage.

NOTE: The Orbea Rise Blue Paper requests that a cylindrical retaining compound be used on the axle splines. The blue paper does not specify which retainer compound to use. The Orbea Rallon shares a similar linkage design. The Orbea Rallon Blue Paper recommends Loctite 638 as the "cylindrical retaining compound" to be placed upon the upper pivot axle splines.

3) Hold the left (Non-drive side) linkage arm in your hand and insert the axle into the left linkage arm. Apply blue thread locker onto a linkage arm pinch bolt and thread it into the arm. Insure the axle is fully seated into the linkage arm interface and torque the pinch bolt to 10 N.m. Wipe off any excess Loctite 638 that may drip out.

4) Apply a film of grease to the shoulders of the axel. While holding onto the left linkage arm, insert the axle into the two frame mounted pivot bearings. The axle will slide in easily through the first bearing. You will meet resistance when the axle meets the bearing on the opposite side. Move the axle about to align it squarely with the bearing race on the opposite side. Using a soft rubber mallet, lightly tap the linkage arm and axle into place. No pounding or forcing. Check that the left linkage arm is fully seated against the pivot bearing.

5) Your Rise should have come with a purple colored Orbea pre-load tool. The tool is used to set upper linkage arm pre-load and also to measure rear shock sag. Insure that the rubber pre-load spacer is threaded onto the pre-load tool.

7) Apply Loctite 638 to the axle splines on the right side of the axle. Do not apply any thread locker or retaining compound to the axle threads. Insure the threads are clean. Install the right side linkage arm onto the axel. Insure that the linkage arm is fully seated on the splined axle.

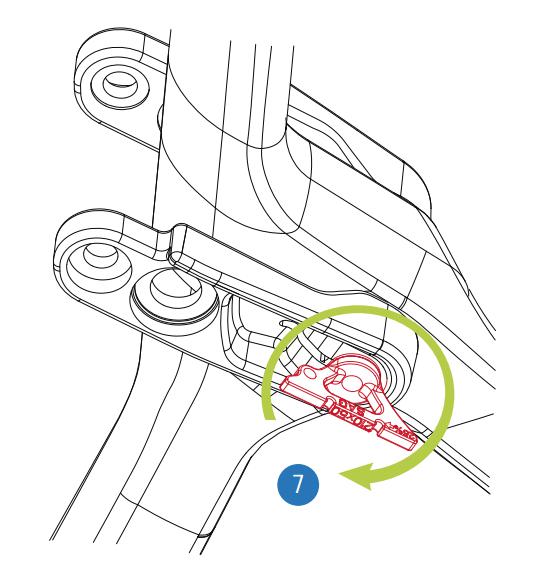

8) Thread the purple pre-load tool into the axle. As you thread, insure the rubber spacer is seated correctly and not cocked to where it can become pinched. If it is not centered correctly, it will become damaged during the tightening of the pre-load tool and a false pre-load will occur. Turn the pre-load tool until it stops. Do not overly tighten the purple pre-load tool as it will damage the rubber preload spacer. Check that no axle is visible between the inside of the linkage arm and the frame. Insure that the axle assembly rotates freely. If everything checks okay, apply a small dab of blue thread lock to a linkage arm pinch bolt. Insert it into the arm and torque the pinch bolt to 10 N.m. Remove the purple pre-load tool.

9) Apply a film of grease onto the seat stay mounting bolt shoulders. Avoid getting grease on the threads. Take two of the small seat stay washers and apply a dab of grease to them. Place the washers on the inner and outer sides of the linkage arm, centered over the seat stay bearings. The grease will keep the washers in place. Line up the seat stay with the bearing opening. Insert the seat stay bolt and torque to 10 N.m. Orbea does not specify thread locker for the seat stay bolt however I place a dab of blue thread locker on the threads.

10) Apply a film of grease to the shock extender mounting bolt shoulders. Avoid getting grease on the threaded portion of the bolt. Apply a small dab of blue thread locker to the threaded portion of each bolt. Take the two large shock extension washers and apply a small dab of grease to each one. This will hold them in place as you work. Position the washers on the inner side of each linkage arm and centered over the shock extender bearings.

Take the shock and slide the extension fork into position between the two linkage arms. Make sure the shock extension washers are sandwiched between the extension fork and the linkage arms. Maneuver the shock extension, washers and linkage arm into alignment so that the mounting bolts can be inserted and threaded into place. Torque both bolts to 15 N.m.

11) Apply a film of grease to the front shock mounting bolt. Apply a film of grease to the inside of the shock bushing and bushing face. Slide the shock up into position and thread the shock bolt into place. Orbea does not specify thread lock on the bolt. Torque the bolt to 6 N.m.

Cheers...you have completed the upper pivot assembly.

