This may sound like an odd question, but it’s an important one as far as your motor is concerned. This article is written more for anyone who owns an ebike with an expired or expiring warranty.

We are probably all guilty of riding a bike with a worn wheel bearing or loose bottom bracket for instance. Many are familiar with the noise of a rough bearing. But, when it comes to an eBike motor, many seem to treat it no different to a normal, old fashioned, bottom bracket.

There is a slight difference of about £700 to £1200 between the two, so paying attention to what your motor's telling you could save you a small fortune.

Please note: We are not discussing terminal motor failure or breakage, we are only looking at the normal slow chronic failure that creeps in, often unnoticed. We will also look at the consequence of ignoring these noises.

An innocent Impulse 2.0 motor ridden to destruction

So how do you know when you should stop?

It will probably be a noise you hear before feeling anything. The problem is, if you start to hear this noise while riding, it’s normally already a bit late. If you start to feel a vibration, stiffness, or roughness through the pedals… It’s normally too late for a cheap fix.

Chronic (over time) motor failure usually start's with the bearings, we will look at that in-depth a little later. But, you can normally spot the symptoms very early…

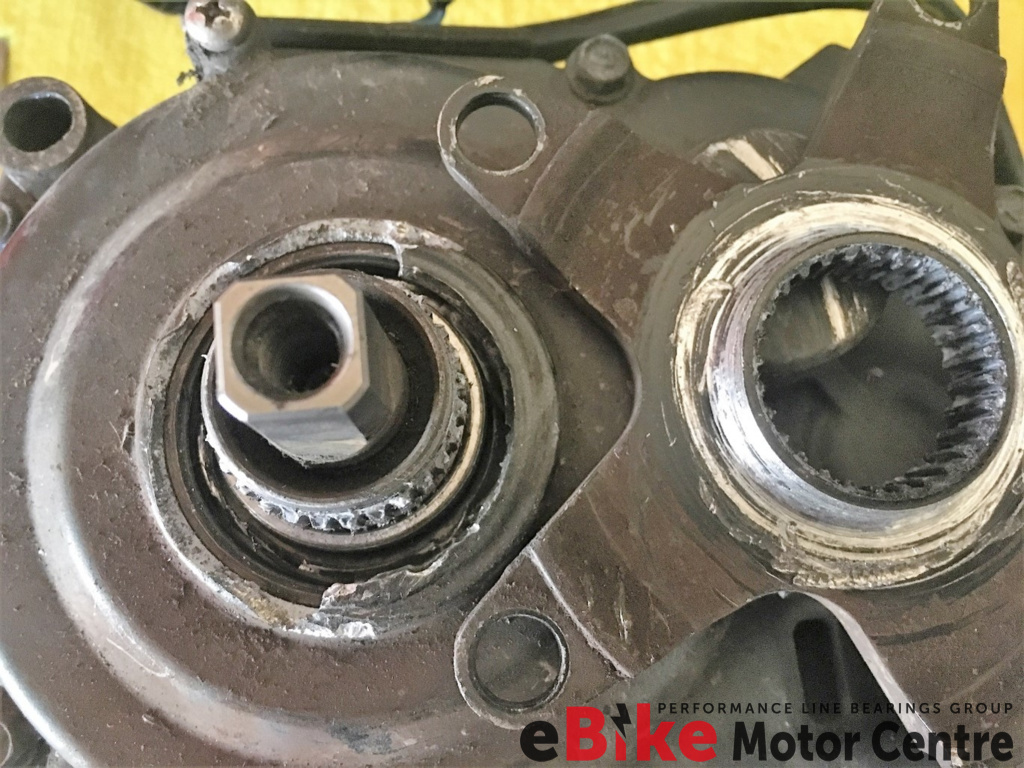

Another Yamaha ridden until the ball bearings broke through the bearing race and side cover!

How do I spot a problem in its early stages?

I'm often dumbfounded when people drop in to see us with their bikes and say… “I think I can hear a slight noise”. I drop the chain off the front chainring, spin the pedals and the crankshaft nearly drops on the floor !

Don’t get me wrong, I understand we’re not all mechanics; so below are some of the main things to look out for, how to check your motor and how to recognise potential issues.

First, familiarise yourself

This is best done when your bike or your motor is new or recently overhauled. First remove the chain from the front chainring to get rid of any chain or gear noise and turn the pedals by hand. Without the chain on, you will only be feeling and hearing the motor (and the pedal of course).

