You don't really notice a slightly stiff crank while pedalling forward, but if you turn your crank arms backwards and feel resistance you may want to dig a little deeper.

The main reason I am writing this post is because of several other posts I have seen on this issue where people with stiff cranks have been advised to "tip oil into the crank" or "just ride until it stops!". The truth is that a stiff crankshaft is usually caused by a dry crankshaft needle roller bearing. This bearing supports the

crankshaft within the sprocket carrier.

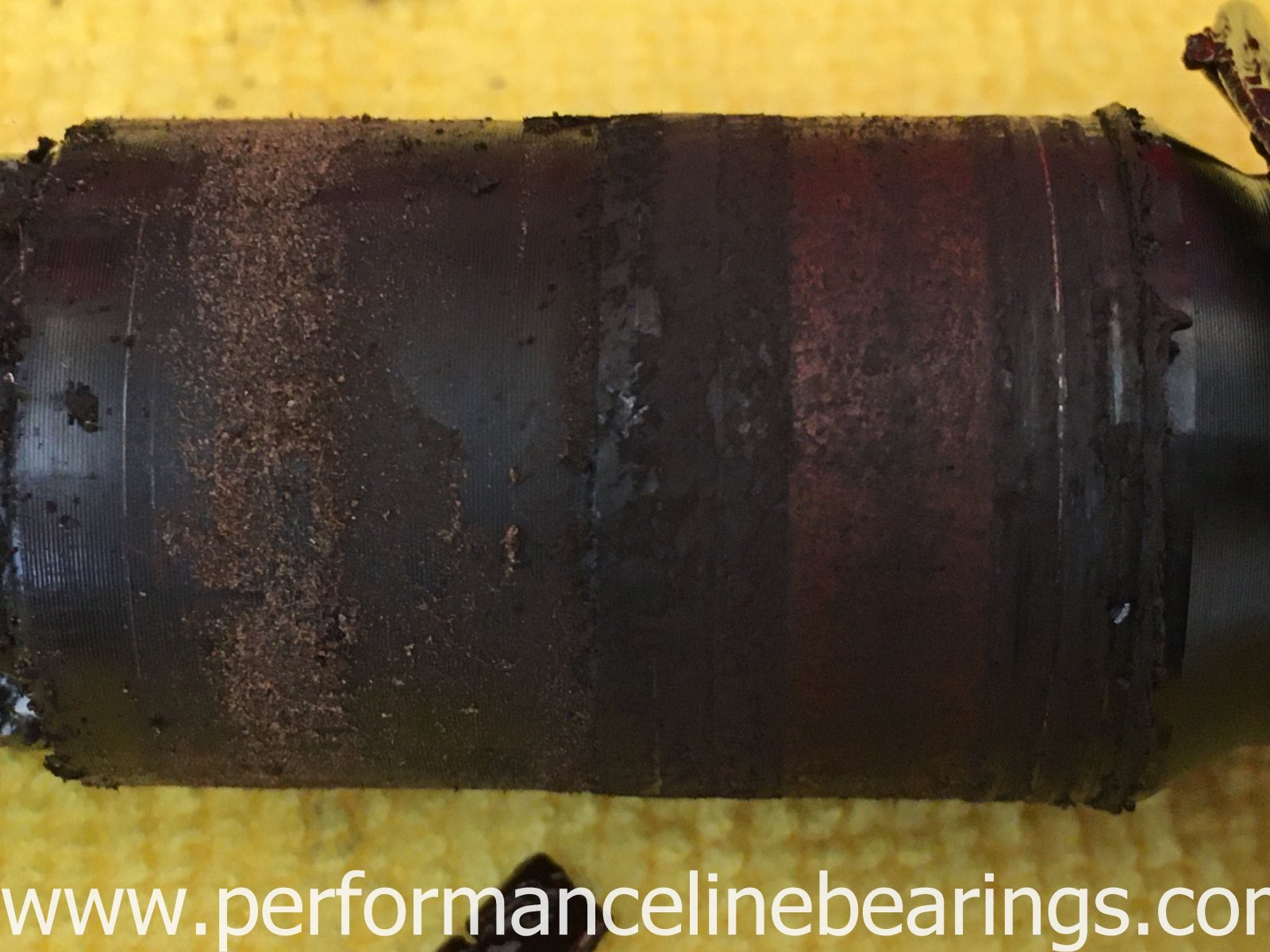

The bearing runs directly on the crankshaft and uses the motors crankshaft as the bearing surface, once this surface is damaged, it is GAME OVER!! You can't buy another one and our stocks are limited.

So what happens and why?

Brose have used a needle bearing with two rubber seals built into it. This is fairly common but this is a bearing designed to keep grease within itself, it's not really designed to keep water out, and this is what it's being used for! Once water breaches the seal, the bearing starts to fail, the worse the bearing gets the less effective the seals become, eventually letting water straight through into the motor.

If your bearing is bad then putting oil into it is like shutting the gate after the horse has bolted. All you are doing is filling your motor up with another substance that is not supposed to be in there (makes my life harder when cleaning it all out too!).

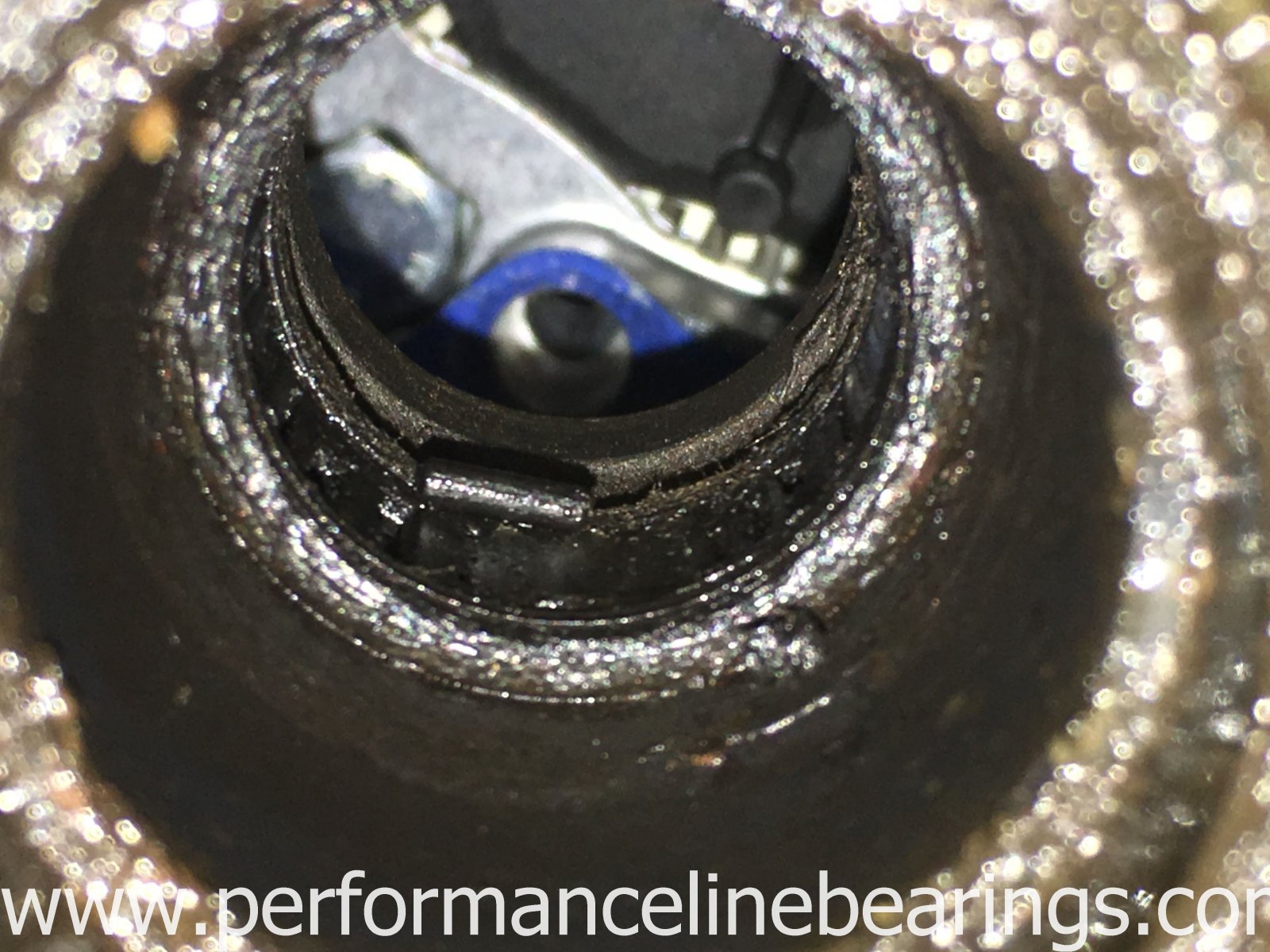

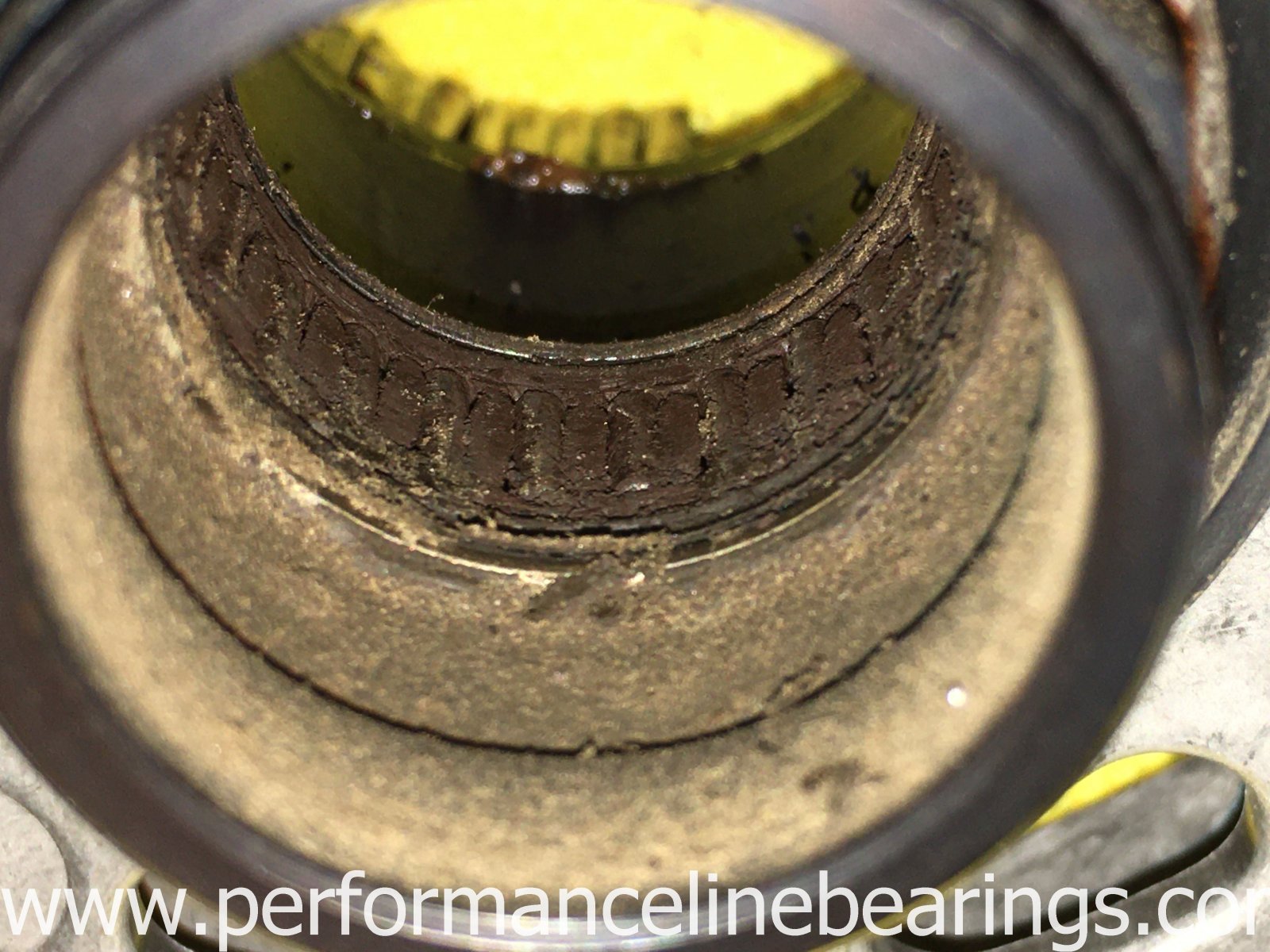

Take a look at some of the pictures below if you wan't to see what this bearing is capable of. (none of these motors had been jet washed)

The main reason I am writing this post is because of several other posts I have seen on this issue where people with stiff cranks have been advised to "tip oil into the crank" or "just ride until it stops!". The truth is that a stiff crankshaft is usually caused by a dry crankshaft needle roller bearing. This bearing supports the

crankshaft within the sprocket carrier.

The bearing runs directly on the crankshaft and uses the motors crankshaft as the bearing surface, once this surface is damaged, it is GAME OVER!! You can't buy another one and our stocks are limited.

So what happens and why?

Brose have used a needle bearing with two rubber seals built into it. This is fairly common but this is a bearing designed to keep grease within itself, it's not really designed to keep water out, and this is what it's being used for! Once water breaches the seal, the bearing starts to fail, the worse the bearing gets the less effective the seals become, eventually letting water straight through into the motor.

If your bearing is bad then putting oil into it is like shutting the gate after the horse has bolted. All you are doing is filling your motor up with another substance that is not supposed to be in there (makes my life harder when cleaning it all out too!).

Take a look at some of the pictures below if you wan't to see what this bearing is capable of. (none of these motors had been jet washed)