I service the linkage, i.e. remove the linkage, axles, inspect, clean and lubricate the bearings about every six months on my Rise. The pivot bearings have held up nicely. Very wet or powdery dirt conditions, or frequent bike washings will dry out the Orbea factory grease lubricating the axles. I remove and lubricate the upper and lower pivot axles every two months.

Here is a great YouTube video on removal and replacement of frame pivot bearings should it become necessary during your inspection.

Let's Begin:

You may notice your Rise has started to make an irritating creaking noise while riding. The creaking noise will sound very similar to a creaking seat post or saddle. The sound will start out small, but become progressively worse. You may also notice the smooth and plush suspension feeling the bike had when new is gone.

In most circumstances, there is nothing wrong with your rear shock, or the seat post or saddle rail clamps. The creaking noise you hear is caused by a pivot axle needing grease or the upper linkage arms have loosened and moved on the upper axle splines. The stiff suspension may possibly be attributed to dirty pivot linkage and bearings requiring a cleaning and service. I cover servicing the lower pivot axle assembly in a separate tech article.

PART # 2: ORBEA RISE - LOWER MAIN LINKAGE AXLE AND BEARING SERVICE

This is Part Two in a two part series on servicing the Rise pivot bearings and linkage. Part Two will discuss servicing the Rise's lower main pivot axle and bearings. If possible, please read Part One before continuing with this article. In Part One, "Orbea Rise - Upper Linkage Axle and Bearing...

Before you begin taking you bike linkage apart, consider buying a pivot bearing kit from Orbea. If during the inspection process you do encounter a bad bearing, you won't be caught short handed trying to source a new bearing.

The upper pivot axle is made out of aluminum and rides upon two steel bearings mounted in the frame. The fit between the bearings and the axel is a close tolerance fit. The axle does not have a seal to keep dirt or water from working between the bearing race and axle. Dry powdery conditions or exposure to water will wash lubrication from the axle area. If the axle runs dry of lubrication, creaking and wear on the axle's aluminum shoulders will occur. This leads to sloppy rear linkage and replacement of the splined axle if wear is excessive.

Each linkage arm is held in place with a single pinch bolt. Many Rise owners have experienced a problem with linkage arm slippage on the splined axle. When this occurs, the linkage arms open up and play develops. The side to side axle play will cause a creaking noise as it shifts on the bearings. If you feel the rear end sway or flex sideways during cornering, a loose linkage arm may be the culprit. If you experience this issue, check the upper axle. There should be no axle visible between the frame and inside of the linkage arm. There should also be no side to side lateral play in the axle assembly. If you are experiencing an issue with the linkage arms slipping on the axle, I highly suggest buying Loctite 638 cylindrical retaining compound. Loctite 638 works similar to Loctite thread locker. It will keep the splined axle mated securely to the linkage arms and create a firm attachment.

Bearings:

Bearings used on the Rise are manufactured by Enduro. They have a black oxide finish which inhibits corrosion. The Enduro bearings on the Rise are a "LLU" and "Max" design.

"LLU" indicates a bearing that has a full contact, dual lip seal, which rides in a groove on the inner race. This type of seal is good at keeping contaminants out of the bearing.

"Max" is a term used by Enduro. It refers to the absence of an inner bearing retainer. By removing the bearing retainer, Enduro is able to pack the Maximum amount of ball bearings into the bearing.

Cross section of a typical bearing with inner nylon bearing retainer

Cross section of Enduro LLU Max bearing. Note the absence of the nylon retainer

The Cleaning Process:

Because the pivot bearings are mounted in the frame and linkage arm, you will only have access to one side of the bearing. I like to use a spray cleaner to forcibly clean and dissolve the old grease from the bearing. I've found Maxima chain cleaner works well to dissolve old bearing grease. It's safe to use on rubber, metal and carbon fiber components. If you don't have access to a spray detergent cleaner, WD40 also works well at dissolving grease.

Seal Removal:

After you have cleaned the exterior of the bearing, linkage arm and frame. You will need to remove the bearing's outer rubber seal. I use a hobby knife like what's pictured below. Any razor or thin blade will work. You want to be careful and not cut or bend the seal during the removal process. To remove the seal, insert the tip of the razor slightly between the outer bearing race and the edge of the seal. Gently pry up. You may have to free up the seal in several places to get it to pop up.

The rubber seal on cartridge bearings has an inner and outer side. The inner side of the seal which faces the ball bearings, will have an exposed metal grove to accommodate the bearings. The picture below depicts the inner side of a bearing seal with the groove.

Bearing Inspection:

Pivot bearings typically only rotates a few degrees. Because of this, only a few of the ball bearings consistently take the brunt of impact force. Those few ball bearings will eventually develop flat spots which hinders smooth rotating suspension.

After you have fully cleaned the bearing, rotate it with your fingers. Feel for a bumpy rough feeling. If the bearing is hard to rotate or exhibits a rough feeling, the bearing will need replacement.