Once you are familiar with how your motor should sound and feel, you should be able to recognise any change. How often you should do this will depend on your riding terrain, weather, washing habits, how you transport the bike and so on.

This Brose motor damage did not happen in one day!

What am I checking for ?

Once you’ve dropped the chain, start turning the crank arms. The first thing you will notice is that the motor makes a different noise depending on which way you turn the crankshaft, this normal. The motor is turning different components internally depending on crank direction.

What you’re listening for is a rough sounding noise like a hard plastic wheel rolling on a wooden floor, remember playing with a toy car on a wooden floor or desk ? It's a similar sound. On most motors this is easiest to hear when the crank is turned backwards because this usually allows the crankshaft to turn independently of the internal motor components .

Some motors, like the Bosch Gen 4, Impulse and Yamaha will click like a freewheel hub when turned in reverse, this is normal. Turning these particular motors in reverse only turns the left hand (non-drive side) bearing so best done from that side of the bike.

Some examples :

Brose motors (Specialized, Bulls, BH, Fantic etc.) when turned in reverse should be completely silent and very free and easy to turn.

Bosch Gen 2 and the Specialized Mahle motor should be smooth and quiet with a very slight amount of drag.

Bosch Gen 3 will be stiff to turn in reverse because the motor is not disengaged.

It is worth mentioning here that the Brose motor technically has 3 crankshaft bearings, this disguises premature bearing failure because the crankshaft tends to float on its centre bearing, usually this is the last one to fail. The crankshaft should be turned forcefully to try and side load it against the outer bearings.

Now, turn the motor forward. On all motors, this is best done from the drive side. With the exception of the Brose motor, all other motors should sound slightly louder. This noise should sound like two gears meshing, rather than someone racing a toy car over a hard surface - or worse, a coffee grinder!

The Brose motor should be almost as silent as it was in reverse, but there will be a very slight drag on the crankarm going forward .

You should feel no roughness through the pedal arm. Looking back at the second image (the Yamaha), this would have caused the crankshaft to bind and seize occasionally and would have felt very rough.

Depending on the motor make and model, you may feel movement in the crankshaft, either up and down (radial play) or in and out (end float), this should be minimal though. You can also try moving the chainring up and down to ensure the sprocket carrier or the spider it's fastened to are also relatively tight.

This is how your motor should feel :

Note: End float differs from motor to motor but is generally around 1mm.

Why does this happen ?

Chronic ebike motor failure is usually a cascading event. Let’s look a very typical example :

A bearing will get a tiny bit of water in it, maybe from the ride, maybe when cleaned, maybe while on the car rack in the rain.

You put the bike away and for the next few days, weeks, months, the ball bearings start to rust to the bearing race. Next time you go out you may notice the crank sticks temporarily when you go to push the bike backwards, this usually signals the beginning of the end. The ball and race will have corroded together and once moved again both the ball and the bearing race will have a pitted surface, each ball going over that surface will now be damaged, and the wear will start.

Bearing issue deep dive

We are seeing hundreds of motors where if the failure was picked up a few miles earlier, the repair would cost £50 to £60. But , by the time the motor gets to us, it’s all but written off.

Perhaps I can explain in some detail what’s going on here. If you’re unfamiliar with some of the terminology, this may help as reference as we go a little deeper.

Below, is an example of a typical ebike motors crankshaft bearing. Its official name is "deep groove roller bearing", abbreviated to "bearing". This makes it difficult when talking about this topic because the ball bearings inside the bearing are also called bearings. For the purpose of this article, I will call them “ball bearings” going forward.

Deep Groove Roller Bearing - Terminology

It's rarely understood how fast a bearing can deteriorate and what happens once it starts. Firstly, most crankshaft or drive bearings in the latest ebike motors are designed for weight saving, so these tend to be relatively large bearings containing very small ball bearings within them.

This means when water, dust or grit penetrates the bearing the wear rate is extremely fast. Unlike a bearing with large ball bearings, these will generally last quite a few rides before destruction. Not that this helps some people!

Large ball bearings worn so badly they are dropping out the side of the bearing.

What happens?

