You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon Quality - Levo Expert Edition Question

- Thread starter MartynG

- Start date

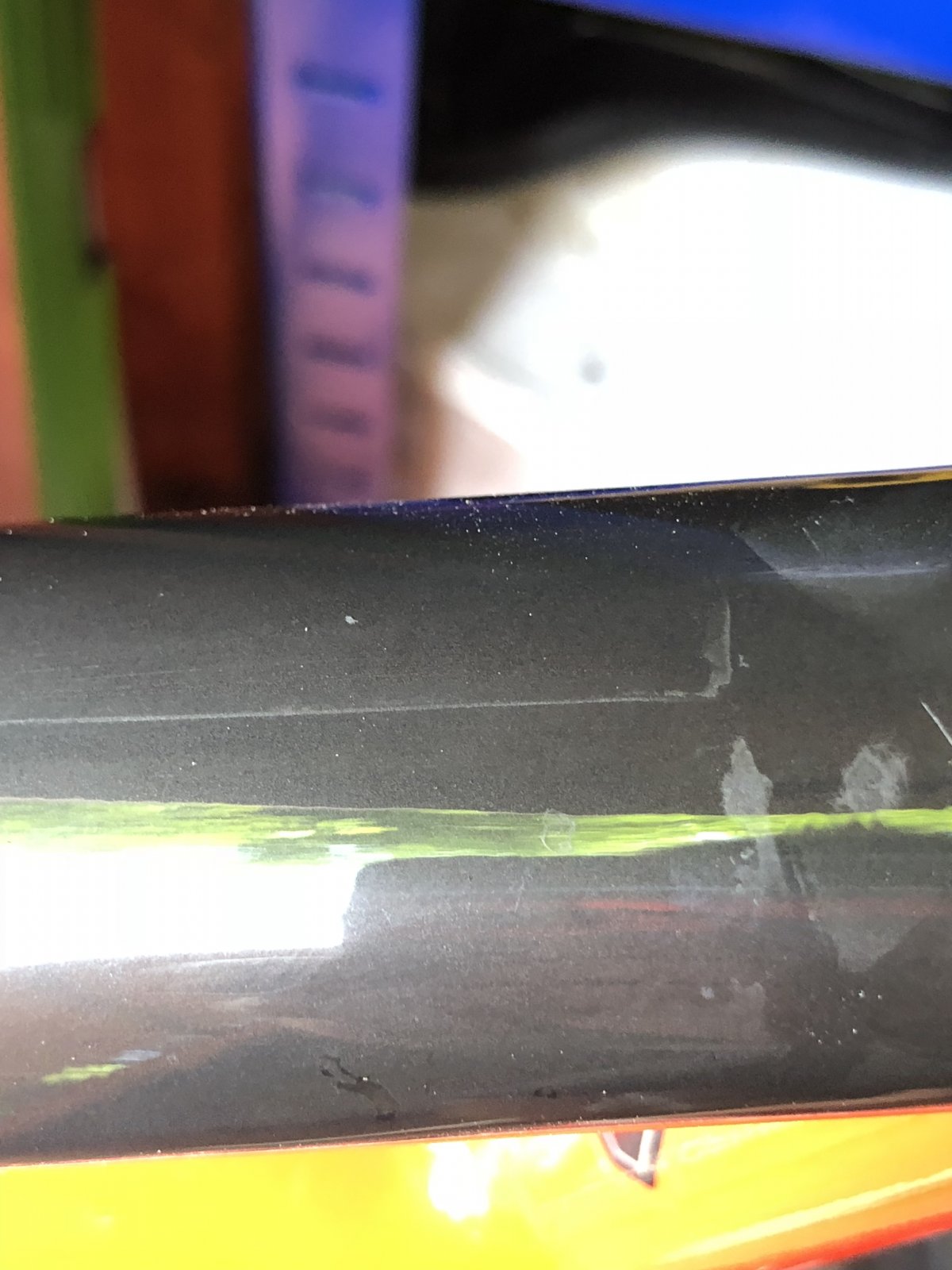

Mine doesn't look like that - is that a new bike? Also in the second pic, it looks like there is some invisiframe or other kind of clear transfer protection on it???took delivery of my levo expert carbon today, pulled it out the box tonight and noticed the carbon fibre black strip Is badly finished is that normal. It's the red and black edition

View attachment 1693

View attachment 1694

View attachment 1695

View attachment 1696

- Thread starter

- #3

Hello.

