OK lets get one thing out of the way first. This is not about derailleurs being crap/hub gearboxes are better. It’s not about weight, it’s certainly not about cost. This is simply about me indulging myself.

Perhaps one caveat regarding 1x drive trains on mtbs, is there a less aesthetically pleasing thing in the cycling world? They’re just too big and ugly.

Right, strap in!

First job was to get hold of the A12 Rohloff hub. This, for the un-initiated, is the “through axle” Boost version. Inverted commas there as it’s not strictly a through axle, it uses two M7 bolts through the drop out’s into the axle. Rohloff refuse to sell these unless it’s via an approved adult whose measured the frame and ok’d it for fitting. It’s not a difficult process, just a series of measurements made with a kit of parts to mimic the hub in the frame.

I spoke to several Rohloff dealers about this and about the project. As soon as I mentioned the belt drive they refused to get involved, this despite me only wanting to order the correct parts to allow me to design the system. Anyway, fortunately I ended up at Ghyllside Cycles in Ambleside. Ghyllside are not just Rohloff agents, they’re one of three (I think?) super-dealers in the UK so they have special powers. Fantastic couple of guys. As soon as I described what I had in mind they were super keen to get involved.

So I left the bike with them for a few hours to do the measuring etc. When I returned they said it was fine however, there were two issues. First, the “dog bone”. This is the torque arm that mounts on the caliper posts and stops the hub from rotating. Rohloff supply a couple of standard options but neither of them was going to work with my frame architecture. Simple enough solution, just make a custom one. All it required was a slightly longer one with a revised angle.

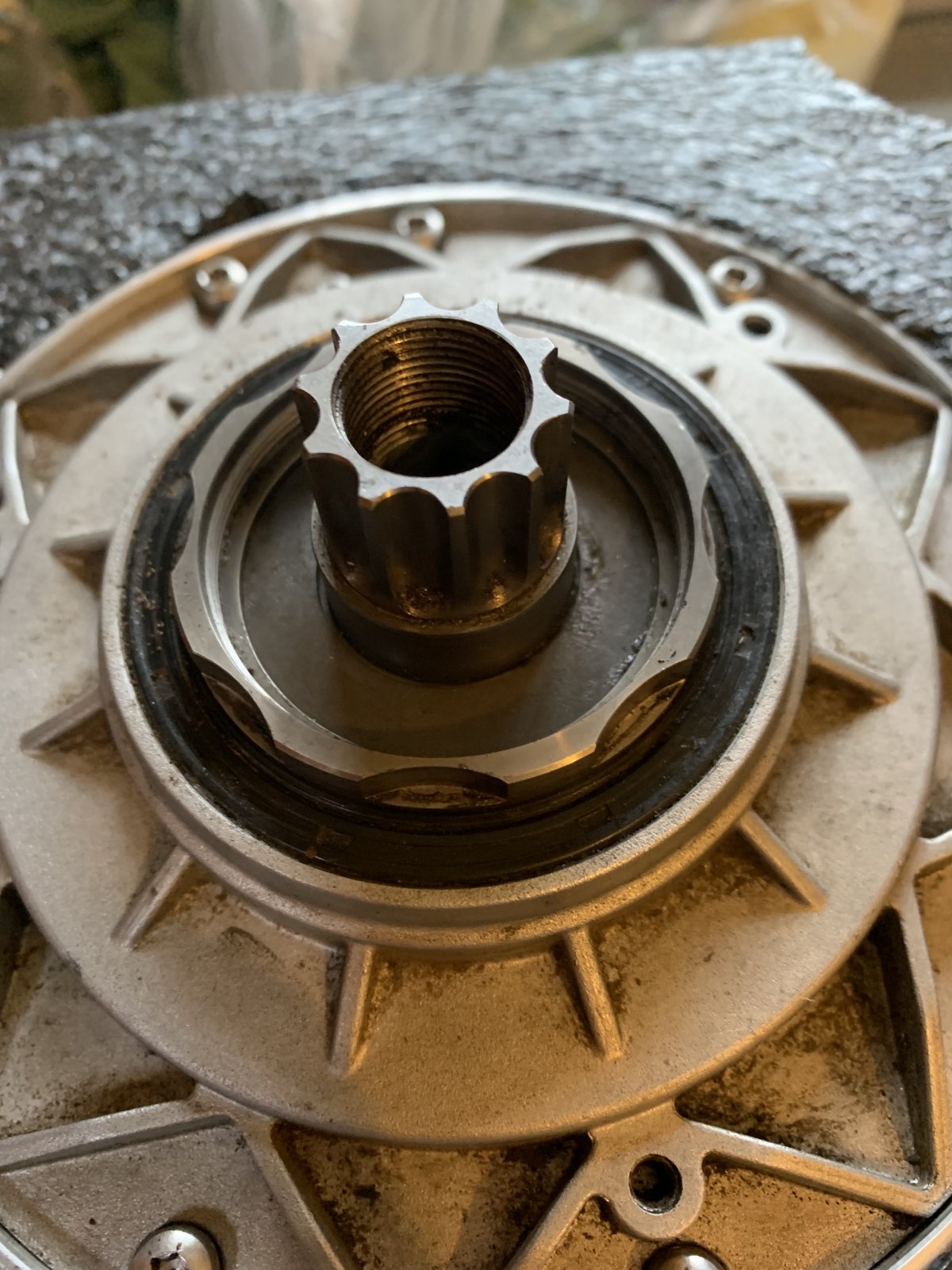

Second problem, the Flyon uses a disc mounted speed sensor ring with six bolts. The Rohloff hub comes with it’s own 4 bolt disc. Again, a simple enough issue to solve…..or so I thought.