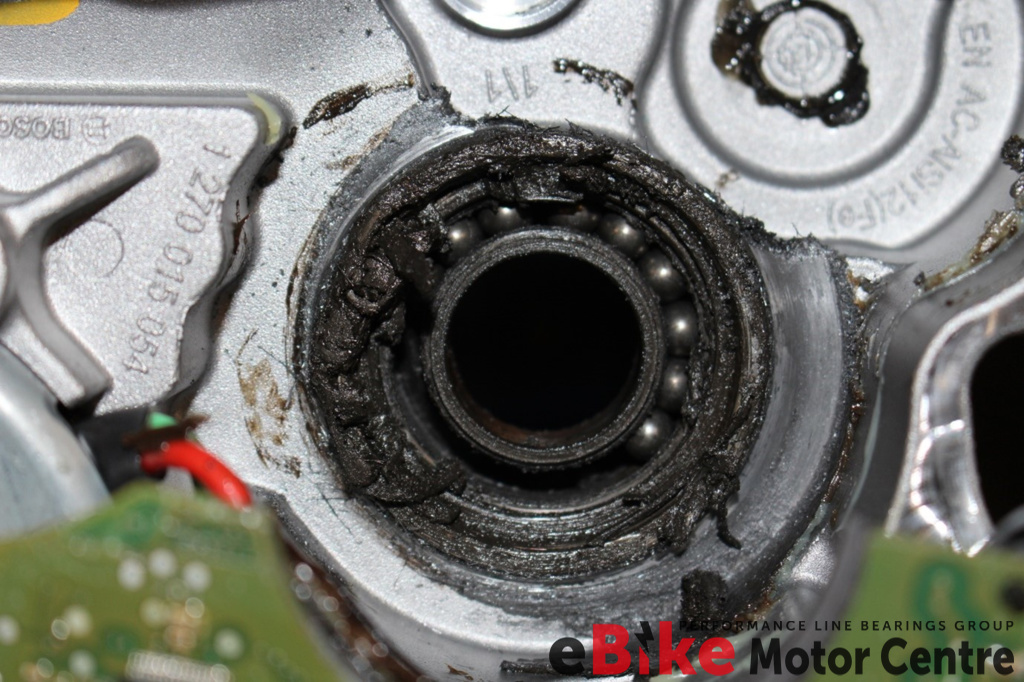

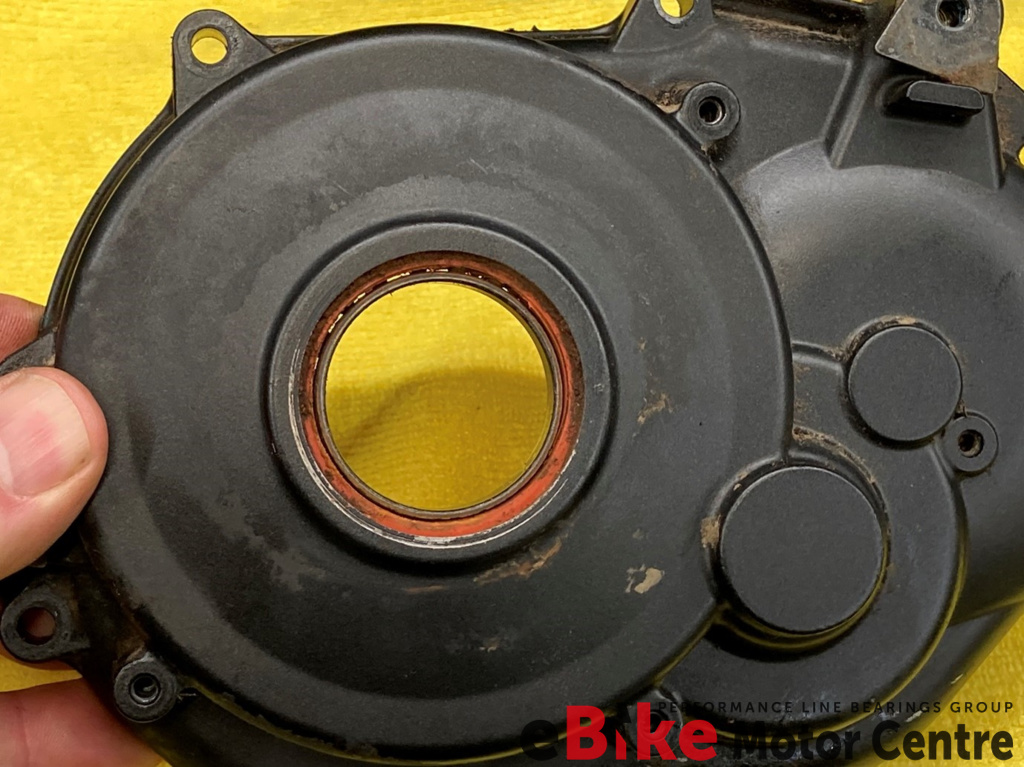

As the inner ball bearings wear, they become smaller and begin to allow movement or “radial play” in the bearing, this allows the inner bearing race to move with the piece its attached to. This movement of the inner bearing race starts to wear the bearing seal and slowly begins to lift the seal away from the race it’s sealing against.

The inner bearing race has lifted from the bearing seal and lack of lubricant has damaged it.

Once this situation begins, it allows even more dirt, grit and water into the bearing - speeding up the wear until there is enough room for this contamination to pour into the motor itself.

This “small ball bearing” type can go from slightly noisy to completely destroyed in one ride.

Daylight should not get through your bearings

What happens if you ignore the noise ?

You really do this at your peril and at the risk of killing your motor. All ebike motors are assembled in cleanroom conditions which are generally pristine inside. There is no oil or filters, so nothing to catch any contaminants.

Anything which gets into the motor is in there for life. (Always makes me cringe watching YouTube when a motor is being assembled on a grit strewn bench or dirty towel).

Once contamination begins, it starts a chain reaction. The particles coming from the failed component starts spreading to the other components and then it’s all downhill .

Once dirt or water ingress into the motor, it’s just a matter of time before you’re walking home.

Why are these bearings so bad, why do they let the water in in the first place ?

Don’t be so hard on the bearings, it’s not really their fault. Bearings are not designed to be waterproof; it would lead to far too much friction if they were.

There are many different types of bearing seals available from open metal shields to the best rubber “labyrinth” type seals, but even these are just slash proof, fine in the rain or road puddles, but not so good against a deep water crossing, a long flooded rut, garden hose, car rack in the rain and so on.

Why don’t the motor manufacturers fit a seal in front of the bearings ?

Seals add friction and friction = less battery range . It's as simple as that.

90% of the ebike market is made up of commuter and road bikes, especially in Europe. These bearings are fine in the rain so why add extra friction.

How do you sell your motor if it doesn't go quite as far as your competitor on a full charge?

Shimano and Mahle are sealed but they still have bearing problems

This is true but the seals they use are springless - to keep friction down, relatively small, and in the case of Shimano very soft. They are still no match for a keen garden hoser or a pressure washer and they will both still allow grit to creep in.

A Yamaha ridden until the ball bearings broke through the motor cover leaving just the inner bearing race and a bit of seal.

I probably have 3,000 or 4,000 more photographs just like these

Next time you’re thinking… "It feels a bit rough, but it should be fine! I’ll just go for one more ride before I get that noise sorted out"

GAME OVER !

But you own a motor repair business, why are you telling me this!?

To be honest, this is a win, win situation . If we can repair your motor, you save money, and we make money. If you damage your motor beyond economical repair, it costs you 3 times as much and we make nothing!

We are probably all guilty of riding a bike with a worn wheel bearing or loose bottom bracket for instance. Many are familiar with the noise of a rough bearing. But, when it comes to an eBike motor, many seem to treat it no different to a normal, old fashioned, bottom bracket.

There is a slight difference of about £700 to £1200 between the two, so paying attention to what your motor's telling you could save you a small fortune.

Please note: We are not discussing terminal motor failure or breakage, we are only looking at the normal slow chronic failure that creeps in, often unnoticed. We will also look at the consequence of ignoring these noises.

An innocent Impulse 2.0 motor ridden to destruction

So how do you know when you should stop?

It will probably be a noise you hear before feeling anything. The problem is, if you start to hear this noise while riding, it’s normally already a bit late. If you start to feel a vibration, stiffness, or roughness through the pedals… It’s normally too late for a cheap fix.

Chronic (over time) motor failure usually start's with the bearings, we will look at that in-depth a little later. But, you can normally spot the symptoms very early…

Another Yamaha ridden until the ball bearings broke through the bearing race and side cover!

How do I spot a problem in its early stages?

I'm often dumbfounded when people drop in to see us with their bikes and say… “I think I can hear a slight noise”. I drop the chain off the front chainring, spin the pedals and the crankshaft nearly drops on the floor !

Don’t get me wrong, I understand we’re not all mechanics; so below are some of the main things to look out for, how to check your motor and how to recognise potential issues.

First, familiarise yourself

This is best done when your bike or your motor is new or recently overhauled. First remove the chain from the front chainring to get rid of any chain or gear noise and turn the pedals by hand. Without the chain on, you will only be feeling and hearing the motor (and the pedal of course).

Once you are familiar with how your motor should sound and feel, you should be able to recognise any change. How often you should do this will depend on your riding terrain, weather, washing habits, how you transport the bike and so on.

This Brose motor damage did not happen in one day!

What am I checking for ?

Once you’ve dropped the chain, start turning the crank arms. The first thing you will notice is that the motor makes a different noise depending on which way you turn the crankshaft, this normal. The motor is turning different components internally depending on crank direction.

What you’re listening for is a rough sounding noise like a hard plastic wheel rolling on a wooden floor, remember playing with a toy car on a wooden floor or desk ? It's a similar sound. On most motors this is easiest to hear when the crank is turned backwards because this usually allows the crankshaft to turn independently of the internal motor components .

Some motors, like the Bosch Gen 4, Impulse and Yamaha will click like a freewheel hub when turned in reverse, this is normal. Turning these particular motors in reverse only turns the left hand (non-drive side) bearing so best done from that side of the bike.

Some examples :

Brose motors (Specialized, Bulls, BH, Fantic etc.) when turned in reverse should be completely silent and very free and easy to turn.

Bosch Gen 2 and the Specialized Mahle motor should be smooth and quiet with a very slight amount of drag.

Bosch Gen 3 will be stiff to turn in reverse because the motor is not disengaged.

It is worth mentioning here that the Brose motor technically has 3 crankshaft bearings, this disguises premature bearing failure because the crankshaft tends to float on its centre bearing, usually this is the last one to fail. The crankshaft should be turned forcefully to try and side load it against the outer bearings.

Now, turn the motor forward. On all motors, this is best done from the drive side. With the exception of the Brose motor, all other motors should sound slightly louder. This noise should sound like two gears meshing, rather than someone racing a toy car over a hard surface - or worse, a coffee grinder!

The Brose motor should be almost as silent as it was in reverse, but there will be a very slight drag on the crankarm going forward .

You should feel no roughness through the pedal arm. Looking back at the second image (the Yamaha), this would have caused the crankshaft to bind and seize occasionally and would have felt very rough.

Depending on the motor make and model, you may feel movement in the crankshaft, either up and down (radial play) or in and out (end float), this should be minimal though. You can also try moving the chainring up and down to ensure the sprocket carrier or the spider it's fastened to are also relatively tight.

This is how your motor should feel :

| Bosch Gen 1 | No play or end float on the crankshaft or sprocket carrier |

| Bosch Gen 2 | No play or end float on the crankshaft or sprocket carrier |

| Bosch Gen 3 | No play on the crankshaft but slight end float. Slight radial play on the sprocket carrier |

| Bosch Gen 4 | No play on the crankshaft but slight end float. Slight radial play on the sprocket carrier |

| Brose C, T, TF, S & S-Mag | No play or end float on the crankshaft or sprocket carrier |

| Impulse 2.0, 2.3, EVO & EVO RS | Slight end float on the crankshaft but no play or end float on the sprocket carrier |

| Mahle 1.1 | Slight end float on the crankshaft but no play or end float on the sprocket carrier |

| Shimano E7000, 8000 & EP8 | Slight end float on the crankshaft but no play or end float on the sprocket carrier |

| Yamaha PW, PW-ST, TE, CE, ST & Giant SyncDrive Sport | Slight end float on the crankshaft but no play or end float on the sprocket carrier |

| Yamaha PW-X, PW-X2 & Giant SyncDrive Pro | No play or end float on the crankshaft or sprocket carrier |

Why does this happen ?

Chronic ebike motor failure is usually a cascading event. Let’s look a very typical example :

A bearing will get a tiny bit of water in it, maybe from the ride, maybe when cleaned, maybe while on the car rack in the rain.

You put the bike away and for the next few days, weeks, months, the ball bearings start to rust to the bearing race. Next time you go out you may notice the crank sticks temporarily when you go to push the bike backwards, this usually signals the beginning of the end. The ball and race will have corroded together and once moved again both the ball and the bearing race will have a pitted surface, each ball going over that surface will now be damaged, and the wear will start.

Bearing issue deep dive

We are seeing hundreds of motors where if the failure was picked up a few miles earlier, the repair would cost £50 to £60. But , by the time the motor gets to us, it’s all but written off.

Perhaps I can explain in some detail what’s going on here. If you’re unfamiliar with some of the terminology, this may help as reference as we go a little deeper.

Below, is an example of a typical ebike motors crankshaft bearing. Its official name is "deep groove roller bearing", abbreviated to "bearing". This makes it difficult when talking about this topic because the ball bearings inside the bearing are also called bearings. For the purpose of this article, I will call them “ball bearings” going forward.

Deep Groove Roller Bearing - Terminology

It's rarely understood how fast a bearing can deteriorate and what happens once it starts. Firstly, most crankshaft or drive bearings in the latest ebike motors are designed for weight saving, so these tend to be relatively large bearings containing very small ball bearings within them.

This means when water, dust or grit penetrates the bearing the wear rate is extremely fast. Unlike a bearing with large ball bearings, these will generally last quite a few rides before destruction. Not that this helps some people!

Large ball bearings worn so badly they are dropping out the side of the bearing.

What happens?

As the inner ball bearings wear, they become smaller and begin to allow movement or “radial play” in the bearing, this allows the inner bearing race to move with the piece its attached to. This movement of the inner bearing race starts to wear the bearing seal and slowly begins to lift the seal away from the race it’s sealing against.

The inner bearing race has lifted from the bearing seal and lack of lubricant has damaged it.

Once this situation begins, it allows even more dirt, grit and water into the bearing - speeding up the wear until there is enough room for this contamination to pour into the motor itself.

This “small ball bearing” type can go from slightly noisy to completely destroyed in one ride.

Daylight should not get through your bearings

What happens if you ignore the noise ?

You really do this at your peril and at the risk of killing your motor. All ebike motors are assembled in cleanroom conditions which are generally pristine inside. There is no oil or filters, so nothing to catch any contaminants.

Anything which gets into the motor is in there for life. (Always makes me cringe watching YouTube when a motor is being assembled on a grit strewn bench or dirty towel).

Once contamination begins, it starts a chain reaction. The particles coming from the failed component starts spreading to the other components and then it’s all downhill .

Once dirt or water ingress into the motor, it’s just a matter of time before you’re walking home.

Why are these bearings so bad, why do they let the water in in the first place ?

Don’t be so hard on the bearings, it’s not really their fault. Bearings are not designed to be waterproof; it would lead to far too much friction if they were.

There are many different types of bearing seals available from open metal shields to the best rubber “labyrinth” type seals, but even these are just slash proof, fine in the rain or road puddles, but not so good against a deep water crossing, a long flooded rut, garden hose, car rack in the rain and so on.

Why don’t the motor manufacturers fit a seal in front of the bearings ?

Seals add friction and friction = less battery range . It's as simple as that.

90% of the ebike market is made up of commuter and road bikes, especially in Europe. These bearings are fine in the rain so why add extra friction.

How do you sell your motor if it doesn't go quite as far as your competitor on a full charge?

Shimano and Mahle are sealed but they still have bearing problems

This is true but the seals they use are springless - to keep friction down, relatively small, and in the case of Shimano very soft. They are still no match for a keen garden hoser or a pressure washer and they will both still allow grit to creep in.

|

|

|

|

|

|

|

|

A Bosch Gen 2 thoroughly contaminated with steel dust |

|

|

The source of all the steel dust |

|

A Yamaha ridden until the ball bearings broke through the motor cover leaving just the inner bearing race and a bit of seal.

I probably have 3,000 or 4,000 more photographs just like these

Next time you’re thinking… "It feels a bit rough, but it should be fine! I’ll just go for one more ride before I get that noise sorted out"

GAME OVER !

But you own a motor repair business, why are you telling me this!?

To be honest, this is a win, win situation . If we can repair your motor, you save money, and we make money. If you damage your motor beyond economical repair, it costs you 3 times as much and we make nothing!