Note: You may get a rough or bumpy feeling if the grease is dry or grit has gotten into the bearing and contaminated the grease. Therefore, it's important to fully clean the bearing before checking for bearing flat spots or ease of movement. A good bearing will rotate smoothly and easily.

Bearing Grease:

The type of grease you use, will depend on your riding environment. Enduro recommends three types of lubricants for the Enduro bearings on your Rise. They are:

1. Mobil XHP 222

2. Almagard 3752

3. CRC Marine (Stalube Product #SL3120)

Grease and Lubricants

When greasing the bearing pivot points and hardware, try not to over grease. Excess grease will accumulate in the pivot points, attract dirt and cause linkage stiction which we don't want.

To grease a bearing, take a dab of grease with your finger and begin pushing the grease into the bearing. Work your way around the circumference of the bearing. Do not completely pack the bearing solid with grease. You want lubrication, but you also want easy bearing movement after the seal has been re-installed.

Install the rubber seal on the bearing, smooth rubber side out, groove side of seal inwards. Lightly push the seal into place with the pad of your thumb. It should install easily. If you push hard or use your fingernails to push the seal into place. You will bend and deform the seal. After seal installation, wipe off excess grease from the bearing surfaces to prevent dirt accumulation.

Here is an excellent YouTube video on greasing bearings:

Orbea Rise diagram showing the upper axle pivot linkage, areas requiring grease, and hardware torque settings

Tools:

The Rise linkage screws can easily be deformed or scratched. Because of this, I like to use hex sockets to remove and install the linkage. I find they tend to cause less damage than a "T" handle hex wrench.

If you don't own a torque wrench, consider buying one. Without a torque wrench, it's very easy to over or under tighten a bolt, or possibly damage a carbon fiber frame by over tightening a bolt.

When shopping for a torque wrench, buy a torque wrench which reads in Newton Meters. Bike specs are typically listed in Newton Meters. Lastly, buy a torque wrench that has a low torque range i.e. 1 to 20 N.m. A torque wrench which reads 1 to 200 N.m. won't be as accurate at the lower torque settings used on bicycles, i.e. 4 or 6 N.m.

Pro Bike Tool on Amazon has a nice 1-20 Nm, 1/4" drive torque wrench that comes with hex and Torx sockets for $75.

Upper Axle and Linkage Removal & Installation:

When I do a full service cleaning and lubrication, I like to do the upper pivot linkage separately from the lower main pivot axle. You can remove the upper and lower pivot assembly all at once, however you'll have to contend with a loose chain stay flopping about. Lastly, if I am just greasing the upper axle, I do a shortcut disassembly by leaving the shock in place and I just remove the upper linkage arms and axle for greasing. I am providing a full blown and in depth disassembly of the linkage. I leave it up to you to decide which method or shortcut in the procedure you wish to do.

1) Place your Rise in a bike stand. Remove the rear axle and wheel to unweight the rear triangle.

2) Wrap a rag around the front portion of the rear shock. Using a hex wrench/driver, remove the front shock mounting bolt. The rag will prevent the shock from dropping down and damaging the paint on the downtube.

With the front of the rear shock removed, move the rear triangle up and down to see if you can feel or hear binding, grinding etc. This will give you an idea of what condition your pivot linkage is in.

3) Remove the right/left seat stay hex bolts where they attach to the linkage arms.

4) Remove the right/left rear shock extender hex bolts where they attach to the linkage arms.

5) Remove the right and left pinch (Clench) bolts located on the bottom side of the linkage arms.

6) Six spacer washers are used in the upper suspension linkage. Two large spacer washers are used for the shock extender. They mount on the inner side of the linkage arm. Four smaller spacer washers are used for the seat stay. They mount on the inner and outer sides of the linkage arms. They may fall out, don't lose them.

7) After both pinch bolts have been removed, pull the seat stay arms away from the linkage and remove each linkage arm from the upper axle. The arms easily come off. Sometimes rocking the arms or a gentle tapping with a soft rubber mallet helps.

8) With the linkage arms removed, the upper axle will be exposed in the frame. Rotate the axle to see if it is binding or hard to remove. This will give you a general idea of what condition your upper pivot frame bearings are in.

9) The upper axle is threaded on one side to accept an Orbea pre-load tool. Your bike may come with the axle threads facing to the left side. The Rise Blue Paper requests the threaded axle side be located on the right, drive side.

10) With a rubber mallet, gently tap the upper axle out of the frame bearing assembly. The axle has a tight fit and will not easily slide out of the bearings. A soft rubber mallet and a soft wood dowel may be required to fully release the axle. Be very careful not to deform or mar the aluminum axle.

11) After the upper linkage assembly has been removed, begin the cleaning process. I like to place the dirty items on a towel. As I clean, I transfer the cleaned hardware to an adjacent clean towel.