Anyway, the good news, the chaps at Ghyllside were happy I was confident I could make it fly so they rubber stamped it and ordered the hub and all of the associated paraphernalia to add the Gates drive sprocket/carrier etc. I let them take care of the wheel building schizz. “Ain’t no baddy gat time f’dat”

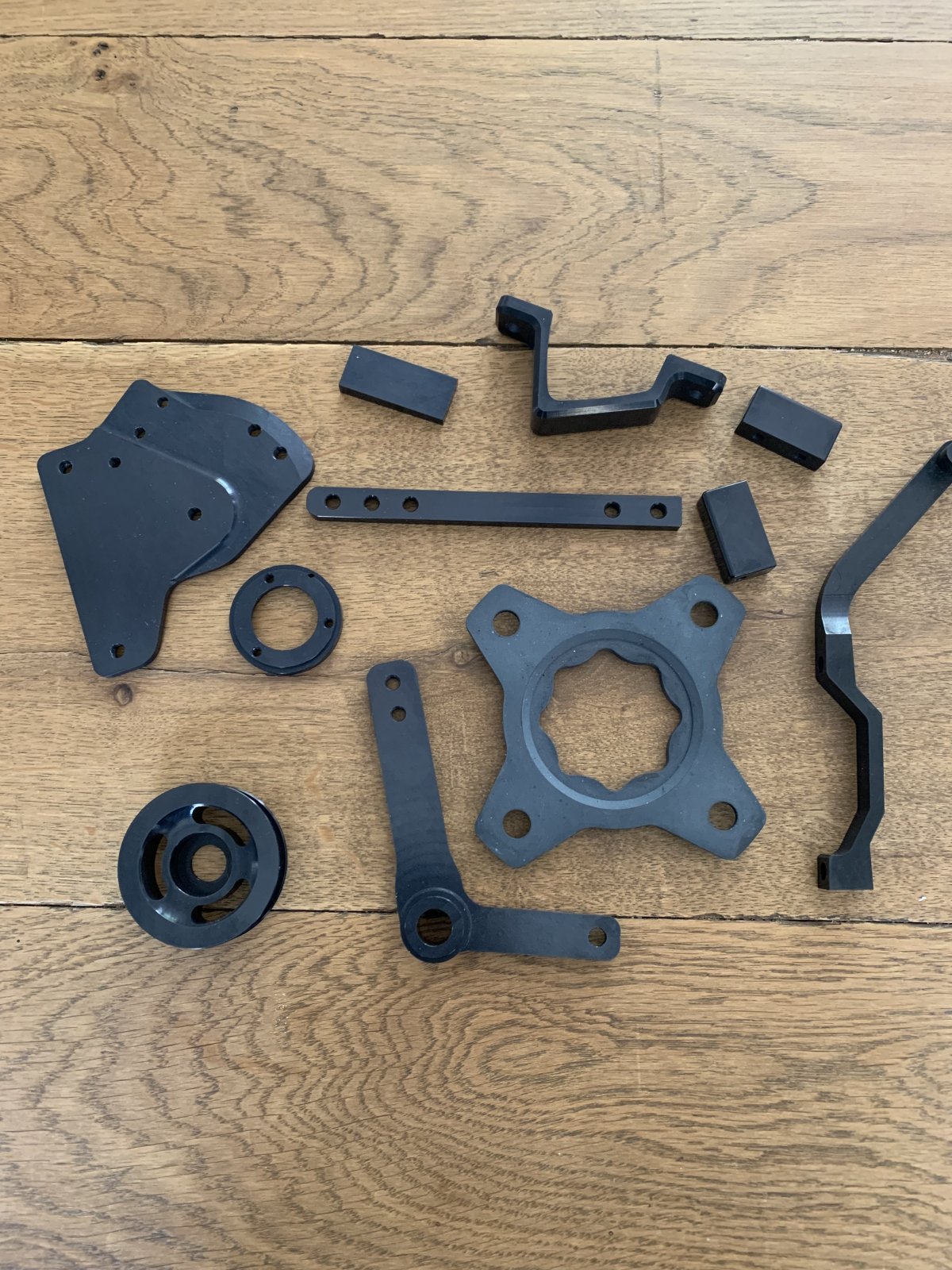

So whilst I was waiting for the hub to turn up I set about designing the parts I needed. The intention was to get it installed with a normal chain first and then do the belt stuff in slow time.

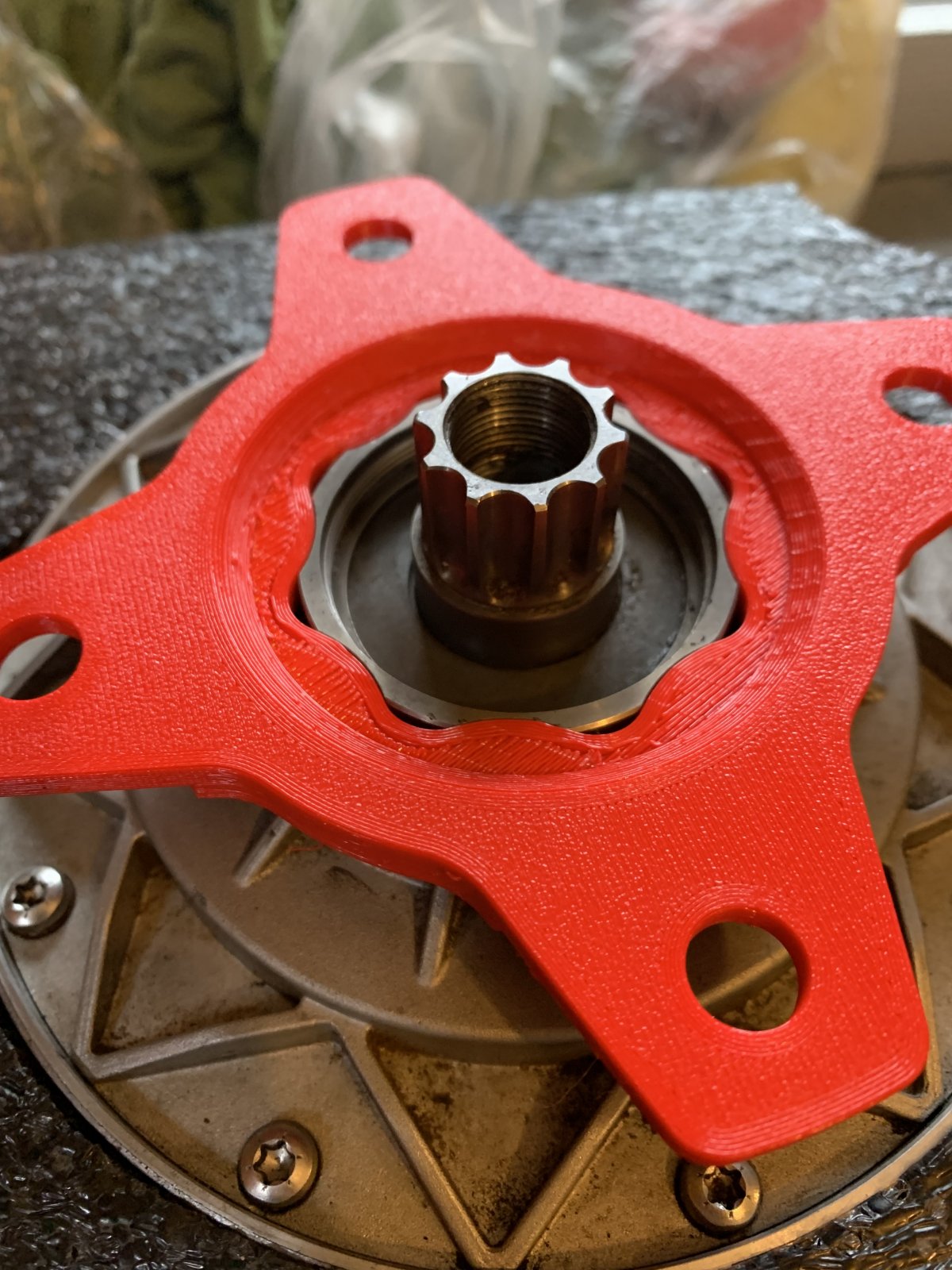

The Haibike Flyon comes with a one piece chainring that slots directly onto the motor spigot. This is fine for a chain drive but I wanted a belt drive so this had to go. Sadly there is no off the shelf solution for this so I had to make one. All that was required was a standard spider arrangement with a 104 PCD 4 bolt chainring mounted on it. This is also the same fitment the Gates sprockets use so I could swap between a chain ring and a CDX belt sprocket.

So out with the verniers/rulers etc to establish the chain line (distance from frame centreline to chain/belt centreline. I measured it at 57mm. As a quick aside, this is what stopped me going for the Kindernay VII system. For reasons that escape me, when they designed it they mounted the gear change mechanism on the drive side. This effectively restricts the chain/belt line.

So 57mm is a good number for Rohloff. There is a bewildering amount of data on their website for mounting hubs, some of it contradicting! At 57mm there are parts/sprocket combo’s available to achieve this. The Gates sprockets are offset/reversable. Gates belts are much less forgiving than chains, the max allowable offset from front to rear is only 1mm so stuff has to line up. For MTB’s Gates recommend using the CDX Centretrack which has a rib in the centre of the belt. Any misalignment will just accelerate wear.

Having established the chainline dimension and the motor mount face/chain line offset etc I designed the spider and 3d printed for proof of concept. Gates belts are wider than a chain. Website says 11m, actual is 12mm. The clearance to the frame motor casing was reduced but still ample.

The motor drive interface is unique to Flyon but pretty simple. Essentially it’s an 8 pointed star with the corners rounded into each other. The outer chain ring interface is standard 4 bolt/104.

The CAD design was simple enough. The 3D print worked well. I sent it for machining. I went with 7075 ally as per the standard chainring. Probs a bit OTT but without some FE analysis on the loadings, difficult to say if the design would be strong enough. Gut feeling said yes.

Next job was the custom “dog bone” torque arm for the caliper post mount.

The caliper section is no different to the standard spacer fitted to the bike so that was easy enough to measure/replicate in CAD. A bit of fiddling/guessing with some bent welding rods and I established the dimensions required to pick up on the hub torque arm. Again 3D print/adjust/re-print. This needs to be quite strong so again, 7075 ally.

Onto the speed sensor disc. This almost put a stop to the whole project and caused a few sleepless nights trying to come up with a workable solution.

As I mentioned earlier, the standard Flyon uses a bolt-on sensor disc that picks up on the six brake disc mount bolts. The Rohloff has a dedicated brake disc with a 4 bolt mount so reusing the existing speed sensor wasn’t an option. Re-manufacturing the speed sensor disc wasn’t viable as it’s a sheet steel pressed/stamped item so tooling would be required etc.

I settled on making an additional disc, cutting the spokes out of the speed sensor and bonding them together. Again clearance between the brake disc and the back face of the Rohloff selector housing is tight so not much room to play with. I designed the part and sent it off for water jet cutting in 0.8mm plate. Unfortunately it came back measuring 0.9mm. With the outer part of the speed sensor bonded to it the thickness was too great and it just skimmed the back of the Rohloff. PITA.

I considered machining 0.5mm off the back of the Rohloff casing but decided against it. I tried a 0.5mm carbon sheet to replace the water jet steel part but that didn’t work too well.

In the end I simply bonded the speed sensor ring directly to the disc. Initially I thought temperature would be an issue with this. I used Sikaflex 221 which is pretty bomb proof stuff. I’ll run it and see how it performs. Thankfully a much better solution dawned on me so that can go into the MkII version.

So that’s the three parts required to get the Rohloff running with a chain, which I never bothered with. Time/weather etc meant there was no opportunity to ride. On with the belt tensioner.

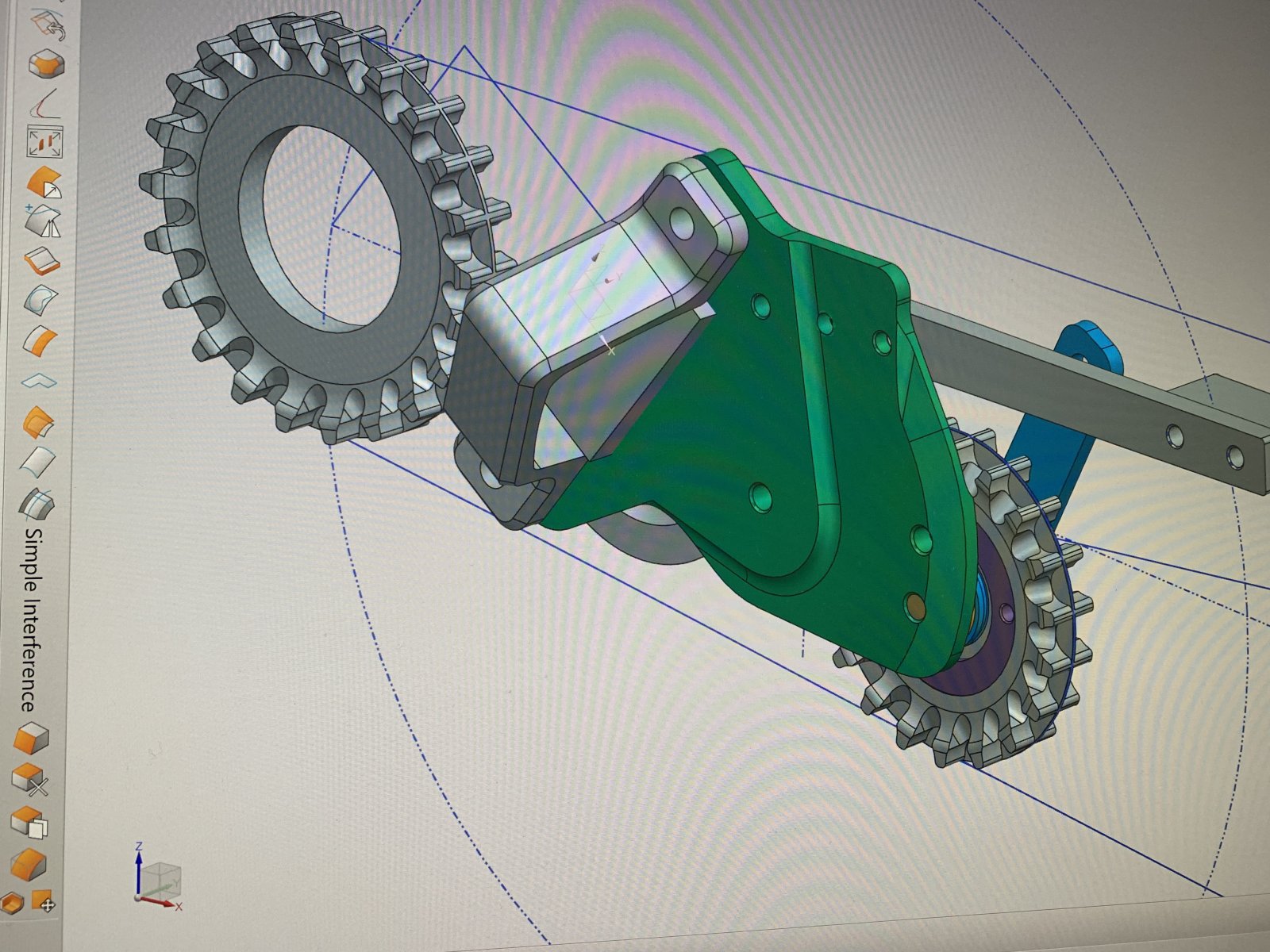

Many hours were spent pouring over photos of Nicolai G1 eBoxx units trying to establish how best to create a tensioner system.

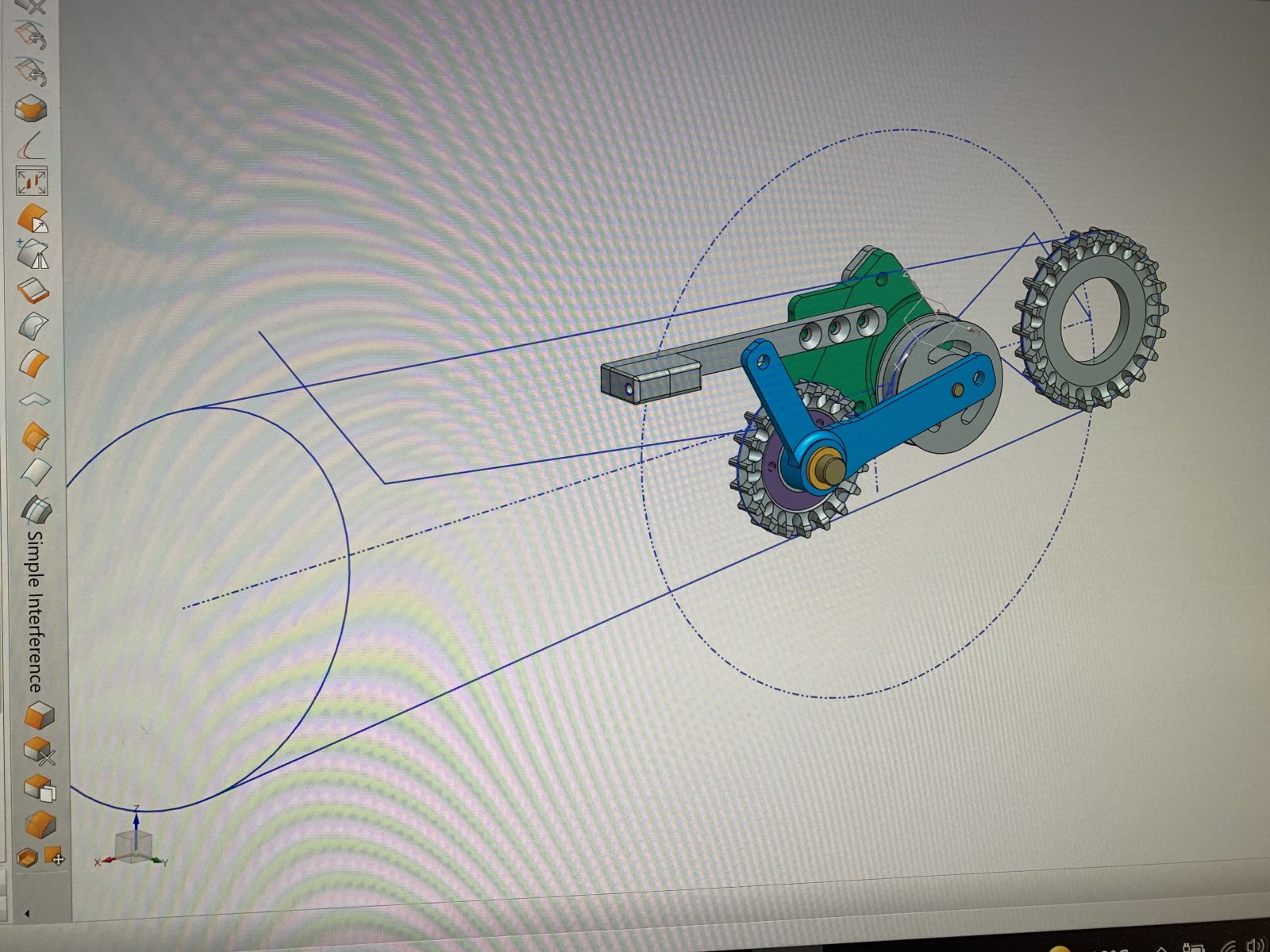

I measured the frame hard points/pivots/chain stay lengths etc and knocked up a kinematic in CAD. Obviously I didn’t have access to the original Haibike CAD data so my own careful measurements had to suffice. To be honest, the main thing here is chain/belt growth with suspension travel. Easy to establish this, it’s simply the delta between static ride height and full bump measured between crank and axle centres. In my case 46mm of growth. I’ve no idea if that’s a lot or average. The rear travel is 180mm so it’s probs on the high side?

So using the OD of the belt sprockets front and rear, it’s a simple task to work out the total belt/chain length. I made up an old chain of the required length and put it on the bike. It’s quite surprising just how much slack there is to take up with a chain sized for full bump when the bike is sitting static (full droop). In my case just over 70mm of slack to take up.

It soon became obvious there was just no way I was going to be able to design a front tensioner like the Nicolai to sit under/behind the front chain/belt ring. The frame design/architecture just wouldn’t accommodate it. In addition to this, the lower section of the chain/belt, with suspension travel, when utilising a single rear sprocket at 57mm, crashes into the chain stay. Bugger!

Luckily for me, Haibike designed the frame with a hollow pivot bolt at the rear linkage point. Inside dia of 6mm. This turned out to be the perfect location for part of the tensioner mount. Bingo. As part of the tensioner I added an idler sprocket. This solved the belt clash with the chainstay. This idler uses a standard Gates sprocket so it’s interchangeable with the rear sprocket on the hub which means I can change ratio’s without altering belt length.

Given that I had to use the same pivot point for both idler and tension arm I had no space to fit a derailleur style torsion spring. The tension loads are a lot higher than a derailleur so the spring would’ve been huge and custom made. The solution I came up with may look a bit Heath Robinson but it’s simple and it works. I went for a 200N rated spring. I can’t recall where I got that number from but it’s roughly worked backwards from the Gates specified tension. Using the Gates App on the iphone ,I record a frequency of around 57hz which is within the spec for a mtb/hub g-box.

A quick note on the tension roller size. The Gates belts don’t like back bending so this needs to be controlled. The minimum back bend radius I believe is 25mm or a dia 50mm roller. Again, looking at the Nicolai, you can see around 3-4 belt teeth for a quadrant of the tension roller. Belt teeth spacing is 11mm so a bit of school boy maths can give you the circumference required.

So that’s it . There’s tons more but you get the idea. It’s a working prototype. I went through at least four designs for this. You can stare at something all day in CAD and it works fine, the minute you see it in reality, it becomes obvious how it could be improved. MkII is already on the drawing board.

When I started this one of the main aims was to get the e-shift system for the Rohloff. Sadly, according to Rohloff they’re only compatible with Bosch and Panasonic. Not strictly true. The Flyon motors are made by TQ. If you look at their OEM data page on the website, it states compatibility with Rhloff e shifting. Sadly, Haibike didn’t take up this option. I contacted TQ about getting this to work and they agreed it was possible but refused to engage with me. How annoying is that?. I have the hardware but I can’t unlock it to use it’s potential.

I originally intended to get a Bosch powered bike for this project for the very reasons above. I probably still will do this. I looked at several Bosch powered bikes/frames for compatibility. I don’t think there are that many. I preferred the Orbea but, on closer inspection, the rear pivot joint in the frame (access required to fit the belt) shares a location with the rear axle. Massively complicated and I’d be amazed if the Rohloff A12 could work with that arrangement given that it uses custom inserts in the drop outs. The only other candidate I could find is the Scott Genious. This looks favourable in several ways especially for tensioner design/mounting. I think a standard Pinion unit could be made to work easily.

On to the shifter(s). I’ve gone with the stock Rohloff twist grip for now. There are surprisingly few options available. Cinq do a two lever option you can pair with a Gebla Rohbox which is a replacement for the standard Rohloff shifter. It’s basically two levers, LH and RH with a single click to shift up of down. A bit crude, looks awful, it’s expensive and, crucially, it means you can no longer quickly shift from 14 to 1 without 14 separate clicks. The twist grip I find is nice. It’s comfortable, slick and super fast to shift several gears. I’ve gone with the dedicated Ergon grips to match the stubby twist grip.

All of this could be so much better with the e-shift system!!

To conclude. A great success. The Rohloff is sublime. It can shift under load but a momentary easing of pedal pressure is all that’s required, after a few miles you don’t even notice you’re doing it. The ability to rapidly shift down several gears if you get caught out is useful as is the stationary shifting.

The belt drive is sweet, smooth and quiet but then so is a well sorted chain setup. Maintenance speaks for itself and it’s less messy. I’m a convert.

Again a huge thanks to Ghylside cycles, fab service and enthusiasm.

Not for the faint hearted perhaps but hopefully inspiration for others to do something similar.

If anyone want’s the CAD files for the Chain ring spider and/or the caliper torque arm, let me know. Alternatively, if enough show interest, I’ll get a batch made.

For Sale – Two bottles of chain lube (one half empty).

Perhaps one caveat regarding 1x drive trains on mtbs, is there a less aesthetically pleasing thing in the cycling world? They’re just too big and ugly.

Right, strap in!

First job was to get hold of the A12 Rohloff hub. This, for the un-initiated, is the “through axle” Boost version. Inverted commas there as it’s not strictly a through axle, it uses two M7 bolts through the drop out’s into the axle. Rohloff refuse to sell these unless it’s via an approved adult whose measured the frame and ok’d it for fitting. It’s not a difficult process, just a series of measurements made with a kit of parts to mimic the hub in the frame.

I spoke to several Rohloff dealers about this and about the project. As soon as I mentioned the belt drive they refused to get involved, this despite me only wanting to order the correct parts to allow me to design the system. Anyway, fortunately I ended up at Ghyllside Cycles in Ambleside. Ghyllside are not just Rohloff agents, they’re one of three (I think?) super-dealers in the UK so they have special powers. Fantastic couple of guys. As soon as I described what I had in mind they were super keen to get involved.

So I left the bike with them for a few hours to do the measuring etc. When I returned they said it was fine however, there were two issues. First, the “dog bone”. This is the torque arm that mounts on the caliper posts and stops the hub from rotating. Rohloff supply a couple of standard options but neither of them was going to work with my frame architecture. Simple enough solution, just make a custom one. All it required was a slightly longer one with a revised angle.

Second problem, the Flyon uses a disc mounted speed sensor ring with six bolts. The Rohloff hub comes with it’s own 4 bolt disc. Again, a simple enough issue to solve…..or so I thought.

Anyway, the good news, the chaps at Ghyllside were happy I was confident I could make it fly so they rubber stamped it and ordered the hub and all of the associated paraphernalia to add the Gates drive sprocket/carrier etc. I let them take care of the wheel building schizz. “Ain’t no baddy gat time f’dat”

So whilst I was waiting for the hub to turn up I set about designing the parts I needed. The intention was to get it installed with a normal chain first and then do the belt stuff in slow time.

The Haibike Flyon comes with a one piece chainring that slots directly onto the motor spigot. This is fine for a chain drive but I wanted a belt drive so this had to go. Sadly there is no off the shelf solution for this so I had to make one. All that was required was a standard spider arrangement with a 104 PCD 4 bolt chainring mounted on it. This is also the same fitment the Gates sprockets use so I could swap between a chain ring and a CDX belt sprocket.

So out with the verniers/rulers etc to establish the chain line (distance from frame centreline to chain/belt centreline. I measured it at 57mm. As a quick aside, this is what stopped me going for the Kindernay VII system. For reasons that escape me, when they designed it they mounted the gear change mechanism on the drive side. This effectively restricts the chain/belt line.

So 57mm is a good number for Rohloff. There is a bewildering amount of data on their website for mounting hubs, some of it contradicting! At 57mm there are parts/sprocket combo’s available to achieve this. The Gates sprockets are offset/reversable. Gates belts are much less forgiving than chains, the max allowable offset from front to rear is only 1mm so stuff has to line up. For MTB’s Gates recommend using the CDX Centretrack which has a rib in the centre of the belt. Any misalignment will just accelerate wear.

Having established the chainline dimension and the motor mount face/chain line offset etc I designed the spider and 3d printed for proof of concept. Gates belts are wider than a chain. Website says 11m, actual is 12mm. The clearance to the frame motor casing was reduced but still ample.

The motor drive interface is unique to Flyon but pretty simple. Essentially it’s an 8 pointed star with the corners rounded into each other. The outer chain ring interface is standard 4 bolt/104.

The CAD design was simple enough. The 3D print worked well. I sent it for machining. I went with 7075 ally as per the standard chainring. Probs a bit OTT but without some FE analysis on the loadings, difficult to say if the design would be strong enough. Gut feeling said yes.

Next job was the custom “dog bone” torque arm for the caliper post mount.

The caliper section is no different to the standard spacer fitted to the bike so that was easy enough to measure/replicate in CAD. A bit of fiddling/guessing with some bent welding rods and I established the dimensions required to pick up on the hub torque arm. Again 3D print/adjust/re-print. This needs to be quite strong so again, 7075 ally.

Onto the speed sensor disc. This almost put a stop to the whole project and caused a few sleepless nights trying to come up with a workable solution.

As I mentioned earlier, the standard Flyon uses a bolt-on sensor disc that picks up on the six brake disc mount bolts. The Rohloff has a dedicated brake disc with a 4 bolt mount so reusing the existing speed sensor wasn’t an option. Re-manufacturing the speed sensor disc wasn’t viable as it’s a sheet steel pressed/stamped item so tooling would be required etc.

I settled on making an additional disc, cutting the spokes out of the speed sensor and bonding them together. Again clearance between the brake disc and the back face of the Rohloff selector housing is tight so not much room to play with. I designed the part and sent it off for water jet cutting in 0.8mm plate. Unfortunately it came back measuring 0.9mm. With the outer part of the speed sensor bonded to it the thickness was too great and it just skimmed the back of the Rohloff. PITA.

I considered machining 0.5mm off the back of the Rohloff casing but decided against it. I tried a 0.5mm carbon sheet to replace the water jet steel part but that didn’t work too well.

In the end I simply bonded the speed sensor ring directly to the disc. Initially I thought temperature would be an issue with this. I used Sikaflex 221 which is pretty bomb proof stuff. I’ll run it and see how it performs. Thankfully a much better solution dawned on me so that can go into the MkII version.

So that’s the three parts required to get the Rohloff running with a chain, which I never bothered with. Time/weather etc meant there was no opportunity to ride. On with the belt tensioner.

Many hours were spent pouring over photos of Nicolai G1 eBoxx units trying to establish how best to create a tensioner system.

I measured the frame hard points/pivots/chain stay lengths etc and knocked up a kinematic in CAD. Obviously I didn’t have access to the original Haibike CAD data so my own careful measurements had to suffice. To be honest, the main thing here is chain/belt growth with suspension travel. Easy to establish this, it’s simply the delta between static ride height and full bump measured between crank and axle centres. In my case 46mm of growth. I’ve no idea if that’s a lot or average. The rear travel is 180mm so it’s probs on the high side?

So using the OD of the belt sprockets front and rear, it’s a simple task to work out the total belt/chain length. I made up an old chain of the required length and put it on the bike. It’s quite surprising just how much slack there is to take up with a chain sized for full bump when the bike is sitting static (full droop). In my case just over 70mm of slack to take up.

It soon became obvious there was just no way I was going to be able to design a front tensioner like the Nicolai to sit under/behind the front chain/belt ring. The frame design/architecture just wouldn’t accommodate it. In addition to this, the lower section of the chain/belt, with suspension travel, when utilising a single rear sprocket at 57mm, crashes into the chain stay. Bugger!

Luckily for me, Haibike designed the frame with a hollow pivot bolt at the rear linkage point. Inside dia of 6mm. This turned out to be the perfect location for part of the tensioner mount. Bingo. As part of the tensioner I added an idler sprocket. This solved the belt clash with the chainstay. This idler uses a standard Gates sprocket so it’s interchangeable with the rear sprocket on the hub which means I can change ratio’s without altering belt length.

Given that I had to use the same pivot point for both idler and tension arm I had no space to fit a derailleur style torsion spring. The tension loads are a lot higher than a derailleur so the spring would’ve been huge and custom made. The solution I came up with may look a bit Heath Robinson but it’s simple and it works. I went for a 200N rated spring. I can’t recall where I got that number from but it’s roughly worked backwards from the Gates specified tension. Using the Gates App on the iphone ,I record a frequency of around 57hz which is within the spec for a mtb/hub g-box.

A quick note on the tension roller size. The Gates belts don’t like back bending so this needs to be controlled. The minimum back bend radius I believe is 25mm or a dia 50mm roller. Again, looking at the Nicolai, you can see around 3-4 belt teeth for a quadrant of the tension roller. Belt teeth spacing is 11mm so a bit of school boy maths can give you the circumference required.

So that’s it . There’s tons more but you get the idea. It’s a working prototype. I went through at least four designs for this. You can stare at something all day in CAD and it works fine, the minute you see it in reality, it becomes obvious how it could be improved. MkII is already on the drawing board.

When I started this one of the main aims was to get the e-shift system for the Rohloff. Sadly, according to Rohloff they’re only compatible with Bosch and Panasonic. Not strictly true. The Flyon motors are made by TQ. If you look at their OEM data page on the website, it states compatibility with Rhloff e shifting. Sadly, Haibike didn’t take up this option. I contacted TQ about getting this to work and they agreed it was possible but refused to engage with me. How annoying is that?. I have the hardware but I can’t unlock it to use it’s potential.

I originally intended to get a Bosch powered bike for this project for the very reasons above. I probably still will do this. I looked at several Bosch powered bikes/frames for compatibility. I don’t think there are that many. I preferred the Orbea but, on closer inspection, the rear pivot joint in the frame (access required to fit the belt) shares a location with the rear axle. Massively complicated and I’d be amazed if the Rohloff A12 could work with that arrangement given that it uses custom inserts in the drop outs. The only other candidate I could find is the Scott Genious. This looks favourable in several ways especially for tensioner design/mounting. I think a standard Pinion unit could be made to work easily.

On to the shifter(s). I’ve gone with the stock Rohloff twist grip for now. There are surprisingly few options available. Cinq do a two lever option you can pair with a Gebla Rohbox which is a replacement for the standard Rohloff shifter. It’s basically two levers, LH and RH with a single click to shift up of down. A bit crude, looks awful, it’s expensive and, crucially, it means you can no longer quickly shift from 14 to 1 without 14 separate clicks. The twist grip I find is nice. It’s comfortable, slick and super fast to shift several gears. I’ve gone with the dedicated Ergon grips to match the stubby twist grip.

All of this could be so much better with the e-shift system!!

To conclude. A great success. The Rohloff is sublime. It can shift under load but a momentary easing of pedal pressure is all that’s required, after a few miles you don’t even notice you’re doing it. The ability to rapidly shift down several gears if you get caught out is useful as is the stationary shifting.

The belt drive is sweet, smooth and quiet but then so is a well sorted chain setup. Maintenance speaks for itself and it’s less messy. I’m a convert.

Again a huge thanks to Ghylside cycles, fab service and enthusiasm.

Not for the faint hearted perhaps but hopefully inspiration for others to do something similar.

If anyone want’s the CAD files for the Chain ring spider and/or the caliper torque arm, let me know. Alternatively, if enough show interest, I’ll get a batch made.

For Sale – Two bottles of chain lube (one half empty).