Yea the bike is brand new, odometer is 0.8km and battery shows 1 charge. It's not been outside yet box opened only yesterday.

I thought it looked unusual, I have not added any invisiframe on the bike.

Does the Carbon fibre frame come with any plastic film attached, i can't peel anything off as there is no edge tobgrip, it's completly smooth where those cracks are.

Yea the bike is brand new, odometer is 0.8km and battery shows 1 charge. It's not been outside yet box opened only yesterday.

I thought it looked unusual, I have not added any invisiframe on the bike.

Does the Carbon fibre frame come with any plastic film attached, i can't peel anything off as there is no edge tobgrip, it's completly smooth where those cracks are.

npatrix

Active member

If you are not comfortable with what you got (is because something is wrong), I believe you have to return it, probably some problem in the transportation, but for the price of these bikes, don't accept nothing less than perfect...Here are some more pics. I've checked to see if there is any film and it's completely smooth, these cracks appear to be below the surface and cover the entire Carbon structure .

View attachment 1699

View attachment 1700

- Thread starter

- #7

If you can find the link that describes and displays that I will read it over, thanks.

Tori Could you post some photos of your bike close up with a light shining on it for comparison, after you mentioned invisishield I googled it and actually saw a video from a user from here adding invisishield to his expert and it didn't look like that either.

Tori Could you post some photos of your bike close up with a light shining on it for comparison, after you mentioned invisishield I googled it and actually saw a video from a user from here adding invisishield to his expert and it didn't look like that either.

Hi Martin. I also have the Expert.

What you are seeing is the raw carbon that has been lacquered to finish it. It is purely cosmetic and that’s the risk with raw carbon, you’re always going to get these (cosmetic) imperfections underneath as a part of the process.

However, yours is a particularly noticeable. Whilst I’m sure that there is nothing faulty about it it’s definitely worth expressing to your dealer that you’re not happy and go from there.

Cheers

Rob.

What you are seeing is the raw carbon that has been lacquered to finish it. It is purely cosmetic and that’s the risk with raw carbon, you’re always going to get these (cosmetic) imperfections underneath as a part of the process.

However, yours is a particularly noticeable. Whilst I’m sure that there is nothing faulty about it it’s definitely worth expressing to your dealer that you’re not happy and go from there.

Cheers

Rob.

Here’s what Specialized say:

Specialized frames utilize a unidirectional carbon weave. This means that the carbon strands all align to the same direction. When constructing a frame it will be built from numerous individual pieces of carbon which can be seen as seams or joints throughout the frame. Since the fibers all orient the same direction when positioned in opposing directions these seams can become more visible. The entire frame layup is impregnated with resin which when cured effectively turns the individual panels into one large carbon form. The visible seams and joints have no effect on the handling of the frame or the structural integrity and are purely cosmetic.

Specialized frames utilize a unidirectional carbon weave. This means that the carbon strands all align to the same direction. When constructing a frame it will be built from numerous individual pieces of carbon which can be seen as seams or joints throughout the frame. Since the fibers all orient the same direction when positioned in opposing directions these seams can become more visible. The entire frame layup is impregnated with resin which when cured effectively turns the individual panels into one large carbon form. The visible seams and joints have no effect on the handling of the frame or the structural integrity and are purely cosmetic.

- Thread starter

- #11

Would you mind quickly posting images of your frame (Ron Dom Tori) as you 3 have the same bike for comparison. Im going look at 3 more today in store to see if they exhibit the same issue, just don't want to hurtle myself down the side of a cliff if it's unsafe

It’s hard with the lighting and I have Invisiframe but you can see the Carbon joins and layup underneath.

- Thread starter

- #13

Cheers, I see some marks but are those marks the invisifrane joints or marks under the Carbon, can't tell  my frame seems to have a melted plastic texture and bumpy especially under the handbar area and also around the bespoke rear shock mount area. It looks heavily cracked, melted and bumpy too. Ive counted around 20+ cracks plus around 8 areas where the Carbon has a melted or a bumpy damaged looking or feeling texture.

my frame seems to have a melted plastic texture and bumpy especially under the handbar area and also around the bespoke rear shock mount area. It looks heavily cracked, melted and bumpy too. Ive counted around 20+ cracks plus around 8 areas where the Carbon has a melted or a bumpy damaged looking or feeling texture.

The photos actually make it look better than it actually is in real life.

In reality it looks and like Freddy Krugers face and is littered in cracks. It's also not "black" it's more like a washed out black or a darkish grey colour as if it's not been painted or has been damaged by the heat process.

The photos actually make it look better than it actually is in real life.

In reality it looks and like Freddy Krugers face and is littered in cracks. It's also not "black" it's more like a washed out black or a darkish grey colour as if it's not been painted or has been damaged by the heat process.

They are the carbon marks under the invisiframe. I tried to get no invisiframe joins in the pics ?Cheers, I see some marks but are those marks the invisifrane joints or marks under the Carbon, can't tellmy frame seems to have a melted plastic texture and bumpy especially under the handbar area and also around the bespoke rear shock mount area. It looks heavily cracked, melted and bumpy too. Ive counted around 20+ cracks plus around 8 areas where the Carbon has a melted or a bumpy damaged looking or feeling texture.

The photos actually make it look better than it actually is in real life.

In reality it looks and like Freddy Krugers face and is littered in cracks. It's also not "black" it's more like a washed out black or a darkish grey colour as if it's not been painted or has been damaged by the heat process.

Hi there.

Just come across this thread as I thought I could give some advice on what I’m seeing.

1.the first photo to your head tube is crease due the ply not being the correct size and has buckled under vacuum at temperature.

2.from what I can see in the third photo is where the fibres have lifted due to unsufficient amount of resin (dry fibre) and when they have debugged the consumables off the part they have been very harsh in doing so.

3.when you see the different plies joined together this is a it naughty in my eyes and will cause a weakness in the structure. To explain it easily if you see the direction of fibre wheich is a +45 they really in my eyes should be laying up the splices in the same direction for strength and quality of finish.

All of the photos say to me that I wouldn’t hesitate in giving this back and giving you another one until your happy.

Other photos could be down to poor bagging of the part and using poor consumables..?

All I’m doing in this is giving advice on what I’m seeing in the pix.

I wouldn’t be happy with it.

This is general run of the mill prepreg material from what I can see so the plies will already be cut laid up to the part and cured off in autoclave.

If can help in any other way please let me know thanks.

Just come across this thread as I thought I could give some advice on what I’m seeing.

1.the first photo to your head tube is crease due the ply not being the correct size and has buckled under vacuum at temperature.

2.from what I can see in the third photo is where the fibres have lifted due to unsufficient amount of resin (dry fibre) and when they have debugged the consumables off the part they have been very harsh in doing so.

3.when you see the different plies joined together this is a it naughty in my eyes and will cause a weakness in the structure. To explain it easily if you see the direction of fibre wheich is a +45 they really in my eyes should be laying up the splices in the same direction for strength and quality of finish.

All of the photos say to me that I wouldn’t hesitate in giving this back and giving you another one until your happy.

Other photos could be down to poor bagging of the part and using poor consumables..?

All I’m doing in this is giving advice on what I’m seeing in the pix.

I wouldn’t be happy with it.

This is general run of the mill prepreg material from what I can see so the plies will already be cut laid up to the part and cured off in autoclave.

If can help in any other way please let me know thanks.

Thanks

Thanks for the info, you have experience in the industry? Curious to know how you’ve got your knowledgeHi there.

Just come across this thread as I thought I could give some advice on what I’m seeing.

1.the first photo to your head tube is crease due the ply not being the correct size and has buckled under vacuum at temperature.

2.from what I can see in the third photo is where the fibres have lifted due to unsufficient amount of resin (dry fibre) and when they have debugged the consumables off the part they have been very harsh in doing so.

3.when you see the different plies joined together this is a it naughty in my eyes and will cause a weakness in the structure. To explain it easily if you see the direction of fibre wheich is a +45 they really in my eyes should be laying up the splices in the same direction for strength and quality of finish.

All of the photos say to me that I wouldn’t hesitate in giving this back and giving you another one until your happy.

Other photos could be down to poor bagging of the part and using poor consumables..?

All I’m doing in this is giving advice on what I’m seeing in the pix.

I wouldn’t be happy with it.

This is general run of the mill prepreg material from what I can see so the plies will already be cut laid up to the part and cured off in autoclave.

If can help in any other way please let me know thanks.

- Thread starter

- #18

Hi there.

Just come across this thread as I thought I could give some advice on what I’m seeing.

1.the first photo to your head tube is crease due the ply not being the correct size and has buckled under vacuum at temperature.

2.from what I can see in the third photo is where the fibres have lifted due to unsufficient amount of resin (dry fibre) and when they have debugged the consumables off the part they have been very harsh in doing so.

3.when you see the different plies joined together this is a it naughty in my eyes and will cause a weakness in the structure. To explain it easily if you see the direction of fibre wheich is a +45 they really in my eyes should be laying up the splices in the same direction for strength and quality of finish.

All of the photos say to me that I wouldn’t hesitate in giving this back and giving you another one until your happy.

Other photos could be down to poor bagging of the part and using poor consumables..?

All I’m doing in this is giving advice on what I’m seeing in the pix.

I wouldn’t be happy with it.

This is general run of the mill prepreg material from what I can see so the plies will already be cut laid up to the part and cured off in autoclave.

If can help in any other way please let me know thanks.

Thanks for the information, I'll raise it as an issue with specialized. Do you think I should speak to specialized support directly as I never bought the bike from a local store, it was a specialized store, just not one near me.

Do you have advice how I should approach the situation with specialized?

- Thread starter

- #20

Yes I would.

Tbh just by looking at the photos they should come back with something to yourself.

But me personally I would be asking for a new/replacement bike if you're happy with that and see what that produces or ask for a refund.

So do you think I should email them directly on their specialized user support channel (website) rather than just call the shop. Not sure what the shop can do, but if I send pictures and description to specialised themselves that may be the better solution?

I might have to go back to sim racing until they fix it then as I'm not happy with that at all

- Thread starter

- #22

See firstly if the shop can help at all,I'm sure they wouldn't want unhappy customers spending good money to be disappointed and see what that brings for a start.I'm sure they could do something.

I'll get them a call tomorrow and discuss it with them, they are a really nice bunch of guys but I don't know what they can do, as I don't think they will be able to exchange it as they have none left in stock and none expected to come in any time soon

I was hoping specialized direct may have more options than a store with none in stock.

I suppose I could drop down to a Comp and take a partial refund if they have no stock maybe.

I believe specialized give a life time warranty on the frame, so hopefully if that is the case, they will replace the 24hr old one that looks as bad as this.

Thanks for your advice and feedback, having an experts advice and view point on the subject is incredibly insightful and valuable.

cheekynuke

New Member

I have a carbon road bike and my frame looks nothing like this. If i were you i'd be taking it back to the dealer.

Similar threads

- Replies

- 171

- Views

- 43K

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 555K

- Messages

- 28,046

- Members

Latest articles

-

Introducing the Forestal e-Cygnus - a downcountry and XC emtb

The new Forestal e-Cygnus is a slightly unusual emtb. It comes in two... -

2025 M1 Sporttechnik EN 8.0 review

The M1 EN is one of four M1 models built on the same frame. Well, it’s...