- Clean the mounting hardware and washers.

- Clean the axle and each linkage arm. The axle splines and splined linkage arm interface must be free of oil for Loctite 638 to work.

- Clean the two bearings in each linkage arm. Check the bearings for smooth action.

- Check the two pivot bearings mounted in the frame. Check the bearings for smooth action.

Reinstallation:

Note: Because the axles are not sealed, water can wash out the grease lubricating the axle. If you wash your bike frequently or ride in wet and muddy conditions you should use a waterproof grease. I like Schaeffer's 219 SynForce Green which is a synthetic waterproof grease. It holds up extremely well in wet conditions or frequent bike washings. I also like that it's a "Green" grease with low aquatic toxicity and won't contaminate waterways during stream crossings.

1) With the upper linkage hardware and bearings cleaned and lubricated, you can begin the upper re-assembly.

2) Apply a liberal amount of grease around the inside race of the two axle bearings mounted in the frame. Apply Loctite 638 or similar to the splines on the left non-threaded side of the axle and also inside the splined interface on the left linkage arm. I use my finger to spread the retaining compound around to insure full coverage.

NOTE: The Orbea Rise Blue Paper requests that a cylindrical retaining compound be used on the axle splines. The blue paper does not specify which retainer compound to use. The Orbea Rallon shares a similar linkage design. The Orbea Rallon Blue Paper recommends Loctite 638 as the "cylindrical retaining compound" to be placed upon the upper pivot axle splines.

3) Hold the left (Non-drive side) linkage arm in your hand and insert the axle into the left linkage arm. Apply blue thread locker onto a linkage arm pinch bolt and thread it into the arm. Insure the axle is fully seated into the linkage arm interface and torque the pinch bolt to 10 N.m. Wipe off any excess Loctite 638 that may drip out.

4) Apply a film of grease to the shoulders of the axel. While holding onto the left linkage arm, insert the axle into the two frame mounted pivot bearings. The axle will slide in easily through the first bearing. You will meet resistance when the axle meets the bearing on the opposite side. Move the axle about to align it squarely with the bearing race on the opposite side. Using a soft rubber mallet, lightly tap the linkage arm and axle into place. No pounding or forcing. Check that the left linkage arm is fully seated against the pivot bearing.

5) Your Rise should have come with a purple colored Orbea pre-load tool. The tool is used to set upper linkage arm pre-load and also to measure rear shock sag. Insure that the rubber pre-load spacer is threaded onto the pre-load tool.

7) Apply Loctite 638 to the axle splines on the right side of the axle. Do not apply any thread locker or retaining compound to the axle threads. Insure the threads are clean. Install the right side linkage arm onto the axel. Insure that the linkage arm is fully seated on the splined axle.

8) Thread the purple pre-load tool into the axle. As you thread, insure the rubber spacer is seated correctly and not cocked to where it can become pinched. If it is not centered correctly, it will become damaged during the tightening of the pre-load tool and a false pre-load will occur. Turn the pre-load tool until it stops. Do not overly tighten the purple pre-load tool as it will damage the rubber preload spacer. Check that no axle is visible between the inside of the linkage arm and the frame. Insure that the axle assembly rotates freely. If everything checks okay, apply a small dab of blue thread lock to a linkage arm pinch bolt. Insert it into the arm and torque the pinch bolt to 10 N.m. Remove the purple pre-load tool.

9) Apply a film of grease onto the seat stay mounting bolt shoulders. Avoid getting grease on the threads. Take two of the small seat stay washers and apply a dab of grease to them. Place the washers on the inner and outer sides of the linkage arm, centered over the seat stay bearings. The grease will keep the washers in place. Line up the seat stay with the bearing opening. Insert the seat stay bolt and torque to 10 N.m. Orbea does not specify thread locker for the seat stay bolt however I place a dab of blue thread locker on the threads.

10) Apply a film of grease to the shock extender mounting bolt shoulders. Avoid getting grease on the threaded portion of the bolt. Apply a small dab of blue thread locker to the threaded portion of each bolt. Take the two large shock extension washers and apply a small dab of grease to each one. This will hold them in place as you work. Position the washers on the inner side of each linkage arm and centered over the shock extender bearings.

Take the shock and slide the extension fork into position between the two linkage arms. Make sure the shock extension washers are sandwiched between the extension fork and the linkage arms. Maneuver the shock extension, washers and linkage arm into alignment so that the mounting bolts can be inserted and threaded into place. Torque both bolts to 15 N.m.

11) Apply a film of grease to the front shock mounting bolt. Apply a film of grease to the inside of the shock bushing and bushing face. Slide the shock up into position and thread the shock bolt into place. Orbea does not specify thread lock on the bolt. Torque the bolt to 6 N.m.

Cheers...you have completed the upper pivot assembly.

Last edited: